Comprehensive Guide to John Deere 240 Lawn Tractor Parts Diagram

When it comes to maintaining your outdoor equipment, having a clear understanding of its internal structure is essential. A well-organized overview of the various elements can significantly enhance your ability to troubleshoot issues and perform necessary repairs. By familiarizing yourself with the layout of these components, you can ensure optimal performance and longevity of your machine.

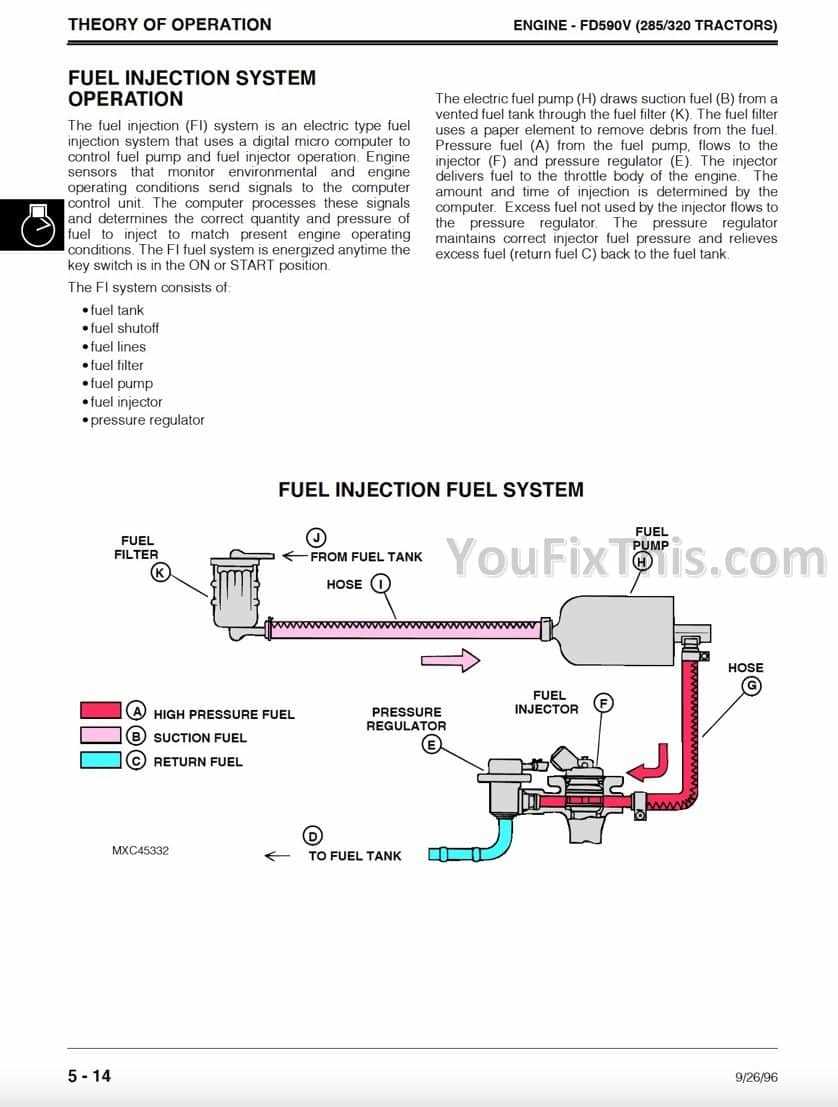

Visual guides play a crucial role in this process. They provide a comprehensive reference that allows users to quickly identify each part’s location and function. This not only streamlines repairs but also empowers owners to engage in routine maintenance with confidence.

Whether you’re a seasoned operator or a newcomer to the world of gardening machinery, knowing how to navigate the intricacies of your equipment’s design will be invaluable. Understanding the relationships between various components can help in troubleshooting and optimizing your device’s efficiency.

Understanding John Deere 240 Lawn Tractor

This section explores the intricacies of a popular outdoor maintenance machine, highlighting its features, components, and functionality. Knowing the essentials can greatly enhance user experience and efficiency when operating this versatile equipment.

Key aspects to consider include:

- Engine performance and specifications

- Transmission types and their advantages

- Maintenance requirements and schedules

The following components play a crucial role in ensuring optimal performance:

- Power system: Understanding the engine’s horsepower and fuel efficiency can lead to better operational decisions.

- Cutting mechanism: Familiarity with blade types and adjustments is vital for achieving a clean cut.

- Chassis design: A robust frame contributes to stability and durability in various terrains.

Furthermore, regular inspections and repairs can prevent unexpected breakdowns. Users are encouraged to keep a comprehensive checklist to monitor:

- Fluid levels and leaks

- Belts and hoses for wear and tear

- Tire pressure and tread condition

Overall, a deeper understanding of this equipment can lead to improved maintenance practices, ultimately extending the lifespan and enhancing the performance of this essential tool for yard care.

Key Features of the 240 Model

This model is designed with a range of characteristics that enhance its performance and usability for outdoor tasks. Users can expect a robust construction combined with innovative features, making it suitable for various gardening and maintenance activities.

Durability and Build Quality

The structure of this machine is crafted to withstand tough conditions, ensuring longevity and reliability. Key aspects include:

- Heavy-duty frame that provides stability.

- High-quality materials that resist wear and tear.

- Weather-resistant components for outdoor use.

Enhanced Performance Features

Performance is a critical aspect of this model, with several features that contribute to its efficiency:

- Powerful engine for consistent operation.

- Ergonomic design that offers comfort during prolonged use.

- Easy-to-use controls for a seamless user experience.

These features come together to create a reliable and efficient machine, perfect for maintaining your outdoor space with ease.

Importance of Parts Diagrams

Understanding the intricacies of machinery relies heavily on visual representations that illustrate the various components and their relationships. Such visuals serve as essential tools for technicians, enabling them to efficiently diagnose issues, conduct repairs, and perform maintenance. By offering a clear overview of the structure, these illustrations streamline the process of identifying necessary elements and facilitate better communication among professionals.

Furthermore, these graphical aids play a critical role in enhancing the user’s knowledge, empowering them to undertake repairs with confidence. When individuals can visualize the assembly of different parts, they are more likely to engage in effective troubleshooting, ultimately leading to improved performance and longevity of the equipment.

| Benefit | Description |

|---|---|

| Efficiency | Speeds up the identification of components for quick repairs. |

| Clarity | Provides a clear view of how parts fit together and function. |

| Confidence | Empowers users to tackle repairs and maintenance independently. |

| Communication | Facilitates better discussions among technicians and users regarding repairs. |

Common Replacement Parts for Lawn Tractors

Regular maintenance of outdoor mowing equipment is essential for optimal performance and longevity. Knowing the typical components that may require replacement can help ensure that your machinery runs smoothly and efficiently. This section highlights some frequently needed items that contribute to the functionality of grass-cutting machines.

Blades are one of the most crucial elements, as they directly impact cutting efficiency. Over time, blades can become dull or damaged, requiring replacement to maintain a clean cut and prevent stress on the engine.

Filters, including air and fuel varieties, play a vital role in keeping the engine running smoothly. Clean filters are necessary for optimal airflow and fuel intake, while clogged ones can lead to decreased performance or engine issues.

Batteries are another common item that may need attention. Regular use can lead to battery degradation, impacting the starting capabilities of the machine. Ensuring you have a reliable battery is key for efficient operation.

Belts are responsible for transmitting power from the engine to various components. Wear and tear can lead to slippage or breakage, so timely replacement is important to avoid operational disruptions.

Finally, wheels and tires may also require periodic checks and replacements, particularly if they show signs of wear or damage. Maintaining proper traction is essential for effective maneuverability and performance.

How to Read Parts Diagrams

Understanding visual schematics is essential for effective maintenance and repair of machinery. These illustrations provide a clear representation of various components, helping users identify and locate specific elements. By familiarizing oneself with these visuals, one can streamline troubleshooting and ensure accurate assembly or disassembly of equipment.

Familiarizing with Symbols and Labels

Each illustration features a unique set of symbols and annotations. It’s important to recognize what each symbol signifies, as they represent different components or functions. Labels often indicate part numbers, descriptions, and quantities, making it easier to source replacements or accessories. Take time to review the legend or key, which typically accompanies these visuals, as it clarifies the meaning of the symbols used.

Following the Layout

These visuals are usually organized in a logical manner, showcasing components in the order they are assembled or connected. Start from the main body and work your way through the sections. This method not only aids in understanding how components fit together but also assists in identifying any missing or damaged elements. By following the layout methodically, you can effectively navigate through the schematic.

Finding Authentic John Deere Parts

When maintaining your equipment, sourcing genuine components is crucial for optimal performance and longevity. Authentic items not only ensure compatibility but also enhance the reliability of your machinery. Understanding how to identify and acquire these components can save time and prevent future issues.

Here are some key factors to consider when searching for original elements:

| Factor | Description |

|---|---|

| Manufacturer Reputation | Always opt for parts from reputable manufacturers known for their quality and reliability. |

| Authorized Dealers | Purchase from authorized retailers or distributors to ensure authenticity and warranty coverage. |

| Part Numbers | Verify part numbers to match those specified in your equipment’s manual for proper fit. |

| Reviews and Ratings | Check customer reviews and ratings to gauge the reliability of the supplier and their offerings. |

By following these guidelines, you can confidently locate the components needed to keep your machinery running smoothly.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires regular attention and care. By following a few essential practices, you can keep your machinery running smoothly and efficiently, ultimately saving time and resources.

Regular Inspections

- Check fluid levels frequently, including oil and coolant.

- Inspect belts and hoses for signs of wear or damage.

- Look for loose bolts and connections to prevent mechanical failures.

Cleaning and Lubrication

- Remove debris from the engine and cooling fins to ensure proper airflow.

- Lubricate moving parts to reduce friction and wear.

- Clean air filters regularly to maintain optimal performance.

Implementing these maintenance tips will contribute to the reliability and efficiency of your equipment, allowing it to perform at its best for years to come.

Identifying Parts by Model Number

Understanding the components of your equipment can greatly enhance maintenance and repair efficiency. Recognizing specific elements by their model number simplifies the process of locating the correct items, ensuring that you obtain the necessary replacements without confusion. This approach not only saves time but also minimizes the risk of ordering incorrect components.

Importance of Model Number

Each piece of machinery is assigned a unique identifier that provides vital information about its specifications and compatible accessories. This identifier allows users to reference the correct catalog or resource for finding the right components tailored to their model. Inaccurate identification can lead to costly mistakes and unnecessary delays in maintenance.

Steps to Identify Components

To successfully identify elements, start by locating the model number on the equipment. Typically, it can be found on a label or plate attached to the frame. Once you have the model number, consult the manufacturer’s documentation or an online resource to access detailed information regarding compatible elements. This systematic approach ensures you make informed decisions while sourcing replacements.

In summary, leveraging the model number is crucial for efficient maintenance and repair. By following the outlined steps, you can confidently navigate the complexities of equipment upkeep and ensure optimal performance.

Tools Needed for Parts Replacement

Replacing components in your outdoor machinery requires a specific set of tools to ensure efficiency and accuracy. Having the right instruments on hand can simplify the process, minimize the risk of damage, and help achieve the best possible results. Below is a guide to essential tools that can facilitate component replacement.

Essential Hand Tools

Basic hand tools are crucial for disassembling and reassembling parts. Commonly used items include wrenches, screwdrivers, and pliers. A socket set is also invaluable for dealing with various bolt sizes, while a torque wrench helps ensure that fasteners are tightened to the correct specifications, preventing future issues.

Power Tools and Safety Equipment

Power tools can expedite the removal and installation of components, particularly in larger machinery. A cordless drill is useful for various tasks, including driving screws and drilling holes. Additionally, safety gear such as gloves and goggles should always be worn to protect against debris and injuries during the maintenance process.

Common Troubleshooting Issues

When maintaining outdoor machinery, it’s essential to recognize frequent challenges that may arise during operation. Understanding these common issues can significantly improve efficiency and prolong the lifespan of the equipment.

1. Engine Won’t Start: A non-starting engine can stem from various causes, including a depleted battery, faulty spark plug, or a clogged fuel line. It’s crucial to check these components systematically to identify the root of the problem.

2. Uneven Cutting Performance: If the cutting results are inconsistent, the blades may be dull or damaged, or the height settings might be incorrect. Regular inspection and sharpening of the blades are vital for optimal performance.

3. Overheating Issues: Excessive heat can lead to severe damage. Ensure that the cooling system is clean and free of debris, and monitor the fluid levels to prevent overheating.

4. Leaking Fluids: Any visible fluid leaks should not be ignored, as they can indicate serious issues. Common sources of leaks include hoses and seals that may require replacement or tightening.

5. Difficulty in Steering: If maneuvering becomes challenging, check the steering components for wear and tear. A thorough inspection of the linkage and bearings can help diagnose the problem.

By addressing these typical concerns promptly, users can maintain smooth operation and avoid more significant repairs in the future.

Where to Purchase Replacement Parts

Finding quality components for maintenance or repairs is crucial for ensuring optimal performance of your equipment. With various sources available, it’s essential to identify the most reliable options for acquiring the necessary items.

Authorized Dealers

One of the best places to start is through official dealers. These establishments often stock genuine components and provide expert advice. Additionally, they may offer warranties and guarantees on their products, ensuring peace of mind with your purchase.

Online Retailers

Another convenient option is to shop through online platforms. Many websites specialize in offering a wide range of components at competitive prices. It’s important to check the credibility of the seller and read customer reviews before making a purchase.

| Source | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Genuine items, expert support, warranties | Potentially higher prices |

| Online Retailers | Wide selection, competitive pricing | Check seller reputation |

| Local Repair Shops | Personalized service, immediate availability | Limited stock |

Benefits of Regular Maintenance Checks

Regular upkeep of machinery is essential for ensuring optimal performance and longevity. By conducting frequent inspections and servicing, owners can prevent small issues from escalating into significant problems. This proactive approach not only enhances efficiency but also contributes to safety and reliability.

- Increased Efficiency: Regular maintenance helps machinery run smoothly, reducing energy consumption and improving overall productivity.

- Cost Savings: Identifying and addressing minor repairs early can save considerable expenses compared to major overhauls later on.

- Enhanced Safety: Regular checks can uncover potential hazards, minimizing the risk of accidents during operation.

- Extended Lifespan: Consistent care ensures that components remain in good condition, prolonging the usable life of the equipment.

- Better Performance: Routine maintenance keeps machinery operating at peak performance, ensuring tasks are completed efficiently.

Implementing a regular maintenance schedule can lead to substantial benefits, fostering a reliable and productive work environment.