Understanding the John Deere 325 Lawn Tractor Parts Diagram for Efficient Maintenance

Understanding the intricate details of mechanical assemblies is crucial for maintaining and optimizing the performance of any outdoor equipment. By focusing on the structural layout and interaction between various elements, users can ensure efficient operation and prolong the lifespan of their machine. This section provides a clear and detailed breakdown of the essential components that make up the device, enabling you to make informed decisions about repairs and replacements.

Within this guide, we explore the different elements that contribute to the overall functionality of your equipment. These include everything from essential drive systems to smaller elements that work together to ensure smooth operation. By familiarizing yourself with the detailed layout of these components, you can enhance your understanding of how each part contributes to the machine’s overall performance.

Whether you’re conducting routine maintenance or handling a complex repair, having a solid grasp of how each mechanical element fits into the larger system is key. This resource will help you navigate through various technical elements, making it easier to diagnose issues and maintain the equipment at its peak efficiency.

Understanding the Key Components of John Deere 325

In this section, we will explore the essential elements that contribute to the functionality and performance of this versatile piece of equipment. Each component plays a crucial role in ensuring smooth operation, durability, and efficiency, making it a reliable tool for various tasks. By understanding these components, users can maintain and troubleshoot the machine more effectively.

Engine and Power System

The engine is the heart of the equipment, providing the necessary power for all operations. This system includes the fuel tank, carburetor, and ignition system, working together to ensure consistent performance. Regular maintenance of these parts is essential to prevent issues such as stalling or reduced power output.

- Fuel Tank: Stores fuel and ensures a steady supply to the engine.

- Carburetor: Mixes air and fuel in the correct ratio for combustion.

- Ignition System: Sparks the fuel mixture to start the engine.

Transmission and Steering

The transmission system enables smooth shifting between gears, allowing the operator to control speed and direction. Steering components ensure precise maneuverability, making it easier to navigate various terrains and obstacles.

- Transmission: Transfers power from the engine to the wheels, ensuring proper speed control.

- Steering Wheel: Directs the wheels and helps maintain control during operation.

- Hydraulics: Assists with steering and adjusting attachments for different t

How to Identify Engine Parts on a 325 Model

Understanding the various components of the engine is essential for maintaining and repairing your equipment. This guide will help you recognize key elements of the power unit, enabling you to better manage the upkeep and resolve potential issues efficiently.

Main Components of the Engine

The engine consists of several critical elements that ensure optimal performance. The cylinder head is one of the most visible parts, housing the combustion chamber. Beneath it, the crankshaft converts linear energy into rotational force, driving the machine forward. Other essential parts include the pistons, responsible for generating power, and the spark plugs, which ignite the fuel-air mixture.

Identifying Auxiliary Systems

Aside from the core components, there are auxiliary systems that play crucial roles in the engine’s operation. The fuel system supplies the necessary mixture of fuel and air, while the cooling system ensures that the engine doesn’t overheat. The electrical system, powered by the alternator, keeps all electronic components running smoothly.

Maintenance Tips for Your Outdoor Riding Mower

Regular upkeep is essential to ensure the smooth operation and longevity of any outdoor riding machine. By following simple steps and routines, you can keep your equipment performing at its best, while also preventing costly repairs. In this section, we will discuss key maintenance tasks to help you care for your equipment effectively.

Here are some recommended maintenance actions:

Task Frequency Notes Oil Change Every 50 hours of use Check oil level regularly and change it as per the manufacturer’s recommendations. Air Filter Cleaning/Replacement Every 25 hours of use Ensure the air filter is clean to avoid engine damage. Replace if necessary. Blade Sharpening At the start of the mowing season Sharp blades provide a cleaner cut and reduce engine strain. Battery Inspection Monthly Check for corrosion and ensure the terminals are clean and tight. Belts and Pulleys Every 100 hours of use Inspect for wear and tear to avoid breakdowns during operation. By following these maintenance guidelines, your outdoor equipment will

Steering System Breakdown for Optimal Performance

The steering mechanism is essential for smooth and precise control, ensuring easy maneuverability during operation. Understanding its components and how they interact can help maintain consistent handling and prevent unnecessary wear. Regular checks and maintenance of key elements will significantly enhance the system’s reliability and extend its lifespan.

Steering Wheel Assembly: The control begins here. It’s crucial to inspect for any looseness or excessive play, which could indicate underlying issues with the connecting parts.

Linkage and Tie Rods: These components transmit movement from the wheel to the front wheels, making it important to check for any signs of bending or damage. Proper alignment ensures smooth steering and minimizes friction.

Spindles and Axles: The spindles connect to the front wheels, allowing them to pivot as you turn. Regular lubrication of these joints reduces resistance and improves overall responsiveness.

Maintenance Tips: Ensure all moving parts are properly greased, and regularly check the alignment of the front wheels. Address any unusual noises or difficulty in turning immediately to prevent larger issues.

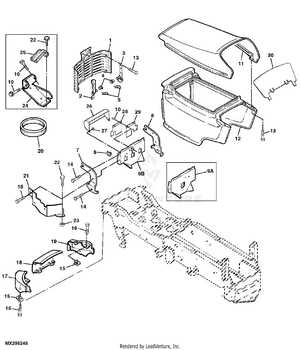

Guide to Replacing Blades on a 325 Tractor

Maintaining the cutting efficiency of your equipment is essential for optimal performance. Over time, the blades wear down, reducing their effectiveness. This section provides a clear, step-by-step process for removing and replacing the blades to ensure smooth operation and longevity.

Tools You Will Need

- Socket wrench set

- Blade removal tool (optional but recommended)

- Protective gloves

- Jack or lift

Step-by-Step Blade Replacement

- Preparation: Ensure the machine is turned off and the key is removed. Use a jack to lift the front, giving you clear access to the deck.

- Remove the Deck: Detach the deck by releasing the connecting pins and lowering it to the ground.

- Loosen the Blades: Using a socket wrench, unscrew the bolts securing the blades. Hold the blade in place with a removal tool or carefully by hand if necessary.

- Install New Blades: Align the new blades with the bolt holes and secure them tightly with the wrench. Double-check that they are fastened securely.

- Reattach the Deck: Once the new blades are installed, raise the deck and reattach it using the connecting pins.

- Test Operation: Lower the

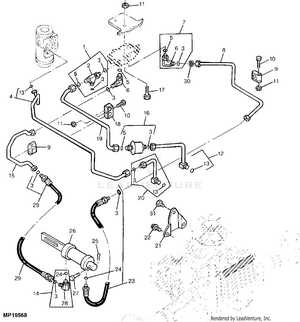

Locating Electrical Components for Repairs

When undertaking maintenance on outdoor power equipment, understanding the placement of electrical components is crucial for effective troubleshooting and repair. Familiarizing oneself with the layout can streamline the process, ensuring that necessary adjustments or replacements can be made efficiently. Proper identification of these elements contributes to the longevity and functionality of the machine.

Understanding the Electrical System

The electrical system in any machinery typically consists of various components such as batteries, fuses, switches, and connectors. Each of these parts plays a vital role in the overall operation. It is essential to consult a comprehensive reference guide that details the layout and function of each component. This knowledge will aid in pinpointing issues more swiftly.

Using a Wiring Schematic

A wiring schematic is an invaluable tool when locating electrical components. This diagram provides a visual representation of the connections and pathways within the system. By studying the schematic, one can trace the flow of electricity and identify potential problem areas. Make sure to have this schematic on hand during repairs to ensure a methodical approach.

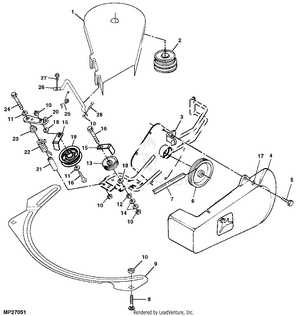

Fuel System Overview of John Deere 325

The fuel system in this garden machine plays a vital role in ensuring optimal performance and efficiency. It is designed to deliver the right amount of fuel to the engine, allowing for smooth operation and effective power generation. Understanding its components and functionality is essential for maintenance and troubleshooting.

Key Components

- Fuel Tank: Stores the gasoline required for operation.

- Fuel Pump: Responsible for moving fuel from the tank to the engine.

- Fuel Filter: Cleans the fuel before it reaches the engine, preventing contaminants from causing damage.

- Fuel Lines: Transport fuel between the tank, pump, and engine.

- Carburetor: Mixes air and fuel in the appropriate ratio for combustion.

Maintenance Tips

- Regularly check the fuel level in the tank to avoid running out during operation.

- Inspect fuel lines for any signs of wear or leaks.

- Replace the fuel filter as recommended to ensure clean fuel supply.

- Keep the carburetor clean to prevent clogging and ensure proper air-fuel mixture.

- Store fuel in a cool, dry place and avoid using stale gasoline.

Troubleshooting Hydraulic System Issues

Hydraulic systems play a crucial role in the operation of various equipment, enabling smooth movement and functionality. Identifying and resolving problems within these systems is essential for maintaining optimal performance. This section outlines common issues and their solutions, providing a systematic approach to troubleshooting.

Common Symptoms of Hydraulic Problems

- Inconsistent or slow movement of attachments

- Unusual noises during operation

- Fluid leaks around hoses and connections

- Overheating of hydraulic fluid

- Failure to lift or lower implements

Troubleshooting Steps

- Check the hydraulic fluid level and condition.

- Inspect hoses and connections for leaks or damage.

- Examine filters for clogs or contamination.

- Test the operation of valves and cylinders.

- Monitor for unusual noises indicating mechanical failure.

By following these guidelines, operators can effectively diagnose and rectify hydraulic issues, ensuring reliable equipment performance and longevity.

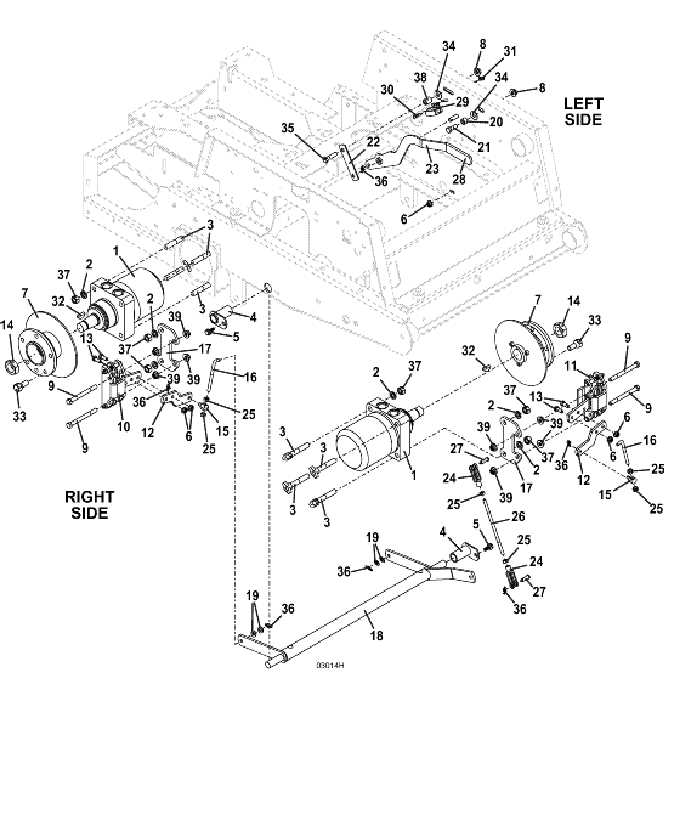

John Deere 325 Transmission System Explained

The transmission system is a crucial component that ensures the smooth operation of a riding machine, facilitating the transfer of power from the engine to the wheels. This system allows the operator to control speed and torque, adapting to various terrains and mowing conditions efficiently. Understanding the intricate workings of this assembly enhances maintenance and troubleshooting capabilities.

At the heart of the transmission system are several key components that work together to provide optimal performance. Each element plays a specific role, contributing to the overall efficiency and reliability of the machinery. Below is a detailed overview of the essential components:

Component Description Gearbox This assembly houses gears that regulate speed and torque, allowing for smooth transitions during operation. Drive Belt The drive belt connects the engine to the gearbox, transferring power and enabling movement. Clutch The clutch mechanism allows the operator to engage or disengage the drive system as needed, enhancing control. Hydraulic System This system provides the necessary force to operate various functions, including gear shifting and steering. Transmission Fluid Essential for lubrication, the fluid reduces friction and helps maintain optimal operating temperatures within the system. Regular inspection and maintenance of the transmission system are vital to ensure longevity and peak performance. Understanding each component’s function enables operators to address potential issues promptly, ensuring a reliable and efficient operation.

Common Issues with John Deere 325 Brakes

Brake systems are essential for the safe operation of any machinery, providing control and stability during use. However, various challenges can arise that may affect their performance. Understanding these common issues is vital for ensuring optimal functionality and safety.

Worn Brake Pads

One frequent problem involves the degradation of brake pads. Over time, these components can wear down due to friction, leading to reduced stopping power. Regular inspections and timely replacements are crucial to maintain effective braking performance.

Fluid Leaks

Another concern is the presence of fluid leaks within the braking system. These leaks can compromise the hydraulic pressure necessary for the brakes to function correctly. Identifying the source of any leaks and addressing them promptly is essential for the reliability of the braking mechanism.