Comprehensive Guide to John Deere Tractor Parts Diagram

The world of agricultural machinery is intricate and essential for modern farming. Each machine is composed of numerous elements that work in harmony to enhance efficiency and productivity. Gaining insight into these components not only aids in maintenance but also empowers operators to optimize their use.

Familiarizing oneself with the various segments of machinery allows for a better grasp of their functions and interrelations. When issues arise, knowing how each element fits together becomes crucial for timely repairs and replacements. This knowledge ultimately leads to improved performance and longevity of the equipment.

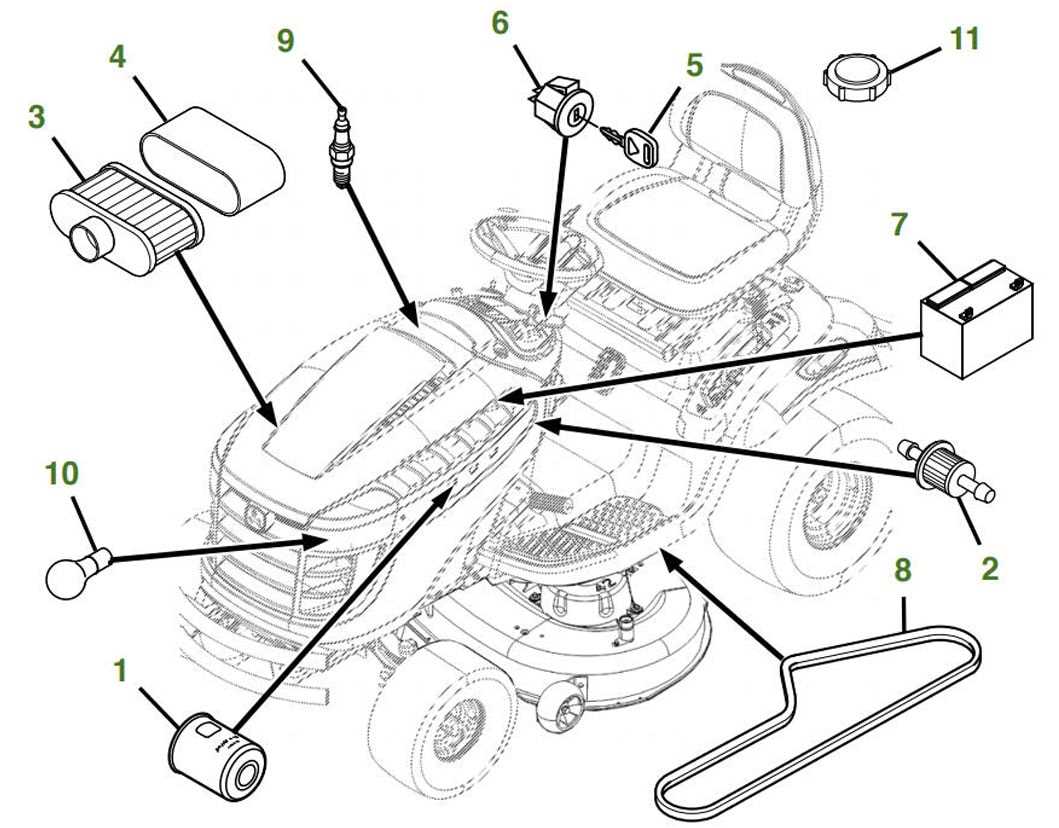

For enthusiasts and professionals alike, visual representations of these elements can serve as valuable resources. By examining layouts and structures, individuals can quickly identify necessary components and streamline their maintenance routines. Such illustrations foster a deeper understanding of the machinery, bridging the gap between theory and practice.

Understanding John Deere Tractors

This section delves into the intricacies of agricultural machinery renowned for their reliability and performance. These machines play a crucial role in modern farming, transforming various tasks into streamlined processes. Their design and engineering are tailored to meet the diverse needs of users, ensuring efficiency in every operation.

One of the key aspects of these vehicles is their adaptability. Whether for large-scale farming or smaller operations, they come equipped with a range of features that enhance usability. Components can be customized to fit different agricultural practices, allowing operators to maximize productivity.

Moreover, understanding the functionality of each element is essential for maintenance and operation. Familiarity with these mechanisms enables users to troubleshoot issues effectively, ensuring that machinery remains in peak condition. This knowledge is invaluable for optimizing performance and extending the lifespan of the equipment.

Importance of Equipment Component Illustrations

Understanding the intricate details of machinery is crucial for effective maintenance and operation. Visual representations of individual elements play a vital role in simplifying the complexities associated with machinery. These illustrations serve as essential tools for technicians and operators alike, enabling them to grasp the functionality and interconnections of various components.

Enhancing Maintenance Efficiency

Utilizing visual guides significantly improves the speed and accuracy of maintenance tasks. Technicians can quickly identify required components and assess their condition. This leads to more efficient repairs, reducing downtime and ensuring that the equipment operates at peak performance. Clear visual aids help eliminate confusion, allowing for a streamlined workflow during maintenance sessions.

Facilitating Training and Learning

Illustrations are invaluable in the training of new personnel. By providing a clear view of how different elements work together, they enhance the learning experience. Trainees can develop a deeper understanding of machinery functionality, which fosters confidence in their abilities. Visual learning is often more effective than textual descriptions alone, making these resources indispensable in educational settings.

Key Components of John Deere Tractors

Understanding the essential elements of agricultural machinery is crucial for efficient operation and maintenance. These fundamental units work together to enhance performance and productivity in the field. From power sources to control mechanisms, each component plays a vital role in the overall functionality.

Engine: The heart of any machine, the engine provides the necessary power for various operations. Modern engines are designed for fuel efficiency and reduced emissions, ensuring sustainability in farming practices.

Transmission: This system is responsible for transferring power from the engine to the wheels. Different types of transmissions, such as manual or automatic, allow operators to optimize speed and torque based on the task at hand.

Hydraulic System: This system uses fluid power to perform work, such as lifting heavy loads or adjusting implements. A well-maintained hydraulic setup enhances the versatility and adaptability of the machinery.

Chassis: The framework supports all other components and provides stability during operation. A robust chassis ensures durability and can withstand the rigors of various terrains.

Electrical System: This component powers lights, controls, and other electronic devices. An efficient electrical system is essential for modern machines, allowing for advanced features and enhanced operator comfort.

Cabin: Designed for operator safety and comfort, the cabin provides an enclosed space with controls and visibility. Modern cabins are equipped with climate control and ergonomic seating, ensuring long hours of work can be done with minimal fatigue.

Each of these vital elements contributes to the machinery’s effectiveness, making them indispensable for modern agriculture. Understanding their functions helps operators maximize efficiency and maintain their equipment properly.

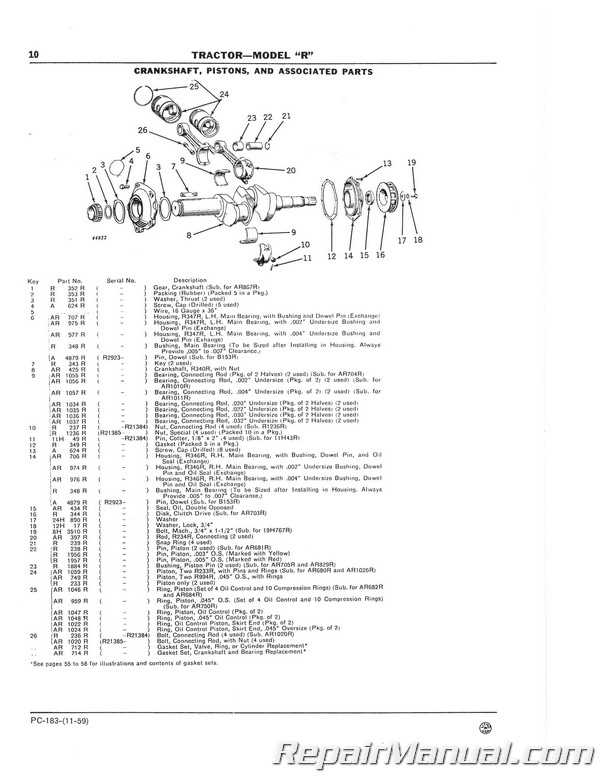

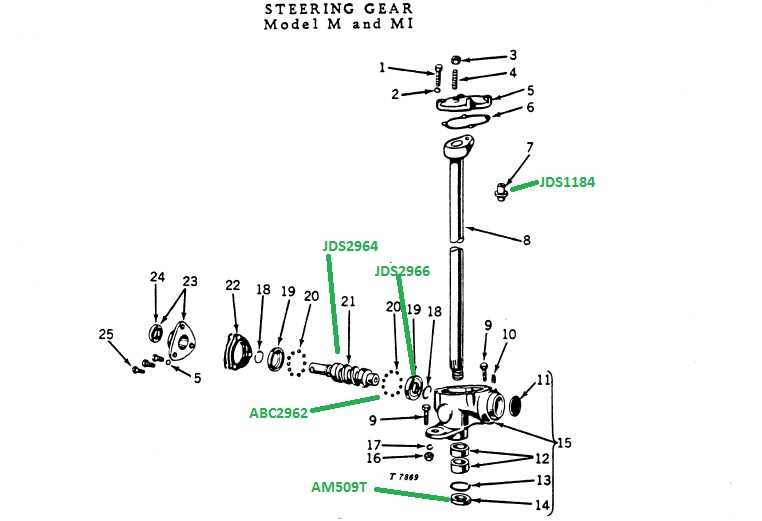

How to Read Parts Diagrams

Understanding technical illustrations can significantly enhance your ability to maintain and repair machinery. These visual guides offer a wealth of information, illustrating the components and their relationships within a system. Familiarity with these illustrations allows users to locate specific items and comprehend their functions efficiently.

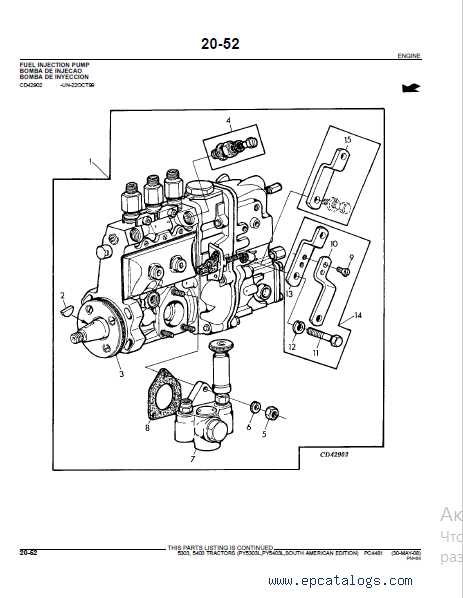

Key Elements of Technical Illustrations

When examining these illustrations, several critical elements will help in deciphering the information presented:

| Element | Description |

|---|---|

| Labels | Identifiers that specify each component, often accompanied by numbers or letters for easy reference. |

| Legends | Explanations of symbols or colors used throughout the illustration, providing context and clarity. |

| Sections | Divided areas within the illustration that focus on specific components or systems, aiding in understanding. |

Steps to Effectively Interpret the Illustration

To navigate these visuals successfully, follow these straightforward steps:

- Start by reviewing the legend to understand the symbols used.

- Identify the labeled components that are relevant to your task.

- Refer to the sections to locate specific areas that require attention.

- Use the numbers or letters as a guide for ordering replacement items or referencing further documentation.

Common Issues and Solutions

In the realm of agricultural machinery, various challenges may arise during operation and maintenance. Understanding these common problems and their corresponding solutions can significantly enhance performance and longevity.

- Engine Performance Issues:

- Solution: Regularly check fuel quality and filters.

- Solution: Ensure proper oil levels and change oil as needed.

- Electrical Failures:

- Solution: Inspect battery connections and charge levels.

- Solution: Test and replace faulty fuses or relays.

- Hydraulic System Problems:

- Solution: Monitor fluid levels and replace hydraulic fluid as required.

- Solution: Examine hoses and fittings for leaks or damage.

- Transmission Difficulties:

- Solution: Check and adjust transmission fluid levels.

- Solution: Ensure that the clutch is functioning properly and adjust if necessary.

- Cooling System Malfunctions:

- Solution: Regularly clean the radiator and ensure unobstructed airflow.

- Solution: Inspect coolant levels and top up as needed.

By proactively addressing these typical issues, operators can maintain optimal functionality and reduce downtime.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your agricultural machinery requires consistent care and attention. By implementing a regular maintenance routine, you can prevent costly repairs and extend the lifespan of your equipment. This section provides essential strategies for keeping your machinery in optimal condition.

Regular Inspections

Frequent assessments of machinery components can identify potential issues before they escalate. Focus on the following areas during your inspections:

| Component | Inspection Frequency | Key Checks |

|---|---|---|

| Fluid Levels | Weekly | Check oil, coolant, and hydraulic fluids |

| Filters | Monthly | Inspect and replace air and fuel filters |

| Tires | Monthly | Examine tread depth and inflation |

Proper Storage

Storing your machinery correctly can significantly impact its longevity. Consider these storage tips:

- Keep equipment in a sheltered area to protect it from the elements.

- Use tarps or covers for added protection against dust and debris.

- Ensure that machinery is clean before storage to prevent corrosion.

Finding Replacement Parts Easily

Locating suitable components for machinery can be a straightforward process if approached with the right strategies. The key lies in understanding how to efficiently navigate resources and utilize various tools at your disposal. With a little guidance, you can streamline the search and ensure you acquire the exact elements needed for repairs or upgrades.

Start by utilizing online platforms that specialize in agricultural equipment. Many websites offer extensive catalogs and search features, allowing you to filter results based on specifications or compatibility. Make use of customer reviews and ratings to gain insights into the quality and reliability of the components.

Another effective method is consulting with local suppliers who possess in-depth knowledge of your equipment. Building a relationship with these experts can provide you with invaluable advice and recommendations, saving you time and effort in your search. Additionally, many suppliers maintain inventories that might not be fully listed online, so don’t hesitate to ask for assistance.

Consider joining online forums or communities dedicated to machinery enthusiasts. These groups often share experiences, tips, and resources that can lead you to hard-to-find components. Engaging with fellow users can enhance your understanding and provide access to a wealth of information.

By leveraging these strategies, you can simplify the process of finding necessary components, ensuring your machinery remains in optimal condition without unnecessary delays.

Upgrading vs. Replacing Components

When it comes to maintaining heavy machinery, two primary strategies often arise: enhancing existing elements or substituting them entirely. Each approach has its own set of benefits and considerations, making it crucial for operators to assess their specific needs and circumstances.

Benefits of Upgrading

Opting to enhance certain features can lead to improved performance without the need for a complete overhaul. Here are some advantages:

- Cost-Effectiveness: Upgrading tends to be less expensive than a full replacement.

- Extended Lifespan: Enhancements can significantly extend the usability of existing equipment.

- Minimal Downtime: Upgrading usually requires less time, allowing for quicker returns to operation.

When to Consider Replacement

While upgrading is often beneficial, there are scenarios where replacing components is the better option:

- Severe Damage: If a part is heavily worn or damaged, replacement may be necessary for safety and functionality.

- Obsolete Technology: Older components might lack the efficiency of newer models, warranting a complete swap.

- Comprehensive Upgrades: If multiple parts require enhancement, it may be more efficient to replace them all at once.

Ultimately, the decision between upgrading and replacing hinges on factors such as budget, urgency, and the specific needs of the machinery in question.

Benefits of Genuine John Deere Parts

Opting for authentic components offers numerous advantages that enhance both performance and longevity of machinery. These items are meticulously engineered to meet strict quality standards, ensuring they function seamlessly with the equipment.

One significant benefit is reliability. Genuine components are designed to work harmoniously within the system, minimizing the risk of breakdowns. This leads to reduced maintenance costs and increased operational efficiency.

Furthermore, using original products often helps maintain the equipment’s warranty. Manufacturers typically stipulate that only authentic components should be used to preserve coverage, safeguarding your investment over time.

Additionally, genuine components contribute to the overall resale value of the machinery. Prospective buyers often prefer equipment with original parts, as they are synonymous with quality and dependability.

In summary, choosing authentic components not only ensures optimal performance but also protects your investment and enhances the overall longevity of your machinery.

Using Online Resources Effectively

In the digital age, accessing information has never been easier. However, navigating the vast sea of online resources can be overwhelming. Utilizing these tools effectively requires a strategic approach to ensure you find accurate and relevant information quickly.

Identifying Credible Sources

When searching for information, it is crucial to discern credible sources from unreliable ones. Look for websites that are well-known and have established reputations in the field. Peer-reviewed articles, official publications, and expert blogs can be great starting points. Always verify the author’s credentials and the date of publication to ensure the information is current.

Organizing Your Findings

As you gather information, it is helpful to maintain a systematic approach to organization. Consider using tables to categorize your discoveries. This will allow for easy reference and comparison later on. Below is an example of how to structure your findings:

| Resource Type | Source Name | Key Information |

|---|---|---|

| Article | Expert Insights | Latest advancements in agricultural machinery. |

| Blog | AgriTech Hub | Tips on maintaining equipment efficiently. |

| Video | Farm Equipment Pro | Visual guide on troubleshooting common issues. |

By following these strategies, you can enhance your research process and make the most out of online resources available to you.

Identifying Your Tractor Model

Determining the specific model of your agricultural machine is essential for effective maintenance and repair. Knowing the correct designation allows for precise ordering of components and ensures compatibility with your equipment’s needs.

Here are some key methods to identify your model:

- Check the Identification Plate: Most machines have an identification plate located in a visible area. This plate typically includes the model number and serial number.

- Consult the Owner’s Manual: The manual provides comprehensive information about the equipment, including the model and specifications.

- Use Online Resources: Various websites offer databases to help you find your model based on provided features or serial numbers.

In addition, pay attention to the following features that can aid in identification:

- Engine type and horsepower

- Chassis design and size

- Transmission system

- Wheel configuration

By using these strategies, you can accurately identify your machine, ensuring you have the right information for repairs and enhancements.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is essential for preventing accidents and injuries. Proper precautions must be taken to protect both the individual performing the repairs and the surrounding environment. Following a few key guidelines can help create a secure work area and reduce risks during the repair process.

Before starting any maintenance work, it is important to wear appropriate personal protective equipment (PPE). This includes items such as gloves, goggles, and sturdy footwear to shield against potential hazards.

| Safety Gear | Purpose |

|---|---|

| Gloves | Protect hands from cuts and chemicals |

| Goggles | Shield eyes from debris and harmful substances |

| Footwear | Provide stability and prevent injuries from falling objects |

Additionally, it is crucial to work in a well-ventilated area to avoid inhaling harmful fumes. Keeping the workspace organized and free of clutter can also prevent accidents, allowing for easy access to tools and materials. Always ensure that equipment is properly secured before beginning any task, and be aware of your surroundings to avoid potential hazards.

Tips for DIY Tractor Maintenance

Keeping your agricultural machinery in optimal condition requires regular attention and care. Implementing a few simple practices can enhance performance, prolong lifespan, and ensure reliability during crucial tasks. This section provides essential tips to help you maintain your equipment effectively.

Regular Inspections

- Check fluid levels: Ensure that oil, coolant, and hydraulic fluids are at appropriate levels to prevent overheating and mechanical failure.

- Inspect belts and hoses: Look for signs of wear, cracking, or leaks to avoid unexpected breakdowns.

- Examine tires: Maintain proper inflation and tread depth for better traction and stability.

Routine Maintenance Tasks

- Change oil and filters: Regularly replace oil and filters to keep the engine running smoothly.

- Clean air filters: Ensure optimal airflow by regularly cleaning or replacing air filters.

- Sharpen blades: If your machinery includes cutting implements, keep them sharp for efficient operation.

By adhering to these guidelines, you can significantly improve the efficiency and reliability of your agricultural equipment, ensuring it is always ready for the task at hand.