Understanding the Oliver Tractor Parts Diagram for Efficient Repairs

In the realm of farming machinery, a comprehensive grasp of the individual elements that contribute to overall functionality is essential for optimal performance. Each component plays a vital role, and knowing how they interconnect can significantly enhance maintenance and repair processes.

Visual representations serve as valuable tools for both seasoned professionals and newcomers. They provide a clear overview of how different sections interact, simplifying complex concepts and allowing for efficient troubleshooting.

By examining these illustrations, users can familiarize themselves with essential functionalities and identify potential areas for improvement. A thorough understanding empowers operators to make informed decisions, ensuring their equipment remains in peak condition throughout its operational life.

Understanding Oliver Tractor Models

Exploring the diverse range of agricultural machinery can be both fascinating and complex. Each model embodies unique characteristics and features that cater to different farming needs. Gaining insight into these models allows users to make informed decisions about their equipment and optimize performance in the field.

When examining various models, it is essential to consider several key factors:

- Design Specifications: Each model may differ in size, engine capacity, and operational capabilities.

- Technological Advancements: Innovations over the years have introduced enhanced features that improve efficiency and ease of use.

- Market Variations: Certain models may be more popular in specific regions due to local agricultural practices and terrain.

- Maintenance Requirements: Understanding the upkeep needs of each model ensures longevity and reliability.

To gain a clearer perspective, consider categorizing models based on:

- Power Output: Grouping by horsepower can help in selecting equipment suitable for various tasks.

- Utility Applications: Identifying models designed for specific functions, such as plowing or hauling, can streamline operational processes.

- Year of Manufacture: Older models might have different characteristics compared to the latest releases, influencing performance and support.

By familiarizing oneself with these elements, users can navigate the array of machinery more effectively, ensuring they select the most suitable option for their agricultural endeavors.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations serve as invaluable tools, guiding users through the intricate details of assembly and functionality. They enhance clarity, enabling technicians to identify and troubleshoot issues more efficiently.

Comprehension: These visual aids provide an immediate grasp of the various elements involved, simplifying complex systems. With a well-structured illustration, users can quickly locate specific components and understand their relationships within the overall framework.

Efficiency: Time is of the essence in repairs. Having a clear visual guide reduces the likelihood of errors, streamlining the process and minimizing downtime. This leads to faster resolutions and improved operational efficiency.

Documentation: A detailed illustration also serves as a crucial reference for future maintenance. It ensures that all users have access to the same foundational knowledge, promoting consistency in service and repairs.

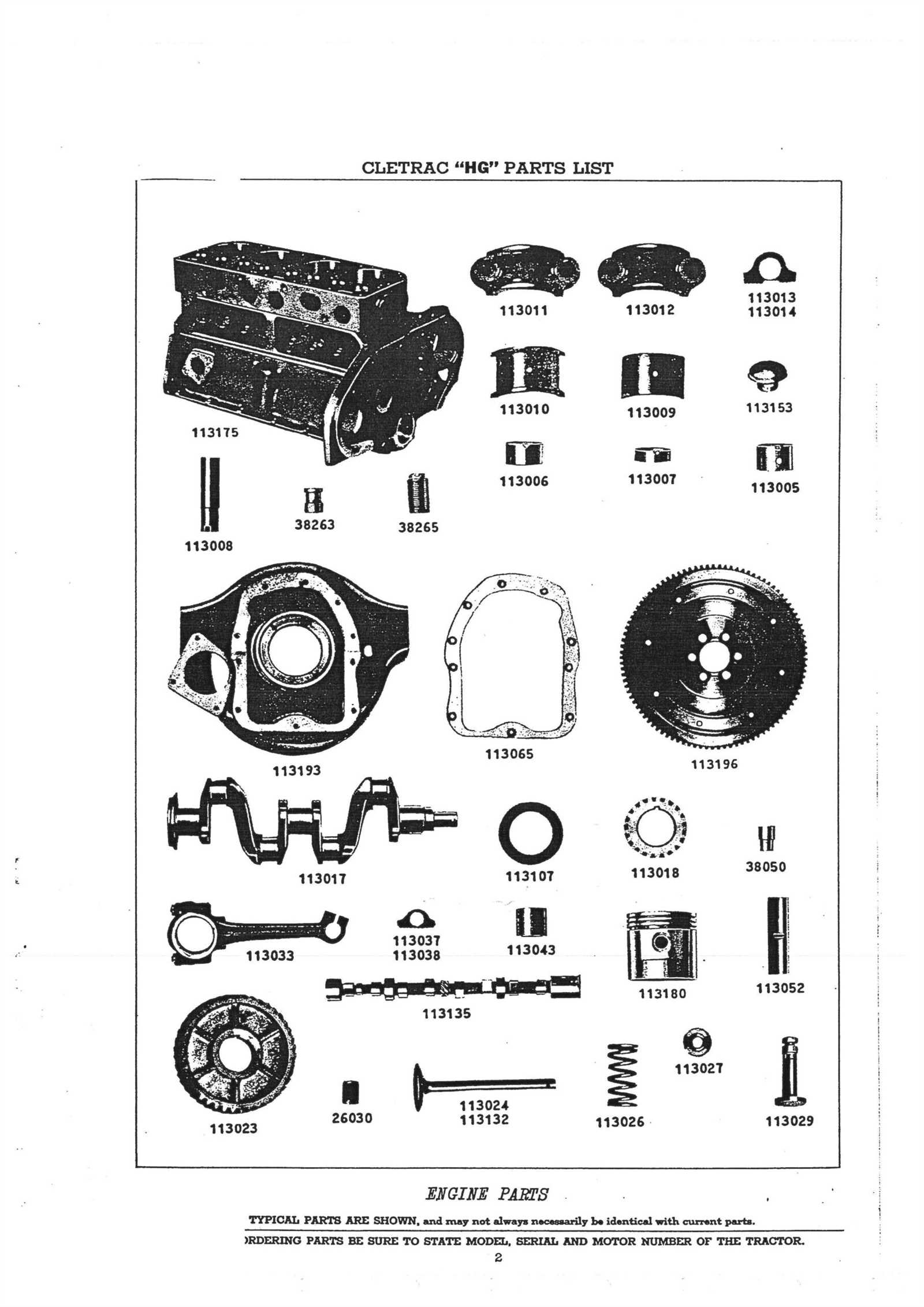

Common Components of Oliver Tractors

This section explores the essential elements that contribute to the functionality and efficiency of these agricultural machines. Understanding these components is crucial for maintenance and optimal performance.

Powertrain Elements

The powertrain includes critical systems such as the engine, transmission, and drive shafts. These parts work together to deliver the ultimate performance, ensuring smooth operation across various terrains.

Hydraulic and Electrical Systems

Hydraulic mechanisms and electrical configurations are vital for controlling attachments and enhancing operational capabilities. Maintaining these systems is essential for reliable performance and long-lasting use.

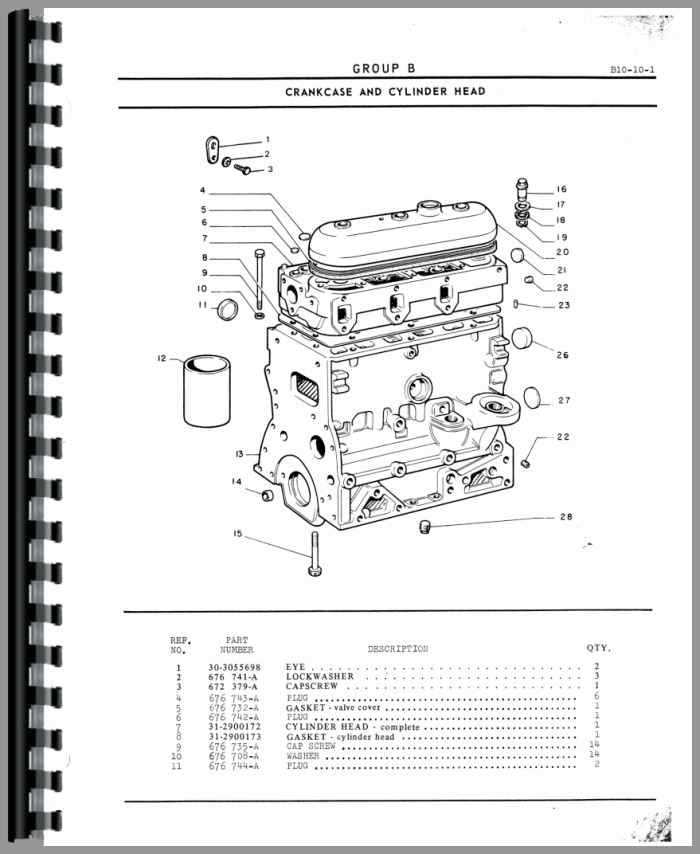

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. Familiarizing yourself with these illustrations can greatly enhance your troubleshooting skills and ensure the longevity of your equipment.

Identifying Key Elements

- Labels: Look for annotations that specify component names and numbers.

- Symbols: Familiarize yourself with common representations used for various parts.

- Connections: Pay attention to lines indicating how different pieces interact.

Using the Illustration Effectively

- Start by locating the section relevant to your repair.

- Cross-reference the labels with your inventory of components.

- Take note of any special instructions or warnings associated with specific items.

Finding Replacement Parts Online

Locating essential components for machinery can be a straightforward process if approached methodically. With the right resources, you can ensure that your equipment remains operational without excessive downtime. Online platforms provide a wealth of options to explore and procure the items you need.

Here are some effective strategies to assist you in your search:

- Utilize Specialized Websites: Look for websites dedicated to equipment supplies. These often feature comprehensive catalogs and user-friendly search tools.

- Join Online Forums: Engage with communities of enthusiasts and professionals. They can offer insights and recommendations for reputable sources.

- Check Manufacturer Sites: Visit official pages of the equipment brands, as they may offer direct sales or links to authorized dealers.

- Explore Auction Sites: Online auction platforms may have listings for used or surplus components at competitive prices.

By implementing these strategies, you can streamline your search and increase the likelihood of finding the correct items efficiently. Don’t forget to compare prices and read reviews to ensure a satisfactory purchasing experience.

Maintenance Tips for Oliver Tractors

Regular upkeep is essential to ensure optimal performance and longevity of machinery. Proper care not only enhances functionality but also prevents costly repairs. Following a structured maintenance routine can significantly improve efficiency and reliability.

Routine Checks

Conducting frequent inspections is vital. Here are key areas to focus on:

| Component | Maintenance Task | Frequency |

|---|---|---|

| Engine | Check oil level and change as necessary | Every 50 hours of use |

| Fuel System | Inspect fuel filters and lines for leaks | Monthly |

| Cooling System | Ensure coolant is at proper levels | Before each use |

| Tires | Check pressure and tread condition | Weekly |

Seasonal Maintenance

Different seasons bring unique challenges. Be proactive by preparing for changes in conditions:

| Season | Maintenance Task |

|---|---|

| Spring | Inspect belts and hoses for wear |

| Summer | Clean air filters and check cooling efficiency |

| Fall | Prepare for winter by checking battery and antifreeze levels |

| Winter | Store in a dry, covered area to prevent damage |

History of Oliver Tractors

The evolution of this renowned agricultural machinery brand reflects a commitment to innovation and quality. Its origins can be traced back to the early 20th century, when a vision for superior farming equipment began to take shape.

Founding and Early Years

In the late 1800s, a small company emerged, focusing on producing farm implements. This venture quickly expanded, leading to the creation of more advanced machinery. Key milestones during this period include:

- Introduction of the first steam-powered equipment.

- Development of innovative designs that improved efficiency.

- Strategic partnerships that enhanced production capabilities.

Growth and Innovation

Throughout the mid-20th century, the brand solidified its position in the market by embracing technological advancements. Significant contributions include:

- Launch of diesel engines that revolutionized performance.

- Incorporation of ergonomic designs for user comfort.

- Focus on sustainability and fuel efficiency in later models.

This legacy continues to influence modern agricultural practices, making it a staple in farming communities across the globe.

Identifying Parts by Model Number

Understanding components through model identifiers is crucial for effective maintenance and repair. Each model has unique specifications that help users locate the correct items needed for their machinery. By referencing these identifiers, one can ensure compatibility and optimal performance.

| Model Number | Description |

|---|---|

| 1234AB | Standard engine assembly |

| 5678CD | Hydraulic pump unit |

| 9101EF | Transmission casing |

Tools Needed for Repairs

When undertaking maintenance or restoration tasks, having the right implements is essential for efficiency and effectiveness. Each job requires specific tools that facilitate precision and ease of use, ensuring that repairs are conducted smoothly.

Basic Hand Tools: A good set of wrenches, screwdrivers, and pliers forms the foundation of any repair kit. These essentials allow for adjustments and replacements with minimal hassle.

Specialized Equipment: Depending on the complexity of the task, certain specialized tools may be necessary. Items such as torque wrenches and impact guns provide added power and accuracy for more demanding jobs.

Measuring Instruments: Tools like calipers and tape measures are vital for ensuring components are correctly sized and fitted. Accurate measurements prevent complications and enhance overall performance.

Safety Gear: Never overlook the importance of protective equipment. Gloves, goggles, and masks are crucial for safeguarding against injuries and ensuring a safe working environment.

Ultimately, being well-equipped not only streamlines the repair process but also contributes to achieving a higher standard of workmanship.

Where to Buy OEM Parts

Finding high-quality components for your machinery can significantly enhance performance and longevity. Authentic replacements ensure compatibility and reliability, making it crucial to know where to source them.

- Manufacturer Websites: Start by visiting the official sites of your equipment makers. They often have dedicated sections for genuine replacements.

- Authorized Dealers: Check with local dealers who are certified to sell authentic components. This guarantees the quality you seek.

- Online Retailers: Numerous e-commerce platforms specialize in genuine components. Be sure to read reviews to confirm their authenticity.

- Trade Shows and Expos: Attending industry events can connect you with vendors offering original equipment solutions.

Investing time in finding the right sources will ultimately lead to superior performance and reduced downtime for your machinery.

DIY Repairs vs. Professional Services

When it comes to maintaining machinery, individuals often face the choice between self-repair and hiring experts. Each approach has its benefits and drawbacks, influencing the decision based on skill level, time availability, and cost considerations.

| Aspect | DIY Repairs | Professional Services |

|---|---|---|

| Cost | Generally lower; savings on labor | Higher; includes labor and expertise |

| Time | Variable; depends on experience | Usually quicker; experts handle tasks efficiently |

| Skill Level | Requires some technical knowledge | Performed by trained professionals |

| Risk | Potential for mistakes, leading to further issues | Lower risk; experts ensure quality |

Upgrading Your Oliver Tractor

Enhancing your agricultural machinery can significantly improve performance and efficiency. By focusing on specific components and integrating modern technology, you can breathe new life into your equipment. This process not only increases productivity but also extends the lifespan of your machinery.

Key Areas for Improvement

Several critical areas can be addressed during the upgrade process. Prioritizing these elements will lead to more effective results and a smoother operation:

| Component | Upgrade Options | Benefits |

|---|---|---|

| Engine | Fuel injectors, performance tuning | Increased horsepower, better fuel efficiency |

| Transmission | New gears, hydraulic systems | Smoother shifting, enhanced control |

| Hydraulics | Upgraded pumps, hoses | Improved lifting capacity, faster operation |

| Electrical System | Modern wiring, LED lighting | Better visibility, reduced energy consumption |

Planning Your Upgrade

Before embarking on enhancements, careful planning is essential. Assess the current condition of your machinery and identify the areas that require attention. Research potential upgrades and consult with experts to ensure compatibility and effectiveness. This strategic approach will maximize your investment and lead to successful outcomes.