Comprehensive Guide to 4L60E Transmission Parts Diagram

Exploring the intricate design of a crucial vehicle mechanism can unveil the secrets behind its functionality and performance. This section aims to provide a comprehensive overview of the essential elements that contribute to the efficient operation of this automotive device.

By examining the individual components, one can truly appreciate their roles and how they interconnect to ensure smooth operation. The ultimate goal is to deepen your knowledge and facilitate informed decisions regarding maintenance and upgrades.

Whether you’re a seasoned mechanic or an enthusiastic DIYer, having a visual representation of these components can enhance your understanding and troubleshooting skills. Join us as we delve into the fascinating world of automotive engineering!

Understanding the 4L60E Transmission

This section explores the intricate system responsible for power delivery in certain vehicles. Understanding its components and their functions is essential for anyone interested in automotive engineering or performance enhancements. Each element plays a crucial role in ensuring smooth operation and efficiency.

Key Components

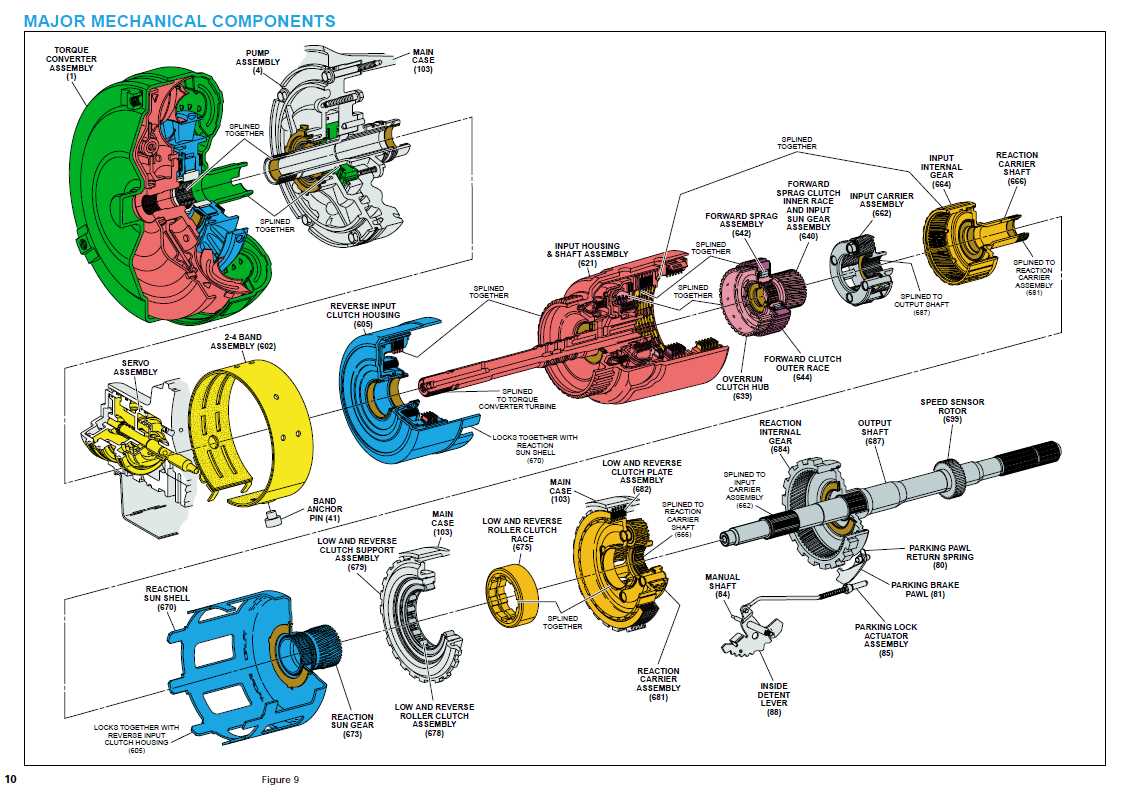

The main elements of this assembly include clutches, gears, and hydraulic systems that work together seamlessly. Familiarity with these components helps in diagnosing issues and improving overall performance.

Functionality Overview

| Component | Function |

|---|---|

| Clutches | Engage and disengage power transfer |

| Gears | Control speed and torque output |

| Hydraulic System | Manage fluid pressure for operation |

Key Components of 4L60E

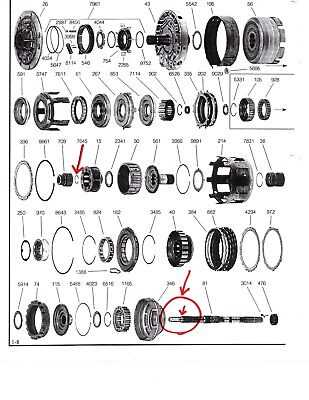

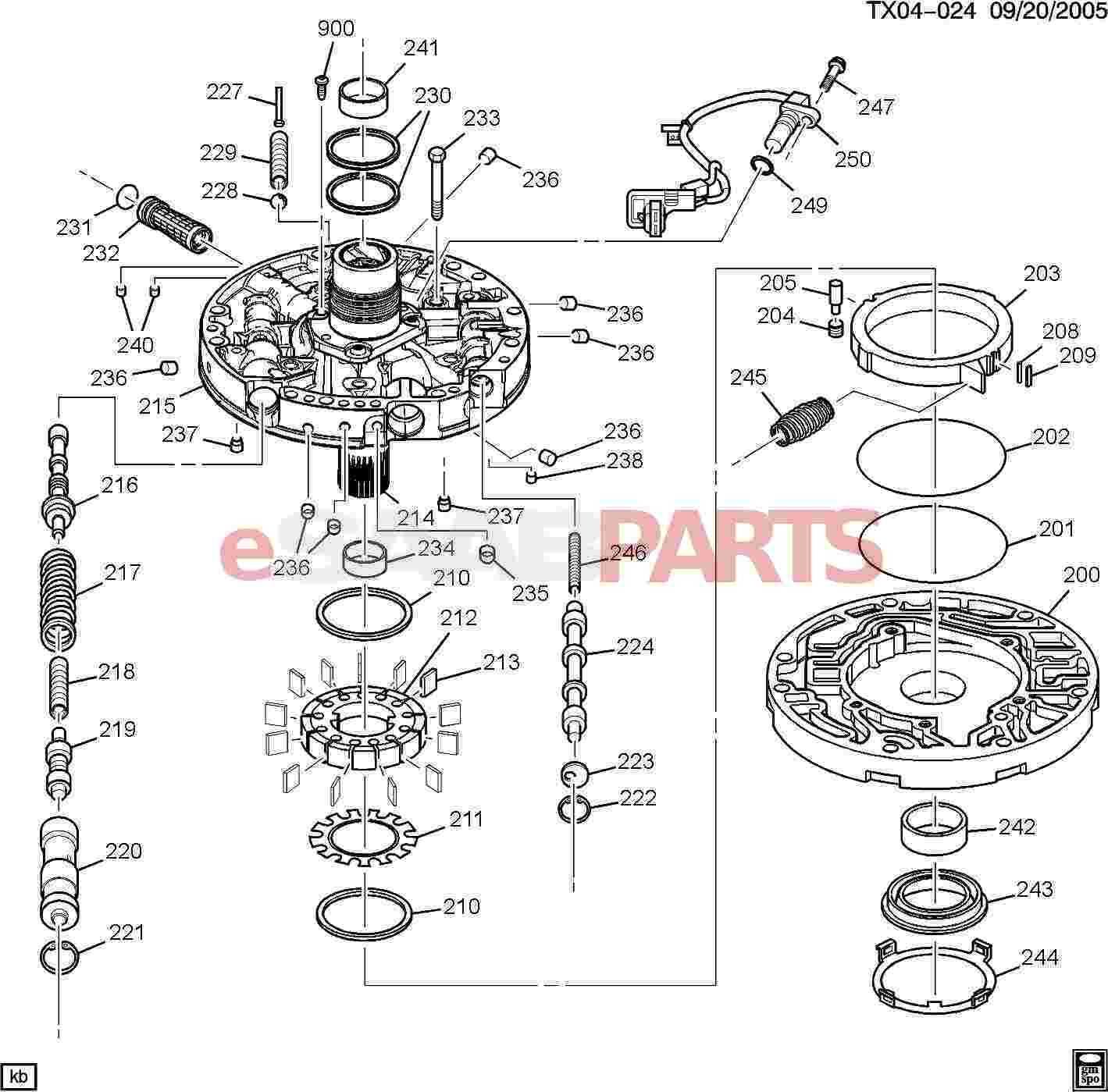

Understanding the fundamental elements of an automatic gear system is crucial for both enthusiasts and professionals in the automotive field. Each component plays a vital role in ensuring efficient operation, durability, and smooth shifting. A closer examination reveals a complex interplay between various mechanisms that contribute to overall performance.

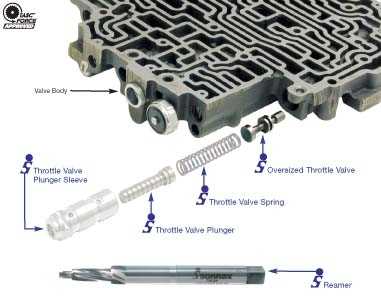

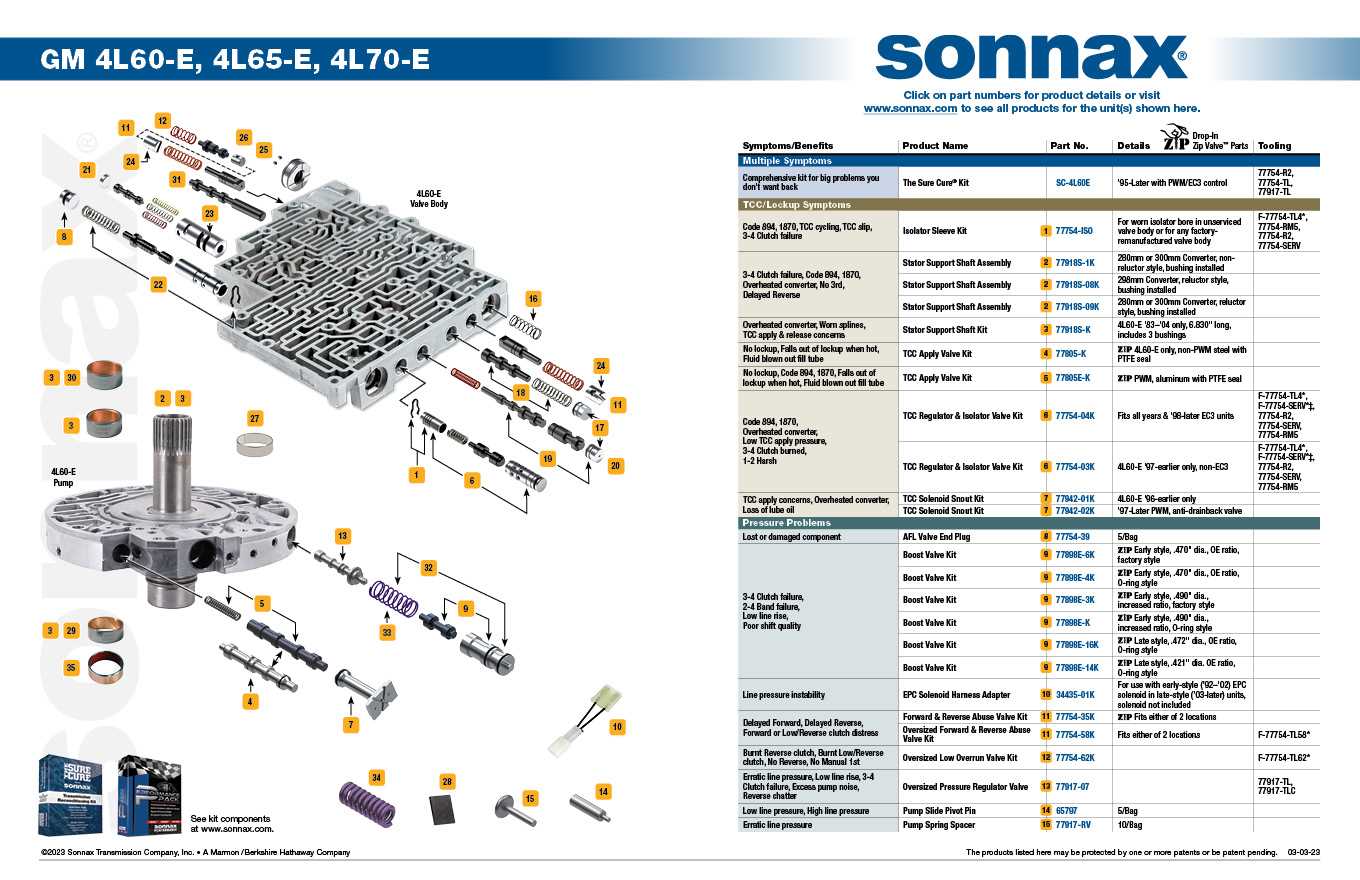

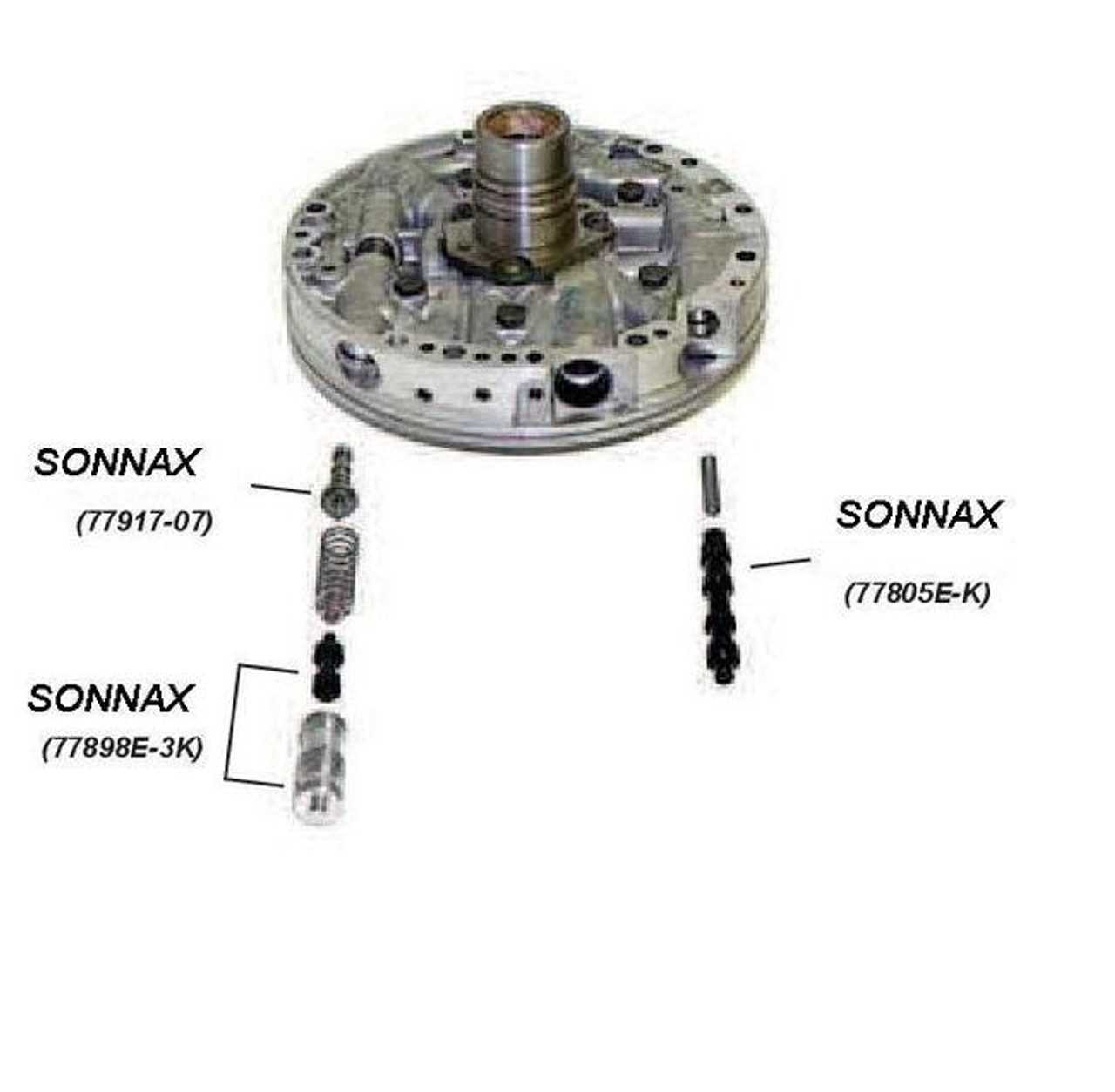

Among the essential elements, the hydraulic system stands out, as it controls the engagement and disengagement of gears through fluid pressure. The clutch packs are equally important, allowing for the transfer of power while facilitating seamless transitions between different gear ratios. Additionally, the valve body orchestrates the flow of transmission fluid, acting as the control center for gear changes.

Another significant component is the torque converter, which provides the necessary coupling between the engine and the drive wheels, enhancing acceleration and efficiency. The input and output shafts also play critical roles in transmitting power and maintaining stability during operation. Understanding these key components helps in diagnosing issues and optimizing performance in modern vehicles.

Common Issues with 4L60E Parts

Understanding the frequent challenges faced by these components is essential for maintaining optimal performance. Many users encounter symptoms like slipping, overheating, or erratic shifting, which can often be traced back to specific flaws in the design or wear over time.

One prevalent issue involves seal degradation, leading to fluid leaks that compromise efficiency. Additionally, improper alignment or damage to internal clutches can result in harsh engagement, negatively affecting driving experience. Regular inspections can help identify these problems early.

Another common concern is electrical failures within the control system, which can disrupt shifting patterns and cause operational delays. Keeping an eye on wiring and connectors can prevent these electrical gremlins from escalating into larger issues.

Lastly, wear and tear on bearings and bushings can create unwanted noise and vibrations, signaling the need for prompt attention. Addressing these common challenges not only extends the lifespan of components but also ensures a smoother ride.

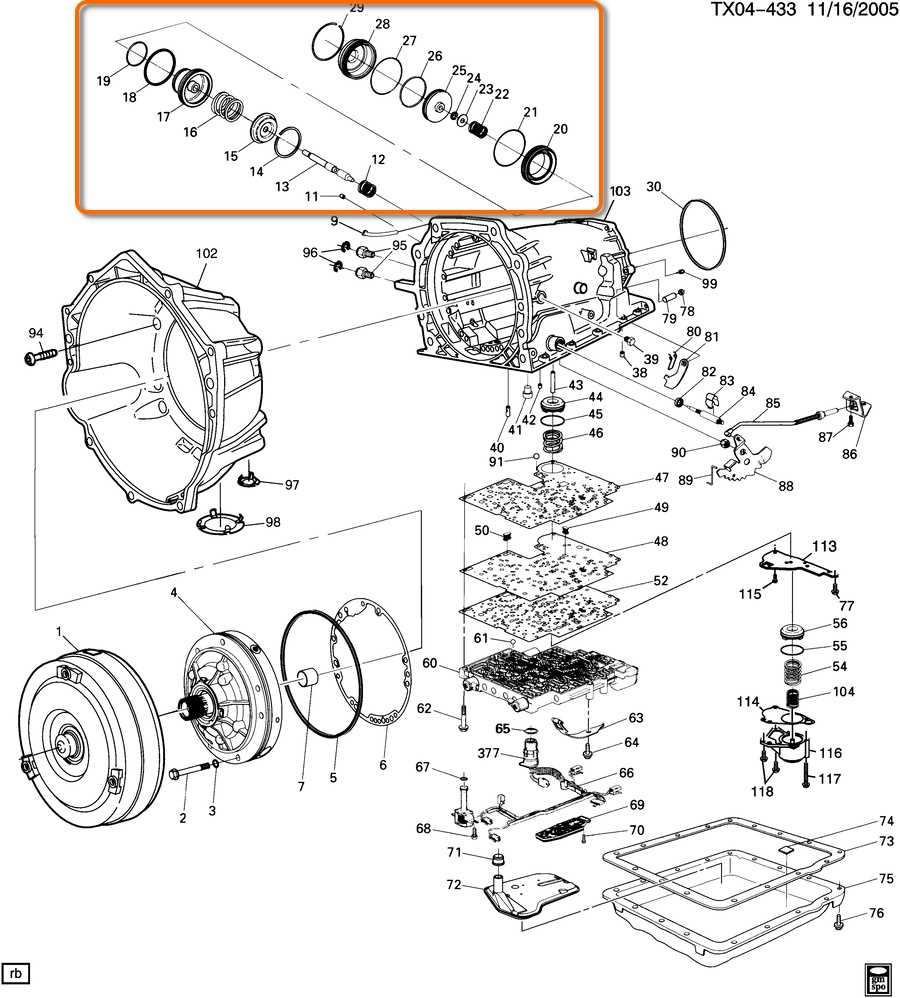

4L60E Diagram Overview

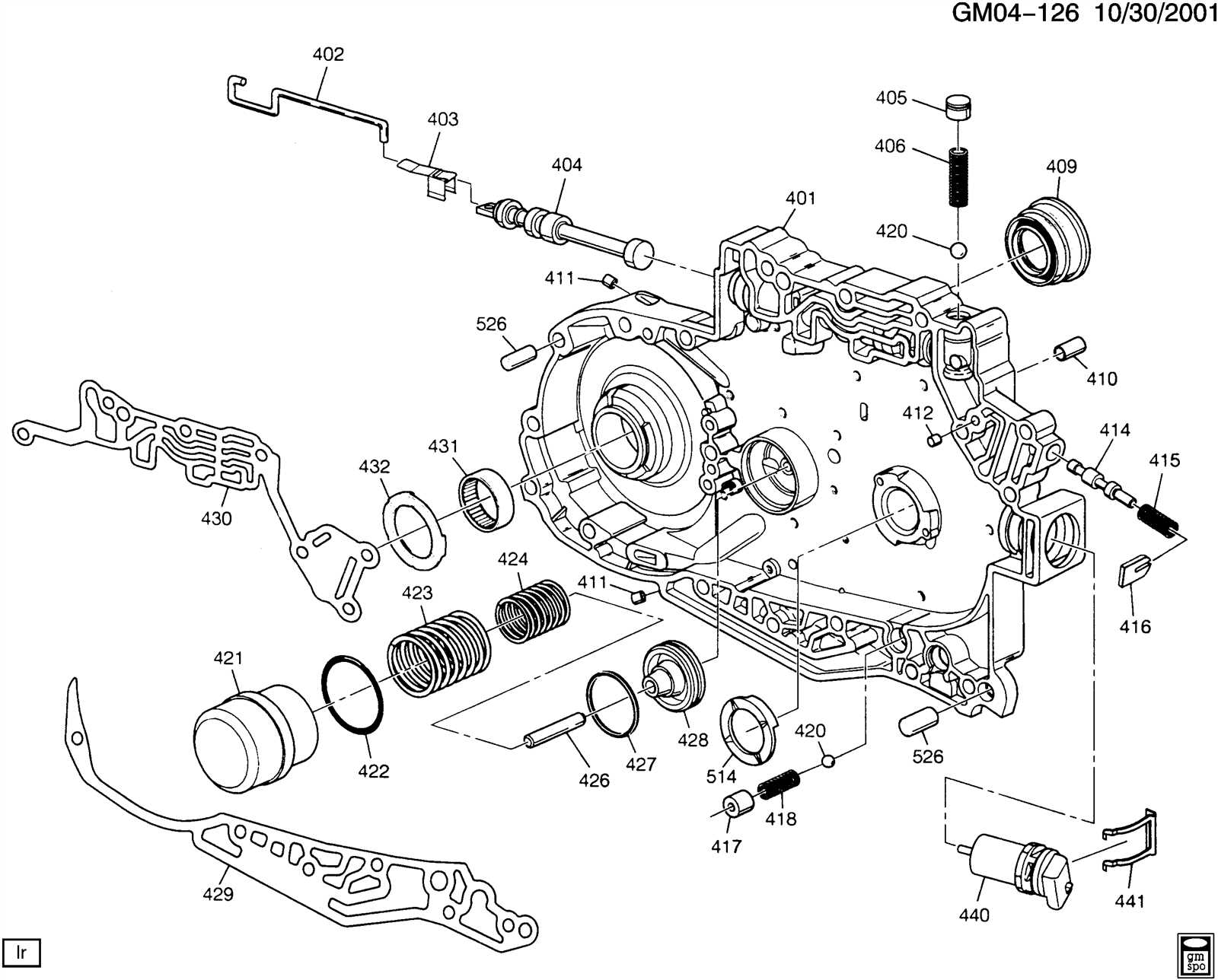

This section provides a comprehensive look at the schematic representation of the hydraulic system and mechanical components within a specific automotive gear mechanism. Understanding this layout is essential for anyone interested in maintenance, repair, or enhancement of performance.

Key Components

The assembly consists of various crucial elements that work together to ensure optimal functionality. These include the clutch packs, valve body, and servo mechanisms, each playing a vital role in the shifting process.

Functionality Insight

By examining the layout, one can delve into how fluid dynamics influence the shifting characteristics. This knowledge is ultimately beneficial for diagnosing issues and improving efficiency.

Importance of Maintenance Practices

Regular upkeep of automotive systems is crucial for ensuring optimal performance and longevity. Implementing effective maintenance routines not only enhances reliability but also minimizes the risk of unexpected failures. By understanding the significance of these practices, vehicle owners can safeguard their investment and enhance overall functionality.

Benefits of Regular Upkeep

Consistent maintenance provides numerous advantages. It ensures that components operate efficiently, reducing wear and tear. Additionally, it helps in identifying potential issues early, allowing for timely interventions.

Key Maintenance Practices

| Practice | Description |

|---|---|

| Fluid Changes | Regularly replacing fluids prevents contamination and maintains system efficiency. |

| Inspections | Routine checks for wear can identify problems before they escalate. |

| Filter Replacements | Changing filters ensures contaminants are removed, protecting sensitive components. |

| Adjustments | Fine-tuning parts can optimize performance and prolong service life. |

How to Read Transmission Diagrams

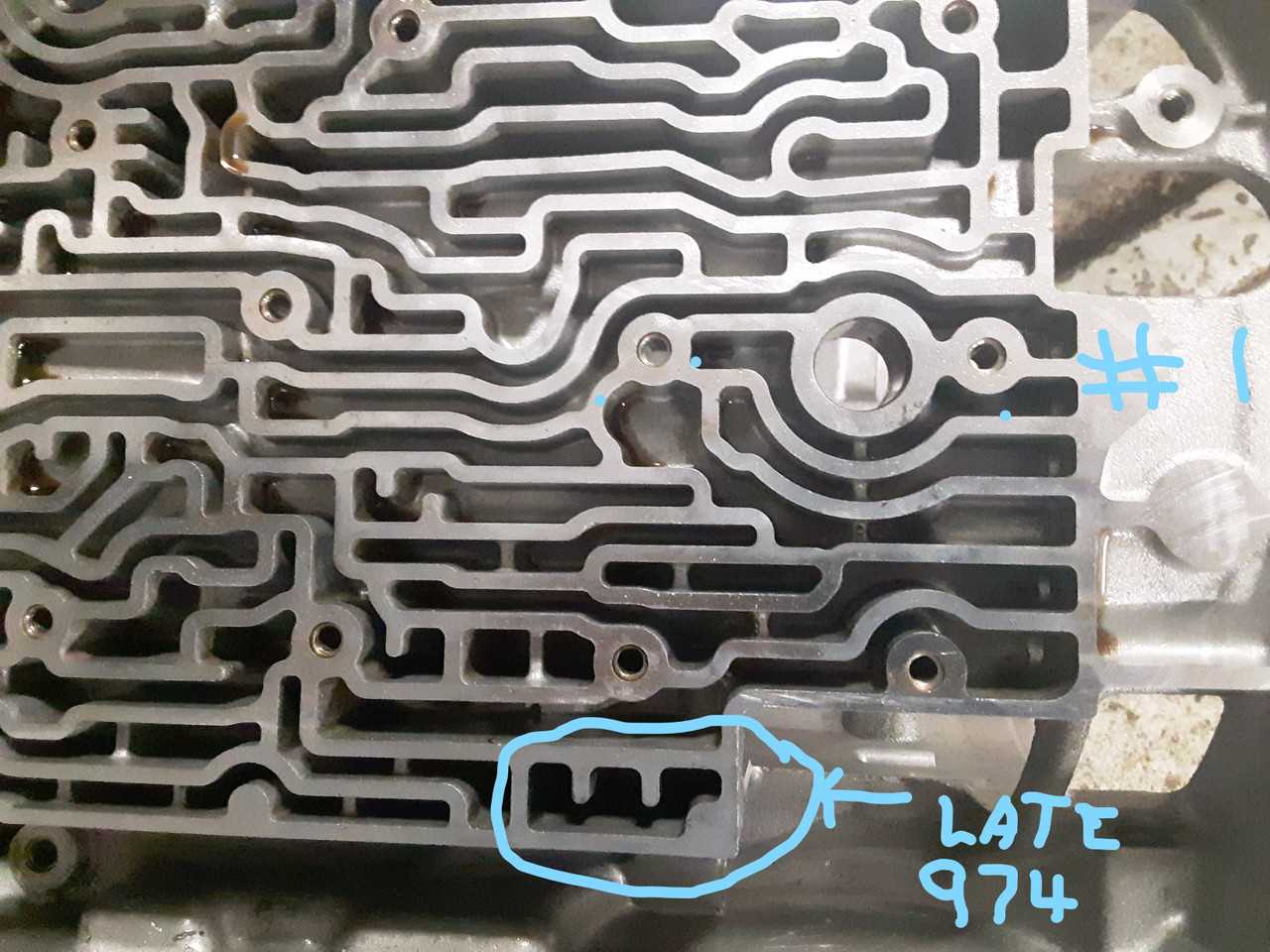

Understanding technical illustrations can significantly enhance your ability to troubleshoot and repair machinery. These visuals serve as a roadmap, guiding you through various components and their functions. Familiarity with the symbols and layout is crucial for effective interpretation.

Key Elements to Identify

Start by recognizing the main features depicted in the illustration. Look for symbols representing different components and their connections. Typically, lines indicate the flow or relationship between parts, while labels provide essential information on each element’s function.

Interpreting Symbols and Connections

Pay attention to the legend, if available, as it clarifies what each symbol represents. Understanding the connectivity between components helps you grasp how the entire system operates, ultimately allowing for more informed decision-making during repairs or upgrades.

Identifying Wear in Components

Recognizing deterioration in mechanical elements is crucial for maintaining optimal performance and longevity of a vehicle’s drivetrain system. Various signs can indicate the need for attention, from unusual noises to compromised functionality. Understanding these indicators can help in early diagnosis and prevent further damage.

Visual Inspection is one of the most effective methods for identifying wear. Look for any signs of discoloration, scoring, or pitting on the surfaces. Components that exhibit uneven wear patterns or excessive corrosion are likely in need of replacement.

Physical Examination involves checking for play or movement in components that should remain fixed. Any excessive looseness can signal that the parts are no longer fitting together properly, which may affect overall efficiency. Additionally, components that show signs of friction, such as burnt areas or melted edges, require immediate attention.

Fluid Analysis is another essential aspect of monitoring wear. Contaminated or discolored fluid can indicate that particles are being shed from internal elements, pointing to potential failure. Regular fluid changes can also help in identifying these issues before they escalate.

In conclusion, vigilance in inspecting for wear in mechanical components can significantly enhance vehicle reliability. By being proactive and addressing concerns early, one can avoid costly repairs and ensure smoother operation.

Tools for Repairing 4L60E

Successful maintenance of an automatic gearbox requires a specific set of instruments that ensure efficiency and precision during repairs. Utilizing the right tools not only facilitates the process but also enhances the overall outcome of the work.

Below is a list of essential instruments that are beneficial for effective servicing:

- Torque Wrench: Ensures proper fastening of bolts to manufacturer specifications.

- Fluid Pump: Useful for adding or removing hydraulic fluid without spills.

- Snap Ring Pliers: Assists in the installation and removal of snap rings.

- Seal Installer: Helps in accurately placing seals to prevent leaks.

- Transmission Jack: Provides stable support while removing or installing the unit.

In addition to these tools, a well-equipped workstation should include:

- Socket Set: Essential for loosening and tightening various fasteners.

- Measuring Tools: Ensure correct fluid levels and component dimensions.

- Diagnostic Scanner: Helps in identifying electronic issues or error codes.

Having the right tools not only streamlines the repair process but also increases the longevity and performance of the system being serviced.

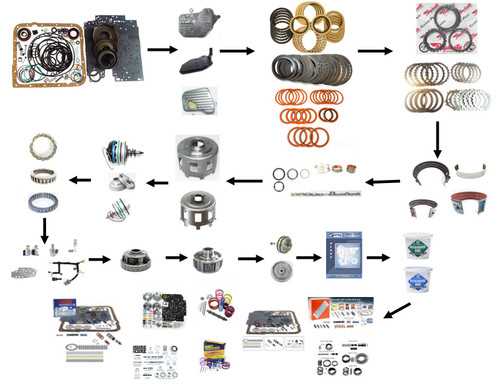

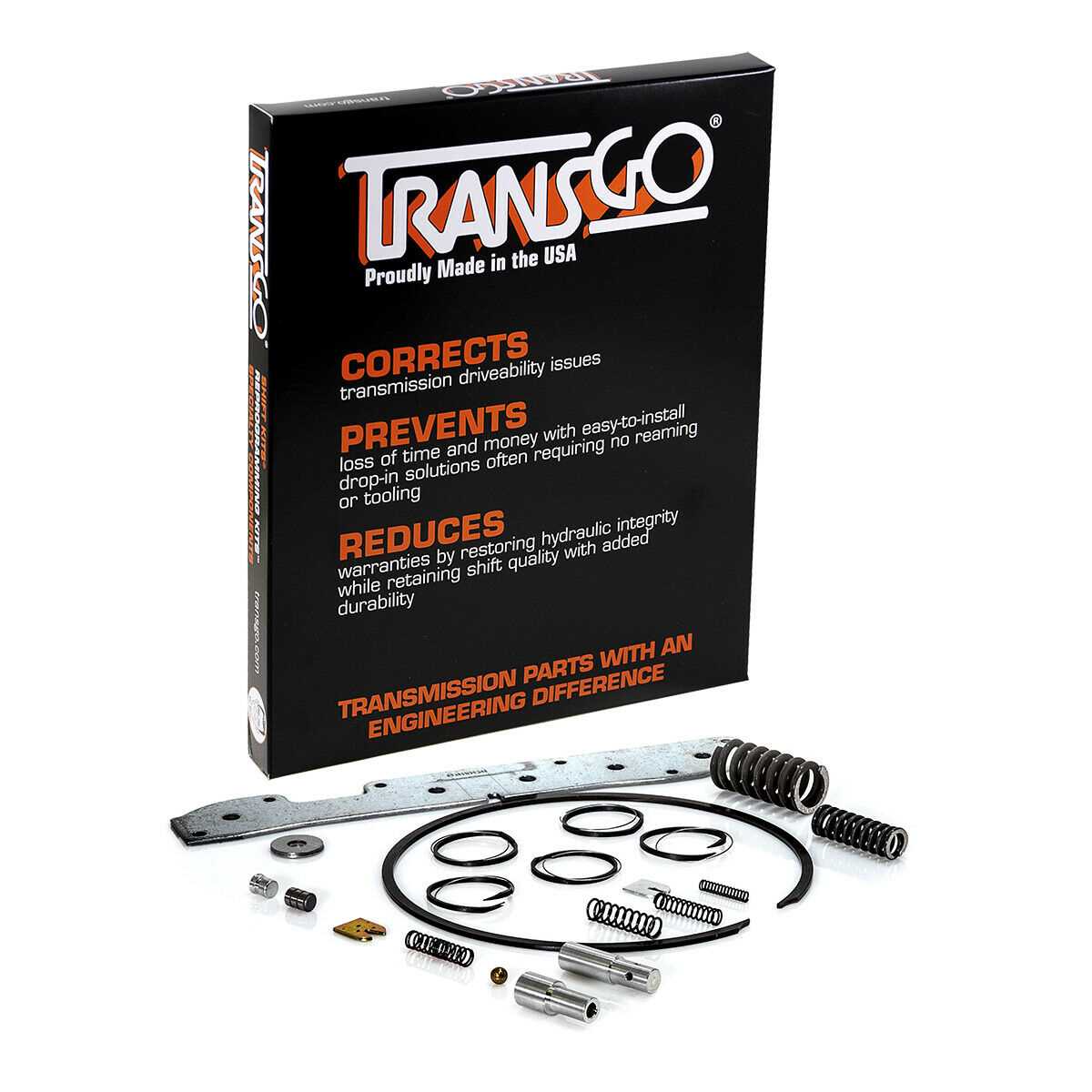

Aftermarket vs. OEM Parts

When considering components for vehicle systems, one often faces the choice between original equipment manufacturer (OEM) and aftermarket alternatives. Each option carries distinct advantages and disadvantages that can impact performance, durability, and cost. Understanding these differences is crucial for making informed decisions.

OEM components are produced by the original manufacturer, ensuring that they meet the exact specifications of the vehicle. This guarantees compatibility and reliability, often resulting in longer lifespans and optimal performance. However, these components can come with a higher price tag, which may deter some vehicle owners.

In contrast, aftermarket alternatives are crafted by third-party manufacturers. They typically offer a wider range of pricing options and can be more accessible for budget-conscious consumers. While some aftermarket components can match or even exceed the quality of OEM items, others may vary significantly in performance and longevity. This variability necessitates careful research and consideration when choosing aftermarket solutions.

Ultimately, the decision between OEM and aftermarket offerings hinges on individual priorities such as cost, quality, and intended use. By weighing these factors, vehicle owners can select the best option for their specific needs.

Upgrading Your 4L60E Transmission

Enhancing your vehicle’s shifting system can significantly improve performance and reliability. By focusing on key components and making thoughtful modifications, you can achieve smoother gear changes and increased durability. This process often involves selecting high-quality materials and addressing any weaknesses in the existing setup.

Assessing Your Goals: Before beginning any enhancements, define your objectives. Whether aiming for better towing capacity, improved acceleration, or increased longevity, understanding your needs is crucial.

Component Selection: Upgrading internal elements such as clutches, bands, and valve bodies can yield remarkable results. Opt for heavy-duty alternatives that can withstand higher power levels and stress.

Fluid Quality: Don’t overlook the importance of quality fluids. Using synthetic lubricants can enhance performance and protect critical components from wear.

Professional Assistance: While some upgrades can be DIY, consulting with experts ensures optimal results. Their experience can guide you through complex modifications and help avoid common pitfalls.

Typical Cost of Repairs

Repairing vehicle components can vary significantly based on the specific issues encountered and the complexity of the work required. Understanding the general price range can help owners budget effectively and make informed decisions when maintenance is needed.

Labor costs typically account for a substantial portion of the total expenses. Depending on the region and shop reputation, hourly rates can range from $75 to $150. Parts replacements also contribute, with common items often costing between $50 to $500 based on quality and brand.

In total, simple fixes might amount to around $300, while more intricate repairs could escalate to $1,500 or more. Owners should always seek multiple estimates to ensure the ultimate value for their investment.

Expert Tips for DIY Repairs

When it comes to undertaking repairs on complex machinery, having the right approach can make all the difference. With a bit of preparation and understanding, even novice enthusiasts can tackle various challenges successfully. Here are some expert insights to guide you through your repair journey.

Preparation is Key

- Gather all necessary tools and materials beforehand.

- Ensure you have a clean, well-lit workspace to avoid mishaps.

- Consult reliable manuals or guides for reference.

Step-by-Step Approach

- Start by identifying the issue thoroughly before disassembling anything.

- Document the process with photos or notes to aid reassembly.

- Take your time; rushing can lead to mistakes and additional problems.

Following these guidelines will not only simplify the repair process but also enhance your confidence in handling similar tasks in the future.