Comprehensive Guide to Allison Transmission Parts Diagram

In the realm of heavy machinery and automotive engineering, grasping the intricate relationships among various elements is essential for optimal performance. This exploration focuses on the essential components that contribute to the functionality of a complex system, enabling smooth operation and efficient power transfer.

Each segment plays a critical role, and comprehending their arrangement and interaction is crucial for both maintenance and enhancement. By examining these interconnections, one can ultimately improve the reliability and effectiveness of the entire mechanism.

Furthermore, visual representations serve as invaluable tools for both novices and seasoned professionals alike. They provide a clear perspective on how each element fits within the broader system, facilitating deeper insights into their respective functions and importance.

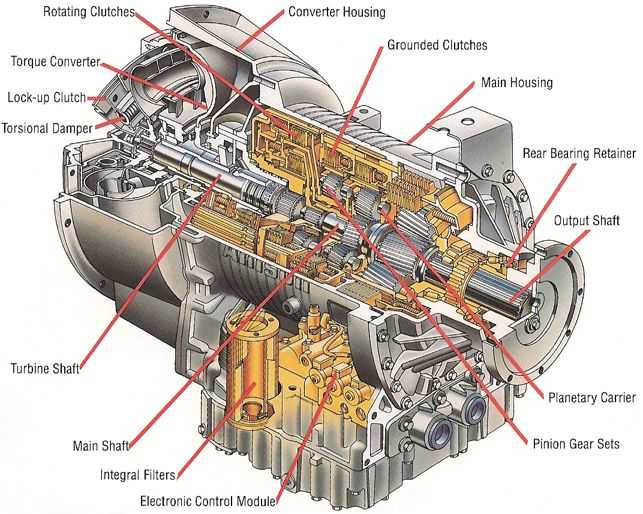

Understanding Allison Transmission Components

In the realm of automatic gear systems, a myriad of elements work in harmony to ensure smooth operation and efficiency. These components collectively play a pivotal role in enhancing vehicle performance, providing the ultimate driving experience.

Key Elements: Each essential unit serves a distinct function, from managing fluid dynamics to controlling gear ratios. Grasping the intricacies of these units can significantly improve maintenance and troubleshooting approaches.

Fluid Management: At the core of any effective system is the fluid pump, which circulates hydraulic fluid to facilitate gear shifts. The effectiveness of this mechanism directly influences overall responsiveness and power delivery.

Control Mechanisms: Advanced electronics govern the operation of these units, allowing for precise adjustments based on driving conditions. Understanding these controls can enhance operational efficiency and performance.

Wear and Maintenance: Regular inspections and timely replacements of worn components are crucial for longevity. Familiarity with the various elements involved helps in identifying potential issues before they escalate.

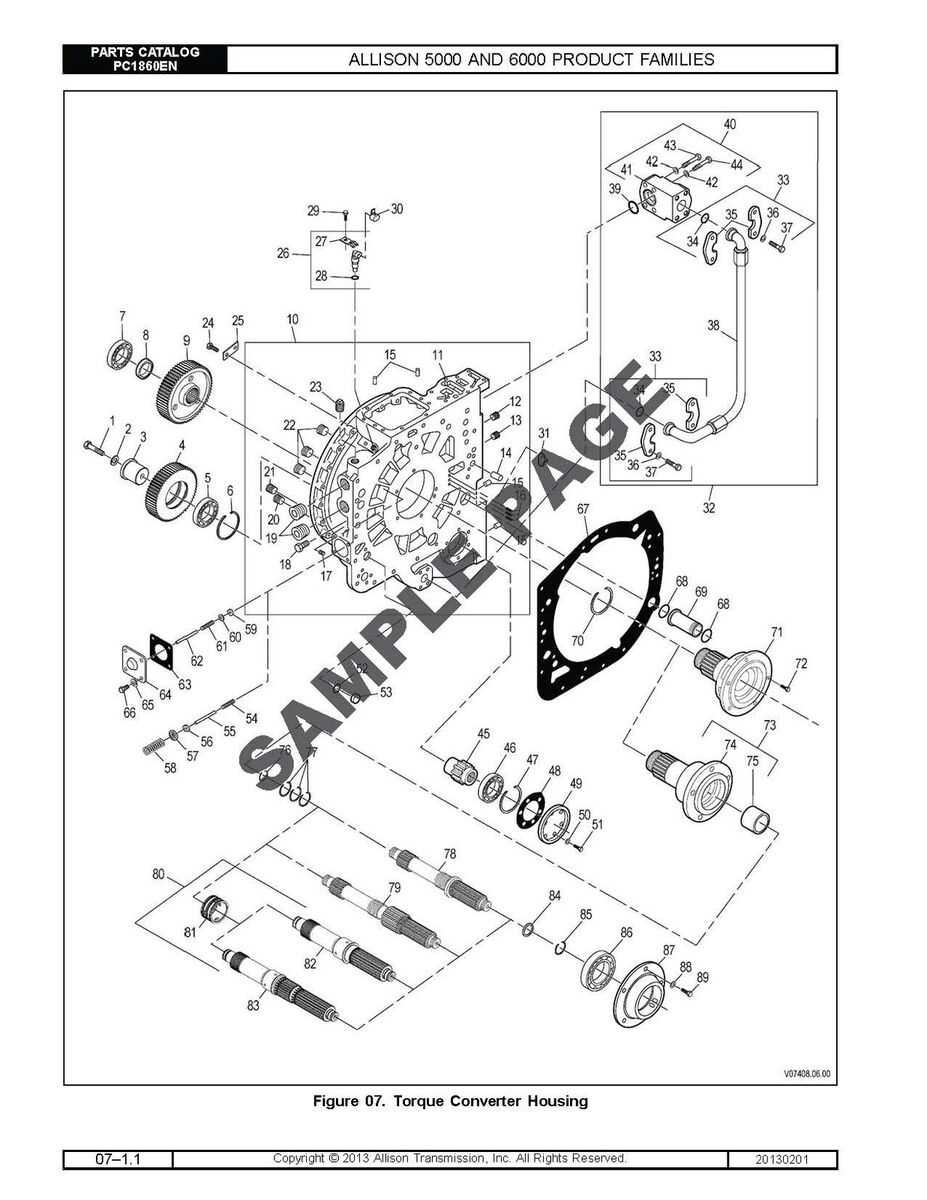

Overview of Transmission Diagrams

Understanding the intricate layouts of vehicle gear systems is essential for effective maintenance and repair. These visual representations provide a clear insight into the various components and their interconnections, facilitating a deeper comprehension of how power is transferred within the mechanism. Familiarity with these illustrations not only aids technicians in troubleshooting issues but also enhances the overall efficiency of the system.

Importance of Visual Representations

Visual aids serve as crucial tools for both professionals and enthusiasts. They allow for quick identification of parts and their functions, streamlining the diagnostic process. Moreover, they help in training new personnel, ensuring that everyone involved has a solid grasp of the system’s architecture. This knowledge is vital for maintaining optimal performance and longevity.

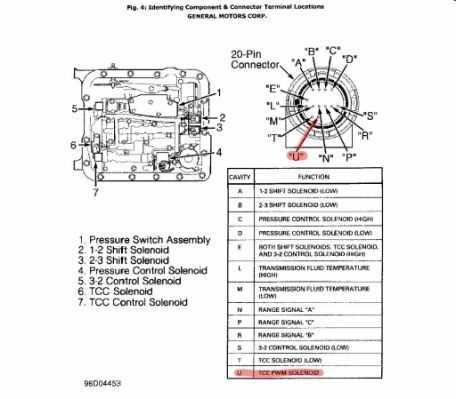

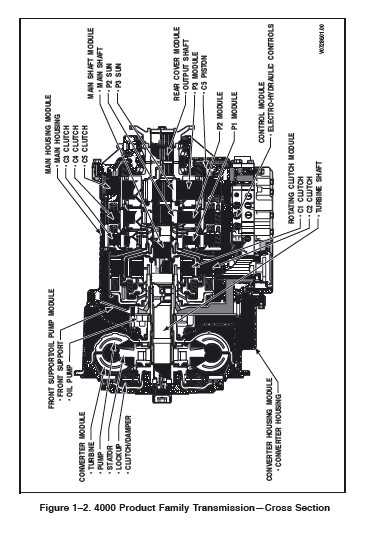

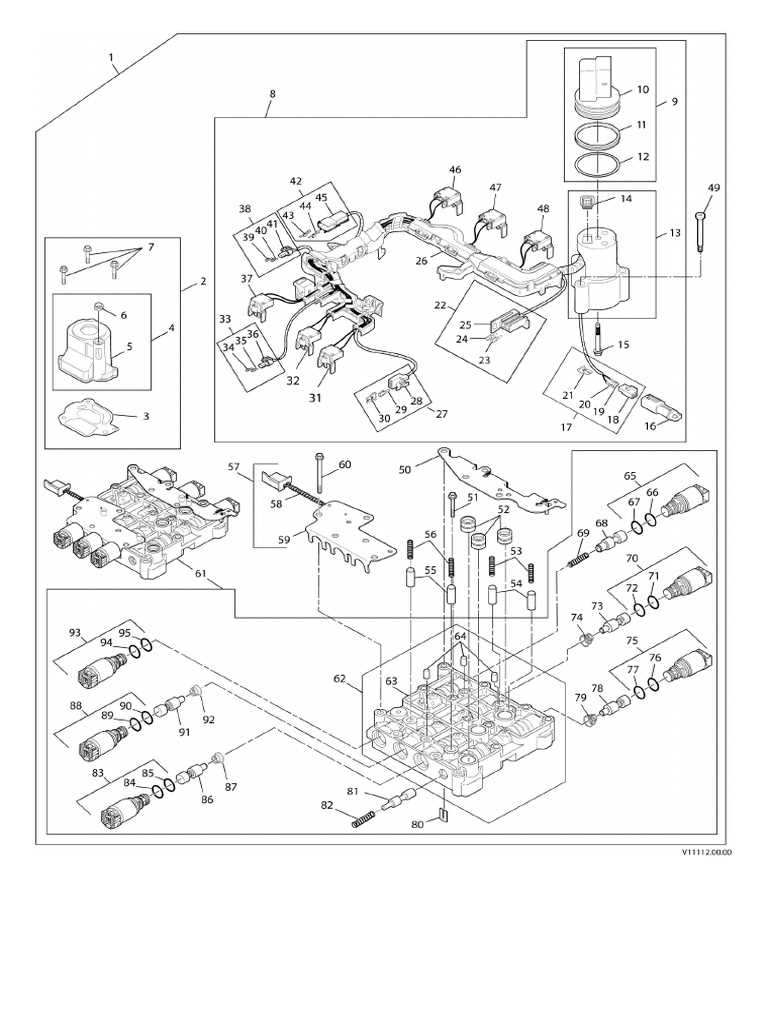

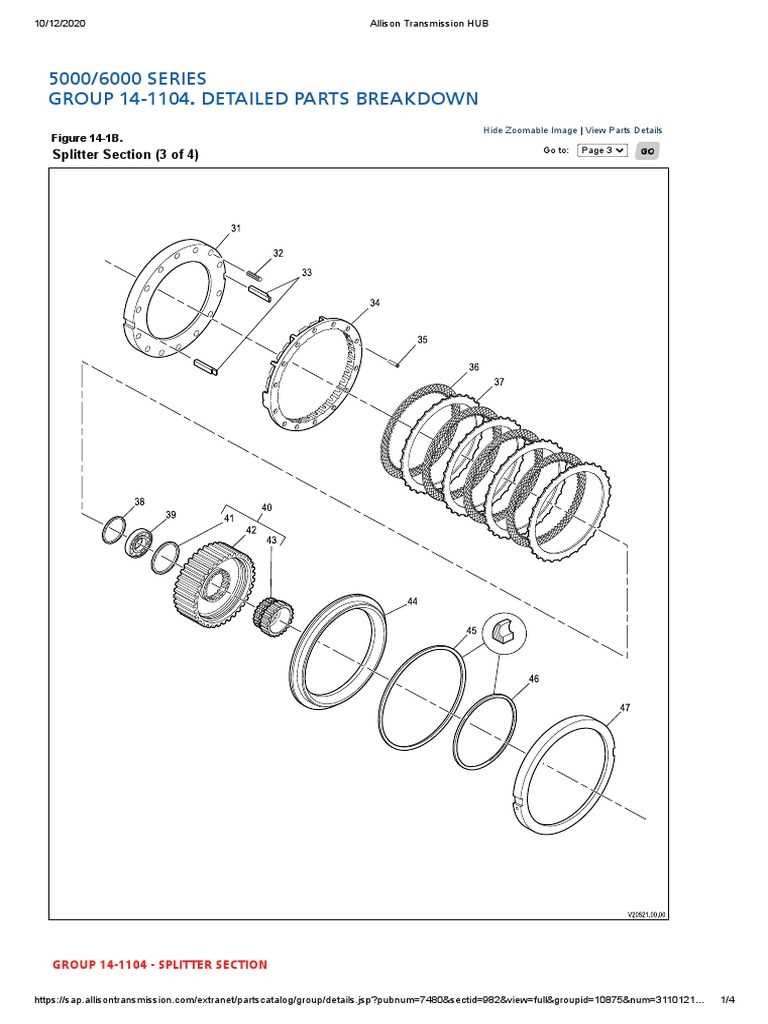

Components Illustrated in Layouts

Typically, these schematics include a variety of elements such as gears, clutches, pumps, and electronic controls. Each component plays a specific role, and understanding their positions and relationships is key to mastering the overall operation. By examining these detailed layouts, one can gain insights into the complexities of the system, leading to more informed decision-making during repairs and upgrades.

Key Parts in Allison Transmissions

This section explores essential components that contribute to the functionality and performance of automatic gear systems, providing insights into their roles and significance.

- Torque Converter: This crucial element facilitates smooth power transfer from the engine to the drivetrain.

- Planetary Gear Sets: These assemblies allow for varying gear ratios, enabling efficient speed changes.

- Clutches and Bands: These components engage and disengage different gear sets, ensuring seamless operation.

- Control Module: This electronic unit manages shifting patterns and optimizes performance based on driving conditions.

- Oil Pump: This vital part circulates fluid throughout the system, ensuring proper lubrication and cooling.

Understanding these key elements can enhance maintenance and troubleshooting efforts for optimal operation.

How to Read Transmission Diagrams

Understanding visual representations of mechanical systems is essential for effective maintenance and troubleshooting. These illustrations provide a roadmap, enabling technicians to identify components, their functions, and how they interact within the assembly. Familiarity with the symbols and layout is crucial for deciphering these complex visuals.

Start by familiarizing yourself with the symbols used in the illustration. Each shape or line often represents a specific element or action. For example, circles may indicate rotating parts, while arrows can show the direction of movement. A legend is typically included to clarify these symbols, making it easier to interpret the overall structure.

Next, analyze the flow of energy or motion depicted in the representation. Look for pathways that illustrate how power is transmitted through various components. Understanding this flow is key to diagnosing issues and ensuring optimal performance of the system.

Finally, pay attention to any annotations or notes provided alongside the illustration. These may include specifications, maintenance tips, or troubleshooting advice that can enhance your understanding and guide your actions. By combining these elements, you can effectively navigate the complexities of mechanical systems and improve your diagnostic skills.

Common Issues with Transmission Parts

Understanding the typical challenges associated with key components is crucial for maintaining optimal performance. Various factors can lead to malfunction, affecting efficiency and longevity. Awareness of these common problems can help in early detection and resolution.

Typical Problems Encountered

- Wear and tear due to age

- Fluid leaks affecting lubrication

- Overheating caused by inadequate cooling

- Erratic shifting patterns

Signs of Malfunction

- Unusual noises during operation

- Warning lights on the dashboard

- Unresponsiveness when shifting gears

- Increased fuel consumption

Maintenance Tips for Allison Systems

Regular upkeep is crucial for optimal performance and longevity of your vehicle’s intricate machinery. Adhering to a routine schedule can prevent costly repairs and ensure smooth operation. Understanding key maintenance strategies will empower you to keep your system in peak condition.

First, regularly check fluid levels and quality. Clean fluids are vital for efficient operation, so ensure they are free from contaminants. Replace them according to the manufacturer’s recommendations.

Inspecting filters is another essential task. Clogged filters can hinder performance and lead to system failure. Replace them periodically to maintain airflow and fluid cleanliness.

Additionally, monitoring temperature is important. Overheating can cause severe damage, so ensure cooling systems are functioning correctly and radiators are clean.

Lastly, schedule routine inspections by a qualified technician. Professional evaluations can catch potential issues early, saving you from unexpected breakdowns and ensuring reliable operation.

Upgrading Allison Transmission Components

Enhancing the performance and reliability of your vehicle’s drivetrain is crucial for optimal efficiency and power delivery. By focusing on specific enhancements, enthusiasts and professionals alike can achieve improved torque handling, better fuel efficiency, and overall superior driving experience. This section will explore various components that can be upgraded to maximize functionality and longevity.

Before diving into the specifics, it is essential to assess the existing components and identify areas that require enhancement. Regular inspections and performance evaluations can guide your choices, ensuring that upgrades align with your vehicle’s requirements.

| Component | Benefits | Recommended Upgrades |

|---|---|---|

| Clutch | Improved engagement and durability | High-performance friction materials |

| Fluid | Enhanced cooling and lubrication | Synthetic high-temperature fluids |

| Torque Converter | Better torque multiplication and responsiveness | Upgraded stall speed converters |

| Control Module | Optimized shifting patterns and efficiency | Tuning software or performance chips |

| Filters | Improved filtration and fluid cleanliness | High-capacity and synthetic filters |

By strategically selecting components for enhancement, you can significantly boost performance metrics. Always consider compatibility and specific performance goals when planning upgrades. Consulting with professionals can also provide valuable insights tailored to your vehicle’s unique needs.

Diagnostic Tools for Transmission Problems

Identifying issues in complex machinery requires specialized instruments that can provide insights into performance and functionality. These tools enable technicians to pinpoint faults effectively, ensuring optimal operation and longevity of the system.

Common Diagnostic Instruments

Among the most prevalent devices are electronic scanners that interface with onboard systems. These scanners retrieve error codes, highlighting specific areas of concern. Additionally, pressure gauges are vital for measuring hydraulic performance, while temperature sensors monitor heat levels to prevent overheating.

Advanced Diagnostic Techniques

For a deeper understanding, oscilloscope analysis can visualize electrical signals, aiding in diagnosing wiring or electronic component issues. Data loggers are also invaluable, capturing performance metrics over time, allowing for a thorough review of operational patterns and irregularities.

Comparing Allison Models and Diagrams

This section explores the nuances between various models and their respective schematics, highlighting the similarities and differences in design and functionality. Understanding these variations can enhance comprehension of how each system operates and interrelates.

Key Differences in Models

Each variant is engineered for specific applications, influencing performance and efficiency. Recognizing these distinctions is crucial for making informed decisions regarding selection and maintenance.

Understanding Schematic Representations

Schematic representations serve as visual aids to elucidate the internal mechanisms. They offer insights into the layout and flow, facilitating better troubleshooting and repair processes.

| Model | Application | Key Features |

|---|---|---|

| Model A | Heavy-duty vehicles | High torque capacity |

| Model B | Medium-duty vehicles | Optimized for fuel efficiency |

| Model C | Light-duty vehicles | Compact design |

Impact of Design on Performance

The design of mechanical components plays a crucial role in determining their efficiency and functionality. Thoughtful engineering not only enhances the performance of the system but also contributes to longevity and reliability. A well-structured design can lead to smoother operations, improved fuel efficiency, and reduced wear and tear, making it essential to understand how various elements interact within the assembly.

Key Design Elements Influencing Performance

- Geometry: The shape and size of each component can greatly affect flow dynamics and overall performance.

- Materials: The choice of materials impacts strength, weight, and durability, influencing how components withstand stress.

- Clearances: Proper spacing between parts minimizes friction and heat generation, enhancing operational efficiency.

Benefits of Optimal Design

- Enhanced Efficiency: Improved designs lead to reduced energy consumption and better output.

- Reduced Maintenance: Components designed for durability require less frequent servicing, lowering overall operational costs.

- Better Adaptability: Innovative designs can accommodate varying conditions and applications, providing versatility.

Resources for Further Learning

Expanding your knowledge about complex mechanical systems is essential for both enthusiasts and professionals. Numerous resources are available to deepen your understanding and enhance your skills in this field.

- Online Courses: Many platforms offer specialized courses that cover various aspects of mechanical engineering and related technologies.

- Technical Manuals: Detailed guides and manuals provide in-depth information about the components and their functionalities.

- Industry Journals: Academic and industry-specific publications often feature articles and case studies that highlight recent advancements.

- Forums and Communities: Online discussion boards and communities can be invaluable for sharing experiences and troubleshooting issues with peers.

- YouTube Channels: Many creators focus on educational content, offering visual demonstrations and explanations of intricate systems.

By utilizing these resources, you can build a solid foundation and stay updated on the latest trends and technologies in the mechanical sector.