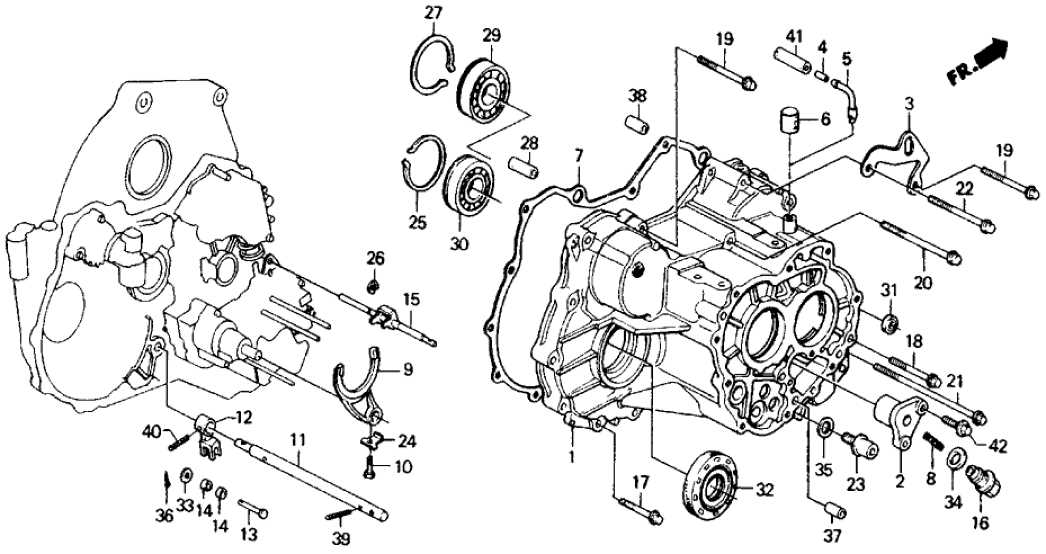

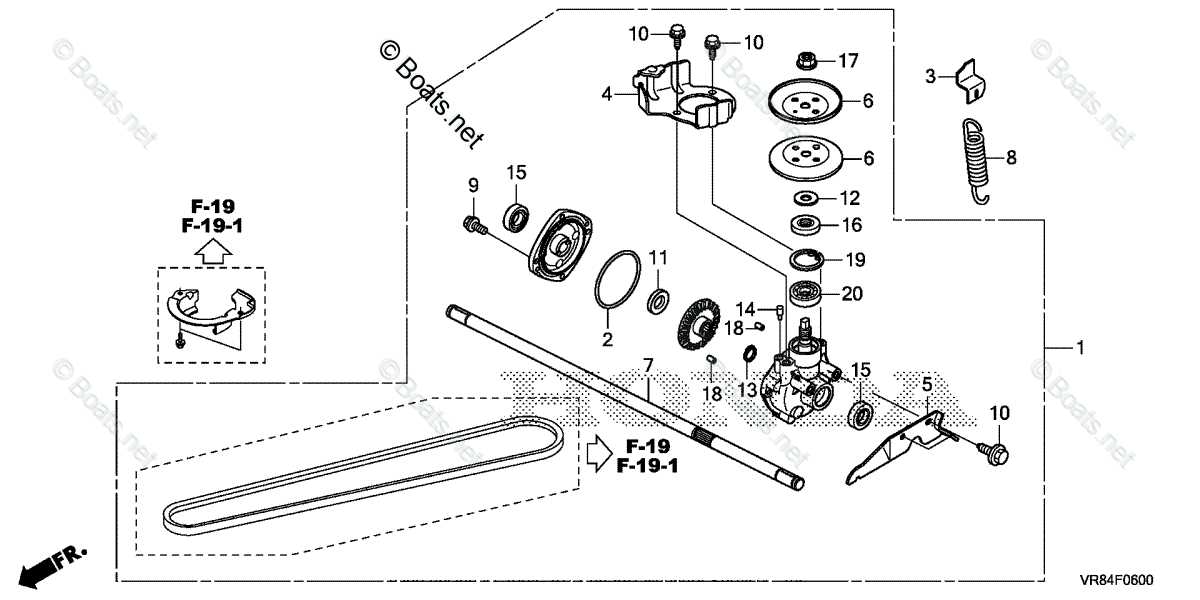

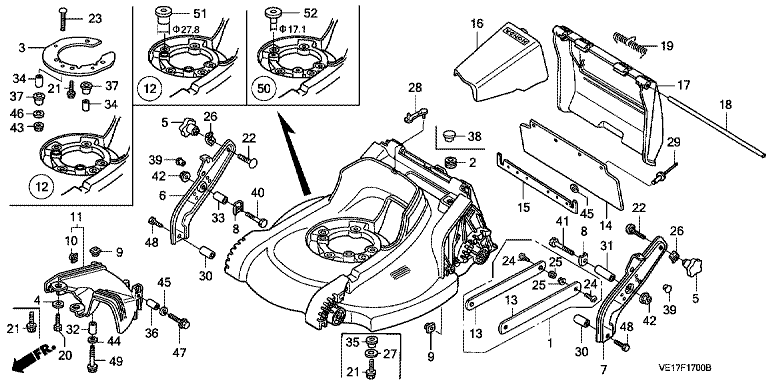

Honda HR214 Transmission Parts Diagram

Exploring the inner workings of a lawn equipment’s power transfer system reveals a complex interplay of various elements that work together to ensure optimal performance. These components play a crucial role in the efficiency and functionality of the machinery, influencing how power is transmitted from the engine to the wheels.

In this section, we will delve into the essential components that form the backbone of this mechanism. By examining these parts closely, we can gain insight into their respective functions and how they contribute to the overall operation of the equipment.

Whether you are a seasoned technician or a DIY enthusiast, understanding these elements can enhance your ability to maintain and troubleshoot your machinery effectively. This knowledge will not only assist in repairs but also improve your comprehension of how each component interacts within the system.

Honda HR214 Transmission Overview

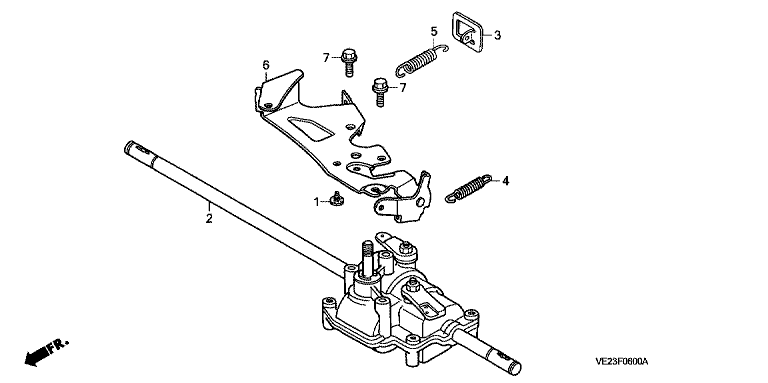

This section provides a comprehensive look at the key mechanisms that facilitate the operation of a specific model’s drivetrain. Understanding these components is essential for anyone looking to maintain or repair the system effectively.

Key Components

- Gear System: This assembly is crucial for power transfer, allowing for different speed settings based on user requirements.

- Clutch Mechanism: Responsible for engaging and disengaging the power flow, this component plays a vital role in operation control.

- Shafts: These elements connect various parts, ensuring smooth rotation and efficient performance.

Maintenance Tips

- Regularly inspect all components for signs of wear or damage.

- Ensure proper lubrication to reduce friction and extend lifespan.

- Follow the manufacturer’s recommendations for adjustments and replacements.

Key Components of Transmission System

The effectiveness of a vehicle’s drive mechanism relies on various crucial elements that work in unison to transfer power from the engine to the wheels. Understanding these essential components is vital for diagnosing issues and performing maintenance effectively.

Essential Elements

- Gearbox: The gearbox alters the torque and speed delivered to the wheels, allowing for smooth acceleration and deceleration.

- Clutch: This component engages and disengages the engine from the drive system, enabling seamless gear shifting.

- Drive Shafts: These shafts transmit power from the gearbox to the wheels, ensuring the vehicle moves forward or backward.

- Differential: This device allows for variations in wheel speed, particularly when turning, enhancing stability and control.

Auxiliary Components

- Linkages: These connect the clutch and gear selector to the gearbox, enabling the driver to choose the desired gear.

- Fluid System: This includes the oil pump and fluid reservoirs, which maintain lubrication and cooling for optimal performance.

- Bearings: Critical for reducing friction between moving parts, bearings enhance the durability and efficiency of the entire system.

Understanding Gear Types and Functionality

Gears play a crucial role in mechanical systems, facilitating the transfer of motion and power between components. Each type of gear serves a specific function, contributing to the overall efficiency and effectiveness of machinery. By examining the various gear types and their operational principles, one can gain insight into how they influence performance in different applications.

Types of Gears

There are several common types of gears, each designed for particular tasks. Spur gears are the simplest, characterized by straight teeth and a cylindrical shape, making them ideal for transferring motion between parallel shafts. Helical gears, on the other hand, feature angled teeth, allowing for smoother engagement and the ability to handle higher loads. Additionally, bevel gears are used to change the direction of motion, connecting shafts that are at right angles to each other.

Functionality and Applications

The functionality of gears extends beyond simple motion transfer. They can also modify speed and torque, enabling machinery to operate under varying conditions. For instance, when a small gear drives a larger one, the output speed decreases while torque increases, making it useful for applications requiring significant force. Understanding these dynamics allows engineers and technicians to select the appropriate gear type for specific tasks, ensuring optimal performance in machinery.

Transmission Assembly and Disassembly Process

The process of assembling and disassembling a drive mechanism is crucial for maintenance and repair tasks. Proper handling ensures the longevity and optimal performance of the equipment. This section outlines the essential steps and considerations for effectively managing the assembly and disassembly stages, providing a comprehensive overview for those involved in mechanical work.

Preparation is vital before starting the procedure. Gather all necessary tools and components to avoid interruptions. Create a clean workspace to ensure that small elements do not get lost during the process. It is advisable to consult relevant manuals or resources to familiarize yourself with the specific configuration and assembly guidelines.

During the disassembly phase, carefully follow the steps in reverse order from the assembly process. Begin by removing any external coverings and securing elements. Take note of the positioning and orientation of each component as they are removed; documenting this can be beneficial for reassembly. Utilize appropriate tools to avoid damaging any fragile pieces.

Once all components are separated, conduct a thorough inspection. Look for signs of wear or damage that may necessitate replacement. Cleaning parts is also important to ensure that debris does not interfere with the functionality of the newly assembled unit.

In the assembly phase, ensure that each element is correctly positioned and aligned. Apply the manufacturer’s recommended torque specifications when securing components. This guarantees that all parts are fitted correctly and can operate as intended. It is also essential to recheck each connection to confirm stability and performance.

Finally, perform a functional test after the assembly is complete. This step verifies that the mechanism operates smoothly and efficiently, confirming that all parts have been reassembled correctly. Regular checks and maintenance will help in prolonging the lifespan of the drive mechanism.

Maintenance Tips for Longevity

Ensuring the durability of your machinery requires consistent attention and care. Implementing effective maintenance practices can significantly enhance performance and extend its lifespan.

Regular Inspections: Conduct periodic checks to identify wear and tear before they escalate into major issues. Look for signs of deterioration in moving components and ensure that everything operates smoothly.

Fluid Levels: Keep an eye on the lubrication levels and quality. Using the appropriate oils and fluids is crucial for minimizing friction and preventing overheating.

Cleaning: Remove dirt, debris, and other contaminants from the system regularly. Accumulated grime can hinder functionality and lead to unnecessary strain on the equipment.

Follow Manufacturer Guidelines: Adhere to the recommendations provided by the manufacturer regarding maintenance schedules and procedures. These guidelines are designed to optimize performance and reliability.

Store Properly: When not in use, ensure that the machinery is stored in a dry, clean environment to prevent rust and other environmental damage.

Timely Repairs: Address any issues as soon as they arise. Prompt repairs can prevent minor problems from developing into costly repairs.

Common Issues and Troubleshooting Steps

When dealing with mechanical equipment, it’s not uncommon to encounter various challenges that can affect performance and functionality. Identifying these issues early can save time and resources, allowing for effective maintenance and repairs. This section outlines some frequent problems users may face, along with practical steps to address them.

Frequent Problems

- Unusual Noises: Grinding, squeaking, or rattling sounds may indicate internal wear or damage.

- Difficulty in Movement: Stiff or jerky motions can suggest alignment issues or lack of lubrication.

- Fluid Leaks: Any signs of leaking fluids could point to seal failures or cracked components.

- Overheating: Excessive heat can result from prolonged use or inadequate cooling systems.

Troubleshooting Steps

- Inspect for Visible Damage: Examine the unit for cracks, broken parts, or any signs of wear.

- Check Fluid Levels: Ensure that all necessary fluids are filled to the appropriate levels and are free of contamination.

- Listen for Anomalies: Start the equipment and pay close attention to any unusual sounds during operation.

- Lubricate Moving Parts: Apply suitable lubricants to reduce friction and improve mobility.

- Consult the Manual: Refer to the manufacturer’s guidelines for specific troubleshooting techniques and recommended maintenance practices.

Parts Replacement and Compatibility Guide

This section provides essential information on the substitution of essential components and their compatibility within specific machinery. Understanding the necessary specifications and standards ensures optimal performance and longevity of your equipment.

Identifying Compatible Components

To achieve the best results, it is crucial to identify components that align with your equipment’s design. Refer to manufacturer guidelines or consult with professionals to ensure that selected elements will fit and function effectively. Look for compatibility markers or codes that indicate suitability.

Replacement Process Tips

When undertaking the replacement of components, always follow the recommended procedures. Start by disconnecting power sources and removing any covers or casings. Take note of the original placement of each part for easy reinstallation. Utilize the appropriate tools to avoid damage, and consider seeking assistance if unsure about any step in the process.

Tools Required for Transmission Repairs

When addressing issues related to the gear mechanism of a lawn mower, having the appropriate instruments is essential for effective and efficient repairs. The right tools not only simplify the process but also ensure that the components are handled correctly, minimizing the risk of damage.

Essential Tools

- Socket Set

- Wrenches

- Screwdrivers (Flathead and Phillips)

- Pliers

- Torque Wrench

- Jack Stands

- Oil Drain Pan

Specialized Instruments

- Gear Puller

- Micrometer

- Caliper

- Seal Installer Tool

- Transmission Jack

Utilizing these tools effectively will help in disassembling and reassembling the mechanisms, ensuring that everything functions as intended. Always prioritize safety by wearing protective gear and following proper procedures during repairs.

Transmission Fluid Types and Recommendations

Choosing the right lubricant for your vehicle’s shifting mechanism is crucial for optimal performance and longevity. Various formulations are available, each designed to meet specific operational requirements. Understanding the different categories can help ensure your machine runs smoothly and efficiently.

There are primarily three types of lubricants: mineral-based, synthetic, and semi-synthetic. Each type has unique properties that make it suitable for different environments and conditions. The following table summarizes the characteristics and recommended applications for each fluid type.

| Fluid Type | Characteristics | Recommended Use |

|---|---|---|

| Mineral-Based | Derived from refined crude oil; generally more affordable. | Ideal for standard applications and older models. |

| Synthetic | Engineered for superior performance; offers better temperature stability. | Recommended for high-performance scenarios and extreme conditions. |

| Semi-Synthetic | A blend of mineral and synthetic fluids; balances cost and performance. | Suitable for everyday driving and moderate use. |

When selecting a fluid, always consult the manufacturer’s guidelines to ensure compatibility. Regular maintenance, including timely fluid changes, can greatly enhance the lifespan and efficiency of the system.

Exploring Aftermarket Parts Options

When it comes to enhancing performance and longevity, considering alternatives can be a smart choice for enthusiasts and everyday users alike. The aftermarket sector offers a variety of components designed to replace or improve existing mechanisms, ensuring that your machinery operates smoothly and efficiently. These options often provide more flexibility in terms of pricing and customization, allowing for tailored solutions to meet specific needs.

Benefits of Aftermarket Components

One of the primary advantages of opting for alternative components is the potential for cost savings. Many suppliers provide similar or superior quality at a lower price compared to original equipment. Additionally, the aftermarket landscape is rich with innovations, leading to improvements in durability and performance. This can translate to enhanced efficiency and a better overall experience during operation.

Choosing the Right Alternatives

When selecting replacement items, it’s crucial to research and ensure compatibility with your machinery. Evaluating customer reviews and seeking advice from knowledgeable sources can significantly aid in making informed decisions. Always prioritize reputable brands that offer warranties, as this can provide peace of mind and protect your investment over time.

Resources for Further Learning

Expanding your knowledge about mechanical systems and their components can greatly enhance your understanding of their functionality and maintenance. Whether you are a beginner or an experienced technician, various resources can assist you in gaining a deeper insight into these essential assemblies.

Online Courses and Tutorials

Numerous online platforms offer courses focused on machinery and engineering principles. Websites like Coursera and Udemy provide comprehensive tutorials that cover various aspects of mechanical design and maintenance. Engaging in these structured programs can help you grasp intricate concepts and practical applications.

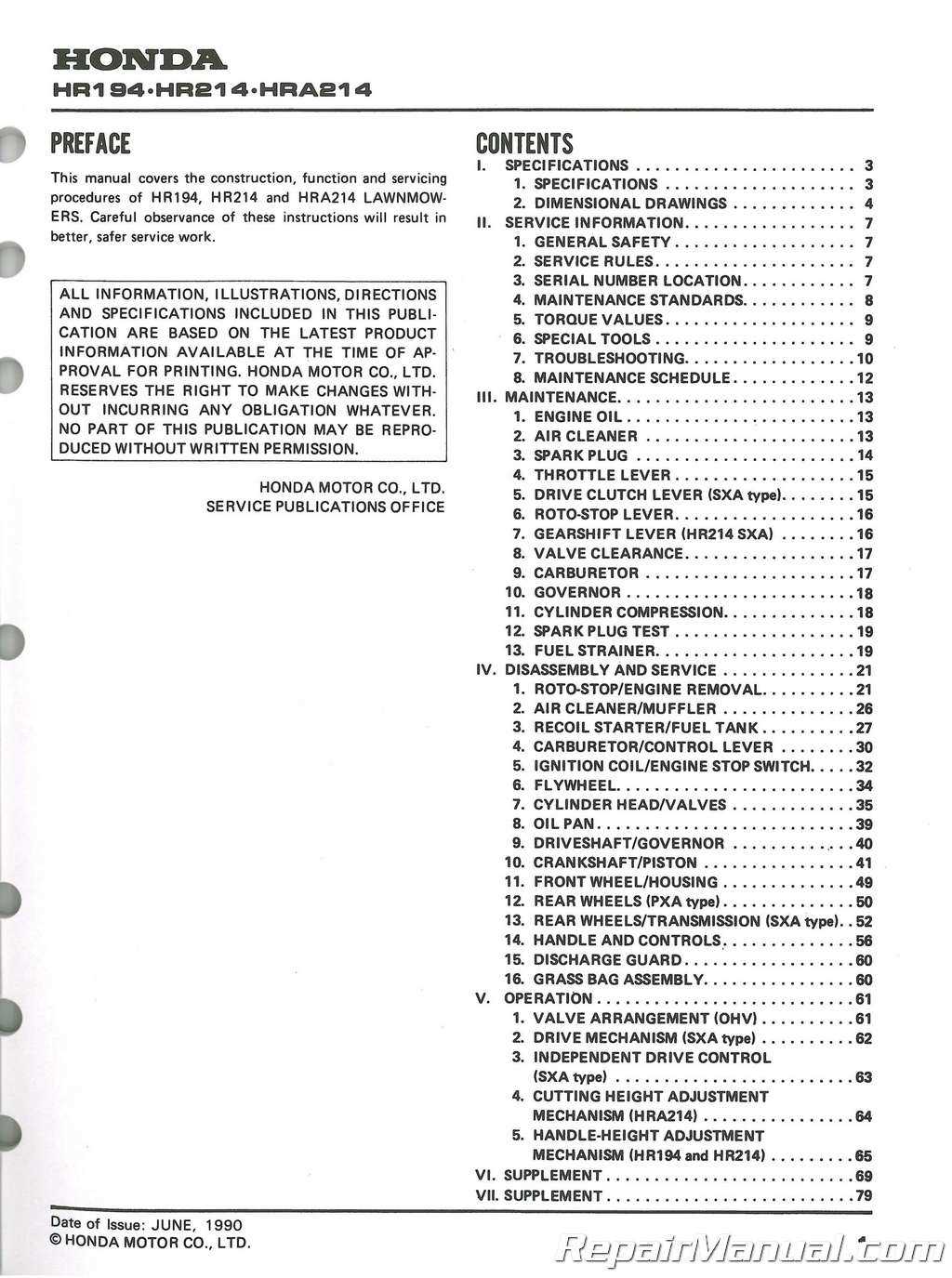

Books and Manuals

Books dedicated to engineering and machinery can be invaluable resources. Consider exploring technical manuals and guides that delve into mechanical systems, offering diagrams and explanations of their components. These texts often provide detailed insights into functionality, troubleshooting, and repair techniques, making them essential for anyone looking to enhance their skills.