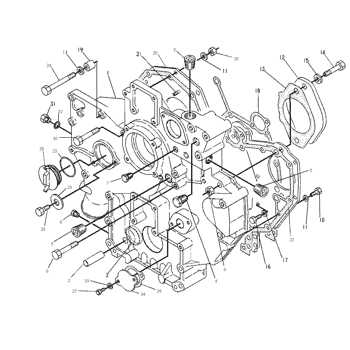

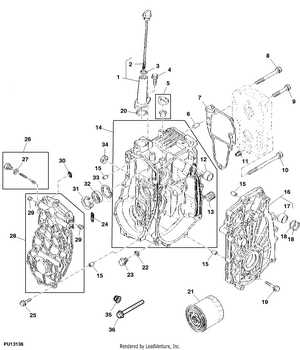

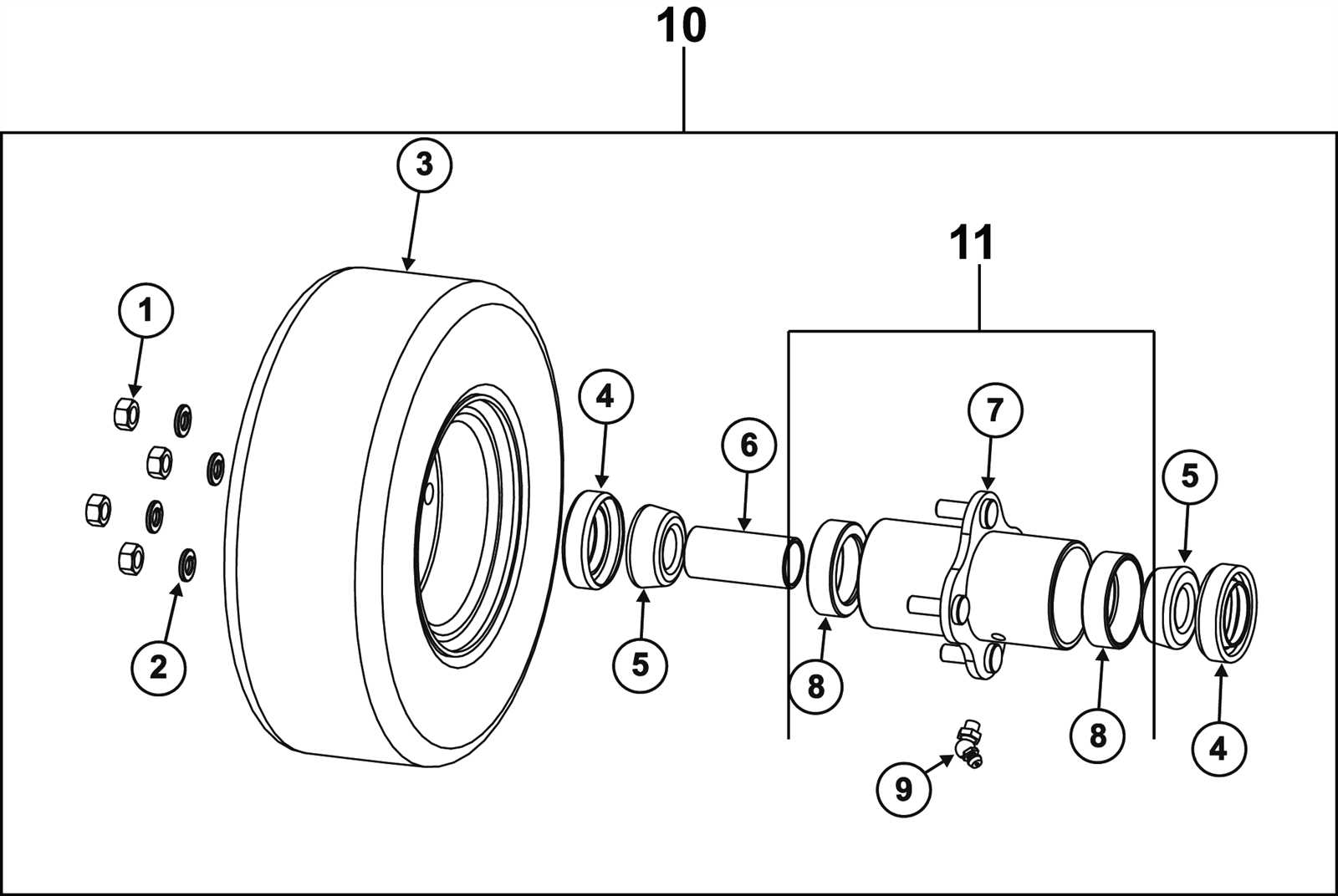

Parts Diagram for John Deere 425 Transaxle

The efficient functioning of lawn maintenance machinery relies heavily on the intricate systems that govern their operation. A pivotal element in this machinery is the transmission system, which facilitates movement and power transfer throughout the equipment. An in-depth examination of its structure and components can provide valuable insights for both enthusiasts and technicians alike.

When maintaining or repairing these systems, it is essential to have a clear visual representation of the various elements involved. By exploring a detailed overview of the essential components, operators can better understand how each part interacts and contributes to the overall performance of the machinery. This knowledge not only aids in effective troubleshooting but also enhances maintenance practices, ensuring optimal functionality.

In the following sections, we will delve into the specific elements that make up this crucial assembly. Each component plays a significant role, and comprehending their functions will empower users to make informed decisions regarding repairs and upgrades. Whether you’re a seasoned professional or a novice user, understanding the intricacies of these systems is key to maximizing the longevity and efficiency of your lawn equipment.

The functionality of a vehicle’s drive system relies heavily on several critical elements that work together to ensure smooth operation and effective power transfer. Understanding these integral components is essential for maintenance and repair, as each part plays a vital role in the overall performance of the assembly.

The main elements include the drive shaft, differential, and brake system, among others. Each of these components contributes to the system’s efficiency and reliability, making it crucial to recognize their functions and interrelationships.

| Component | Description |

|---|---|

| Drive Shaft | Transfers power from the engine to the wheels, allowing for movement. |

| Differential | Distributes torque to the wheels, enabling them to rotate at different speeds while turning. |

| Brake System | Responsible for slowing down or stopping the vehicle, ensuring safety during operation. |

| Gear Assembly | Facilitates the changing of speeds and helps optimize engine performance. |

| Hydraulic System | Controls the movement of various components through fluid pressure, enhancing performance and responsiveness. |

Understanding Transaxle Functionality

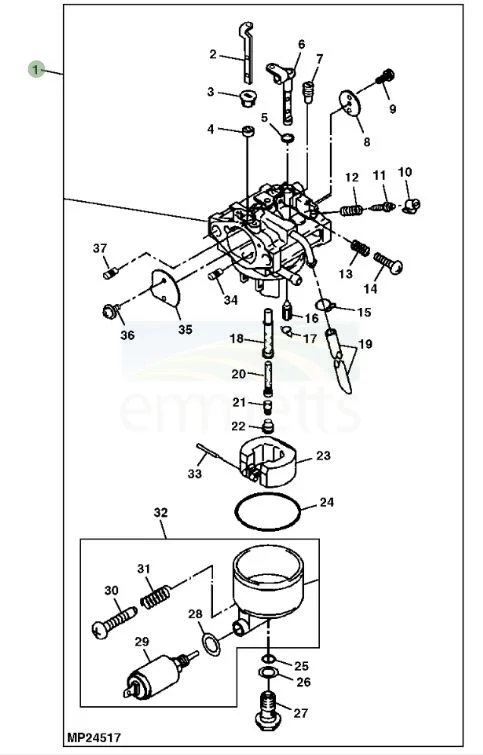

The mechanism responsible for converting rotational motion into linear force plays a crucial role in various machinery. This assembly integrates multiple components to ensure efficient power distribution and movement, allowing equipment to operate smoothly and effectively. A comprehensive understanding of this system can enhance maintenance practices and improve overall performance.

Key Components of the Mechanism

At the heart of this system lies a collection of essential elements, including gears, bearings, and housing. Each component serves a specific purpose, working in unison to facilitate the transfer of energy. Gears enable the modulation of speed and torque, while bearings provide support and reduce friction, promoting longevity and reliability.

Operational Principles

The operational principles of this system hinge on the conversion of energy from one form to another. The input shaft receives power from the engine, which is then transmitted through the assembly, resulting in the desired movement of the wheels or attachments. This transformation is vital for maneuverability and functionality in various applications.

In summary, grasping the intricacies of this mechanism not only aids in troubleshooting but also empowers users to optimize performance and enhance the lifespan of their equipment. By recognizing how each element contributes to the overall function, operators can make informed decisions regarding maintenance and upgrades.

Common Issues with Transaxles

Understanding the typical challenges faced by these essential components is crucial for maintaining optimal performance in various machinery. Many operators encounter issues that can lead to reduced efficiency, operational failures, and increased maintenance costs. Recognizing and addressing these common problems can prolong the lifespan of the equipment and enhance productivity.

Some of the frequent complications include fluid leaks, abnormal noises, overheating, and difficulty in shifting gears. Identifying these signs early can prevent more severe damage and costly repairs.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Fluid Leaks | Puddles under the machine, low fluid levels | Check seals and gaskets, replace if necessary |

| Noisy Operation | Grinding or clunking sounds | Inspect for worn components, lubricate as needed |

| Overheating | Excessive heat, warning lights | Check fluid levels, clean cooling components |

| Shifting Difficulties | Resistance when changing gears | Adjust linkage, check for damaged parts |

Maintenance Tips for Transaxle Parts

Proper upkeep of the drivetrain components is crucial for optimal performance and longevity. Regular maintenance helps prevent wear and tear, ensuring smooth operation and reducing the likelihood of costly repairs. Below are essential practices to keep in mind for maintaining these vital elements.

Regular Inspections

- Check for signs of wear, such as unusual noises or vibrations during operation.

- Inspect fluid levels and condition; replace fluids according to the manufacturer’s guidelines.

- Examine seals and gaskets for leaks, addressing any issues promptly.

Cleaning and Lubrication

- Keep the components clean to prevent dirt and debris from causing damage.

- Apply appropriate lubricants to moving parts to ensure smooth functionality.

- Periodically remove excess grease and contaminants that may accumulate over time.

By following these maintenance suggestions, you can enhance the performance and reliability of your drivetrain system, ultimately extending its lifespan.

Identifying Parts in the Diagram

This section aims to assist users in recognizing various components illustrated in the visual representation. Understanding these elements is crucial for effective maintenance and repair tasks. Familiarity with each component enables operators to address issues swiftly and efficiently.

When examining the visual representation, pay attention to the labeled sections that correspond to individual components. Each element plays a specific role in the overall functionality, contributing to the performance and reliability of the machinery. Here is a brief overview of the key elements to consider:

| Component Name | Description |

|---|---|

| Gearbox | Regulates the speed and torque of the system. |

| Axle | Supports the wheels and transfers motion. |

| Brake Assembly | Ensures safe stopping and control. |

| Drive Belt | Transmits power from the engine to the wheels. |

| Pulleys | Guide and redirect the drive belt within the system. |

| Mounting Brackets | Secure various components to the chassis. |

By understanding these components and their functions, operators can enhance their ability to troubleshoot and perform necessary repairs on the machinery effectively.

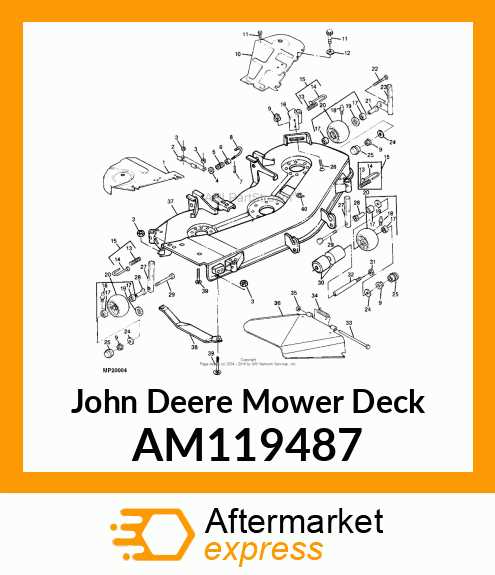

Replacement Parts for John Deere 425

Ensuring optimal performance and longevity of your machinery often requires the timely acquisition of suitable components. Maintaining your equipment in top condition is essential for efficient operation. This section explores the various options available for sourcing high-quality replacements that will keep your machine running smoothly.

Identifying Necessary Components

When considering upgrades or repairs, it’s crucial to identify the specific elements that require attention. Various components may be subject to wear and tear over time, including gears, belts, and hydraulic units. Regular inspections can help pinpoint these areas and ensure you obtain the right replacements to enhance functionality.

Sourcing Quality Replacements

Finding reliable suppliers for your equipment’s needs is vital. Numerous manufacturers offer aftermarket solutions that meet or exceed original specifications. Look for vendors that provide detailed descriptions and compatibility information to guarantee a perfect fit. Investing in quality alternatives can significantly improve performance and reduce downtime.

Tools Needed for Transaxle Repair

When undertaking maintenance on the drive mechanism of your equipment, having the right tools is essential for a successful and efficient repair process. Each task may require a specific set of instruments to ensure everything is properly addressed and reassembled. Below is a detailed list of the necessary tools for this type of repair.

Essential Hand Tools

Start with basic hand tools that are crucial for disassembly and reassembly. These tools will aid in removing fasteners and accessing internal components easily.

| Tool | Purpose |

|---|---|

| Socket Wrench Set | Used to remove bolts and nuts quickly. |

| Screwdriver Set | Necessary for various types of screws; both flat and Phillips. |

| Pliers | Helpful for gripping and twisting tasks. |

| Torque Wrench | Ensures bolts are tightened to the correct specifications. |

Specialized Equipment

In addition to general tools, specialized equipment may be required to address specific challenges encountered during the repair process. These instruments facilitate more intricate work and help achieve precision.

| Tool | Purpose |

|---|---|

| Gear Puller | Assists in removing gears without damaging them. |

| Dial Indicator | Measures the alignment and movement of parts accurately. |

| Hydraulic Jack | Used for lifting heavy components safely. |

| Cleaning Supplies | Essential for maintaining cleanliness during repairs. |

Transaxle Troubleshooting Techniques

Troubleshooting mechanical systems can be a daunting task, especially when it comes to complex drive components. Identifying the source of issues requires a systematic approach and a keen understanding of the various elements involved. By employing effective techniques, one can quickly diagnose problems and implement appropriate solutions to restore optimal functionality.

Common Symptoms and Their Causes

Understanding the symptoms is crucial in diagnosing issues with drive assemblies. Common indicators include unusual noises, reduced speed, or uneven power distribution. Each of these symptoms can stem from various underlying causes, such as worn components, inadequate lubrication, or misalignment. Careful observation and analysis can help pinpoint the exact source of the problem.

Step-by-Step Diagnostic Process

Implementing a step-by-step diagnostic process can significantly enhance the troubleshooting experience. Start by inspecting the system for visible signs of wear or damage. Next, check fluid levels and quality, as proper lubrication is essential for smooth operation. Conducting tests on individual components can also reveal faults that may not be immediately apparent. Finally, compile all findings to develop a comprehensive action plan for repairs.

Upgrades for Enhanced Performance

Improving the efficiency and capabilities of your vehicle can significantly enhance its overall performance. By focusing on key components, operators can optimize functionality, increase durability, and ensure a smoother operation. Below are some effective modifications to consider for maximizing your machine’s potential.

Recommended Modifications

- High-Performance Fluids: Replacing standard lubricants with high-quality fluids can reduce friction and enhance system responsiveness.

- Enhanced Cooling System: Upgrading the cooling system can prevent overheating and maintain optimal operating temperatures, especially during demanding tasks.

- Heavy-Duty Tires: Investing in specialized tires can improve traction and stability, making it easier to navigate rough terrains.

- Custom Gear Ratios: Altering gear ratios can provide better acceleration and improve torque output, tailored to specific applications.

- Performance Filters: Installing high-flow air and fuel filters can increase airflow and fuel efficiency, resulting in improved engine performance.

Installation Considerations

When implementing upgrades, it’s essential to ensure compatibility with existing components. Here are a few tips for a successful installation:

- Consult the manufacturer’s guidelines to confirm the suitability of chosen modifications.

- Work with qualified technicians or service providers to guarantee proper installation and performance.

- Regularly maintain upgraded components to ensure longevity and optimal performance.

Safety Considerations During Repairs

When engaging in maintenance tasks, prioritizing safety is paramount. Proper precautions ensure not only the well-being of the individual performing the repairs but also the longevity and functionality of the machinery involved. Understanding potential hazards and implementing safety measures can significantly reduce the risk of accidents and injuries.

Protective Gear

Wearing appropriate protective equipment is essential when conducting any form of mechanical work. This includes safety goggles to shield the eyes from debris, gloves to protect the hands from sharp objects, and sturdy footwear to prevent injuries from falling components. Additionally, using ear protection can help mitigate noise exposure during operation.

Work Environment

Maintaining a clean and organized workspace is crucial for safe repairs. Ensure that tools and equipment are in good condition and stored properly when not in use. Adequate lighting is also important to enhance visibility and reduce the likelihood of accidents. Furthermore, be mindful of the surrounding area to avoid tripping hazards and ensure that emergency exits are easily accessible.

Where to Find Transaxle Resources

Finding reliable information and resources related to transmission components can greatly enhance your maintenance and repair experience. Various sources offer insights, manuals, and guides that can assist in troubleshooting and understanding the assembly. Here are some recommended places to explore:

- Manufacturer Websites: Visit the official websites of equipment manufacturers for detailed information on specific models. They often provide downloadable manuals and service guides.

- Online Forums: Engage with community forums dedicated to machinery enthusiasts. These platforms allow users to share experiences, solutions, and recommendations.

- Specialized Retailers: Check with retailers that specialize in machinery components. Many of them offer extensive catalogs and knowledgeable staff who can assist with inquiries.

- YouTube Tutorials: Search for video tutorials that demonstrate repair procedures and parts identification. Visual guides can be particularly helpful for complex tasks.

- Local Libraries: Explore local libraries for books and manuals on machinery maintenance. Many libraries have extensive technical sections that can be useful.

Utilizing these resources will provide valuable knowledge, ensuring you are well-equipped to address any issues that may arise.