Understanding the Components of Manual Transmission

Exploring the intricate relationships within mechanical systems reveals the essential elements that enable smooth operation and efficient performance. Each component plays a vital role, contributing to the overall functionality and reliability of the mechanism. Recognizing how these elements interact is crucial for anyone looking to gain deeper insights into the mechanics behind motion.

From the initial engagement to the precise shifting of forces, the organization and arrangement of these elements are paramount. Familiarity with their structure can aid in troubleshooting and maintenance, enhancing longevity and efficacy. This overview will provide a comprehensive look at the different components involved in gear mechanisms, shedding light on their significance and interdependencies.

Understanding these elements is essential for anyone interested in the field of mechanics. Whether you are a novice or an experienced individual, grasping the fundamental roles of each component will enrich your knowledge and enable you to tackle various mechanical challenges with confidence. Let’s delve into the fascinating world of mechanical systems and uncover what makes them function seamlessly.

This section will provide a comprehensive overview of the essential elements that contribute to the functionality of a specific mechanical system. Understanding these components is crucial for anyone interested in how the system operates and the role each element plays in ensuring smooth performance.

- Clutch Mechanism: This element facilitates the engagement and disengagement of the system, allowing for seamless shifting between gears.

- Gear Selector: This component is responsible for the selection of different gear ratios, enabling optimal power transfer according to driving conditions.

- Input Shaft: This shaft transfers power from the engine to the system, playing a vital role in the overall power flow.

- Output Shaft: The output shaft delivers power to the wheels, determining the speed and torque experienced by the vehicle.

- Synchronizers: These devices ensure that the gears mesh smoothly, preventing grinding and facilitating easier gear changes.

Understanding these key components helps in diagnosing issues, performing maintenance, and appreciating the engineering behind the system. Each element plays a significant role in the overall operation, making knowledge of their functions essential for enthusiasts and professionals alike.

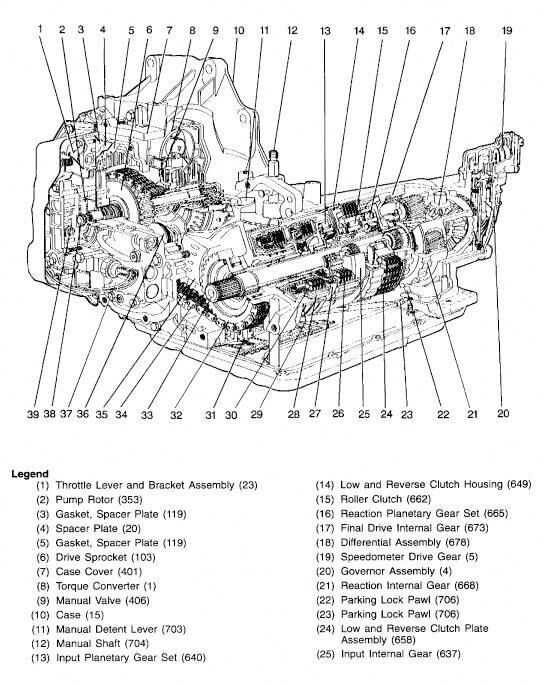

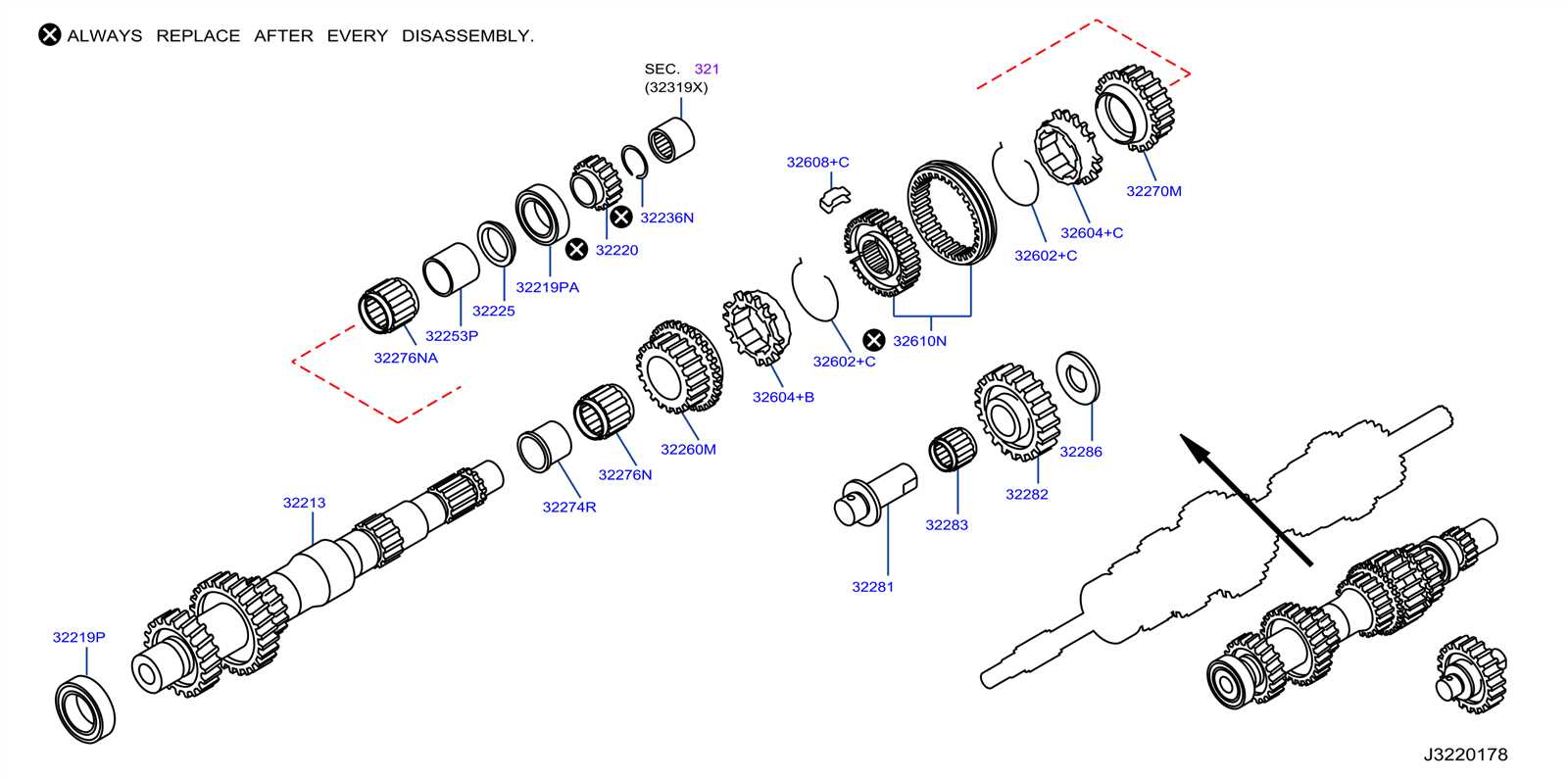

Key Parts of Manual Gearbox

The components of a conventional shifting mechanism play a crucial role in the overall functionality and efficiency of the vehicle’s operation. Understanding these fundamental elements is essential for anyone interested in automotive mechanics and performance.

Clutch is a vital element that allows for smooth engagement and disengagement of the engine from the drivetrain. It ensures that the driver can change gears without causing excessive wear or damage.

Gear Set consists of various gears that determine the speed and torque characteristics of the vehicle. Each gear interacts with others, providing different levels of power and performance based on the driver’s needs.

Selector Mechanism is responsible for enabling the driver to choose the desired gear. This assembly often includes linkages and levers that facilitate smooth shifting between different gear ratios.

Synchronizers are crucial for matching the speed of the gears during shifts, preventing grinding and ensuring a seamless transition between gears. They enhance the durability of the system and improve the overall driving experience.

In summary, the interaction between these elements is fundamental for the efficient functioning of the shifting system, greatly influencing the driving dynamics and vehicle performance.

How the Clutch Functions

The clutch plays a crucial role in facilitating smooth engagement and disengagement between the engine and the driving wheels. It acts as a mediator, allowing the driver to control the power transfer while enabling gear changes without abrupt interruptions. This mechanism is essential for the effective operation of the vehicle, ensuring seamless transitions during acceleration and deceleration.

When the driver presses the pedal, it engages the release mechanism, which in turn separates the clutch plate from the flywheel. This action interrupts the power flow, enabling the driver to shift gears smoothly. Upon releasing the pedal, the clutch plate re-engages, allowing power to resume its transfer to the wheels.

| Component | Function |

|---|---|

| Clutch Plate | Connects and disconnects the engine’s power to the drivetrain |

| Pressure Plate | Applies pressure to the clutch plate, ensuring secure engagement |

| Flywheel | Provides a smooth surface for the clutch plate to engage with the engine |

| Release Bearing | Facilitates the movement of the clutch mechanism during engagement and disengagement |

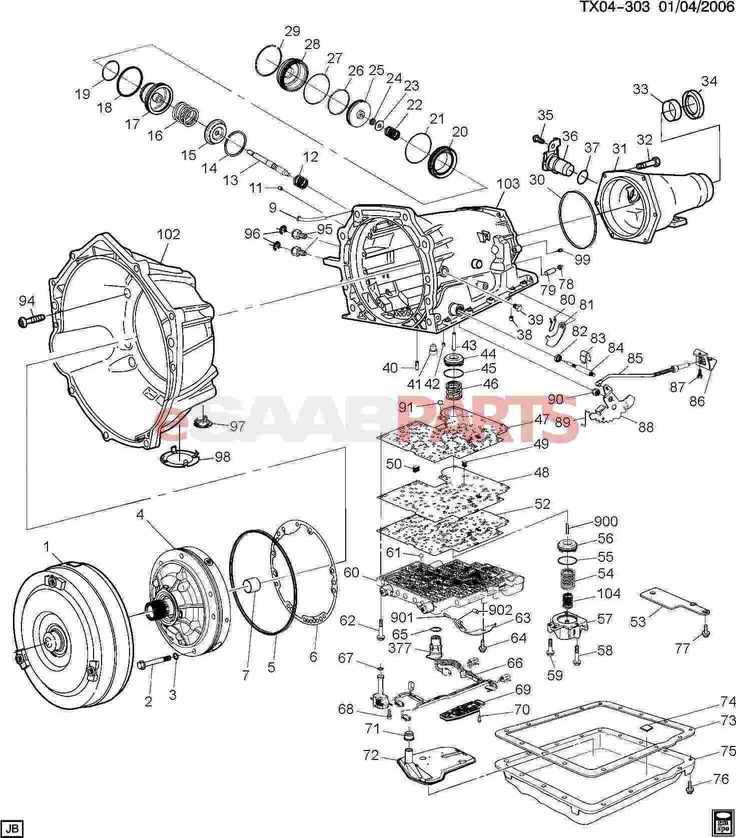

Transmission Fluid Importance

The role of lubricating liquid in a vehicle’s operation is crucial for maintaining optimal functionality. This essential fluid ensures smooth movement of mechanical components, reducing friction and preventing wear and tear over time.

Proper lubrication is vital for the longevity of the system. Without adequate fluid levels, various elements may suffer from overheating, leading to potential failures. Additionally, this liquid helps in cooling and cleaning the internal mechanisms, which is key for maintaining efficiency.

Regular checks and timely replacements of this fluid can significantly enhance performance and reliability. Understanding its importance empowers vehicle owners to ensure their machinery operates at its best.

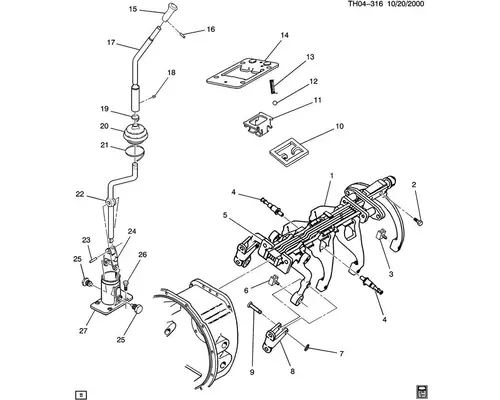

Gear Shift Mechanism Explained

The gear shift mechanism is a crucial component in vehicles that allows drivers to change the power delivery from the engine to the wheels. This process enables optimal performance by selecting the appropriate gear ratio for varying speeds and driving conditions. Understanding how this mechanism operates can enhance one’s appreciation of automotive engineering and driving dynamics.

| Component | Function |

|---|---|

| Shifter | Controls the selection of gears |

| Linkage | Connects the shifter to the gear assembly |

| Selector Fork | Engages and disengages specific gears |

| Gear Lever | Provides the interface for gear selection |

| Interlock System | Prevents accidental gear engagement |

Synchronizers and Their Role

In the realm of vehicle mechanics, certain components are crucial for ensuring smooth transitions between gears. These elements play a vital role in enhancing the overall efficiency and performance of the system, enabling the driver to shift seamlessly without unwanted disruptions. Understanding their function is essential for grasping the complexities of vehicle dynamics.

Synchronizers are specialized mechanisms designed to facilitate gear engagement. They work by matching the speeds of the gears involved, thereby minimizing the likelihood of grinding or misalignment during shifting. By synchronizing the rotation speeds, these components allow for a more fluid interaction between the different elements, which contributes to a more enjoyable driving experience.

Additionally, these mechanisms are instrumental in reducing wear and tear on both the gears and the associated components. When functioning optimally, synchronizers not only enhance the longevity of the system but also improve overall vehicle performance. Their role in providing a smoother operation cannot be overstated, making them indispensable in modern automotive design.

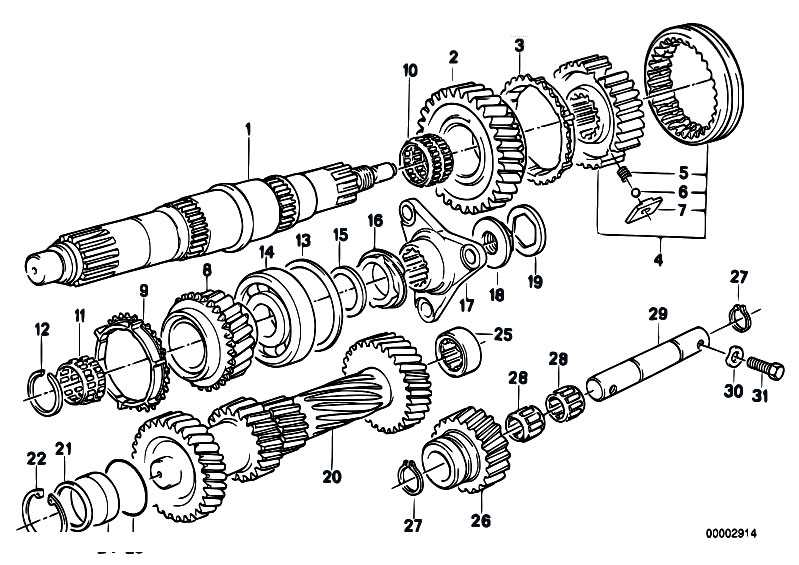

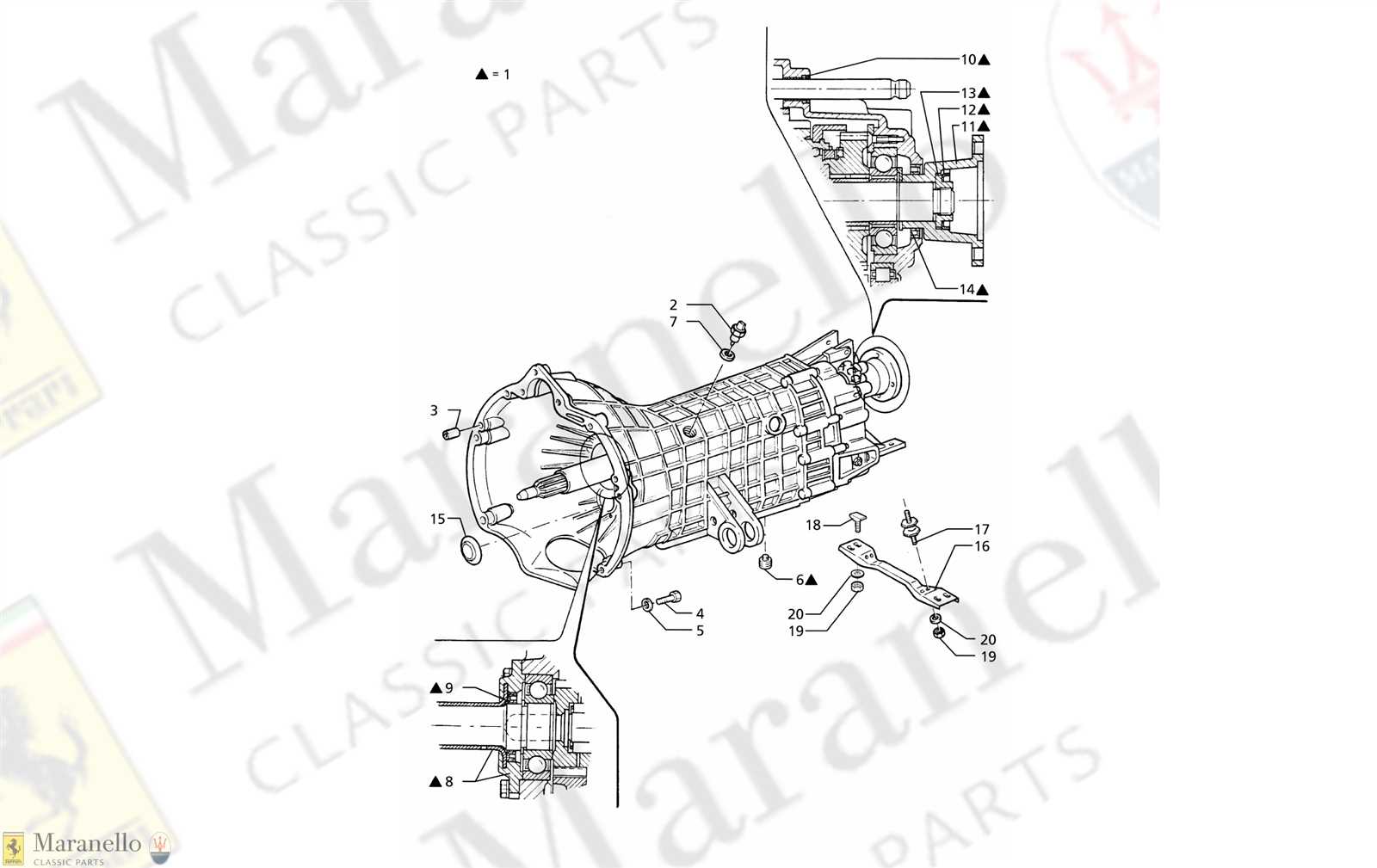

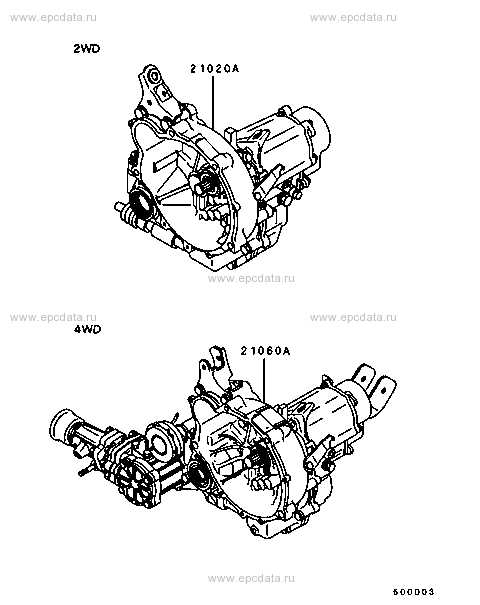

Input and Output Shafts Overview

The input and output shafts play a crucial role in the functioning of various mechanical systems. They are responsible for transferring rotational force between different components, ensuring smooth operation and efficiency. Understanding their structure and function is essential for anyone interested in the mechanics of vehicle systems.

Functionality and Importance

Input shafts connect the engine’s power to the system, receiving torque that is transmitted through gears. This initial transfer of energy is vital for the system’s operation. Conversely, output shafts deliver the final torque to the wheels, enabling motion. Their design is engineered to withstand significant stress, contributing to the overall durability of the system.

Common Issues and Maintenance

Regular inspection of these shafts is important to avoid performance issues. Common problems include wear and tear, which can lead to decreased efficiency or complete failure. Proper maintenance practices, such as lubrication and alignment checks, can prolong their lifespan and ensure optimal performance.

Flywheel Functions in Transmission

The flywheel plays a crucial role in the overall functionality of a vehicle’s power transfer system. It acts as a mechanical device that helps maintain rotational energy and provides stability to the operation of the engine.

One of the primary functions of the flywheel is to store kinetic energy generated during the engine’s operation. This energy is essential for smooth engagement and disengagement of various components, allowing for efficient performance during acceleration and deceleration.

Additionally, the flywheel aids in reducing vibrations and improving the overall balance of the system. By minimizing fluctuations, it enhances the driving experience and prolongs the lifespan of associated components.

Moreover, the flywheel is integral in assisting the starting process of the engine. It provides the necessary momentum to initiate the engine’s function, ensuring a seamless start under various conditions.

In summary, the flywheel serves multiple essential functions that contribute significantly to the efficiency and reliability of the entire vehicle operation.

Detailed Look at Gear Ratios

Understanding the relationship between rotational speed and torque is essential for optimizing performance in vehicles. Gear ratios play a crucial role in determining how power is transmitted from the engine to the wheels. By adjusting these ratios, drivers can enhance acceleration, fuel efficiency, and overall driving experience.

Impact on Performance

Different gear ratios affect how quickly a vehicle accelerates and how efficiently it operates at various speeds. Lower ratios generally provide better acceleration, making them ideal for start-up situations. Conversely, higher ratios are designed for maintaining higher speeds while improving fuel consumption. The balance between these two aspects is critical for achieving desired performance levels.

Choosing the Right Ratio

Selecting the appropriate ratio involves considering factors such as engine power, intended use, and terrain. Sports cars often utilize lower ratios for quicker acceleration, while vehicles intended for long-distance travel may favor higher ratios for better fuel economy. Ultimately, understanding these elements allows for a tailored driving experience that meets specific needs.

How Bearings Support Movement

Bearings play a crucial role in facilitating smooth and efficient motion within various mechanical systems. By reducing friction between moving components, they enable seamless interaction and enhance overall performance. This section will delve into the functions and advantages of these essential components in mechanical assemblies.

Functions of Bearings

- Minimizing friction: Bearings create a layer of separation between surfaces, allowing them to move with less resistance.

- Load distribution: They help to distribute weight and loads evenly across surfaces, preventing wear and damage.

- Supporting rotational movement: Bearings enable components to rotate smoothly, contributing to the overall efficiency of machines.

Benefits of Using Bearings

- Enhanced durability: With reduced friction, bearings decrease wear and extend the lifespan of machinery.

- Improved efficiency: By facilitating smoother movement, they contribute to better energy consumption.

- Noise reduction: Bearings help minimize operational noise, creating a quieter working environment.

Common Transmission Issues

In many vehicles, the system responsible for shifting gears can experience various challenges that affect performance and drivability. Understanding these common issues is essential for maintaining the efficiency and reliability of your vehicle’s operation.

Frequent Symptoms

Drivers may notice a range of symptoms indicating potential problems. These can include unusual noises, difficulty in shifting, or unexpected slippage. Recognizing these signs early can help in diagnosing the underlying issues.

Potential Causes

Several factors can contribute to these complications. Worn components, inadequate lubrication, and improper adjustments are just a few reasons that may lead to malfunction. Regular inspections and timely maintenance can prevent these concerns from escalating.

Maintenance Tips for Longevity

Ensuring the durability of your vehicle’s driving mechanism is essential for optimal performance and reliability. Regular upkeep can prevent unexpected failures and extend the lifespan of various components.

1. Regular Fluid Checks: Keep an eye on the quality and levels of essential fluids. Regularly checking and replacing them helps maintain efficiency and prevents wear.

2. Proper Usage: Adhering to recommended driving practices can significantly impact the longevity of your system. Avoiding sudden starts and aggressive driving helps reduce unnecessary strain on the mechanism.

3. Routine Inspections: Schedule periodic check-ups to identify potential issues before they escalate. Early detection can save time and resources in the long run.

4. Cleanliness Matters: Keeping the system clean from debris and contaminants can enhance its functionality. Regular cleaning of the external surfaces and ensuring seals are intact can prevent foreign substances from causing damage.

5. Seek Professional Assistance: When in doubt, consult a professional mechanic. Expert guidance can provide tailored advice and ensure that all components are in optimal condition.

By following these guidelines, you can significantly improve the reliability and durability of your vehicle’s driving system.

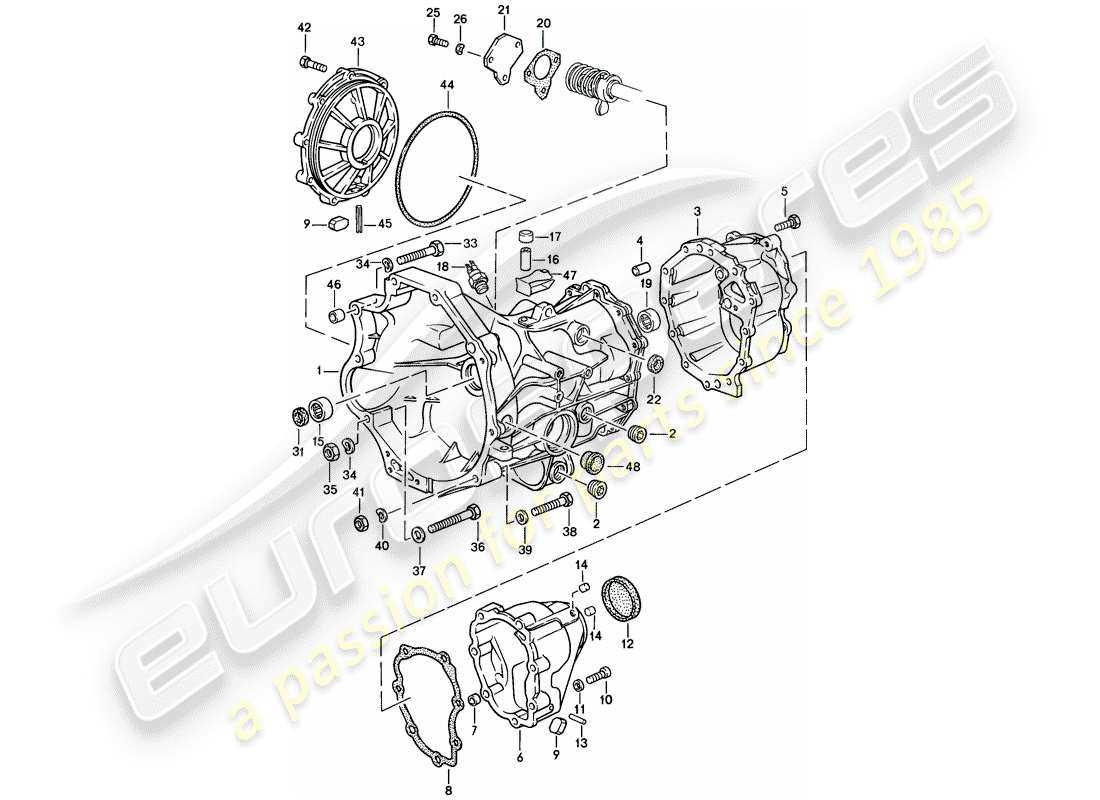

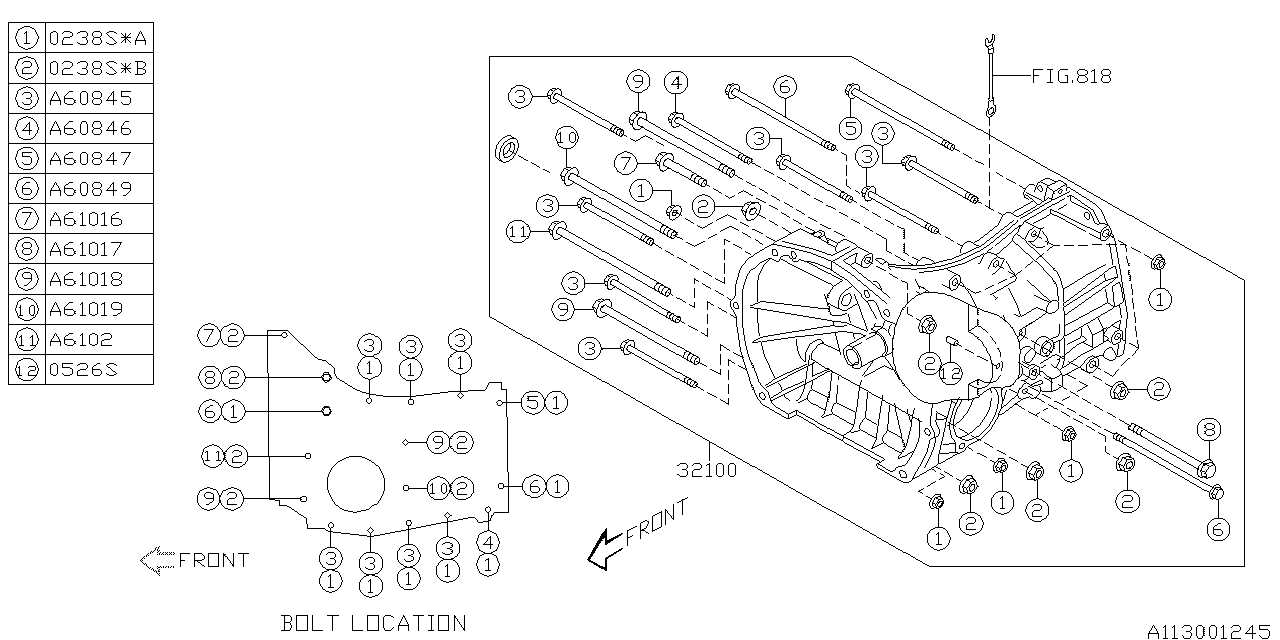

Tools Needed for Repairs

When it comes to performing maintenance or fixing issues in a vehicle’s drivetrain system, having the right instruments is essential for efficiency and accuracy. The correct tools not only facilitate the repair process but also ensure that all components are handled with care to prevent damage.

Essential Instruments: A variety of tools will be necessary to tackle different tasks. These include sockets and wrenches for loosening and tightening bolts, pliers for gripping, and screwdrivers for various fastening applications. Additionally, a torque wrench is crucial for ensuring that components are secured to the manufacturer’s specifications.

Specialized Equipment: Depending on the specific repairs, some specialized devices may be required. Gear pullers can assist in removing stubborn components, while alignment tools help in ensuring everything is correctly positioned. A lift or jack stands are also invaluable for providing access to the underside of the vehicle.

Safety Gear: Lastly, do not forget about safety equipment. Gloves protect your hands from sharp edges and chemicals, while safety glasses safeguard your eyes from debris. Ensuring personal safety is as important as the repair itself.