Understanding the Np542 Transmission Parts Diagram

In the realm of automotive engineering, the intricate interplay of various elements is crucial for ensuring optimal performance and reliability. Each segment of a mechanical assembly serves a distinct purpose, contributing to the overall functionality of the vehicle. A comprehensive grasp of these elements enables enthusiasts and professionals alike to appreciate the sophisticated design and engineering that underpins modern machinery.

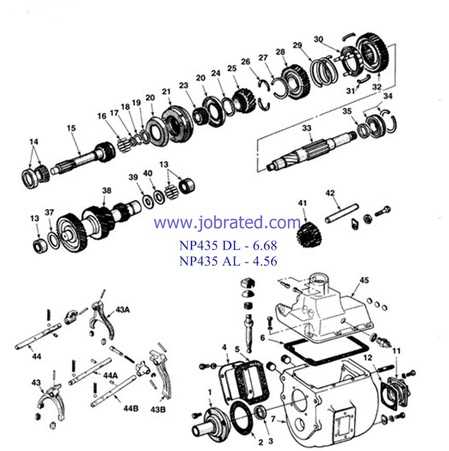

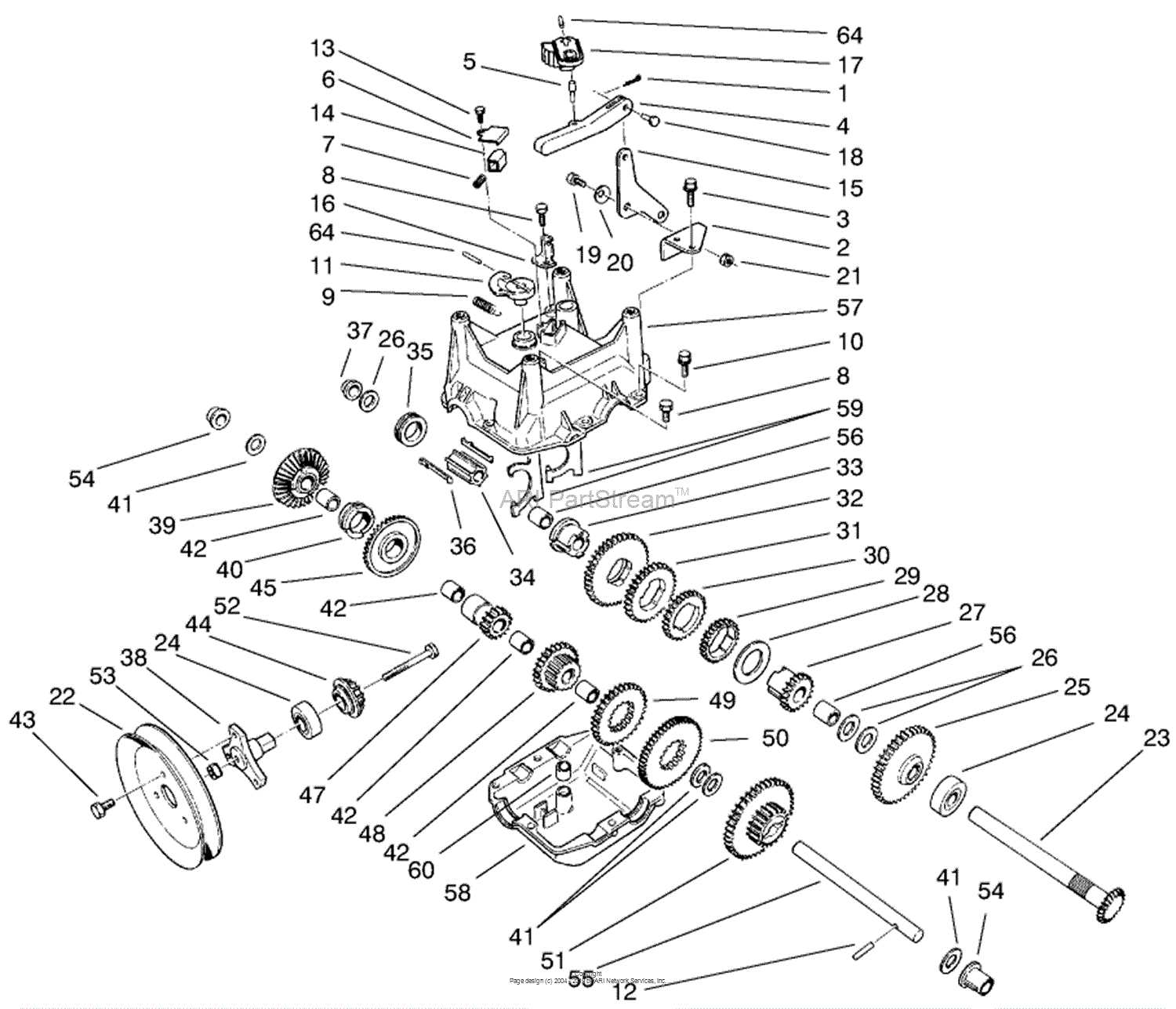

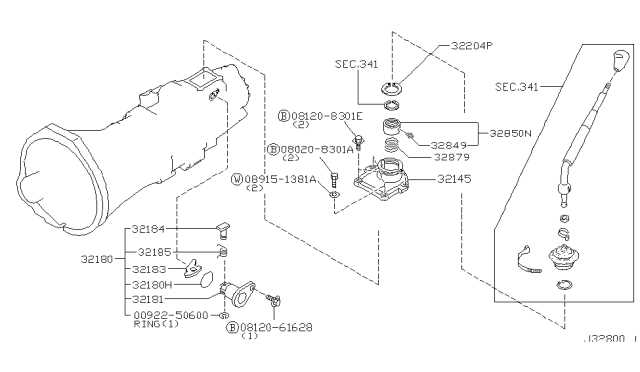

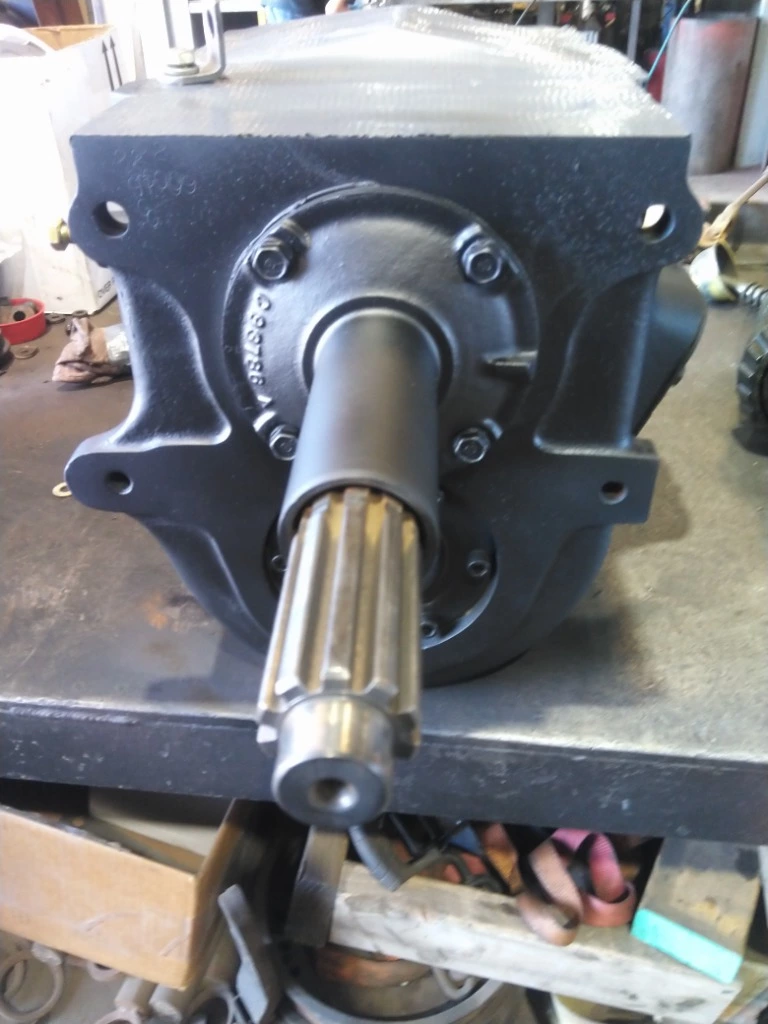

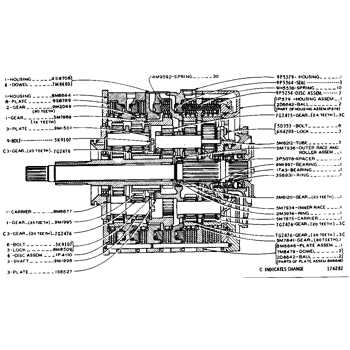

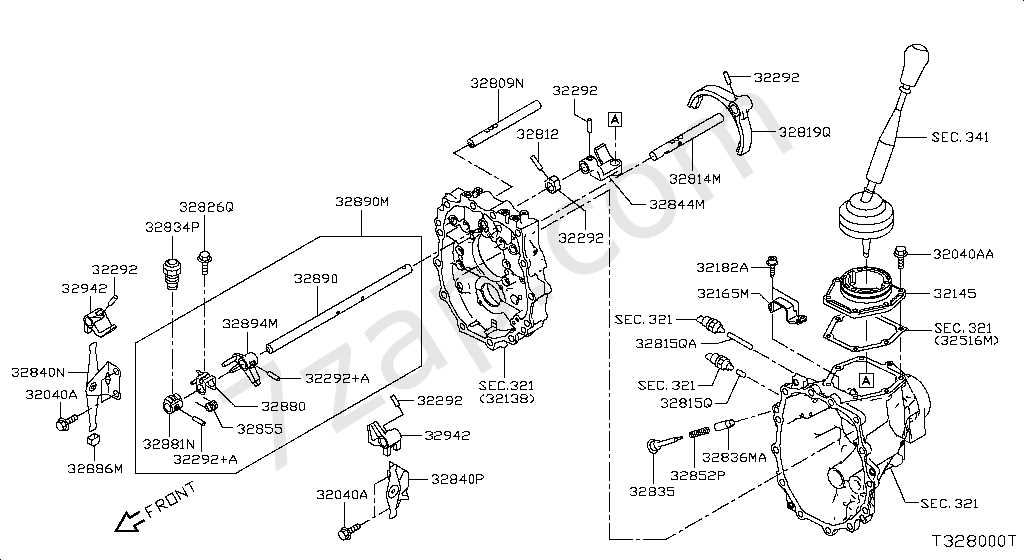

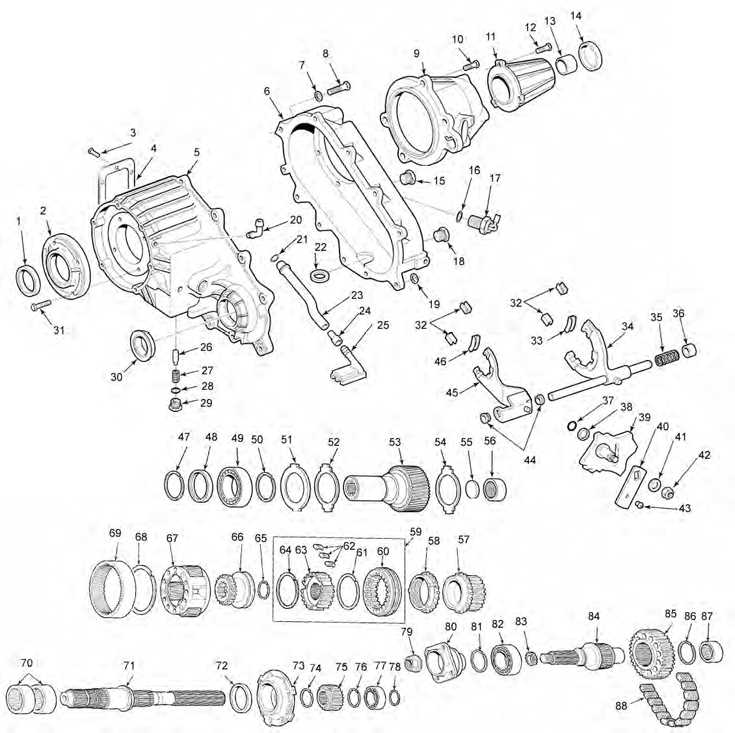

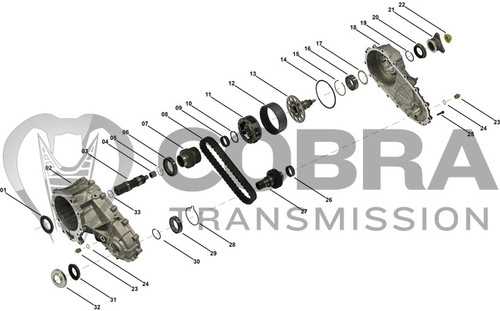

Visual representations of these mechanical systems can significantly aid in understanding how each component interacts with others. Such illustrations provide clarity, allowing one to identify the specific roles of individual elements within the larger framework. By examining these schematics, users can gain insights into maintenance and potential troubleshooting, ensuring the longevity and efficiency of the entire system.

Moreover, recognizing the nuances of these configurations enhances one’s ability to engage with automotive technology on a deeper level. Whether for repair, enhancement, or education, familiarity with the intricacies of these assemblies empowers individuals to make informed decisions and approach challenges with confidence.

Understanding the Np542 Transmission

Grasping the intricacies of a specific type of gear mechanism is essential for anyone involved in automotive maintenance or modification. This system plays a crucial role in enabling smooth power transfer and enhancing vehicle performance. Familiarity with its components and how they interact can significantly improve diagnostic skills and repair efficiency.

Key aspects to consider include:

- Structure and configuration of the gear assembly

- Functionality of each individual component

- Common issues encountered and their resolutions

- Importance of proper lubrication and maintenance

To fully appreciate the design, one should explore:

- The overall layout and arrangement of elements

- The role of various gears and clutches

- The interaction between mechanical and hydraulic systems

By understanding these fundamental concepts, enthusiasts can enhance their expertise and ensure optimal operation of their vehicles.

Key Components of Np542

Understanding the essential elements of this specific drivetrain system is crucial for anyone interested in automotive engineering or vehicle maintenance. Each component plays a vital role in ensuring smooth operation and efficient power transfer, contributing to the overall performance and reliability of the vehicle.

The assembly comprises several integral sections, including the input shaft, which initiates the movement, and the output shaft, responsible for delivering power to the wheels. Additionally, various gears facilitate the necessary adjustments in torque and speed, allowing for adaptable performance under different driving conditions.

Another significant aspect is the engagement mechanism, which allows for seamless shifting between modes. Coupled with these elements, a system of bearings and seals ensures durability and minimizes friction, thus enhancing longevity. Understanding these components can aid in troubleshooting and optimizing vehicle functionality.

Common Issues with Np542 Parts

When dealing with certain components of a vehicle’s shifting system, it’s important to recognize frequent challenges that may arise. These issues can affect performance, efficiency, and overall functionality, leading to potential repairs or replacements. Understanding these common pitfalls can aid in maintenance and troubleshooting, ensuring longevity and reliability.

| Issue | Description | Possible Solutions |

|---|---|---|

| Fluid Leaks | Leakage can occur from seals and gaskets, leading to low fluid levels. | Inspect seals for wear; replace gaskets and ensure proper tightening. |

| Shifting Difficulties | Components may become worn or misaligned, causing trouble in gear changes. | Check linkage adjustments; consider replacing worn components. |

| Overheating | Excess heat can damage internal elements, often due to low fluid levels or contamination. | Regularly check fluid levels; use the correct type and change it periodically. |

| Strange Noises | Unusual sounds can indicate internal damage or lack of lubrication. | Investigate for debris; ensure proper fluid levels and replace if necessary. |

Transmission Fluid Requirements

Understanding the essential fluid specifications is crucial for maintaining optimal performance in any vehicle system. The right type of lubricant ensures proper functionality, reduces wear, and enhances overall efficiency.

Here are the key considerations for selecting the appropriate fluid:

- Viscosity: Ensure the fluid matches the recommended viscosity for your specific model. This impacts how well the lubricant flows and performs under various temperatures.

- Type: Different formulations exist, including synthetic and conventional options. Choose one based on manufacturer recommendations and your driving conditions.

- Additives: Look for fluids that contain essential additives, which enhance performance, prevent oxidation, and reduce foam.

- Change Interval: Regular fluid replacement is vital. Follow the maintenance schedule provided in your owner’s manual to prevent issues.

Always refer to your vehicle’s manual for precise requirements and recommendations. Using the correct lubricant can significantly extend the lifespan and efficiency of the system.

How to Identify Np542 Parts

Recognizing components in a specific mechanical assembly can be challenging, yet it is essential for effective maintenance and repairs. A clear understanding of the individual elements involved not only enhances troubleshooting but also ensures that replacements are accurate and compatible.

Visual Inspection Techniques

Begin by conducting a thorough visual assessment of the assembly. Look for identifying marks or labels that may indicate the manufacturer or part number. Familiarizing yourself with common shapes and features of various components will aid in distinguishing them from one another. Utilize a reference guide or catalog to compare your findings with known specifications.

Consulting Reference Materials

Utilizing technical manuals or online resources can provide valuable insights into the construction and functionality of the assembly. These resources often include detailed descriptions and specifications that can help in identifying components accurately. Engaging with online forums or communities dedicated to mechanical systems can also yield practical advice and shared experiences from other users.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your vehicle’s mechanical components requires a proactive approach to upkeep. Regular maintenance not only prevents unexpected failures but also enhances the overall efficiency of the system. Here are some essential strategies to consider for extending the lifespan of these critical elements.

- Regular Fluid Checks: Consistently monitor and replace fluids according to the manufacturer’s recommendations to prevent wear and tear.

- Routine Inspections: Conduct frequent visual inspections to identify leaks or unusual noises that may indicate underlying issues.

- Temperature Management: Keep an eye on temperature gauges; overheating can significantly damage components.

- Filter Replacements: Replace filters at regular intervals to ensure cleanliness and prevent contaminants from causing damage.

Additionally, it is beneficial to keep records of all maintenance activities. This practice not only helps track the performance over time but also assists in identifying patterns that could signal potential problems.

- Follow Manufacturer Guidelines: Adhere strictly to the suggested maintenance schedule provided by the manufacturer.

- Avoid Overloading: Be mindful of weight limits to prevent unnecessary strain on components.

- Use Quality Parts: Opt for high-quality replacement components that meet or exceed original specifications.

By implementing these strategies, you can significantly enhance the reliability and lifespan of your vehicle’s essential systems.

Replacement Parts Overview

Maintaining the efficiency and longevity of a vehicle’s drivetrain system often requires an understanding of various components and their roles. Ensuring that each element functions optimally is crucial for smooth operation and performance. This section delves into the essential elements that may require attention or replacement over time, highlighting their importance in the overall mechanism.

Key Components: Numerous elements contribute to the seamless functionality of the drivetrain, including gears, seals, and housings. Each component plays a distinct role, and recognizing when these elements wear out can prevent more significant issues down the line. Regular inspections can help identify parts that need to be replaced, ensuring that the system operates as intended.

Selection of Quality Items: When sourcing replacements, it is vital to prioritize quality over cost. High-grade materials not only enhance performance but also extend the lifespan of the system. Considerations such as compatibility and durability should guide the selection process, allowing for efficient repairs and optimal performance.

In conclusion, understanding the essential components and selecting quality replacements are fundamental to maintaining a vehicle’s drivetrain health. Being proactive in addressing wear and tear can lead to improved performance and reliability, ensuring a smooth driving experience.

Tools Needed for Repairs

When undertaking any mechanical repair work, having the right tools at your disposal is essential for efficiency and effectiveness. The correct instruments not only facilitate a smoother workflow but also minimize the risk of damaging components. Below is a comprehensive list of essential equipment that will aid you in your repair endeavors.

Essential Hand Tools

Start with a set of quality hand tools. Wrenches, screwdrivers, and pliers are fundamental for loosening and tightening various fittings. It’s advisable to have a range of sizes available to accommodate different fasteners. Additionally, torque wrenches are crucial for ensuring that all connections are secured to the manufacturer’s specifications.

Diagnostic and Specialty Tools

Beyond basic hand tools, consider investing in diagnostic equipment. Multimeters can help assess electrical systems, while compression gauges are useful for evaluating the health of certain components. Depending on the complexity of the work, you might also need specialized adapters or pullers designed for specific tasks, ensuring you have everything necessary to perform repairs efficiently.

Step-by-Step Disassembly Process

This section outlines the systematic approach to dismantling the specified mechanical assembly, ensuring that each phase is executed with precision and care. Proper techniques will facilitate a seamless reassembly, preserving the integrity of all components involved.

Begin by gathering the necessary tools, including wrenches, screwdrivers, and a clean workspace. It’s crucial to have a clear plan and to document each step for future reference.

First, disconnect any electrical connections or hoses that may interfere with the disassembly process. Labeling these connections can save time during reinstallation. Next, remove the outer casing or cover to expose the internal mechanisms.

Once the casing is off, take note of the arrangement of internal elements. Carefully unscrew and remove each component, starting with the most accessible parts. Use a magnetic tray to keep track of small screws and fasteners.

As you proceed, inspect each piece for wear and tear, documenting any damages. This will assist in identifying necessary replacements. After extracting all internal elements, clean the surfaces before reassembly to prevent contamination.

Conclude the disassembly by reviewing the order of removal, ensuring that every part is accounted for. This meticulous approach not only aids in the current project but also enhances your understanding of the overall structure.

Diagram Interpretation Techniques

Understanding intricate illustrations requires a methodical approach. These visuals often encapsulate complex systems, necessitating a keen eye for detail and an ability to decode symbols and relationships. Mastering interpretation techniques can significantly enhance comprehension and facilitate effective communication of mechanical concepts.

Familiarization with Symbols is paramount. Each icon or notation carries specific meanings, which can vary across contexts. Acquainting oneself with a legend or key that explains these symbols lays a strong foundation for accurate interpretation.

Breaking Down Components into manageable sections can simplify the analysis. By isolating individual elements, one can better grasp their functions and interactions within the larger framework. This technique helps prevent feeling overwhelmed by the overall complexity.

Utilizing Color Coding and labels enhances clarity. Colors often indicate different functions or statuses, making it easier to distinguish between various elements. Pay attention to any associated descriptions that may offer additional insights into the roles of specific parts.

Cross-Referencing with Manuals or supplementary materials can provide deeper understanding. These resources often elaborate on the operational principles and can clarify any ambiguities encountered in the visual representation.

Practice through Real-Life Application can solidify learning. Engaging with actual components or systems related to the illustration can create practical context, reinforcing the theoretical knowledge gained through interpretation.

Aftermarket vs. OEM Components

When it comes to enhancing vehicle performance and ensuring longevity, enthusiasts often find themselves weighing options between original manufacturer offerings and alternatives from third-party suppliers. Each category presents unique benefits and potential drawbacks that can significantly impact both functionality and cost.

Understanding OEM Components

Original Equipment Manufacturer components are those produced by the vehicle’s manufacturer or licensed partners. They are designed to meet specific standards and are often backed by warranties. Choosing these parts typically ensures compatibility and reliability, making them a favored choice for many vehicle owners who prioritize maintaining their automobile’s integrity.

The Appeal of Aftermarket Alternatives

On the other hand, aftermarket options offer a diverse range of choices, often at a lower price point. These components can enhance performance and aesthetics, catering to individual preferences. However, quality can vary significantly among manufacturers, making it crucial for buyers to conduct thorough research and select reputable brands. Additionally, while some alternatives may void warranties, others can provide enhancements that original options do not.

Ultimately, the decision between OEM and aftermarket choices hinges on individual priorities, such as budget, performance expectations, and the desire for customization.

Expert Recommendations for Upgrades

When considering enhancements for your vehicle’s drivetrain, it is essential to focus on components that can significantly improve performance and durability. Experts suggest prioritizing upgrades that not only optimize efficiency but also enhance overall driving experience.

1. Quality Components: Invest in high-grade materials that offer better resilience and longevity. Look for options that are specifically designed to withstand higher stress and temperature levels, ensuring that your system operates smoothly under demanding conditions.

2. Enhanced Cooling Systems: Upgrading your cooling mechanisms can prevent overheating and improve the performance of your setup. Efficient cooling solutions help maintain optimal operating temperatures, which can lead to extended lifespan and reliability.

3. Improved Fluid: Utilizing superior lubricants can dramatically affect the functionality of your system. High-performance fluids reduce friction, enhance shifting quality, and provide better protection against wear, thereby ensuring smoother operation.

4. Calibration and Tuning: Custom tuning can tailor the performance characteristics of your setup to better match your driving style. A professional calibration can unlock potential power gains and improve responsiveness, resulting in a more engaging driving experience.

5. Regular Maintenance: Regularly scheduled checks and maintenance are vital to the longevity of any system. Keep an eye on wear indicators and replace components as necessary to avoid costly repairs and ensure optimal performance.

By implementing these recommendations, you can achieve a notable enhancement in your vehicle’s performance, making your driving experience more enjoyable and reliable.