Comprehensive Guide to T56 Transmission Parts Diagram

Exploring the intricacies of a manual gearbox reveals a complex interplay of mechanisms that work harmoniously to deliver power from the engine to the wheels. Each element plays a critical role, ensuring smooth shifting and efficient performance. By delving into the individual components, we can better appreciate the engineering prowess behind these systems.

Visualizing the layout of these mechanisms can significantly enhance our understanding of how they function. From the various gears to the intricate linkages, each piece contributes to the overall efficiency and reliability of the assembly. A clear representation can aid both enthusiasts and technicians in grasping the essential workings of this mechanical marvel.

In this exploration, we will uncover the specific elements that comprise this type of system. By examining their arrangement and interrelations, we aim to provide clarity on the operation and maintenance of these essential automotive features. A comprehensive overview will not only serve as a practical guide but also deepen the appreciation for automotive engineering.

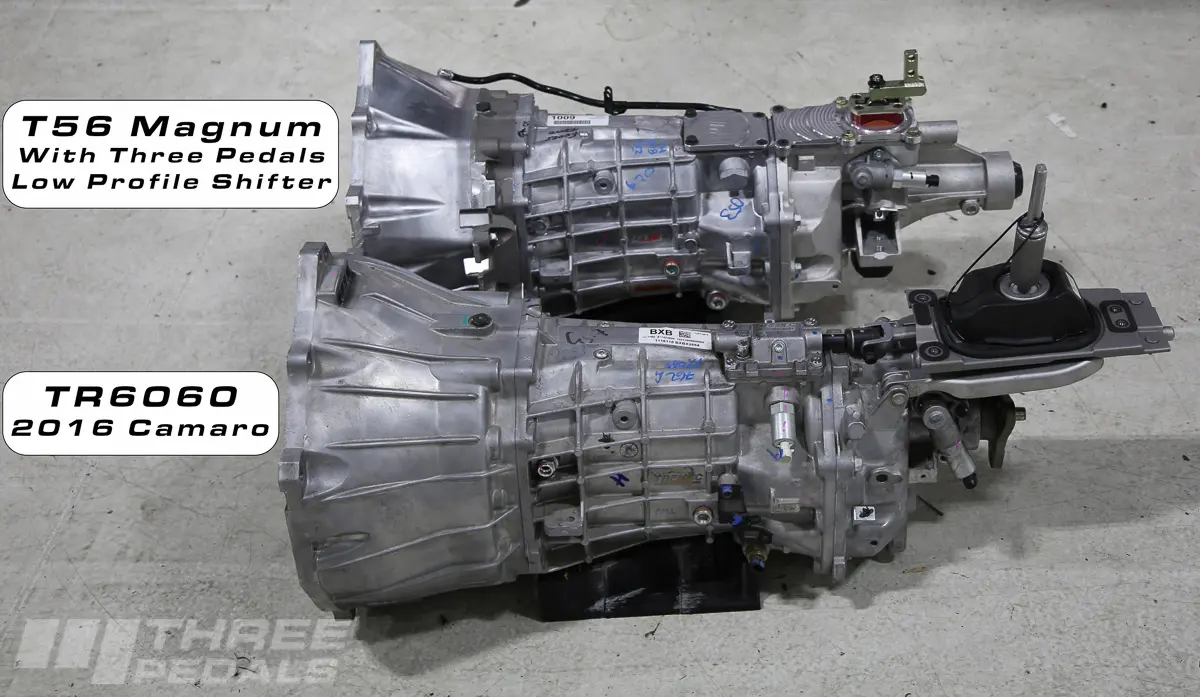

T56 Transmission Overview

This section provides a comprehensive insight into a renowned system utilized for power transfer in various high-performance vehicles. Designed to enhance efficiency and driving experience, it combines precision engineering with innovative features to meet the demands of enthusiasts and professionals alike.

Key characteristics include a robust construction that ensures durability, along with smooth gear engagement for optimal performance. This mechanism has been favored in both street and racing applications due to its ability to handle significant power levels while maintaining reliability.

Moreover, advancements in technology have allowed for improved shifting dynamics, making it a popular choice for those seeking an upgrade in their vehicle’s performance. Enthusiasts often delve into the various elements that contribute to its functionality, ensuring they achieve the ultimate driving experience.

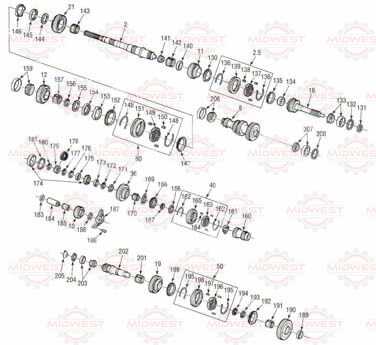

Key Components of T56 Transmission

The assembly of a specific gear-shifting system consists of several crucial elements that work in harmony to ensure smooth and efficient operation. Understanding these fundamental components can enhance one’s knowledge of vehicle mechanics and performance.

Gear Set: The core of the system, this set contains various ratios that allow the vehicle to achieve different speeds and torque outputs. Each gear plays a vital role in optimizing power delivery based on driving conditions.

Synchronizers: These elements facilitate seamless engagement between gears, preventing grinding and ensuring a smooth transition. They adjust the speeds of the gears to match, allowing for quick shifts without interruption.

Clutch Mechanism: Essential for disengaging the engine from the system during gear changes, this mechanism allows for smooth transitions between different ratios. Proper functioning is critical for the overall performance and longevity of the assembly.

Input and Output Shafts: These shafts are responsible for transmitting power to and from the engine and wheels, respectively. Their design and construction are key to the overall efficiency and durability of the system.

Case Housing: The protective exterior encases all internal components, providing structural integrity and shielding against external elements. Its design can also impact heat dissipation and noise levels during operation.

Each of these components plays an integral role in the functionality and efficiency of the gear-shifting assembly, contributing to a reliable driving experience.

Understanding the T56 Gear Set

The intricate assembly of gears plays a crucial role in delivering performance and efficiency in high-powered vehicles. By exploring this complex arrangement, enthusiasts can appreciate how each component contributes to overall functionality and driving experience.

Key Components of the Gear Assembly

At the heart of the system are the gears themselves, which work in unison to provide varying ratios essential for acceleration and speed control. Each gear is designed to withstand significant forces, ensuring durability and smooth operation under stress.

Benefits of an Optimized Gear Arrangement

A well-designed gear setup enhances power transfer and responsiveness, allowing drivers to harness the full potential of their engines. Understanding the mechanics behind this arrangement can ultimately lead to improved performance and driving satisfaction.

Common Issues with T56 Parts

Understanding the typical challenges associated with these components is essential for maintaining optimal performance. Many enthusiasts and mechanics encounter specific problems that can affect reliability and efficiency.

| Issue | Description |

|---|---|

| Shifting Difficulties | Difficulty in changing gears can arise from worn-out synchronizers or misaligned linkages. |

| Fluid Leaks | Leakage can occur due to damaged seals or gaskets, leading to fluid loss and potential overheating. |

| Noise Problems | Unusual sounds may indicate bearing wear or gear misalignment, requiring immediate attention. |

| Overheating | Excessive heat may result from inadequate lubrication or prolonged use under heavy loads. |

Benefits of Upgrading T56 Components

Enhancing key elements of your gear-shifting system can lead to significant improvements in performance and reliability. These upgrades not only elevate driving experiences but also contribute to the longevity of the overall mechanism. Here are some notable advantages of considering these enhancements:

- Improved Performance: Upgraded components can provide smoother shifts and quicker response times, leading to a more enjoyable driving experience.

- Increased Durability: Higher-quality materials are often used in upgraded versions, which can withstand greater stress and wear over time.

- Enhanced Efficiency: Optimized designs can reduce friction and energy loss, resulting in better fuel economy and power delivery.

- Customization Options: With a variety of aftermarket components available, enthusiasts can tailor their system to meet specific performance goals or driving styles.

- Better Heat Management: Advanced designs often include features that improve cooling, reducing the risk of overheating during intense driving conditions.

Overall, investing in the enhancement of these components can transform your vehicle’s capabilities, making it more enjoyable and efficient on the road.

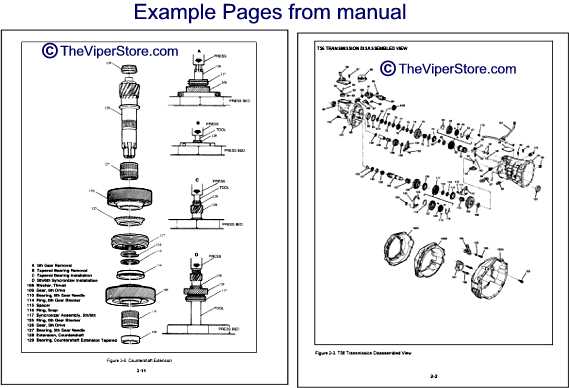

How to Read T56 Diagrams

Understanding complex schematics is essential for effective troubleshooting and maintenance of mechanical systems. By mastering the art of interpreting these visual guides, one can gain insights into the arrangement and function of various components. This knowledge allows for more efficient repairs and enhances overall performance.

To effectively analyze these illustrations, follow a systematic approach. Start by familiarizing yourself with the symbols and notations used. Each element usually represents a specific component or function, and recognizing these will facilitate comprehension.

| Symbol | Description |

|---|---|

| Circle | Indicates a connection point or junction. |

| Arrow | Represents the direction of movement or flow. |

| Square | Denotes a component, such as a gear or lever. |

Additionally, take note of any accompanying labels and references. These often provide crucial information about specifications, torque settings, and other important details that can influence assembly and disassembly processes.

Maintenance Tips for T56 Transmissions

Proper upkeep of your vehicle’s shifting mechanism is crucial for ensuring optimal performance and longevity. Regular care not only enhances driving experience but also prevents costly repairs down the line. Here are some essential practices to keep in mind.

Start by regularly checking and changing the fluid. Quality lubricant is vital for smooth operation, reducing friction and wear. Follow the manufacturer’s recommendations for intervals and type of fluid to use.

Inspecting seals and gaskets is equally important. Look for signs of leaks, as these can lead to inadequate lubrication and potential damage. Replace any worn components promptly to maintain integrity.

Pay attention to the clutch system as well. Ensuring proper alignment and functionality of the clutch pedal can greatly impact shifting quality. Address any unusual noises or difficulties immediately to avoid further complications.

Lastly, periodic professional inspections can catch issues before they escalate. Experienced technicians can identify subtle signs of wear that might go unnoticed, allowing for timely interventions. Keeping a regular maintenance schedule will help ensure your vehicle remains reliable for years to come.

Aftermarket T56 Part Options

Exploring alternative components for high-performance gear systems can significantly enhance your vehicle’s capabilities. Upgrading these essential elements not only improves durability but also optimizes shifting precision and response.

Among the popular choices are clutch kits, designed to handle increased power and torque. Additionally, shifter assemblies can provide a more engaging driving experience, allowing for quicker and smoother gear changes.

Moreover, rear-end gears can be modified for improved acceleration and efficiency, catering to different driving styles. It’s crucial to consider lightweight flywheels, which can reduce rotational mass, enhancing throttle response and overall performance.

In conclusion, the aftermarket offers a variety of options that can elevate your setup, ensuring both reliability and excitement on the road.

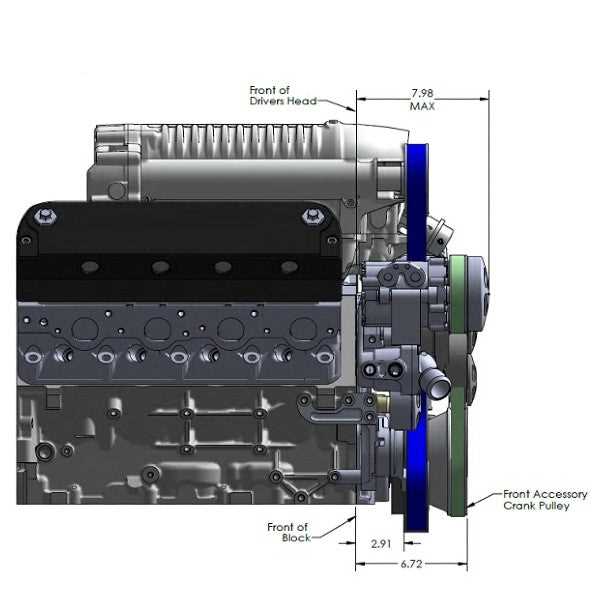

Installation Process for T56 Parts

The process of integrating components into a complex assembly requires careful planning and execution. Ensuring each element is positioned correctly is essential for optimal functionality and performance. This section outlines the crucial steps to successfully complete this integration, highlighting best practices and common pitfalls to avoid.

Preparation is key before beginning the installation. Gather all necessary tools and materials to streamline the workflow. Ensure the workspace is clean and organized to facilitate easy access to components. It is also advisable to review the manual for specific guidance on the assembly sequence.

Begin by positioning the main structure in place. Align the supporting elements accurately to prevent misalignment later in the process. Once everything is situated, secure the foundational pieces with the appropriate fasteners, ensuring a firm grip without overtightening.

Next, install the auxiliary components, paying close attention to any alignment notches or guides that ensure correct placement. It’s important to follow the recommended torque specifications to maintain integrity and prevent damage. Utilize a torque wrench for precision.

After all elements are secured, conduct a thorough inspection to verify that everything is installed according to the guidelines. Look for any potential obstructions or misalignments that could impact performance. This final check is crucial for avoiding issues during operation.

Once the assembly is confirmed, proceed with testing the functionality. Engage the system to ensure that all components work harmoniously. Address any anomalies immediately to avoid complications down the line.

Performance Modifications for T56

Enhancing the efficiency and power transfer of your vehicle’s gear mechanism can lead to significant improvements in overall performance. Various upgrades can be implemented to maximize the potential of your system, ensuring a more responsive and robust driving experience.

Upgrading Internal Components

Swapping out stock internal elements for high-performance alternatives can drastically improve shifting speed and durability. Consider using better syncros and forged gears to handle increased power loads while reducing the risk of failure.

Improving Cooling and Lubrication

Enhanced cooling solutions and superior lubricants play a crucial role in maintaining optimal operating temperatures. Investing in an upgraded cooler and synthetic fluids can ensure longevity and efficiency, ultimately leading to smoother gear engagement.

Comparison with Other Transmissions

This section explores the unique characteristics and performance metrics of a specific gear-shifting mechanism in relation to its peers in the automotive industry. Understanding these differences can aid enthusiasts and professionals in making informed choices based on their specific needs and preferences.

| Feature | Mechanism A | Mechanism B | Mechanism C |

|---|---|---|---|

| Weight | Lightweight | Moderate | Heavy |

| Shift Speed | Fast | Average | Slow |

| Durability | High | Moderate | Low |

| Cost | Affordable | Expensive | Moderate |

By examining these attributes, one can delve into the ultimate advantages and drawbacks of each system, providing a clearer picture for potential applications and enhancements.

Resources for T56 Owners

For enthusiasts and owners of performance vehicles, having access to reliable information and resources is essential for maintenance and upgrades. This section provides valuable references that can help you enhance your driving experience and ensure the longevity of your equipment.

Online Forums and Communities

Joining online forums and communities is a great way to connect with fellow enthusiasts. Websites such as LS1Tech and CorvetteForum offer dedicated sections where you can ask questions, share experiences, and find advice on repairs and modifications. Engaging with other owners can provide insights that are not available in manuals.

Repair Manuals and Guides

Comprehensive repair manuals are indispensable for anyone looking to dive into maintenance tasks. Resources like Haynes Manuals and Chilton provide step-by-step instructions and detailed illustrations. Additionally, video tutorials on platforms like YouTube can visually guide you through complex processes, making repairs more accessible and less daunting.

Future of T56 Transmissions

The evolution of high-performance gear systems is poised to revolutionize the automotive industry. As technology advances, innovations in design and engineering will enhance efficiency, responsiveness, and overall driving experience. These improvements will cater to the growing demand for robust and adaptable mechanisms in various vehicle applications.

Innovative Developments

New materials and manufacturing techniques are set to redefine durability and performance. Lightweight composites and advanced alloys will minimize weight while maximizing strength, leading to improved fuel efficiency and handling.

Shifting Paradigms

With the rise of electric and hybrid vehicles, adaptability will be crucial. Future systems must seamlessly integrate with electric drivetrains, ensuring optimal performance across diverse power sources.

| Innovation | Impact |

|---|---|

| Advanced Materials | Increased strength and reduced weight |

| Smart Technology | Enhanced performance monitoring and adjustments |

| Integration with Electric Systems | Improved efficiency and versatility |