Troy Bilt Sickle Bar Mower Parts Diagram Explained

Maintaining agricultural machinery can be a daunting task, especially when it comes to identifying the various components that contribute to its efficiency. Having a clear understanding of how each part functions not only enhances performance but also prolongs the lifespan of the equipment. This knowledge is essential for anyone looking to optimize their tools for landscaping or farming tasks.

In this section, we will explore a detailed visual representation of the key elements involved in this type of equipment. By breaking down the anatomy of these machines, users can gain insights into their operation, enabling more effective repairs and maintenance. Whether you’re an experienced operator or a newcomer, familiarizing yourself with these components is vital for achieving the best results.

Through this guide, you will discover how to navigate the intricate relationships between the various parts, making it easier to troubleshoot issues and perform necessary upgrades. With the right information at your fingertips, you can ensure that your cutting apparatus runs smoothly and meets the demands of your outdoor projects.

Troy Bilt Sickle Bar Mower Overview

This section explores the essential features and functions of a versatile cutting tool designed for maintaining grassy areas. Known for its reliability, this equipment provides an effective solution for trimming overgrown vegetation.

Key Features: Built with robust materials, it ensures durability while delivering optimal performance in various conditions. Its unique cutting mechanism allows for precise and efficient operation, making it a preferred choice among users.

Applications: Ideal for both residential and commercial use, it excels in clearing tall grass, weeds, and brush. This makes it an ultimate ally for landscaping and agricultural tasks, streamlining the process of land management.

Importance of Maintenance for Mowers

Common Issues with Sickle Bar Mowers

In the realm of agricultural equipment, various challenges can arise, impacting performance and efficiency. Understanding these common hurdles can aid in maintenance and troubleshooting, ensuring optimal functionality.

Mechanical Failures

Mechanical breakdowns often stem from wear and tear or inadequate lubrication. Regular inspections can help identify potential issues before they escalate.

Cutting Performance Problems

Inconsistent cutting can result from dull blades or misalignment. Keeping blades sharp and properly adjusted is crucial for achieving the best results.

| Issue | Symptoms | Solutions |

|---|---|---|

| Wear and Tear | Reduced efficiency | Regular maintenance and timely replacements |

| Dull Blades | Uneven cuts | Sharpen blades regularly |

| Misalignment | Inconsistent cutting | Check and adjust alignment |

Understanding Mower Parts and Functions

Grasping the components and their roles is essential for effective maintenance and operation of cutting equipment. Each element plays a vital part in ensuring efficiency and longevity, ultimately enhancing the user experience. Familiarity with these elements enables operators to troubleshoot issues and perform necessary upkeep.

Key Components and Their Roles

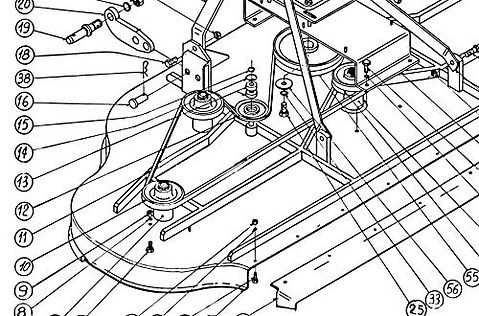

Essential components include the cutting mechanism, drive system, and support structures. The cutting mechanism, responsible for slicing through vegetation, is often composed of sharp blades that require regular sharpening. The drive system facilitates movement, typically powered by a motor, while the support structures provide stability and durability during operation.

Maintenance Tips for Optimal Performance

Regular inspections and timely replacements of worn components are crucial for maintaining functionality. Lubrication of moving parts reduces friction and extends lifespan, while ensuring that blades are sharp and aligned promotes efficient cutting. By understanding these fundamentals, users can maximize their equipment’s performance and reliability.

How to Identify Worn Parts

Recognizing when components have deteriorated is essential for maintaining equipment efficiency and safety. Regular inspection can prevent further damage and costly repairs. Understanding key signs of wear can help in pinpointing which elements need replacement.

Start by visually examining the components for any noticeable cracks, breaks, or deformities. Check for unusual sounds during operation, as these often indicate friction or misalignment. Additionally, look for signs of rust or corrosion, which can compromise structural integrity. Pay attention to performance; if your equipment struggles to operate smoothly, this may signal that certain elements are no longer functioning effectively.

Finally, consult the manufacturer’s guidelines for recommended maintenance intervals, as these can provide insights on when to assess specific components. Keeping a log of inspections and replacements can also help in tracking the health of your machinery over time.

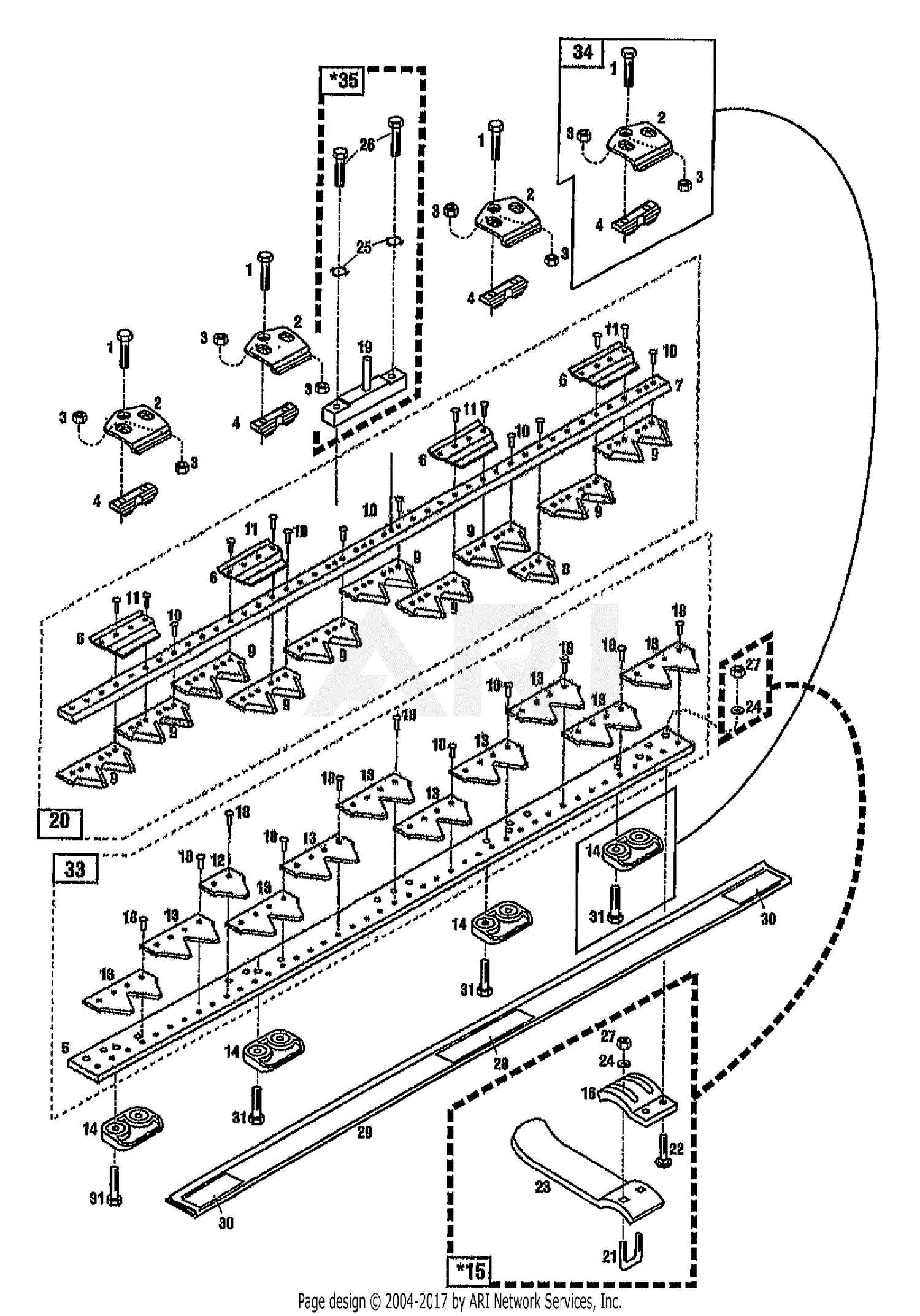

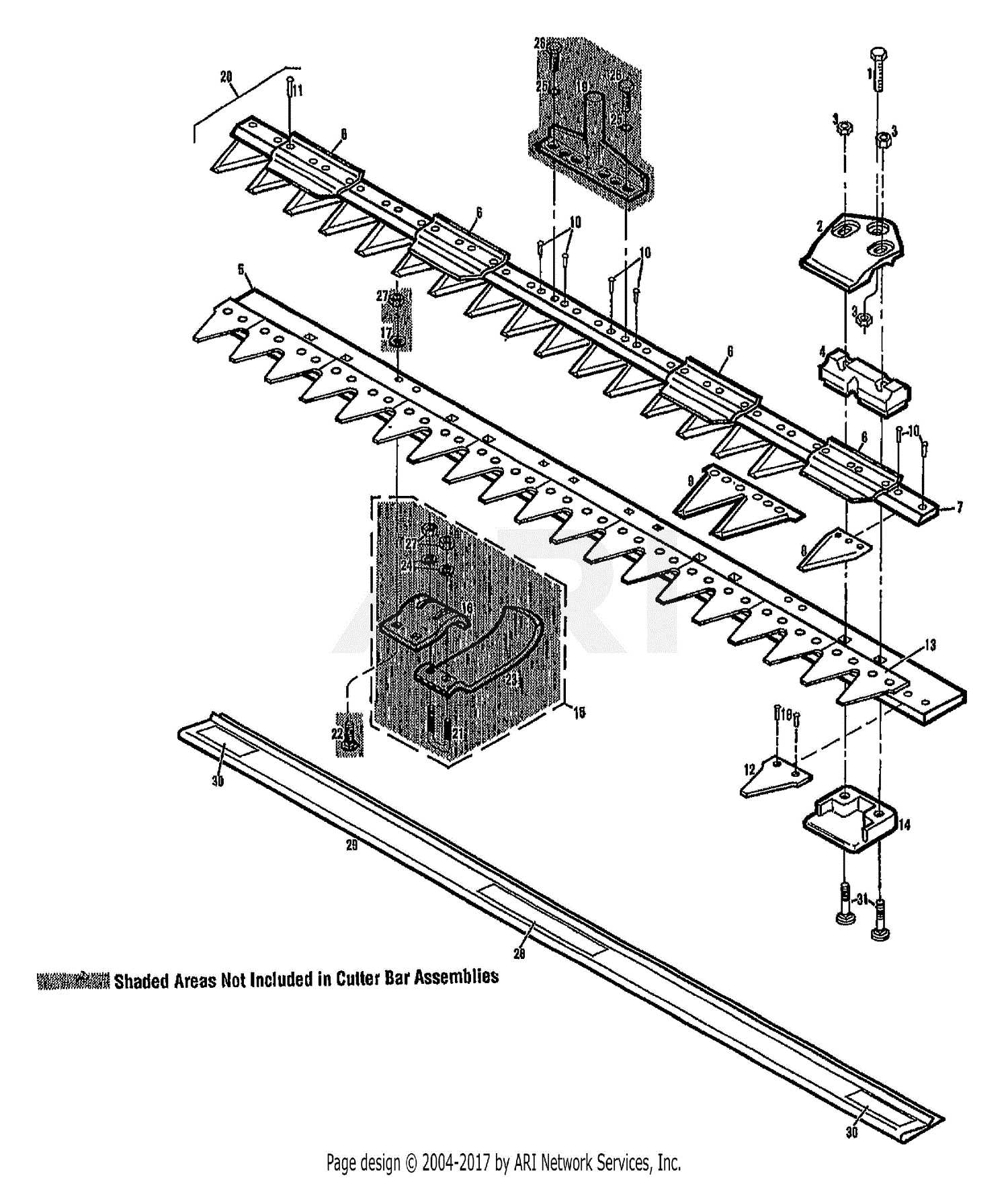

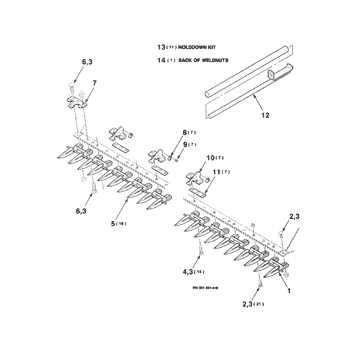

Parts Diagram: Key Components Explained

This section provides a comprehensive overview of essential elements within the machinery, highlighting their functions and interconnections. Understanding these components is crucial for effective maintenance and optimal performance.

Essential Elements

Blade Assembly: The cutting mechanism plays a vital role in the overall efficiency. It is designed to handle various vegetation types, ensuring a clean and precise cut.

Drive System

Power Transmission: This system is responsible for transferring energy from the engine to the cutting unit. Its design is crucial for reliable operation and longevity, allowing for smooth and efficient functionality.

Step-by-Step Repair Instructions

This section provides a comprehensive guide to assist you in restoring your equipment to optimal working condition. Following these detailed steps will help ensure that each component is addressed effectively for a smooth repair process.

Preparation

- Gather necessary tools: wrenches, screwdrivers, and pliers.

- Wear safety gear: gloves and goggles.

- Find a clean, well-lit workspace.

Repair Steps

- Begin by disconnecting the power source.

- Remove any covers or shields to access the components.

- Inspect each part for wear or damage, taking notes on what needs replacement.

- Replace faulty components with new ones, ensuring a secure fit.

- Reassemble the unit carefully, following the reverse order of disassembly.

- Reconnect the power source and test the equipment for proper functionality.

Where to Buy Replacement Parts

Finding high-quality components for your machinery is essential for maintaining optimal performance. There are several reliable sources to consider when searching for these items, each offering unique advantages. Understanding where to look can save time and ensure you get the right pieces for your equipment.

Online Retailers

The internet provides a vast array of options for purchasing replacements. Here are some popular online platforms:

- Amazon: A well-known marketplace with a wide selection and customer reviews.

- eBay: Offers new and used items, often at competitive prices.

- Specialized websites: Many companies focus solely on outdoor equipment, providing an extensive range of components.

Local Stores

Visiting physical stores can also be beneficial. Consider the following options:

- Home improvement centers: Often carry a variety of tools and replacement items.

- Local hardware stores: May have specialized sections for outdoor equipment.

- Authorized dealers: These locations often provide genuine components and expert advice.

When seeking replacements, evaluate the reputation of the supplier and compare prices to ensure you make an informed decision. Whether you choose to shop online or visit a store, having reliable options at your disposal can greatly enhance your maintenance efforts.

Tips for Enhancing Mower Performance

Improving the efficiency and effectiveness of your cutting equipment requires a few strategic adjustments and regular maintenance. By focusing on several key areas, you can ensure that your device operates smoothly and delivers optimal results, whether for residential lawns or larger fields.

1. Regular Maintenance: Consistent upkeep is crucial for any machinery. Clean the cutting blades and inspect them for wear. Sharpen dull blades to enhance cutting precision and prevent stress on the engine.

2. Check Fuel Quality: Using fresh fuel can significantly impact performance. Stale or contaminated fuel can lead to starting issues and reduced power output. Always use high-quality fuel recommended for your equipment.

3. Proper Tire Inflation: Ensuring that tires are inflated to the correct pressure can improve traction and stability. This helps the equipment navigate uneven terrain more effectively, leading to better cutting results.

4. Adjust Cutting Height: Depending on the type of grass and desired appearance, adjusting the cutting height can make a difference. A proper height prevents scalping and promotes healthier grass growth.

5. Inspect Belts and Cables: Regularly check belts for signs of wear or damage. Replacing frayed belts and ensuring cables are intact can prevent performance issues and unexpected breakdowns.

6. Clean the Undercarriage: Grass clippings and debris can accumulate, hindering performance. Regular cleaning of the undercarriage helps maintain efficiency and prolongs the life of your machine.

7. Utilize Accessories Wisely: If your equipment supports attachments, use them as intended. Accessories can enhance functionality and improve the overall effectiveness of your cutting tasks.

By implementing these tips, you can significantly enhance the performance of your cutting equipment, ensuring it runs efficiently and effectively for all your landscaping needs.

Safety Precautions When Using Mowers

Operating landscaping equipment requires awareness and adherence to safety measures to prevent accidents and injuries. Understanding the necessary precautions ensures a safer experience while maintaining your outdoor spaces.

- Always wear appropriate personal protective equipment, including gloves, goggles, and sturdy footwear.

- Inspect the equipment before use to ensure all components are functioning properly.

- Clear the working area of debris, rocks, and other obstacles that could cause injury or damage.

- Maintain a safe distance from others, particularly children and pets, while in operation.

- Follow the manufacturer’s guidelines for safe operation and maintenance.

By following these essential safety guidelines, you can significantly reduce the risk of mishaps and ensure effective performance during your outdoor tasks.

Frequently Asked Questions About Mowers

This section aims to address common inquiries related to various types of cutting machines used in landscaping and agricultural tasks. Whether you’re a novice or an experienced user, finding the right information can enhance your experience and maintenance practices.

- What is the best type of cutting equipment for my property?

- How often should I maintain my equipment?

- What are the common issues I might face?

- Can I use my equipment on uneven terrain?

Consider the size of your land, the type of vegetation, and your budget. For smaller areas, push models may suffice, while larger plots might require riding options.

cssCopy code

Regular maintenance is crucial. Check the manufacturer’s guidelines, but a good rule of thumb is to perform a thorough check at least once a season.

Frequent problems include dull blades, fuel issues, and mechanical failures. Regular inspections can help you catch these early.

Many models are designed for rough ground, but it’s essential to check the specifications and ensure your machine is suitable for such conditions.