Understanding the Billy Goat Vacuum Parts Diagram for Efficient Repairs

In the world of household maintenance, having a clear comprehension of the internal workings of your cleaning device is crucial. Every component plays a vital role in ensuring optimal functionality, contributing to the efficiency and longevity of the equipment. By exploring the intricate layout of these elements, users can enhance their understanding and effectively address any issues that may arise.

Visual representation of the various sections and mechanisms within the apparatus provides valuable insight into its operation. This knowledge empowers users to perform routine maintenance, troubleshoot problems, and identify any worn or damaged sections. Whether you are a seasoned technician or a casual user, a detailed overview can make a significant difference in your cleaning experience.

Moreover, a thorough examination of the assembly not only simplifies repairs but also fosters a deeper appreciation for the technology behind these tools. Recognizing how each segment interconnects will help you make informed decisions when seeking replacements or upgrades. Embrace the opportunity to explore this essential guide and enhance your cleaning capabilities.

Overview of the Collection System

This section provides a comprehensive insight into a specialized device designed for outdoor cleaning. It highlights the essential features, benefits, and operational aspects that make this equipment a valuable asset for maintaining cleanliness in various environments.

- Design: The device is engineered for efficiency, ensuring effective debris collection without causing damage to the surface.

- Functionality: It operates seamlessly, employing advanced mechanisms that enhance performance in diverse conditions.

- Durability: Built with robust materials, it withstands the rigors of frequent use while maintaining optimal functionality.

- User-Friendly: The intuitive controls and ergonomic design make it accessible for users of all experience levels.

- Maintenance: Regular upkeep is simplified, ensuring longevity and reliability over time.

In summary, this cleaning apparatus is an indispensable tool for professionals and homeowners alike, providing a practical solution for effective outdoor maintenance.

Understanding Vacuum Mechanisms

Exploring the principles behind suction devices reveals the intricate interplay of components that enable effective performance. These systems rely on the creation of low-pressure environments to draw in and manage various materials. Understanding the function of each element allows for better maintenance and optimization.

At the core of these systems are motors that generate airflow, while fans or impellers facilitate the movement of substances. The design often incorporates filters to ensure the separation of particulates, enhancing efficiency and prolonging the lifespan of the equipment. Analyzing how these elements interact provides insight into their overall effectiveness.

Additionally, the role of seals and gaskets cannot be overlooked, as they ensure airtight connections that prevent leaks and maintain pressure levels. Proper alignment and assembly of these components are crucial for optimal functionality. By delving into these details, users can achieve the ultimate performance from their devices.

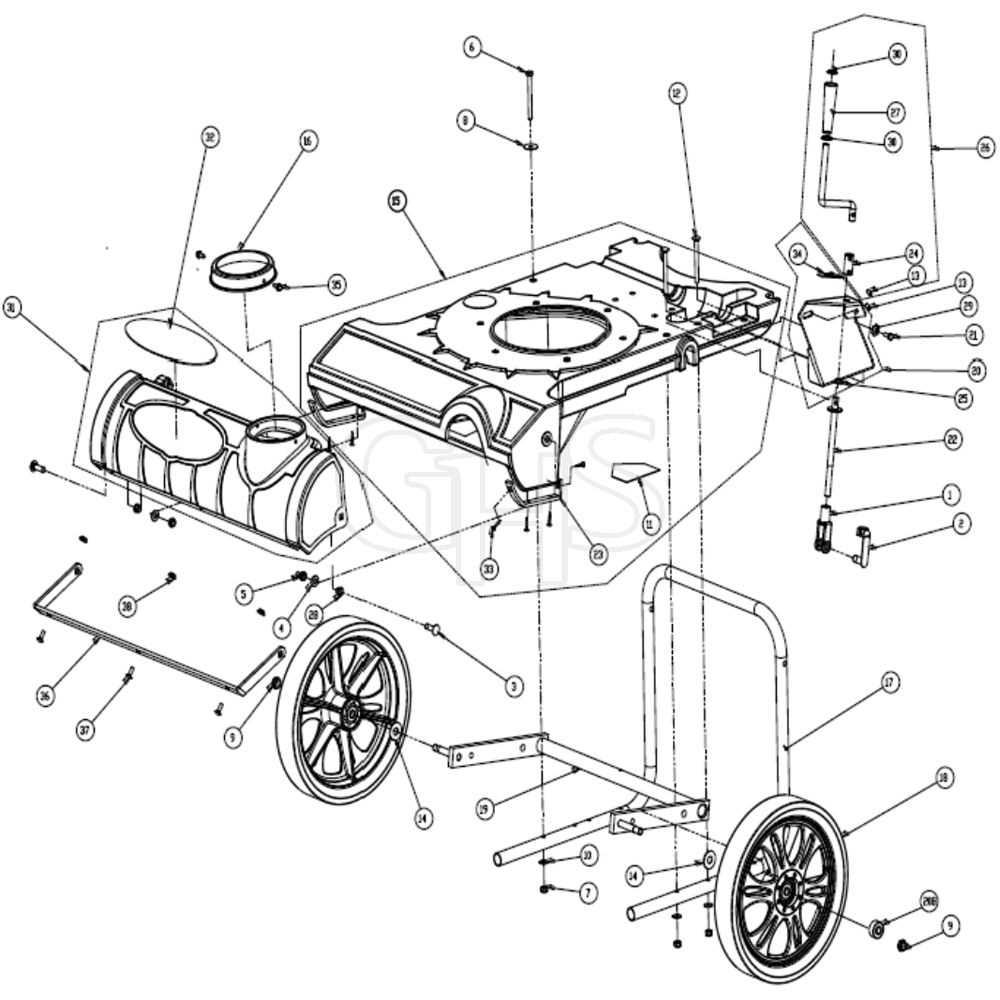

Key Components of the Billy Goat

Understanding the essential elements of this outdoor equipment is crucial for effective operation and maintenance. Each component plays a significant role in ensuring optimal performance, contributing to the overall efficiency and longevity of the machine.

Motor: At the heart of the device, the motor powers all operations. Its strength and reliability directly impact the functionality of the equipment, making it essential for users to recognize its specifications and maintenance needs.

Collection Bag: This feature is vital for gathering debris. A well-designed collection unit maximizes capacity while facilitating easy disposal, ensuring that users can handle clean-up tasks efficiently.

Hoses: Flexible tubing connects various parts, allowing for the smooth movement of air and debris. Proper care and inspection of these hoses can prevent blockages and maintain optimal airflow.

Wheels: Mobility is critical for outdoor tasks, and robust wheels enhance maneuverability across diverse terrains. Understanding their construction and wear can help in ensuring smooth operation.

Filters: Air filtration systems prevent dirt and dust from entering the motor, safeguarding its functionality. Regular checks and replacements of these filters are essential for maintaining performance standards.

By recognizing and understanding these components, users can ensure effective maintenance and enhance the overall performance of their outdoor machinery.

Importance of Regular Maintenance

Enhanced Performance

Cost-Effectiveness

Identifying Common Issues

Understanding the frequent problems encountered with cleaning devices can significantly enhance maintenance and prolong their lifespan. By recognizing these challenges early, users can implement effective solutions, ensuring optimal performance and efficiency. This section delves into typical complications and their underlying causes.

Performance Decline

A noticeable reduction in suction power is often a primary indicator of underlying issues. This can arise from various factors, including clogged filters, obstructed hoses, or full collection containers. Regular inspections and timely cleaning can mitigate these performance drops, restoring functionality.

Unusual Noises

Unwanted sounds during operation can signal mechanical problems. Rattling, grinding, or whirring noises may suggest loose components or damaged internal parts. Identifying these auditory cues promptly can prevent further damage and ensure the device operates smoothly.

Step-by-Step Repair Guide

This guide provides a clear pathway for troubleshooting and fixing common issues with your cleaning device. By following these structured steps, you can efficiently restore functionality and ensure longevity.

- Gather Tools:

- Screwdriver

- Wrench

- Replacement components

- Cleaning supplies

- Identify the Problem:

- Check for unusual sounds

- Inspect for blockages

- Examine the power source

- Disassemble the Unit:

- Remove screws carefully

- Take off outer casing

- Note the arrangement of internal elements

- Replace Damaged Components:

- Swap out any faulty items

- Ensure new pieces are compatible

- Reassemble and Test:

- Reattach the casing

- Secure all screws

- Conduct a functionality test

By adhering to these steps, you can effectively tackle most issues and keep your equipment in optimal condition.

How to Access the Parts Diagram

Understanding the components of your cleaning device is essential for effective maintenance and repairs. To effectively navigate the various elements, you will need to access a visual reference that outlines the configuration and functionality of each section. This guide will help you locate the necessary illustrations to assist in your tasks.

Follow these steps to find the schematic representation:

| Step | Description |

|---|---|

| 1 | Visit the manufacturer’s official website, where comprehensive resources are typically available. |

| 2 | Navigate to the support or resources section, often categorized under product manuals or technical documents. |

| 3 | Use the search function to input the model number of your device for tailored results. |

| 4 | Look for downloadable PDF files or online resources that include detailed visuals of the assembly. |

| 5 | If available, utilize any interactive tools that allow you to explore components in a virtual environment. |

By following these steps, you will gain access to valuable information that can enhance your understanding and repair capabilities.

Comparing Different Billy Goat Models

This section explores the diverse range of models available in a specific equipment line, highlighting their unique features, specifications, and intended applications. Understanding these differences can aid users in selecting the best option for their needs.

Model Features

Each variant comes with distinct characteristics that cater to various tasks. Some models prioritize lightweight design for easy maneuverability, while others focus on enhanced power for heavy-duty jobs. Evaluating these attributes helps in making an informed decision.

Performance and Efficiency

Performance metrics vary across models, affecting efficiency and user experience. Users should consider factors like suction strength, noise levels, and maintenance requirements to determine which model aligns best with their operational demands.

Where to Find Replacement Parts

Locating suitable components for your cleaning device can be a straightforward process if you know where to look. Whether you’re dealing with a minor malfunction or a significant repair, having access to the right resources is crucial for ensuring optimal performance.

- Manufacturer’s Website: The official site is often the best starting point. They typically offer a range of original components and provide detailed specifications.

- Local Retail Stores: Home improvement or appliance stores frequently carry essential items. Visiting in person can allow you to examine the quality before purchasing.

- Online Marketplaces: Websites like Amazon or eBay offer a vast selection. User reviews can help you assess the reliability of the items.

- Specialized Repair Shops: These establishments focus on specific brands and models, often providing expert advice and hard-to-find components.

- Third-Party Vendors: Various companies specialize in aftermarket items that can be cost-effective alternatives to original components.

Ensuring compatibility with your specific model is essential, so always check descriptions carefully and, when in doubt, consult customer support for assistance.

Safety Tips for Using Vacuums

When operating cleaning devices, ensuring safety is paramount. Understanding how to use these machines properly can prevent accidents and enhance efficiency. Familiarizing yourself with safety protocols will not only protect you but also prolong the life of the equipment.

| Tip | Description |

|---|---|

| Read the Manual | Always review the user guide before using any device. This ensures you understand its features and limitations. |

| Check for Damage | Inspect the equipment for any signs of wear or damage. Avoid using damaged devices to prevent electrical hazards. |

| Avoid Overloading | Do not exceed the recommended capacity to maintain optimal performance and prevent overheating. |

| Keep Cords Safe | Ensure power cords are not frayed and avoid placing them in high-traffic areas to prevent tripping hazards. |

| Use Proper Attachments | Utilize the correct accessories for different surfaces to ensure effective cleaning and avoid damage. |

| Unplug After Use | Always disconnect the device from the power source after use to prevent accidental activation. |

| Stay Alert | Maintain focus while operating the machine, avoiding distractions that may lead to accidents. |

Enhancing Performance with Upgrades

Upgrading components can significantly enhance the efficiency and longevity of your equipment. By focusing on key areas for improvement, users can achieve better functionality and a smoother operational experience. Exploring available enhancements not only boosts performance but also ensures that the machinery remains competitive and effective over time.

Key Areas for Improvement

- Motor Efficiency: Upgrading to a high-efficiency motor can lead to reduced energy consumption and increased power output.

- Filtration Systems: Investing in advanced filtration technologies can improve air quality and capture more particles, resulting in better performance.

- Durable Components: Replacing standard parts with more robust alternatives can enhance the overall durability and reliability of the system.

Benefits of Upgrades

- Increased Productivity: Enhanced components lead to faster operation and greater throughput.

- Cost Savings: Improved efficiency often translates to lower operating costs over time.

- Environmental Impact: Upgraded systems tend to consume less energy and produce fewer emissions, contributing to sustainability efforts.

Investing in upgrades not only optimizes performance but also ensures that the equipment meets evolving standards and user expectations. By considering these enhancements, users can create a more effective and sustainable operational environment.

Customer Reviews and Experiences

This section highlights the insights and opinions of users who have engaged with the product. Their feedback offers valuable perspectives on performance, durability, and overall satisfaction, helping potential buyers make informed decisions.

User Feedback Summary

| Rating | Comment | Recommended? |

|---|---|---|

| 5/5 | Exceptional quality and easy to use! | Yes |

| 4/5 | Good performance, but a bit noisy. | Yes |

| 3/5 | Average experience, not what I expected. | No |

| 2/5 | Had issues with durability after a few months. | No |

| 1/5 | Very disappointing; did not meet expectations. | No |

Many users appreciate the effectiveness and ease of maintenance, often highlighting how the product meets their cleaning needs. However, some have expressed concerns regarding noise levels and longevity. These reviews serve as a testament to the varying experiences, encouraging future customers to weigh the pros and cons before purchasing.