Understanding the Shark Cordless Vacuum Parts Diagram

Maintaining the efficiency of your cleaning appliance requires a clear understanding of its structure and components. Familiarity with the intricate parts can enhance performance, extend longevity, and facilitate effective troubleshooting. This section aims to provide insights into the essential elements that make up your portable cleaning solution, ensuring you can make the most out of its features.

By exploring the layout and functions of each segment, you will gain a deeper appreciation of how they work in harmony to deliver exceptional results. This knowledge empowers you to tackle common issues, perform necessary upkeep, and optimize your cleaning routine. Whether you’re seeking to replace a specific component or simply want to know more about the inner workings, this guide serves as a valuable resource.

From the power system to the cleaning attachments, understanding these components will enable you to navigate maintenance tasks with confidence. Join us as we delve into the specifics, ensuring you are well-equipped to keep your device in peak condition and ready for any cleaning challenge that comes your way.

Understanding Shark Cordless Vacuum Components

This section aims to explore the essential elements that contribute to the functionality of a popular cleaning device. By examining its various components, users can gain insight into how these parts work together to enhance efficiency and ease of use. A solid grasp of these elements can facilitate better maintenance and troubleshooting, ensuring optimal performance over time.

Key Elements of the Cleaning Device

The primary components of this device include the motor, which powers the suction mechanism, and the filtration system, designed to capture dust and allergens. Additionally, the brush roll plays a critical role in agitating dirt from carpets and hard floors. Understanding the interaction between these elements allows users to appreciate the engineering behind modern cleaning technology.

Maintenance and Troubleshooting

Regular upkeep of individual components is vital for sustaining performance. Users should be familiar with how to access and clean filters, replace the brush roll, and check for clogs in the suction pathway. Recognizing the signs of wear and tear on these elements can prevent more significant issues, extending the lifespan of the device and ensuring effective cleaning results.

Overview of Vacuum Parts Functionality

This section explores the various components of a cleaning device and their roles in ensuring effective operation. Understanding the functionality of each element can enhance maintenance and improve overall performance.

- Motor: The powerhouse of the unit, responsible for generating suction.

- Filters: Essential for trapping dust and allergens, promoting cleaner air output.

- Brush Roll: Designed to agitate dirt from surfaces, aiding in deeper cleaning.

- Canister: Collects debris and dust, allowing for easy disposal.

- Hoses: Facilitate reach into tight spaces, ensuring thorough cleaning.

- Nozzle: Directs airflow and enhances cleaning effectiveness on various surfaces.

Each component plays a crucial role in the functionality of the device, and their optimal performance is vital for achieving desired cleaning results.

- Regular maintenance of the motor ensures longevity and consistent suction power.

- Replacing filters according to manufacturer guidelines helps maintain air quality.

- Cleaning the brush roll prevents hair and debris buildup, enhancing its efficiency.

- Emptying the canister regularly prevents clogs and maintains optimal performance.

- Inspecting hoses for blockages ensures unobstructed airflow and efficiency.

- Using the appropriate nozzle for different surfaces maximizes cleaning effectiveness.

By understanding these functionalities, users can make informed decisions about care and usage, leading to improved results and prolonged lifespan of the equipment.

Common Issues with Shark Vacuum Parts

Many users encounter various challenges when dealing with their cleaning devices. Understanding these common difficulties can help in troubleshooting and maintaining optimal performance. Over time, components may wear out or become obstructed, leading to decreased efficiency.

One frequent problem is loss of suction. This can occur due to clogged filters or debris blocking airflow. Regularly checking and cleaning these elements can restore functionality. Additionally, users may find that brushes do not spin effectively. Hair and dirt can accumulate around the rotating bristles, preventing them from working properly. Regular maintenance is essential to avoid this issue.

Battery life can also be a concern, as reduced power may affect the device’s runtime. Ensuring that the battery is charged correctly and replaced when necessary is crucial for consistent operation. Furthermore, if the appliance makes unusual noises, it could indicate an internal issue or a loose component that requires attention.

By being aware of these common concerns, users can take proactive steps to address them, ensuring that their cleaning devices remain efficient and reliable.

How to Identify Each Component

Understanding the various elements of your cleaning device is essential for efficient maintenance and optimal performance. Each section plays a vital role, contributing to the overall functionality. Here’s a guide to help you recognize and differentiate each part.

- Handle: This is the primary section you grip while operating the appliance. Look for ergonomic designs that enhance comfort.

- Dust Container: Typically detachable, this component collects debris and should be emptied regularly. Check for indicators showing when it’s full.

- Filter: Essential for trapping fine particles, the filter is often located near the dust container. It may require periodic cleaning or replacement.

- Motor Unit: Found at the base of the device, this is the powerhouse that drives suction. It may have vents for cooling, so ensure they are unobstructed.

- Brush Roll: Located beneath the cleaning head, this rotating component helps lift dirt from surfaces. Look for bristles that are intact for effective performance.

- Wheels: These facilitate movement across various surfaces. Inspect for wear and ensure they spin freely.

- Power Switch: Usually situated on the handle or body, this control activates the device. Ensure it functions smoothly without sticking.

By familiarizing yourself with these components, you can enhance your cleaning routine and address any issues that may arise effectively.

Maintenance Tips for Vacuum Parts

Regular upkeep is essential for ensuring optimal performance and longevity of your cleaning equipment. By following a few straightforward guidelines, you can keep your device functioning at its best, enhancing its efficiency and extending its lifespan.

1. Clean Filters Regularly

Filters play a crucial role in trapping dust and allergens. It’s important to check and clean them frequently. Depending on the model, some filters can be rinsed with water, while others may need replacement. Always consult the user manual for specific instructions.

2. Inspect and Clear Brushes

Brushes can accumulate hair, debris, and dirt, which may hinder their effectiveness. Regularly remove any entangled materials to ensure smooth operation. If the bristles appear worn out, consider replacing them to maintain optimal performance.

3. Check for Blockages

Clogs can significantly reduce suction power. Periodically inspect hoses and nozzles for blockages. Clear any obstructions to ensure efficient airflow and avoid potential damage to the motor.

4. Keep the Exterior Clean

Wiping down the outer surfaces with a damp cloth can prevent dust buildup and keep your device looking new. Avoid using harsh chemicals that may damage the finish.

5. Store Properly

When not in use, store your equipment in a dry place, avoiding extreme temperatures. This can help prevent deterioration of components and ensure that everything is ready for use when needed.

By implementing these simple maintenance practices, you can enhance the efficiency and durability of your cleaning appliance, ensuring it remains a reliable tool in your home care routine.

Where to Find Replacement Parts

Maintaining the efficiency of your cleaning device often requires sourcing components to replace worn or damaged items. Finding the right replacements is crucial for ensuring optimal performance and longevity. Fortunately, there are several avenues to explore when seeking these essential elements.

Online Retailers

One of the most convenient methods is to browse various e-commerce platforms that specialize in home appliances. These websites typically offer a wide selection of components, complete with detailed descriptions and compatibility information. Ensure to check user reviews to make informed decisions about quality and fit.

Authorized Service Centers

For those preferring direct assistance, visiting authorized repair centers can provide personalized support. These locations often carry genuine items and can assist in installation, ensuring that your device operates as intended. Additionally, they can offer guidance on maintenance and best practices for extending the lifespan of your equipment.

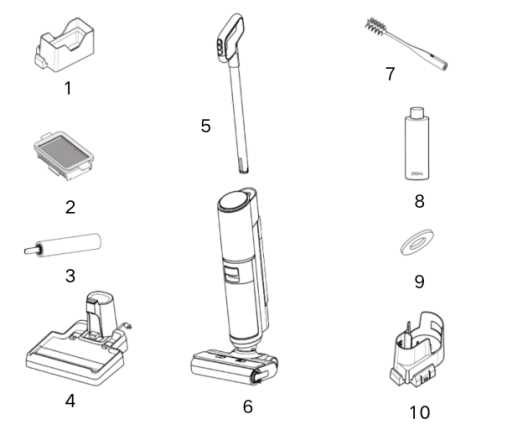

Step-by-Step Assembly Guide

This section provides a detailed guide to help you assemble your cleaning device efficiently and effectively. By following these steps, you’ll ensure that every component is correctly connected, allowing for optimal performance.

- Gather All Components:

Before starting, ensure you have all necessary elements laid out in front of you. This includes the main body, the handle, attachments, and any additional accessories.

- Connect the Handle:

Take the handle and align it with the main unit. Push firmly until you hear a click, indicating a secure fit.

- Attach the Cleaning Head:

Locate the cleaning head and align it with the base of the main unit. Slide it into place until it locks securely.

- Install Accessories:

Choose any additional tools you may need, such as crevice tools or brushes. Attach them to the designated slots on the main unit, ensuring they are firmly in position.

- Check Battery Connection:

Make sure the battery is properly inserted into its compartment. Ensure it clicks into place to confirm it is secured.

- Final Inspection:

Review all connections to ensure everything is tightly assembled. Make any adjustments if necessary before first use.

Following these instructions will help you achieve a fully assembled unit ready for use, providing an effective cleaning experience.

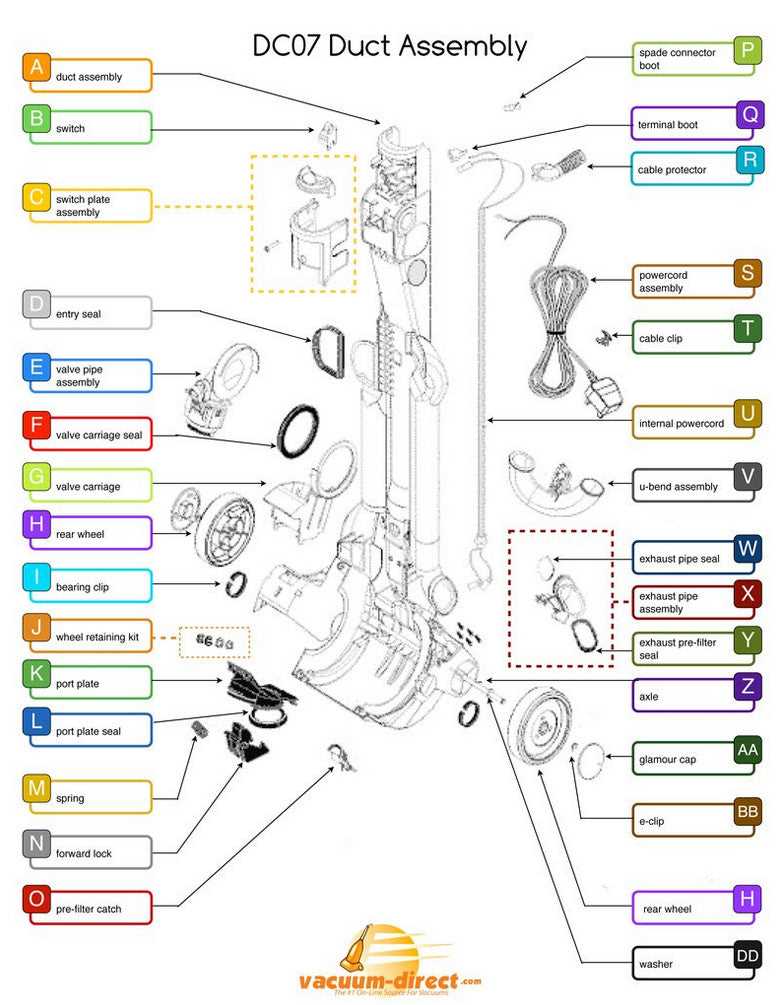

Visual Diagram of Shark Vacuum Parts

This section provides a comprehensive illustration of the components that comprise a leading cleaning device. Understanding the layout and function of each element is essential for effective maintenance and troubleshooting.

Key Components Overview

Every unit consists of various integral sections that contribute to its overall efficiency. Familiarity with these components enables users to optimize performance and address any potential issues swiftly.

Understanding Component Functions

Each section serves a unique purpose. For instance, the motor assembly is crucial for power, while the filtration system plays a vital role in air quality. Knowing how these pieces work together enhances the user experience and prolongs the device’s lifespan. Regular inspection of these elements can lead to more effective cleaning outcomes.

Tools Needed for Repairs

When it comes to restoring functionality to your cleaning device, having the right instruments at your disposal is crucial. A well-prepared toolkit can make the difference between a successful fix and a frustrating experience. Below is a list of essential tools that will aid you in your repair endeavors.

Essential Tools

- Screwdriver set (both flathead and Phillips)

- Pliers (needle-nose and regular)

- Wire cutters and strippers

- Tweezers for handling small components

- Multimeter for electrical diagnostics

- Flashlight to illuminate hard-to-reach areas

Optional Tools

- Socket set for various fasteners

- Heat gun for loosening adhesive

- Lubricant for moving parts

- Cleaning brushes for debris removal

By equipping yourself with these tools, you’ll be well-prepared to tackle most repairs efficiently and effectively.

Comparing Shark Models and Parts

When exploring various cleaning devices, understanding the distinctions among different models is crucial for making an informed choice. Each variant offers unique features and components that cater to diverse cleaning needs. By examining these differences, users can select the most suitable option for their homes.

Many models come with interchangeable elements that enhance their functionality. From motors to brushes, the components can significantly affect performance and user experience. Here’s a comparison of key attributes across popular models:

| Model | Battery Life | Weight | Cleaning Path Width | Accessories Included |

|---|---|---|---|---|

| Model A | 40 minutes | 7 lbs | 10 inches | 2 in 1 Tool, Crevice Tool |

| Model B | 50 minutes | 8 lbs | 12 inches | Dusting Brush, Pet Tool |

| Model C | 60 minutes | 6 lbs | 10.5 inches | Upholstery Tool, Extension Wand |

Evaluating these factors helps to identify the most effective model based on individual requirements, ensuring optimal cleaning efficiency and convenience.

Frequently Asked Questions about Parts

This section addresses common inquiries regarding components of a popular cleaning device. Understanding these elements can help users maintain their equipment effectively and troubleshoot any issues that may arise.

- What are the most common components that may need replacement?

- Filters

- Brush rolls

- Batteries

- Hoses

- How do I know when a component needs to be replaced?

- Check for decreased suction power.

- Listen for unusual noises during operation.

- Look for physical damage or wear.

- Where can I find high-quality replacements?

- Official brand websites

- Authorized retailers

- Reputable online marketplaces

- Is it possible to repair components instead of replacing them?

- Some parts can be repaired if damaged slightly.

- Consult user manuals for specific instructions.

- How often should I inspect the components?

- Regularly, ideally every few months.

- After heavy usage or if performance drops.

Upgrading Your Shark Vacuum System

Enhancing the efficiency and performance of your cleaning device can lead to a more enjoyable experience while maintaining a spotless environment. By exploring various components and accessories, you can tailor the functionality to better suit your cleaning needs.

Choosing the Right Accessories

Investing in compatible attachments can significantly improve versatility. Consider specialized tools designed for different surfaces, such as brushes for upholstery or narrow nozzles for tight spaces. These additions not only expand usability but also enhance cleaning precision.

Maintaining Optimal Performance

Regular upkeep is essential for longevity and effectiveness. Replace filters and brushes periodically to ensure peak performance. Keeping an eye on battery health can also contribute to consistent power levels, allowing for uninterrupted cleaning sessions.

By focusing on these enhancements, you can transform your cleaning experience into a more efficient and satisfying task.