Understanding Volvo Penta 290 DP Outdrive Components

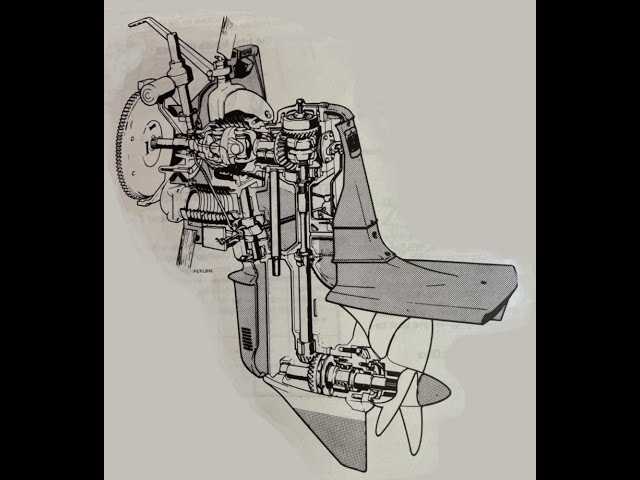

In the realm of recreational boating and marine engineering, comprehending the intricate assembly of propulsion systems is essential for optimal performance and maintenance. This section delves into the essential elements of a specific model of a marine propulsion unit, exploring its various components and their functions. A thorough grasp of these parts aids in troubleshooting, repairs, and ensuring longevity.

As we navigate through the intricacies of this propulsion mechanism, we will highlight key components that play pivotal roles in its operation. Each element, from the housing to the drive shaft, contributes significantly to the system’s efficiency and reliability. Understanding how these components interact is crucial for any marine enthusiast or professional looking to maintain or enhance their vessel’s capabilities.

By examining the layout and interrelations of these parts, one can better appreciate the engineering behind marine propulsion. This knowledge empowers users to undertake informed maintenance practices, ultimately leading to improved performance on the water. Let us embark on this exploration of the assembly that drives many boating adventures.

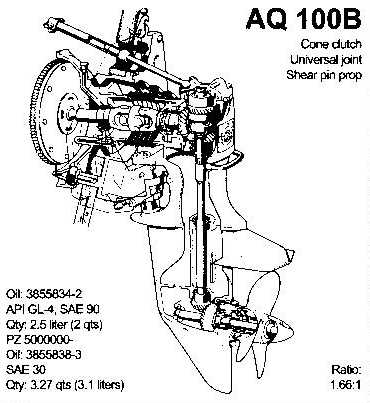

The intricate design of marine propulsion systems plays a crucial role in enhancing vessel performance and maneuverability. Understanding these components is essential for both maintenance and optimal functioning. This section delves into the key elements that constitute a specific drive mechanism, providing insights into their roles and interactions within the system.

| Component | Description | Function |

|---|---|---|

| Gearcase | The housing that contains the gears and provides protection against water ingress. | Transmits power from the engine to the propeller. |

| Propeller | A rotating blade mechanism designed to create thrust. | Moves the vessel through water by converting rotational energy into forward motion. |

| Shift Mechanism | A system that allows the operator to change the direction and speed of the vessel. | Engages different gears for forward, neutral, or reverse operations. |

| Stern Drive | A combination of inboard engine and outboard drive, often mounted on the transom. | Provides propulsion while also steering capabilities. |

| Trim Tab | A movable flap located on the drive unit, used to adjust the boat’s angle. | Helps improve performance and stability while underway. |

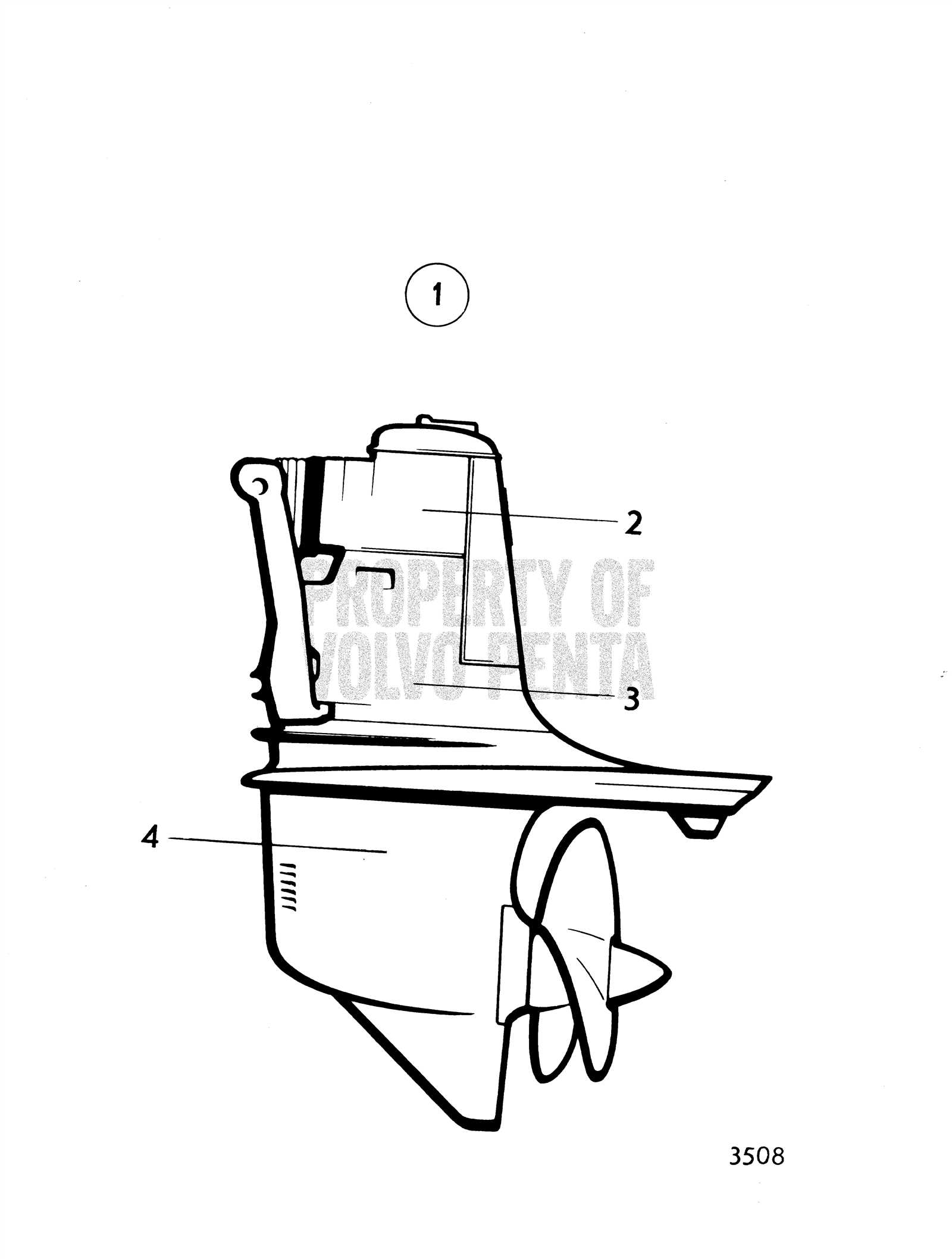

Components of the 290 DP System

The 290 DP system consists of various integral elements that work harmoniously to ensure optimal performance and efficiency in marine applications. Each component plays a vital role in maintaining the functionality and reliability of the entire assembly, contributing to the overall boating experience.

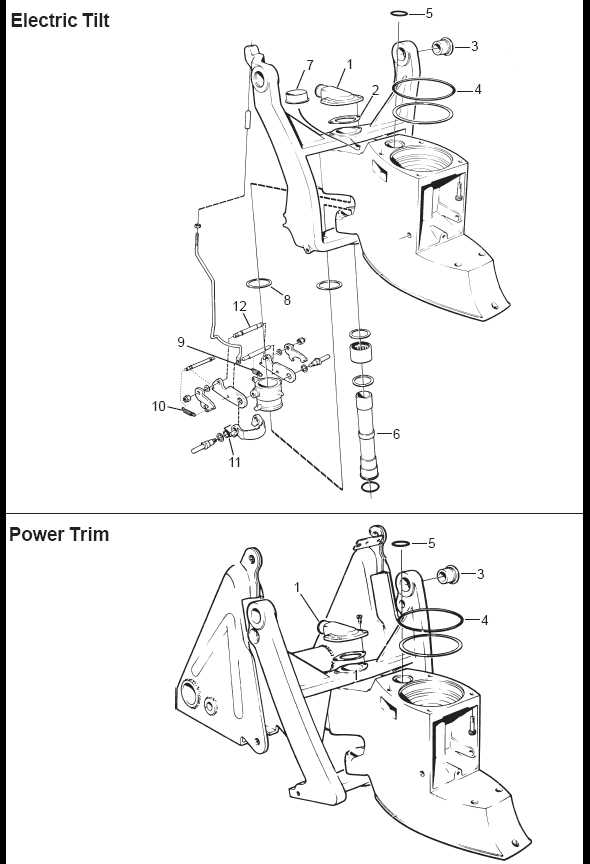

Key Elements of the Assembly

At the core of this system are critical units such as the drive unit, which facilitates propulsion through its advanced gear mechanisms. Additionally, the steering system is designed to provide precise control, enhancing maneuverability in various water conditions. Hydraulic actuators are also present, enabling smooth adjustments to the angle of the drive unit for improved performance.

Supporting Components

Complementing the main elements are various supporting structures, including mounting brackets and seals that protect against water intrusion. Wiring harnesses connect essential electrical systems, ensuring proper communication between components. Overall, the synergy among these parts is crucial for the system’s effective operation and longevity.

Importance of Regular Maintenance

Consistent upkeep of marine equipment is crucial for ensuring optimal performance and longevity. Regular checks and services help identify potential issues before they escalate into significant problems, saving time and resources in the long run. By adhering to a maintenance schedule, operators can enhance the reliability of their vessels and prevent unexpected breakdowns.

Moreover, routine care not only preserves the functionality of components but also contributes to safety on the water. Well-maintained systems are less likely to fail during operation, reducing the risk of accidents. Additionally, proper maintenance can improve fuel efficiency, leading to cost savings over time. Investing in regular servicing is essential for any operator looking to maintain the value and efficiency of their marine craft.

Common Issues with Outdrive Parts

When it comes to marine propulsion systems, various components play crucial roles in ensuring optimal performance and reliability. However, these components can sometimes experience issues that affect their functionality. Understanding these common problems is essential for maintaining efficiency and prolonging the lifespan of the entire system.

One prevalent issue involves wear and tear on the mechanical elements due to prolonged exposure to harsh marine environments. Corrosion can also be a significant factor, particularly in saltwater applications, where metal components are vulnerable to degradation. Furthermore, improper alignment during installation can lead to increased strain and eventual failure of critical components.

Another concern is the buildup of debris and marine growth within the system, which can impede the movement of moving parts, resulting in reduced efficiency. Regular maintenance and inspections are vital to identify and rectify these problems before they escalate into more severe complications.

In summary, being aware of these common challenges can aid in early detection and preventive measures, ultimately enhancing the reliability and performance of marine propulsion systems.

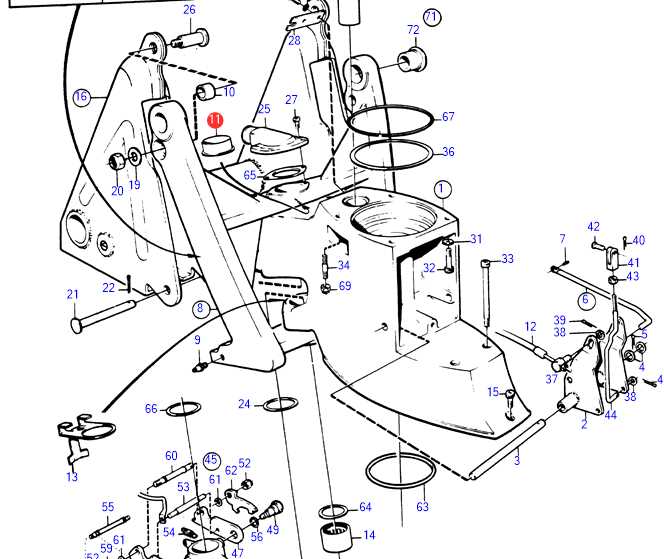

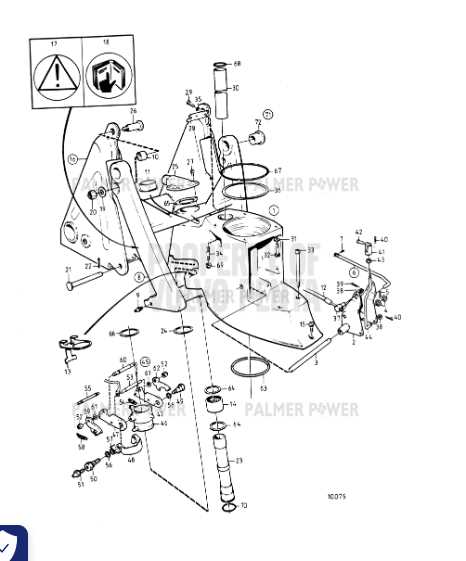

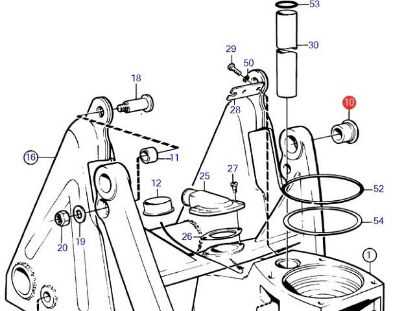

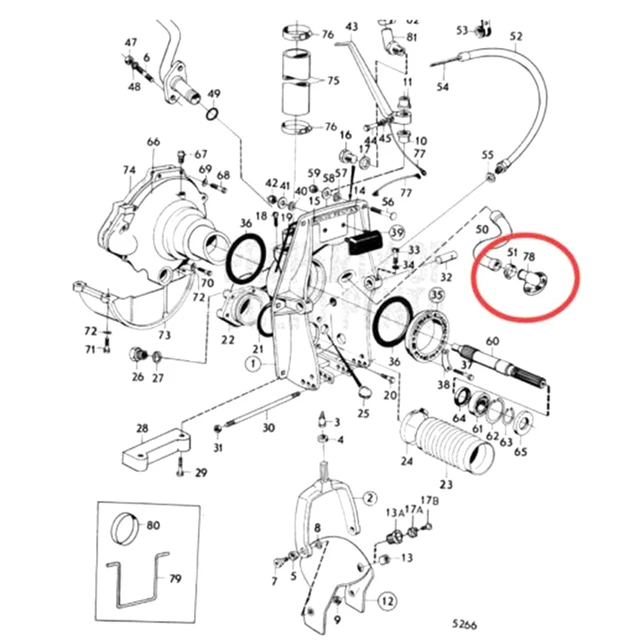

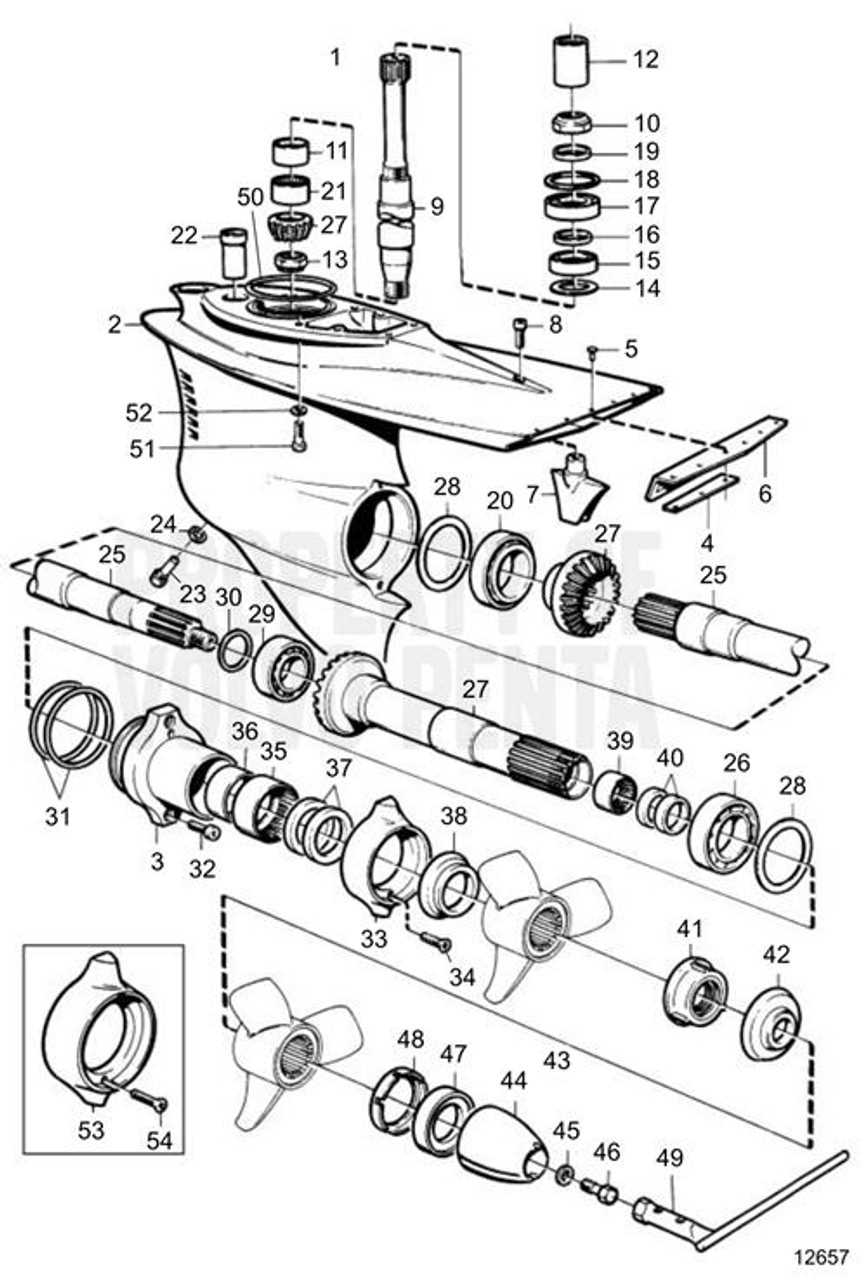

How to Interpret Parts Diagrams

Understanding technical illustrations can greatly enhance your ability to maintain and repair machinery. These visuals provide a detailed representation of components and their relationships, facilitating easier identification and assembly during service. By mastering the art of reading these schematics, you can streamline repairs and ensure the proper functioning of your equipment.

Key Components of Technical Illustrations

Most illustrations will include various elements such as labels, numbers, and reference points. Labels indicate the name or function of a specific item, while numbers often correspond to a list or index that provides further details about each element. Reference points can help you locate parts in relation to others, ensuring you have a comprehensive understanding of the layout.

Steps to Effectively Read Illustrations

Start by examining the overall layout to get a sense of how components are organized. Then, look for the accompanying list or index that corresponds to the labeled items in the visual. Pay attention to any notes or annotations that may highlight important details or specific instructions. By following these steps, you can effectively interpret the schematic and apply the information for your repair or maintenance tasks.

Tools Needed for Repairs

When it comes to performing maintenance or fixes on marine propulsion systems, having the right equipment is essential for ensuring efficient and effective work. This section outlines the necessary instruments and devices that facilitate repairs, enhancing safety and performance during the process.

Essential Hand Tools

- Wrenches: Various sizes, including adjustable and socket types, for loosening and tightening bolts.

- Screwdrivers: A selection of flathead and Phillips screwdrivers to handle different fasteners.

- Pliers: Needle-nose and slip-joint pliers for gripping and manipulating components.

- Hammers: A rubber mallet and a ball-peen hammer for gentle and precise adjustments.

Specialized Equipment

- Torque Wrench: To ensure bolts are tightened to the manufacturer’s specifications.

- Multimeter: For testing electrical systems and ensuring proper function.

- Grease Gun: To apply lubricant to moving parts and prevent wear.

- Inspection Mirror: To view hard-to-reach areas and ensure thorough assessments.

Replacement Procedures for Outdrive Components

Maintaining and replacing components of marine propulsion systems is essential for optimal performance and longevity. This section outlines general steps for the effective replacement of various elements within these assemblies. Proper adherence to procedures ensures that replacements are executed safely and efficiently, minimizing the risk of malfunction.

Identifying Necessary Components

Before commencing the replacement process, it is crucial to identify the specific components requiring attention. Refer to the manufacturer’s guidelines to ascertain compatibility and specifications. Make sure to gather all necessary tools and replacement items beforehand to streamline the workflow.

Executing the Replacement

Begin the replacement by disconnecting power sources and draining any fluids to avoid spills. Carefully remove the faulty components, taking care not to damage surrounding structures. Install the new components, ensuring all fittings are secure. After installation, refill fluids and reconnect power, conducting a thorough inspection to confirm proper function. Regular maintenance checks are advised to prevent future issues.

Upgrading Your Volvo Penta Parts

Enhancing the components of your marine propulsion system can significantly improve performance and reliability. This process involves selecting high-quality alternatives that boost efficiency and extend the lifespan of your equipment. Whether you’re seeking to increase speed, enhance fuel efficiency, or simply replace worn parts, a strategic upgrade can yield impressive results.

Before embarking on this upgrade journey, consider the following steps:

- Assess Current Condition: Evaluate the state of your existing components. Identify parts that show signs of wear and tear, as well as those that could benefit from enhancement.

- Research Upgrades: Look into aftermarket options or OEM replacements that offer improved functionality. Consult user reviews and expert opinions to make informed decisions.

- Compatibility Check: Ensure that any new components are compatible with your existing system. This step is crucial to avoid potential installation issues.

- Professional Consultation: If unsure about the best options, seek advice from professionals who specialize in marine systems. Their expertise can guide you towards the best solutions.

Consider the following benefits when upgrading:

- Increased Performance: Enhanced components often lead to better speed and handling.

- Improved Efficiency: Upgrades can reduce fuel consumption, saving you money over time.

- Extended Lifespan: High-quality replacements can significantly prolong the life of your machinery.

- Enhanced Safety: Reliable parts contribute to a safer boating experience.

By carefully selecting and upgrading your equipment, you can ensure that your marine experience remains enjoyable and trouble-free.

Where to Find Genuine Parts

Ensuring the longevity and efficiency of your marine propulsion system requires the use of authentic components. Sourcing these reliable elements can greatly enhance performance and prevent potential issues. Here are several avenues to consider for acquiring original replacements.

Authorized Dealers

- Visit local dealerships specializing in marine equipment.

- Inquire about their inventory of certified components.

- Utilize their expertise for guidance on the correct items needed.

Online Retailers

- Explore dedicated websites that focus on marine machinery.

- Look for platforms offering warranty and return policies.

- Read customer reviews to ensure quality and service reliability.

By exploring these options, you can confidently obtain the necessary elements to maintain your system’s performance and reliability.

Expert Tips for DIY Repairs

Engaging in maintenance and repair tasks can be a rewarding endeavor for any enthusiast. With the right knowledge and tools, you can address various mechanical issues effectively. This section offers practical advice to help you navigate the intricacies of repairs, ensuring that you achieve optimal results while minimizing potential setbacks.

Gather Essential Tools

Before starting any repair work, it’s crucial to assemble a comprehensive toolkit. Include items such as wrenches, screwdrivers, and pliers, tailored to the specific needs of your project. Having the right instruments on hand not only streamlines the process but also enhances safety and efficiency.

Follow Detailed Instructions

Utilize repair manuals or trusted online resources that provide step-by-step guidance. Following these instructions closely helps prevent mistakes and ensures that each component is handled correctly. Don’t hesitate to take notes or mark steps to keep track of your progress during complex repairs.