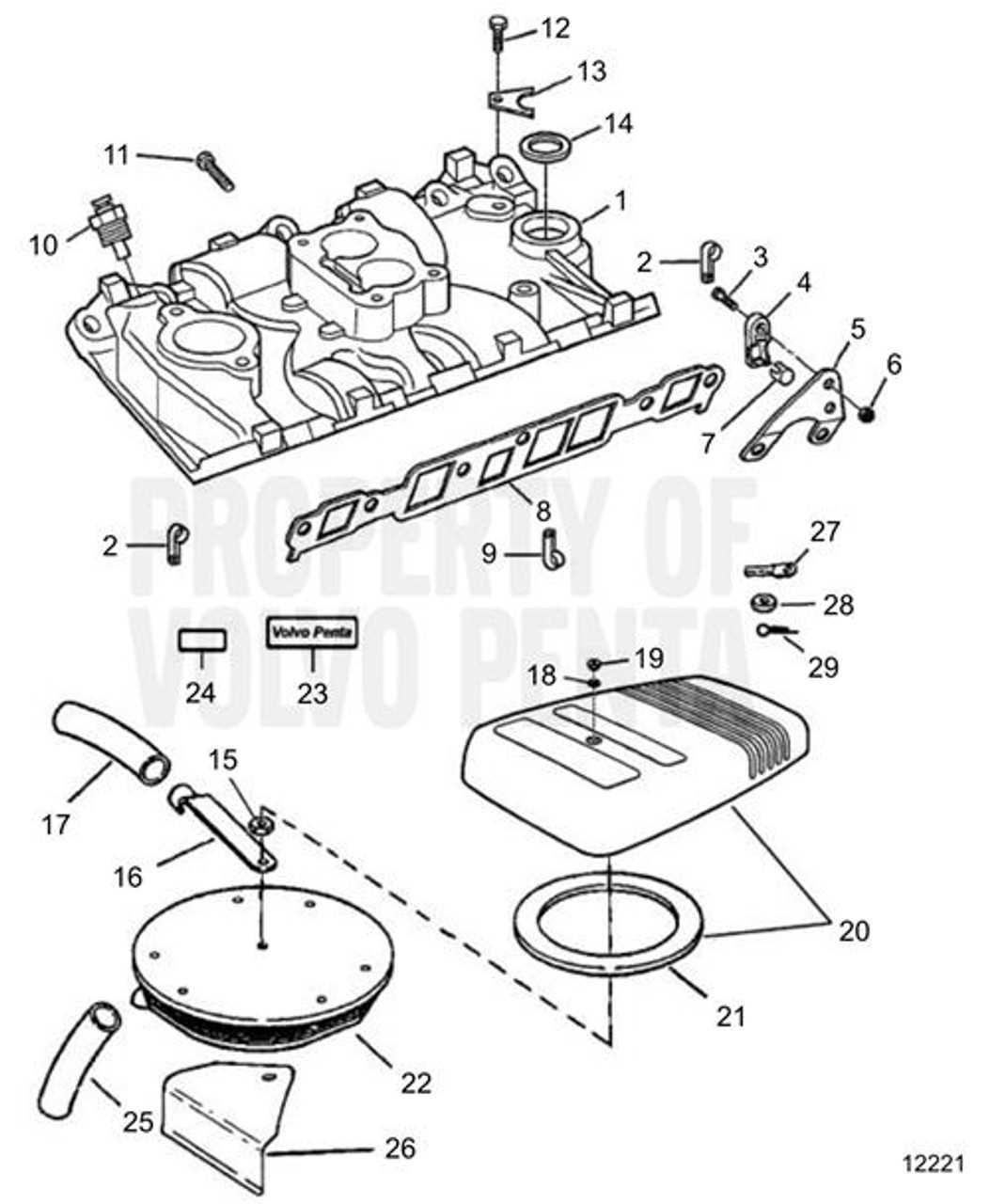

Understanding Volvo Penta 4.3 Parts Diagram

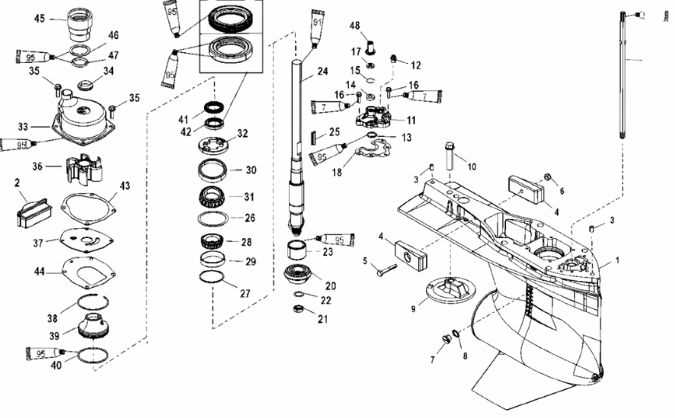

The arrangement of key elements in a modern engine plays a crucial role in ensuring its efficiency and performance. Recognizing the connections and locations of various units is essential for proper maintenance and troubleshooting. This overview will provide insights into how different mechanisms work together, focusing on the layout and structure of the system.

Each section of the machinery serves a distinct purpose, and understanding their relationships is vital for effective operation. By identifying the placement of specific components, you can optimize repair efforts and maintain the overall functionality of the motor.

This guide will assist in navigating through the complex framework of the engine, offering a clear visual representation of its essential parts and their roles.

Understanding the Volvo Penta 4.3 Engine

The marine engine in question is renowned for its balance of power and reliability, making it a popular choice for medium-sized vessels. Its design focuses on delivering consistent performance while remaining fuel-efficient, ensuring smooth operation in a variety of marine conditions. With a robust build, it serves both recreational boaters and commercial users alike. This engine combines advanced technology with ease of maintenance, offering dependable service over time.

Main Features of the Marine Engine

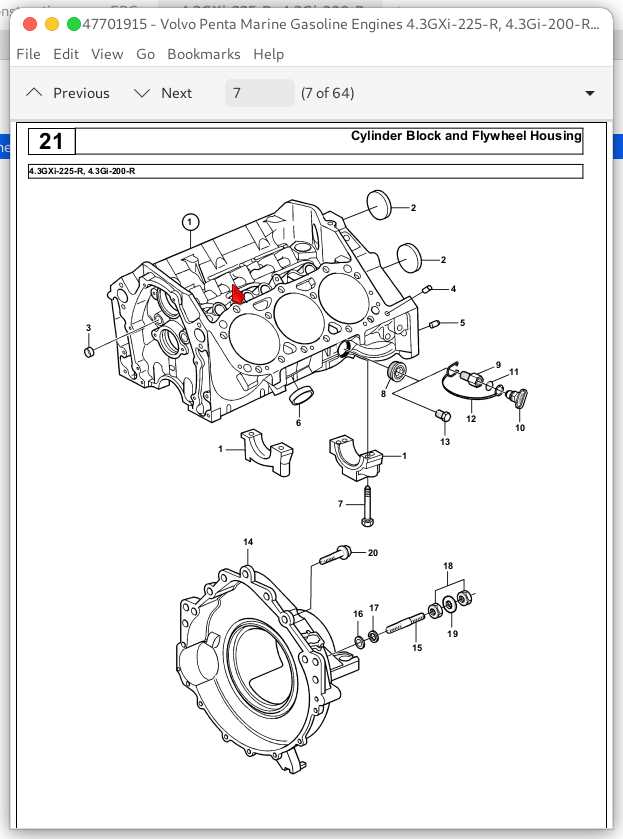

This model is equipped with a V6 configuration, allowing for powerful acceleration and high torque output. It is designed to handle extended use without sacrificing performance. Key innovations enhance fuel efficiency and emission control, making it a more environmentally conscious option. Additionally, its cooling system is optimized to prevent overheating, even in warmer climates.

Performance and Maintenance

Regular maintenance is crucial to ensure the longevity of this engine. Routine tasks include checking the cooling system, monitoring fuel filters, and inspecting the ignition system. This approach prevents potential issues and helps maintain optimal performance levels over time. The engine’s components are designed for straightforward access, making it easier to perform these checks.

| Specification | Detail | ||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Component | Function | ||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Combustion Chamber | Facilitates fuel ignition and power generation | ||||||||||||||||||||||||||

| Cooling System | Regulates engine temperature | ||||||||||||||||||||||||||

| Ignition System | Controls the timing of fuel combustion | ||||||||||||||||||||||||||

| Exhaust System | Manages the release of emissions | ||||||||||||||||||||||||||

| Component | Description |

|---|---|

| Battery | Stores energy required for starting the engine and powering electrical devices. |

| Alternator | Generates electricity while the engine is running, charging the battery and powering electrical systems. |

| Starter Motor | Initiates the engine’s operation by turning the flywheel upon ignition. |

| Wiring Harness | Connects various electrical components, facilitating the flow of electricity. |

Maintenance and Troubleshooting

Regular inspection and maintenance of the electrical system are vital for ensuring reliability. Common issues such as poor connections or battery failures can lead to significant performance setbacks. Therefore, understanding the function of each component enables effective diagnostics and timely repairs.

Maintenance Tips for Volvo Penta Parts

Regular upkeep is essential for ensuring the longevity and optimal performance of marine engine components. Proper care not only enhances reliability but also reduces the likelihood of unexpected breakdowns. Adhering to maintenance guidelines helps preserve the functionality of various systems, contributing to a seamless boating experience.

Here are some essential practices to keep in mind:

| Task | Frequency | Notes |

|---|---|---|

| Inspect fluid levels | Every 50 hours | Ensure oil, coolant, and fuel levels are adequate. |

| Clean filters | Every 100 hours | Replace or clean fuel and oil filters to maintain efficiency. |

| Examine belts and hoses | Every season | Look for signs of wear, cracking, or fraying. |

| Test battery condition | Every 6 months | Check for corrosion and ensure secure connections. |

| Check propeller and shaft | Every trip | Look for damage or debris that could affect performance. |

Identifying Commonly Replaced Parts

Understanding the essential components that often require replacement is crucial for maintaining optimal performance. Regular maintenance helps identify which elements tend to wear out or malfunction over time. By recognizing these frequently replaced items, users can ensure their systems operate efficiently and extend their longevity.

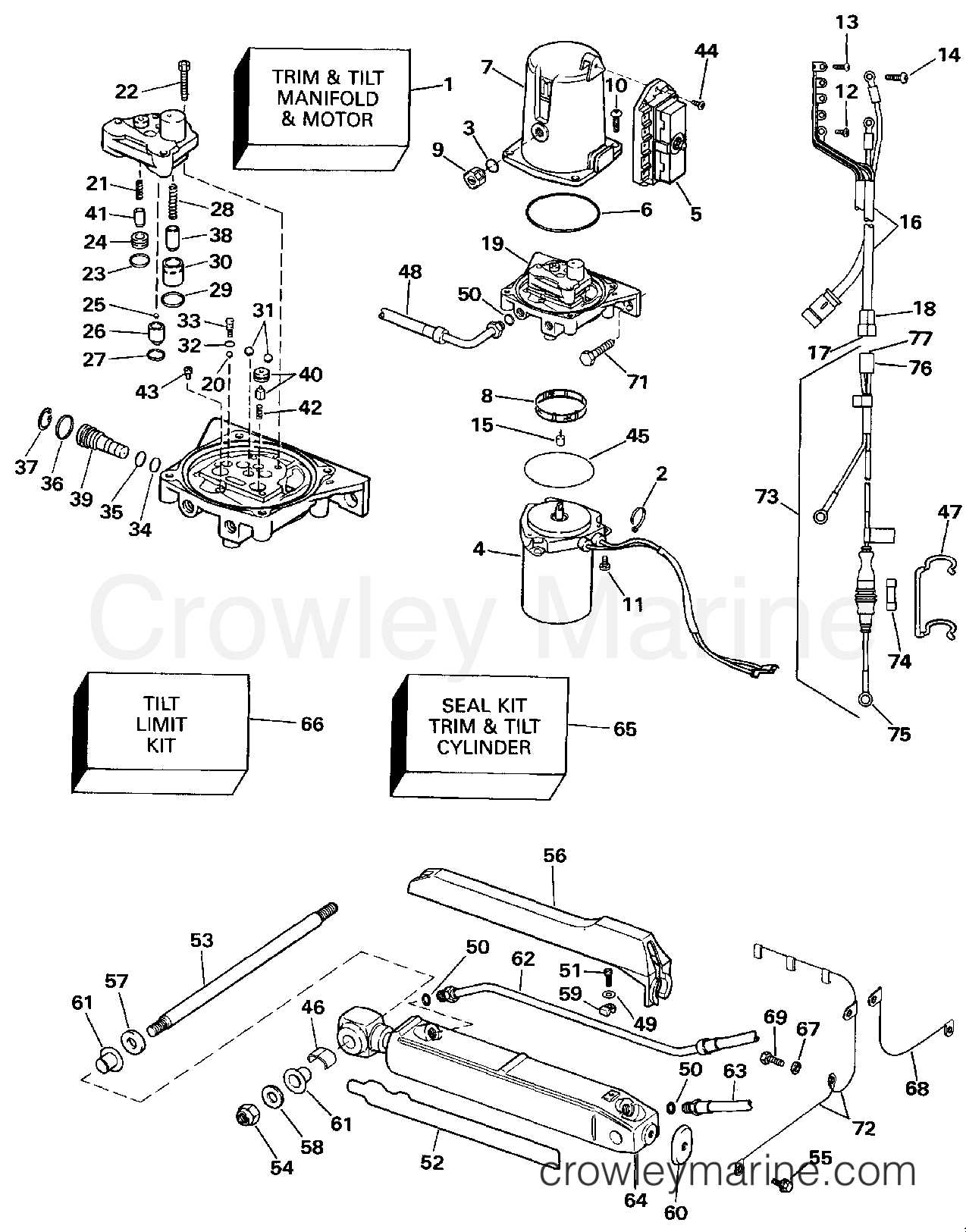

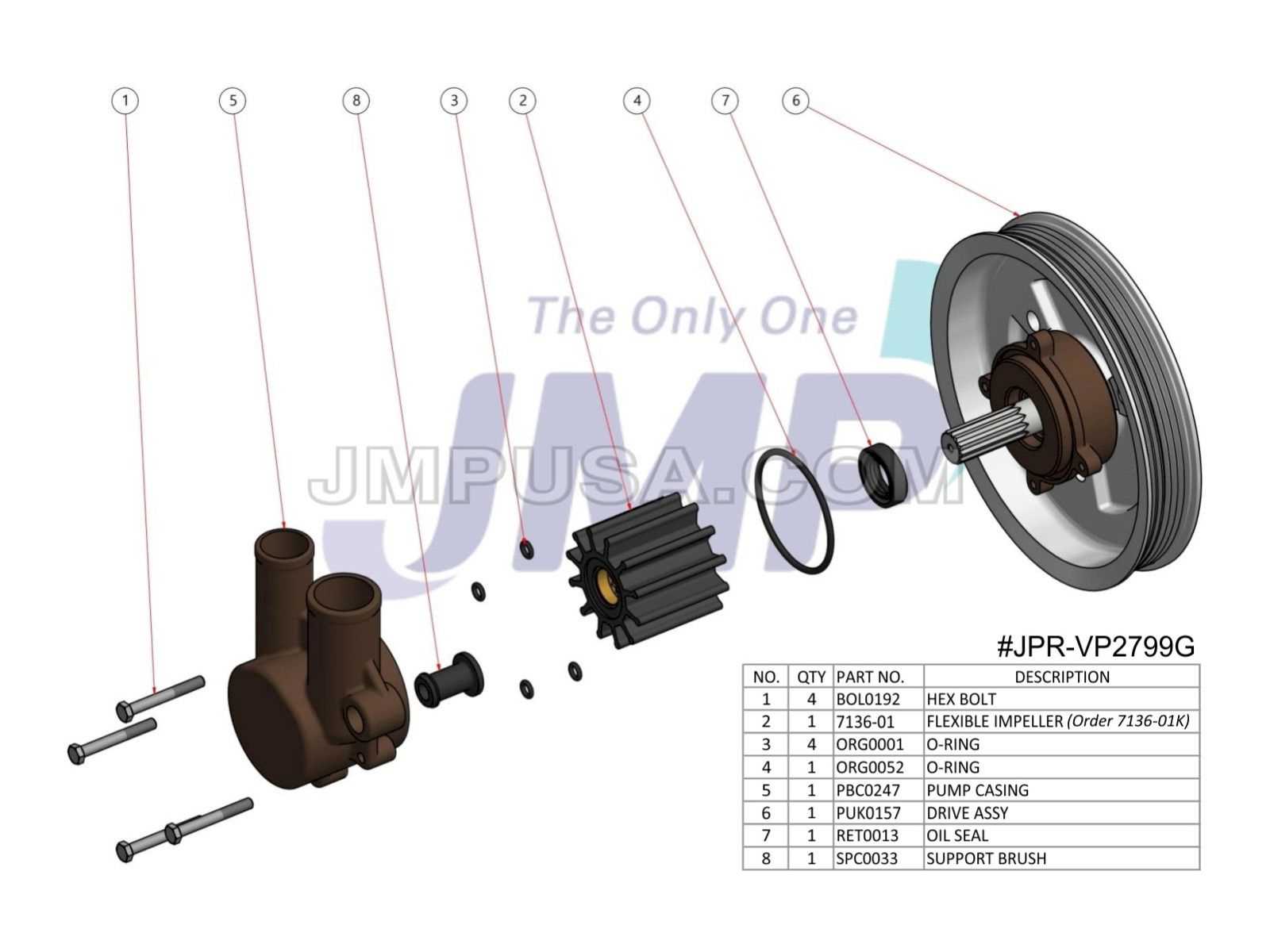

Commonly, components such as filters, gaskets, and pumps are among those that need routine checks. Filters play a vital role in maintaining cleanliness, while gaskets prevent leaks that can lead to severe issues. Additionally, pumps are essential for fluid circulation, making their timely replacement important for overall functionality.

Moreover, electrical connectors and ignition systems should not be overlooked, as they are critical for reliable operation. Keeping a close eye on these areas can help in anticipating failures before they occur, allowing for proactive maintenance and reducing downtime.