Comprehensive Parts Diagram for Volvo Penta 5.7 GSI

In the realm of marine propulsion systems, a comprehensive grasp of engine components is essential for effective maintenance and performance enhancement. Each element plays a crucial role in ensuring smooth operation and longevity, making it imperative for boat owners and technicians to familiarize themselves with these intricate systems.

By delving into the specifics of engine assemblies, one can uncover the relationships between various components and their functions. This knowledge not only aids in troubleshooting but also empowers users to make informed decisions regarding repairs and upgrades. Understanding the layout and interaction of these crucial parts is a key step towards optimizing engine efficiency.

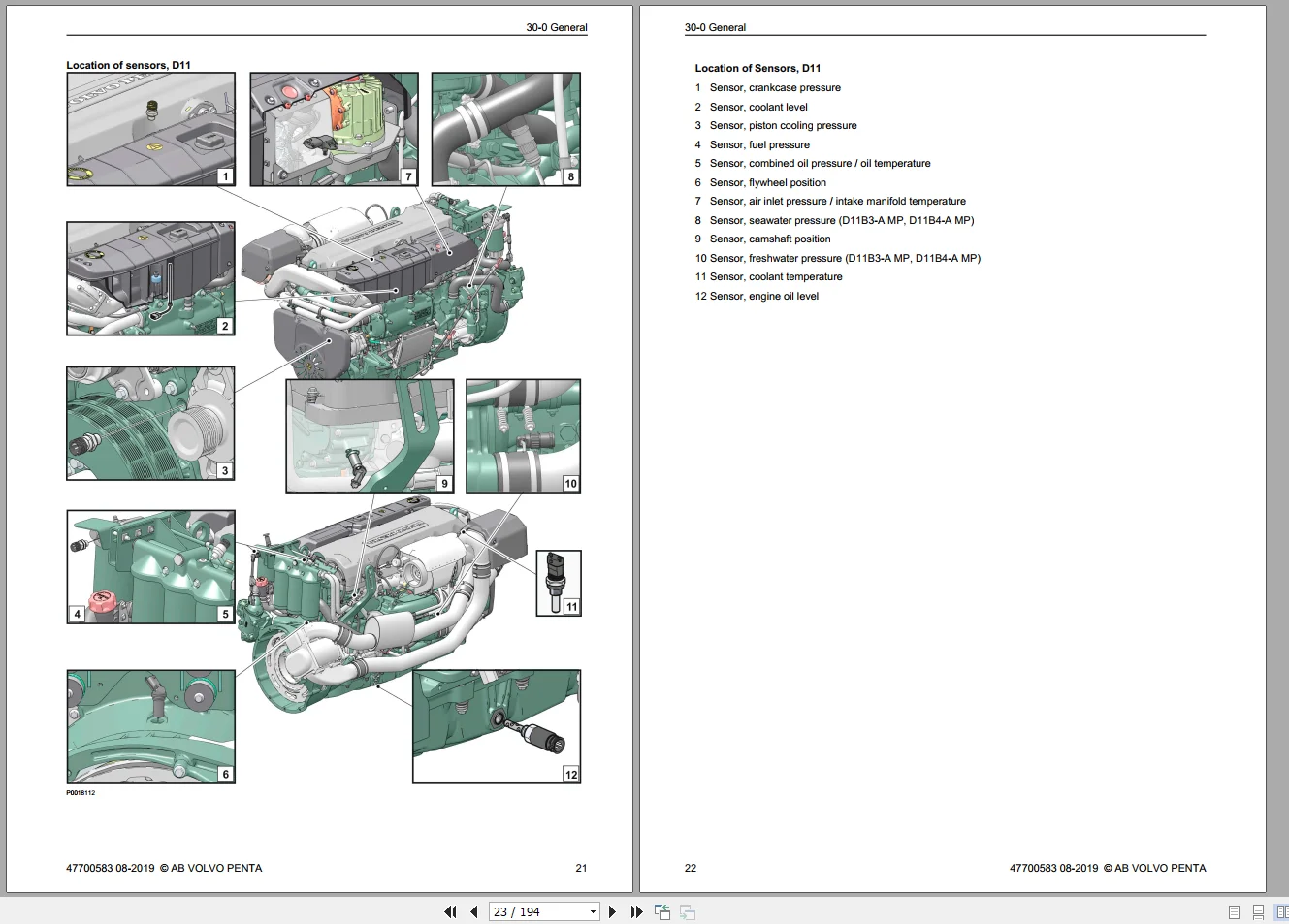

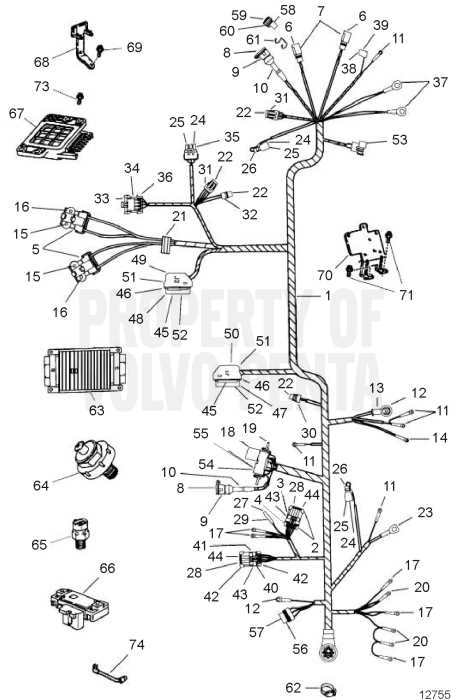

As we explore the intricacies of a particular model, detailed visual representations serve as invaluable tools. They provide clarity on the positioning and connections of various elements, facilitating a more intuitive understanding of the overall machinery. Whether for routine checks or in-depth repairs, having access to accurate schematics can significantly enhance one’s ability to maintain peak performance.

Understanding Volvo Penta 5.7 GSI Engine

This section delves into the intricacies of a specific marine propulsion system, emphasizing its components and functionalities. Understanding these aspects is essential for maintenance and optimal performance.

The engine in focus is widely recognized for its reliability and efficiency in various watercraft applications. Its design integrates advanced technology to provide robust power and excellent fuel economy, making it a preferred choice among boating enthusiasts.

Key features include:

- High displacement design for enhanced torque.

- Efficient fuel injection system for better combustion.

- Robust cooling mechanisms to prevent overheating.

For effective maintenance, familiarity with the main components is crucial. The essential parts can be categorized as follows:

- Engine Block: The core structure housing internal components.

- Cylinder Head: Contains the combustion chamber and valves.

- Intake and Exhaust Systems: Responsible for airflow management.

- Fuel System: Ensures proper delivery of fuel to the engine.

- Ignition System: Initiates combustion to produce power.

Understanding the layout and function of these elements contributes to better troubleshooting and repair practices, ultimately enhancing the lifespan of the marine engine.

Overview of Engine Components

The functionality of any power unit relies on a variety of essential elements that work together seamlessly. Each component plays a specific role in ensuring the engine operates efficiently and reliably. Understanding these parts is crucial for maintenance and troubleshooting.

- Block: The core structure that houses various components and supports the engine’s overall architecture.

- Cylinder Head: This component seals the top of the cylinders and contains passages for air and fuel.

- Pistons: These move within the cylinders, converting combustion pressure into mechanical energy.

- Crankshaft: Transforms linear motion from the pistons into rotational motion, ultimately driving the output.

- Camshaft: Regulates the timing of valve openings and closings, crucial for the engine’s breathing cycle.

- Valves: Control the intake of air and fuel and the exhaust of combustion gases.

- Timing Belt/Chain: Ensures the synchronization between the crankshaft and camshaft.

- Fuel System: Comprises injectors and pumps that deliver the appropriate fuel mixture to the engine.

- Ignition System: Generates the spark necessary for igniting the fuel-air mixture within the combustion chamber.

- Cooling System: Maintains optimal operating temperatures through the circulation of coolant.

Each of these components must function correctly for the entire system to perform effectively. Regular inspection and maintenance of these parts can help prolong the life of the engine and ensure peak performance.

Importance of Parts Diagrams

Visual representations of component layouts play a crucial role in the maintenance and repair of machinery. They provide a clear and organized way to identify individual elements, ensuring that technicians can efficiently address issues and replace items when necessary. Understanding these illustrations is essential for optimal performance and longevity of equipment.

Benefits of Visual Representations

- Enhances Understanding: Diagrams break down complex systems into manageable parts, making it easier to grasp their functions.

- Streamlines Repair Processes: Quick reference aids save time during troubleshooting, allowing for faster diagnosis and repair.

- Facilitates Accurate Replacements: Knowing the exact components helps in selecting the right replacements, reducing the risk of errors.

Key Aspects to Consider

- Clarity: High-quality illustrations should be easy to read and interpret, with clearly labeled components.

- Detail: Comprehensive views should provide enough detail to ensure all elements are accounted for.

- Accessibility: Easily accessible resources are vital for technicians to perform their tasks effectively.

Common Issues with Volvo Penta 5.7 GSI

When it comes to marine engines, certain challenges tend to arise over time, affecting performance and reliability. Understanding these common problems can help boat owners maintain their vessels more effectively and avoid costly repairs.

Several key issues are frequently reported by users of this particular engine model. Below is a table summarizing these problems along with their potential causes and recommended solutions:

| Issue | Potential Causes | Recommended Solutions |

|---|---|---|

| Overheating | Clogged cooling system, low coolant level | Flush the cooling system, check and refill coolant |

| Rough Idle | Dirty fuel injectors, faulty sensors | Clean injectors, inspect and replace sensors as needed |

| Hard Starting | Weak battery, fuel delivery issues | Test battery health, check fuel lines and pump |

| Excessive Vibration | Imbalanced propeller, worn mounts | Inspect and balance the propeller, replace engine mounts |

| Oil Leaks | Worn gaskets, loose fittings | Replace gaskets, tighten or replace fittings |

Addressing these issues promptly can greatly enhance the longevity and efficiency of the engine, ensuring a smoother experience on the water.

Maintenance Tips for Longevity

Ensuring the durability and performance of your marine engine requires regular care and attention. Implementing a systematic maintenance routine not only enhances efficiency but also extends the lifespan of crucial components. Here are several essential practices to consider.

Regular Inspections: Schedule frequent check-ups to identify wear and tear early. Look for leaks, corrosion, and any signs of damage in the system. Addressing small issues promptly can prevent more significant problems down the line.

Fluid Changes: Consistently change oil and coolant as per the manufacturer’s recommendations. Fresh fluids are vital for optimal operation, as they help reduce friction and prevent overheating.

Clean Filters: Maintain clean air and fuel filters to ensure efficient airflow and fuel delivery. Clogged filters can impair performance and lead to engine strain.

Battery Maintenance: Keep your battery connections clean and free from corrosion. Regularly check the charge levels and replace the battery if it shows signs of weakening.

Protective Coatings: Apply anti-corrosive coatings to metal surfaces exposed to water. This extra layer of protection can significantly reduce the risk of deterioration over time.

Storage Practices: When not in use, store the engine properly. Use covers to shield it from dust and moisture, and consider using fuel stabilizers to prevent degradation of fuel during long periods of inactivity.

By adhering to these guidelines, you can ensure that your engine remains reliable and efficient for many seasons to come.

Where to Find Replacement Parts

When it comes to sourcing components for your marine engine, there are several reliable avenues to explore. Whether you’re in need of a specific item or simply looking to stock up on essentials, knowing where to look can save you time and money.

Here are some of the best options for acquiring necessary components:

| Source | Description |

|---|---|

| Authorized Dealers | These establishments offer genuine items and often provide expert guidance to ensure you find the right fit for your engine. |

| Online Retailers | Websites specializing in marine supplies offer a wide selection, often at competitive prices. Be sure to check customer reviews before purchasing. |

| Marine Supply Stores | Local shops may have a variety of components in stock and can offer personalized service to assist you in your search. |

| Salvage Yards | These locations can provide affordable options for used components, making them a budget-friendly choice if you’re willing to do some digging. |

| Forums and Community Groups | Online communities often share resources and may even have members selling or trading components, allowing for potentially great deals. |

Exploring these resources can help you find the necessary items to keep your engine running smoothly and efficiently.

How to Interpret Parts Diagrams

Understanding technical illustrations can greatly enhance your ability to maintain and repair machinery. These visual representations break down complex assemblies into manageable components, allowing users to identify and locate various elements within a system. This section will guide you on how to effectively read and utilize these visual aids.

1. Familiarize Yourself with Symbols

Every illustration uses specific symbols and notations to represent different components. Spend some time reviewing the legend or key that accompanies the illustration. Recognizing these symbols will enable you to quickly understand what each part signifies.

2. Analyze the Layout

Technical drawings typically follow a logical layout. Components are often grouped by function or assembly order. Take a moment to assess the overall structure before diving into the details. This will help you comprehend how each piece interacts with others.

3. Pay Attention to Numbering

Most illustrations include a numbering system that corresponds with a list of parts. This reference list is invaluable when ordering replacements or consulting with suppliers. Make sure to cross-reference the numbers to avoid any confusion.

4. Look for Annotations

Many illustrations feature additional notes or annotations that provide crucial information about assembly, maintenance, or compatibility. These comments can offer insights that are not immediately apparent from the visual alone, making them essential for successful repairs.

5. Practice Makes Perfect

Like any skill, interpreting technical illustrations improves with practice. Engage with different types of visuals, and take the time to study them thoroughly. Over time, you will develop a sharper eye for detail and a deeper understanding of how the components fit together.

Identifying Key Engine Systems

Understanding the fundamental systems within a marine power unit is crucial for effective maintenance and performance optimization. Each system plays a vital role in ensuring the engine operates smoothly and efficiently. By familiarizing yourself with these essential components, you can better diagnose issues and implement necessary repairs.

Major Components to Consider

- Cooling System: This system regulates the temperature of the engine, preventing overheating and ensuring optimal performance.

- Fuel System: Responsible for delivering the necessary fuel to the combustion chamber, this system includes the fuel tank, lines, and injectors.

- Ignition System: This system ignites the air-fuel mixture, playing a critical role in the engine’s ability to start and run efficiently.

- Exhaust System: Properly expelling gases produced during combustion is essential for engine health and performance.

- Lubrication System: Ensuring all moving parts are adequately lubricated reduces friction and wear, prolonging engine life.

Common Issues and Maintenance Tips

- Regular Inspections: Conduct periodic checks on each system to identify wear and tear.

- Fluid Levels: Maintain appropriate levels of coolant, fuel, and oil to ensure smooth operation.

- Clean Filters: Replace or clean filters in the fuel and air systems to prevent blockages.

- Check Connections: Inspect hoses and connections for leaks or cracks that could compromise performance.

Essential Tools for Repairs

When it comes to maintaining and fixing marine engines, having the right set of instruments is crucial for efficiency and effectiveness. Proper tools not only simplify the repair process but also enhance the overall performance of the vessel. This section outlines the key implements that every technician should have on hand for successful maintenance tasks.

Wrenches and Sockets: A comprehensive set of wrenches and sockets is fundamental for loosening and tightening various components. Both standard and metric sizes are essential to accommodate different fittings.

Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specifications, preventing damage and ensuring reliability during operation.

Screwdrivers: A variety of screwdrivers, including flathead and Phillips, are necessary for accessing and securing covers and components throughout the engine.

Pliers: Having a selection of pliers, including needle-nose and slip-joint types, can aid in gripping, twisting, and cutting tasks that may arise during repairs.

Multimeter: A digital multimeter is essential for diagnosing electrical issues, measuring voltage, current, and resistance, and ensuring all electrical components are functioning properly.

Diagnostic Tools: Specialized diagnostic equipment can provide insights into engine performance and pinpoint issues that may not be immediately visible.

Oil Change Kit: This includes oil filters, oil wrenches, and containers for proper disposal, which are vital for routine maintenance and prolonging engine life.

Equipping oneself with these essential tools not only facilitates smoother repair processes but also fosters a deeper understanding of the engine’s intricacies, ultimately enhancing the longevity and reliability of marine vessels.

Performance Upgrades for the 5.7 GSI

Enhancing the performance of marine engines can lead to improved speed, efficiency, and overall handling. Various modifications can be made to achieve these goals, whether for recreational boating or competitive settings. Below are some effective upgrades to consider for optimizing engine output.

Engine Tuning and Management

- ECU Remapping: Adjusting the engine control unit parameters can increase horsepower and torque, providing a noticeable boost in performance.

- Performance Chips: Installing aftermarket chips can enhance throttle response and fuel efficiency, ensuring optimal operation.

Intake and Exhaust Improvements

- High-Flow Air Filters: Replacing standard filters with high-flow alternatives can significantly improve airflow, leading to better combustion and power output.

- Upgraded Exhaust Systems: Installing a performance exhaust system reduces back pressure, allowing for a more efficient exhaust flow, which translates into increased power.

Implementing these modifications can dramatically enhance the engine’s performance, making for a more exhilarating and efficient boating experience. Always ensure that upgrades are suitable for your specific model and usage conditions.

Comparing with Other Volvo Penta Models

When examining various marine engine configurations, it’s essential to consider the differences and similarities among the available models. This comparison not only highlights performance specifications but also addresses aspects such as maintenance, efficiency, and overall user experience.

Performance Characteristics

- Torque Output: Different models exhibit varying torque levels, affecting acceleration and handling.

- Fuel Efficiency: Variations in design can lead to significant differences in fuel consumption rates.

- Horsepower Range: The power output across models can influence their suitability for different types of vessels.

Maintenance and Parts Availability

- Service Intervals: Certain engines may require more frequent maintenance, impacting long-term ownership costs.

- Parts Compatibility: Understanding which components are interchangeable can simplify repairs and upgrades.

- Support and Resources: Availability of service manuals and community forums can greatly assist owners.

By comparing these various aspects, boat owners can make informed decisions about which engine best meets their needs while navigating the complexities of marine propulsion systems.

DIY Repair Tips for Enthusiasts

For those who revel in hands-on projects, repairing marine engines can be both rewarding and challenging. Understanding your vessel’s mechanics empowers you to perform maintenance tasks effectively and can save you significant costs. Here are some practical tips to guide you through your repair endeavors.

Preparation and Planning

Before diving into repairs, ensure you have a solid plan in place. Consider the following steps:

- Gather necessary tools and equipment.

- Review the engine’s service manual for specific guidance.

- Document the disassembly process with photos for easy reassembly.

Common Repair Techniques

Mastering a few essential techniques can make your repair tasks smoother:

- Inspection: Regularly check for leaks, corrosion, and wear. Early detection prevents larger issues.

- Cleaning: Keep components free of dirt and debris to enhance performance and longevity.

- Sealing: Use appropriate sealants to prevent leaks and ensure a tight fit on connections.

- Testing: After repairs, run the engine under supervision to ensure everything operates smoothly.

By applying these tips, you’ll enhance your skills and confidence, making each repair a learning opportunity and a step toward mastery.

Resources for Further Learning

Expanding your knowledge in the field of marine engine maintenance and repair is crucial for both enthusiasts and professionals. Various materials are available to enhance your understanding of different components and their functionalities. This section provides a curated list of resources that can help deepen your expertise.

Books and Manuals

Comprehensive literature is an excellent starting point for anyone looking to learn more about engine systems and their upkeep. Manuals often include detailed illustrations and specifications, making them invaluable for hands-on learning.

Online Courses and Tutorials

Digital platforms offer a wealth of courses and instructional videos that cover everything from basic maintenance to advanced troubleshooting techniques. Engaging with these resources can provide practical insights and improve your skills.

| Resource Type | Example | Link |

|---|---|---|

| Book | Marine Engine Maintenance | View More |

| Online Course | Advanced Engine Repair | Enroll Now |

| Tutorial Video | Basic Troubleshooting | Watch Here |