Comprehensive Parts Diagram for Volvo Penta DP SM

The intricate world of marine propulsion is essential for both performance and safety on the water. A thorough comprehension of the individual elements within these systems can significantly enhance maintenance and repair efforts, ensuring that vessels operate at peak efficiency. This exploration provides valuable insights into the arrangement and functionality of various components, fostering a deeper appreciation for their roles in smooth navigation.

By delving into the specific features and connections of these mechanical assemblies, one can uncover the nuances that contribute to their reliability and effectiveness. Each segment plays a vital role, and understanding how they interact can aid in troubleshooting and optimizing overall performance. Whether for routine checks or more extensive overhauls, knowledge of these structures is indispensable for marine enthusiasts and professionals alike.

Furthermore, an in-depth examination of these systems allows for informed decision-making when it comes to replacements and upgrades. As technology continues to evolve, staying updated on the latest advancements in marine engineering will ensure that vessels remain competitive and safe on the water. Embracing this knowledge can empower owners and technicians to take proactive steps in their maintenance strategies.

Understanding Volvo Penta DP SM Components

When exploring the intricacies of marine propulsion systems, it’s essential to grasp the various elements that contribute to their efficiency and performance. Each component plays a crucial role in ensuring smooth operation and reliability on the water. A thorough understanding of these elements not only aids in maintenance but also enhances overall user experience.

At the heart of these systems lies a sophisticated assembly designed to facilitate seamless power transmission. Each segment is engineered to withstand the challenges of marine environments, including saltwater exposure and varying loads. This robustness ensures longevity and minimal downtime during usage.

Key functionalities are often embedded within the assembly, allowing for better maneuverability and control. Components work in harmony to optimize speed and handling, providing a competitive edge for boaters. Regular inspections and familiarity with these critical parts can significantly impact the overall performance and safety of your vessel.

In summary, an in-depth comprehension of the essential components within this assembly is vital for any maritime enthusiast. Whether for troubleshooting, routine checks, or performance enhancements, knowledge is an invaluable asset in the world of marine engineering.

Importance of Parts Diagrams

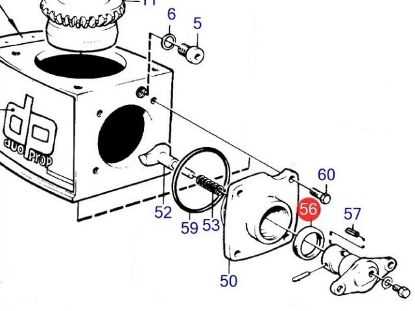

Visual representations of components play a crucial role in understanding complex systems. They provide clarity, allowing users to easily identify each element and its function within the larger assembly. This understanding is vital for effective maintenance and repair, ensuring that operations run smoothly and efficiently.

| Benefits | Description |

|---|---|

| Clarity | Visual aids enhance comprehension of intricate setups. |

| Efficiency | Quick identification of components speeds up repairs. |

| Training | Useful for educating new technicians on system layouts. |

| Communication | Facilitates better discussions among team members. |

Key Features of DP SM Models

The DP SM models are renowned for their exceptional engineering, combining advanced technology and robust design to enhance performance and reliability on the water. These systems are crafted to offer optimal handling and efficiency, making them a preferred choice for many marine applications.

Efficient Performance: The innovative design of these models maximizes thrust and minimizes drag, resulting in improved fuel efficiency and speed. This efficiency ensures that vessels can travel longer distances with reduced operational costs.

Enhanced Maneuverability: Equipped with cutting-edge steering systems, these models provide remarkable control and responsiveness, allowing operators to navigate tight spaces with ease. This feature is particularly beneficial in busy harbors and narrow channels.

Durability: Built with high-quality materials, these systems are designed to withstand harsh marine environments. Their resilience ensures long-lasting performance, even under demanding conditions.

Versatile Applications: Suitable for a variety of vessels, the DP SM models can be adapted to different marine activities, from leisure cruising to commercial shipping, making them a versatile choice for boat owners.

Common Issues with Volvo Penta Units

Marine propulsion systems can encounter various challenges that affect performance and reliability. Understanding these issues is crucial for maintaining optimal functionality and ensuring a safe experience on the water.

Frequent Challenges

- Overheating: This can occur due to cooling system blockages or low coolant levels.

- Fuel Delivery Problems: Clogged filters or failing pumps can disrupt fuel flow.

- Electrical Failures: Corrosion or loose connections may lead to intermittent power loss.

Maintenance Tips

- Regularly check and replace filters to ensure proper fuel and air flow.

- Inspect the cooling system frequently to prevent overheating issues.

- Perform routine electrical system checks to identify and rectify potential faults.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring that marine systems operate smoothly and efficiently. By adhering to best practices, users can enhance longevity and reliability while maximizing performance during each outing.

Routine Checks

- Inspect fluid levels frequently to prevent overheating.

- Examine belts and hoses for wear or cracks.

- Clean filters and replace them as needed to maintain airflow.

Seasonal Maintenance

- Service the engine at the beginning and end of each season.

- Check the anodes and replace them to protect against corrosion.

- Store equipment properly during off-season to avoid damage.

How to Read Parts Diagrams

Understanding technical illustrations is crucial for anyone involved in maintenance or repairs. These visuals provide essential information about various components and their interconnections, enabling users to identify and acquire the necessary elements effectively.

Key Elements of Technical Illustrations

Familiarize yourself with the common features found in these visuals. Most representations include labels, reference numbers, and groupings of similar items, which guide you through the identification process.

| Element | Description |

|---|---|

| Labels | Indicate specific items or groups, often with alphanumeric codes. |

| Reference Numbers | Help correlate components with lists or catalogs for ordering. |

| Grouping | Clusters of similar items, showing how they interact or fit together. |

Tips for Effective Interpretation

Start by reviewing the entire illustration before focusing on specific components. Cross-reference labels with accompanying documentation to ensure accurate identification. Practice will enhance your ability to navigate these visuals confidently.

Essential Tools for Repairs

When undertaking maintenance or fixing machinery, having the right instruments is crucial for efficiency and precision. These essential tools not only streamline the repair process but also ensure quality results.

- Wrenches: Various sizes are necessary for loosening or tightening bolts and nuts.

- Screwdrivers: A set with different types, including flathead and Phillips, is indispensable for assembling and disassembling components.

- Pliers: These are useful for gripping, twisting, or cutting wires and other materials.

In addition to basic tools, consider having specialized equipment for more intricate tasks:

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

- Multimeter: Ideal for diagnosing electrical issues and ensuring proper functionality.

- Oil Filter Wrench: Aids in the removal and installation of oil filters, making routine maintenance easier.

Investing in quality tools will pay off in the long run, enhancing both the repair experience and the durability of your machinery.

Identifying Faulty Components

When it comes to maintaining marine propulsion systems, recognizing defective elements is crucial for ensuring optimal performance. Various symptoms can signal issues within the system, prompting a thorough inspection to pinpoint malfunctions. Understanding the signs and knowing where to look can save both time and resources.

Common indicators of malfunction include unusual noises, vibrations, and unexpected changes in performance. For instance, if you notice a persistent grinding sound or irregular shifts, it may be a sign that components such as gears or bearings are wearing out. Additionally, leaks from seals or connections can indicate a failure in the integrity of the system.

Routine checks and monitoring are essential in identifying these issues early. Visual inspections should focus on areas prone to wear, while operational tests can reveal underlying problems not immediately visible. By adopting a proactive approach, you can significantly extend the lifespan of your equipment and prevent costly repairs.

Upgrading Your DP SM System

Enhancing your drive system can significantly improve performance and efficiency. By implementing the latest components and technologies, you can achieve smoother operation, better fuel efficiency, and increased longevity of your equipment. Understanding the potential upgrades is crucial for maximizing your system’s capabilities.

Identifying Upgrade Opportunities

Begin by assessing the current configuration of your system. Look for outdated components that may hinder performance and consider alternatives that offer advanced features. Pay attention to compatibility to ensure seamless integration with existing elements.

Implementation and Maintenance

Once you’ve selected your upgrades, proper installation is essential for optimal results. Follow manufacturer guidelines and best practices. Regular maintenance of the enhanced system will help maintain its performance and extend its lifespan, allowing you to enjoy the benefits of your investment for years to come.

Aftermarket Parts vs. OEM Parts

When it comes to enhancing or repairing machinery, consumers often face a choice between alternative solutions and original components. Each option presents unique advantages and potential drawbacks, influencing both performance and cost. Understanding these differences is crucial for making informed decisions that suit individual needs and preferences.

Benefits of Alternative Solutions

Alternative components are typically more affordable and widely available, catering to various budgets. They can offer enhanced features or improved performance, attracting users seeking customization. Moreover, the competitive market often drives innovation, leading to advancements that may not be present in original offerings.

Advantages of Original Components

Original components ensure compatibility and reliability, often backed by manufacturer warranties. They are designed specifically for particular machinery, guaranteeing optimal performance and safety. Users may find peace of mind in using these components, knowing they adhere to strict quality standards.

Cost Considerations for Replacements

When it comes to the replacement of marine equipment components, understanding the financial implications is essential. Various factors can influence the overall expense, from the type of components needed to the source of procurement. Careful analysis can lead to significant savings and informed decision-making.

Factors Affecting Costs

- Component Quality: High-quality alternatives often come at a premium but can provide better longevity and reliability.

- Supplier Selection: Prices can vary significantly between different suppliers, making it crucial to research and compare options.

- Installation Costs: Professional installation may add to the expense, but skilled technicians can ensure proper setup and function.

- Warranty and Support: Components with warranties might have a higher upfront cost but can save money in the long run through reduced failures.

Cost-Saving Strategies

- Conduct thorough research to identify the best suppliers and negotiate prices.

- Consider refurbished or aftermarket options that meet quality standards.

- Evaluate the total cost of ownership, including maintenance and potential downtime.

- Plan replacements during off-peak seasons when labor costs may be lower.

By assessing these factors and implementing strategic choices, individuals and businesses can better manage expenses related to component replacements and ensure their marine operations remain efficient and cost-effective.

Understanding Assembly Procedures

Grasping the assembly process is crucial for ensuring optimal functionality and longevity of mechanical systems. A well-structured approach not only facilitates seamless integration of components but also minimizes the risk of errors during installation. By following a systematic methodology, one can enhance both efficiency and effectiveness in achieving the desired outcomes.

Preparation plays a vital role in any assembly task. Prior to commencing, it is essential to gather all necessary components and tools. Familiarizing oneself with the specifications and instructions will provide a solid foundation for the procedure. This preparatory stage helps in identifying potential challenges and addressing them proactively.

During the assembly, attention to detail is paramount. Each part must be meticulously fitted to ensure that everything aligns perfectly. It is advisable to follow the sequence outlined in the documentation, as deviating from the prescribed order can lead to complications. Regular checks and adjustments during this phase will promote a smoother installation process.

Finally, testing the assembled unit is an indispensable step. Conducting a thorough examination to confirm that all components function harmoniously is essential. This verification process not only validates the assembly but also ensures that the system operates safely and efficiently.

Resources for Further Learning

Exploring the intricacies of marine machinery can significantly enhance your understanding and maintenance skills. Numerous resources are available to assist enthusiasts and professionals alike in deepening their knowledge and expertise.

- Online Forums: Engage with communities to share experiences and gain insights.

- Manufacturer Websites: Access manuals, guides, and updates directly from producers.

- YouTube Channels: Discover visual tutorials and walkthroughs for practical guidance.

- Books and eBooks: Seek comprehensive texts covering topics from basics to advanced mechanics.

Utilizing these resources can lead to a more profound appreciation and mastery of marine systems.