Comprehensive Guide to Volvo Penta Parts Diagrams

In the world of marine engineering, having a clear representation of engine components is essential for maintenance and repair. These illustrations serve as invaluable tools for technicians and enthusiasts alike, providing insights into the intricate systems that keep vessels operating smoothly.

By exploring these detailed visuals, one can gain a deeper understanding of the mechanics at play, enabling effective troubleshooting and the ultimate enhancement of performance. Each illustration highlights various sections, making it easier to identify specific components and their interconnections.

As we delve into this topic, we will uncover the significance of these visual aids, examining how they facilitate a more profound comprehension of engine structure and functionality. Whether you’re a seasoned expert or a novice, grasping the layout of these systems is crucial for ensuring reliability and efficiency.

Understanding Volvo Penta Parts Diagrams

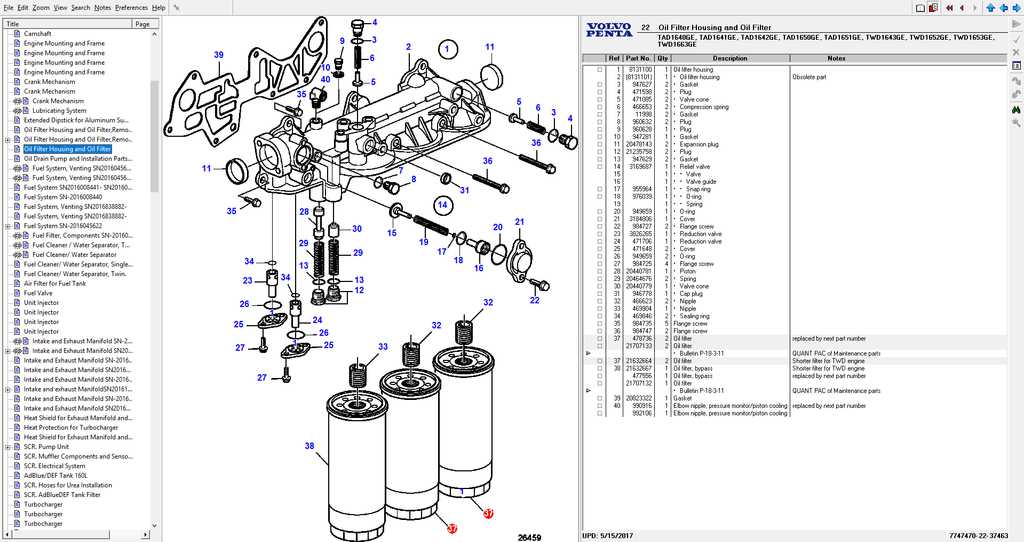

This section explores the intricate illustrations that depict components and assemblies of marine engines and related machinery. These visual guides serve as essential tools for maintenance and repairs, allowing users to identify and locate each element efficiently.

Comprehending these visuals is crucial for anyone working with marine equipment. They provide a clear representation of the various segments, facilitating a better understanding of how everything fits together.

Utilizing these illustrations not only enhances repair accuracy but also aids in ordering the correct replacements. Whether you’re a seasoned technician or a novice, mastering these resources can significantly improve the maintenance process.

Importance of Accurate Parts Identification

Ensuring the correct identification of components is crucial in any mechanical system. This accuracy not only affects the performance and longevity of the equipment but also influences safety and reliability. A thorough understanding of each element contributes to effective maintenance and reduces the risk of failures during operation.

Impact on Performance and Longevity

When components are precisely recognized and matched, it enhances overall functionality. Using incorrect or incompatible elements can lead to inefficient operation, increased wear, and potential breakdowns. Regular maintenance, supported by accurate identification, ensures that each part works harmoniously, extending the lifespan of the entire system.

Safety Considerations

Correct identification is paramount for safety. Misidentified components can result in improper installations, leading to hazardous situations. Accurate knowledge of each element mitigates risks and ensures that all safety standards are met, providing peace of mind for operators and users alike.

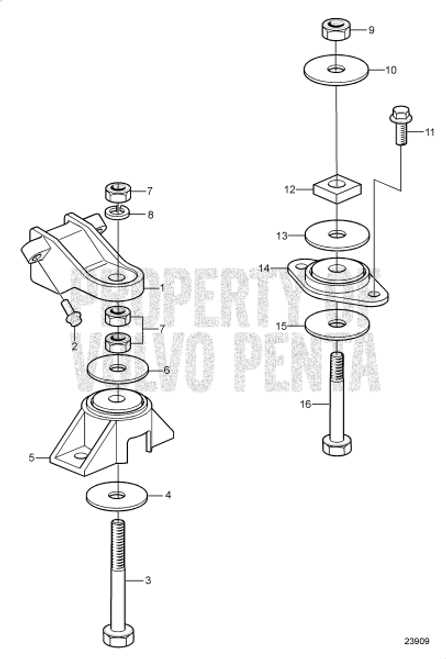

How to Read Volvo Penta Diagrams

Understanding technical illustrations is crucial for effective maintenance and repair tasks. These visual representations provide insights into components and their interactions, allowing users to identify parts and their functions easily.

Step One: Start by familiarizing yourself with the legend or key, which explains the symbols and notations used. This will help you decode the information presented.

Step Two: Identify the main assembly you are working on. Focus on the larger sections before delving into the smaller components to grasp the overall layout.

Step Three: Pay attention to the arrows and lines indicating connections and flow. These details are essential for understanding how different elements work together.

Step Four: Take note of any reference numbers or codes associated with each part. These are crucial for locating replacement items when needed.

By following these steps, you’ll gain the ultimate comprehension needed to navigate these complex illustrations efficiently.

Common Components in Penta Engines

Understanding the fundamental elements of marine engines is essential for effective maintenance and operation. These engines consist of various interconnected parts that contribute to their overall performance and reliability. Here, we explore some of the most prevalent components found in these power units.

- Engine Block: The core structure housing the cylinders and essential mechanisms.

- Cylinder Head: Covers the top of the cylinders and contains the combustion chamber.

- Pistons: Move within the cylinders to convert fuel energy into mechanical power.

- Crankshaft: Transforms linear motion from the pistons into rotational energy.

- Camshaft: Controls the opening and closing of valves, critical for the engine’s timing.

Additionally, several auxiliary components play vital roles in enhancing engine functionality:

- Fuel System: Delivers fuel to the combustion chamber, including pumps and injectors.

- Cooling System: Regulates engine temperature to prevent overheating, featuring radiators and thermostats.

- Lubrication System: Ensures smooth operation by reducing friction among moving parts.

- Exhaust System: Channels away harmful gases produced during combustion.

- Electrical System: Powers various engine components, including the ignition and starter systems.

Each of these elements works in harmony to ensure efficient operation, longevity, and optimal performance in various marine applications.

Benefits of Using Official Diagrams

Utilizing authorized visual guides can significantly enhance the maintenance and repair processes for marine and industrial machinery. These resources offer clarity and precision, ensuring users can navigate complex systems effectively.

- Accuracy: Official visual aids are meticulously crafted, providing precise details that help prevent errors during installation or repairs.

- Comprehensiveness: These guides encompass all necessary components, ensuring no essential part is overlooked during maintenance.

- Ease of Use: Designed with user-friendliness in mind, these resources simplify the understanding of intricate systems.

- Time Efficiency: With clear instructions, users can save valuable time, reducing downtime for equipment.

Incorporating these resources into routine practices not only streamlines maintenance tasks but also enhances overall operational efficiency.

Where to Find Parts Diagrams Online

In today’s digital age, accessing detailed illustrations for components has become increasingly convenient. Numerous platforms offer comprehensive resources to help users identify and locate specific elements for maintenance and repairs. Whether you’re a professional or a hobbyist, knowing where to search can significantly enhance your experience.

| Resource Type | Description |

|---|---|

| Manufacturer Websites | Official sites often provide extensive catalogs and visual aids for their products. |

| Online Retailers | Many e-commerce platforms showcase detailed images alongside product listings. |

| Forums and Community Groups | User-generated content can include shared manuals and helpful tips. |

| Dedicated Parts Websites | Specialized sites focus on aftermarket supplies and usually feature diagrams. |

Understanding Model Variations in Diagrams

Recognizing the differences among various models is crucial for effective maintenance and repair. Each version may have distinct features and components, impacting how they function and interact. By grasping these variations, users can ensure they are referencing the correct information for their specific unit.

In-depth knowledge of these differences aids in identifying the right elements needed for troubleshooting and enhances overall efficiency. Each model might present unique layouts and specifications, which can influence performance and longevity.

Ultimately, delving into the specifics of each variant not only streamlines repair processes but also contributes to a deeper understanding of the machinery’s operation, ensuring that every task is approached with precision and care.

Tips for Ordering Replacement Parts

When it comes to sourcing components for your machinery, having a clear strategy can save you time and money. Understanding how to effectively navigate the ordering process ensures that you receive the correct items promptly, enhancing your overall maintenance experience.

Here are some essential suggestions to consider when placing your orders:

| Tip | Description |

|---|---|

| Know Your Model | Always have your equipment’s model number at hand. This information is crucial for ensuring compatibility with the necessary components. |

| Use Official Sources | Whenever possible, order from authorized dealers or certified suppliers to guarantee the quality and authenticity of the components. |

| Check Availability | Before placing your order, confirm that the items are in stock. This can help avoid delays in your maintenance schedule. |

| Request Assistance | If you are uncertain about the specifics of a component, don’t hesitate to ask for help from customer service or technical support. |

| Keep Records | Maintain a detailed log of your orders and receipts. This will aid in future purchases and warranty claims. |

By following these recommendations, you can enhance your purchasing experience and ensure that your machinery remains in optimal condition.

How Diagrams Aid Maintenance Procedures

Visual representations play a crucial role in the upkeep of machinery, providing clarity and simplifying complex tasks. By illustrating components and their relationships, these tools enable technicians to understand the system’s layout and function more effectively. This understanding is essential for performing maintenance tasks accurately and efficiently.

Enhancing Understanding

When facing intricate systems, detailed visuals can significantly reduce confusion. They allow maintenance personnel to quickly identify parts, understand their roles, and recognize potential issues. This enhanced understanding leads to faster diagnostics and repairs, ultimately improving equipment reliability.

Streamlining Processes

Incorporating visual aids into maintenance routines can also streamline procedures. By following a structured approach outlined in these illustrations, technicians can work methodically, minimizing the risk of oversight. This organized process not only saves time but also ensures that all necessary steps are followed for effective maintenance.

| Benefit | Description |

|---|---|

| Clarity | Visual aids simplify complex information, making it easier to grasp. |

| Efficiency | Streamlined processes lead to quicker diagnostics and repairs. |

| Accuracy | Step-by-step guidance reduces the likelihood of errors. |

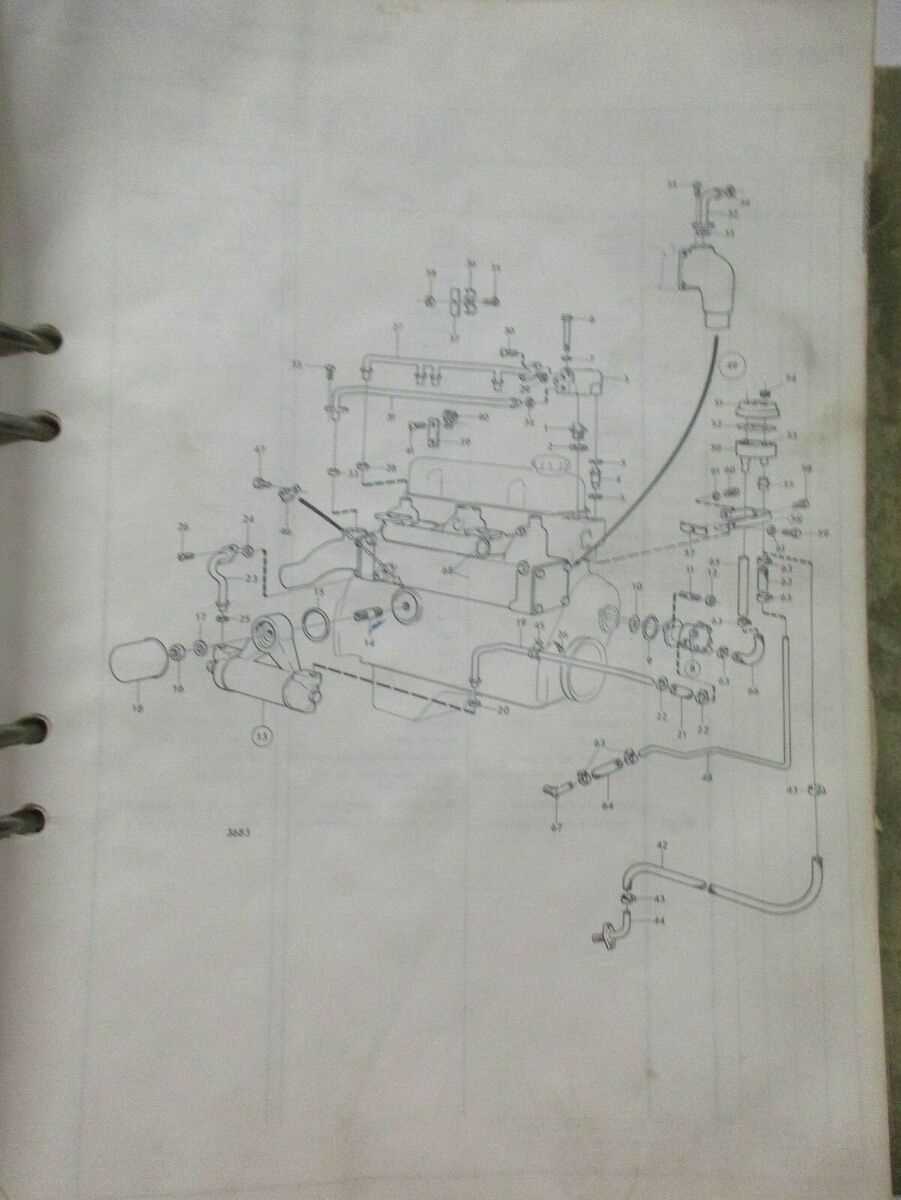

Interpreting Electrical System Diagrams

Understanding the intricacies of electrical systems is crucial for effective maintenance and troubleshooting. These visual representations provide insights into the components and their interconnections, allowing for a clearer grasp of how the system functions as a whole. By analyzing these illustrations, technicians can identify potential issues and devise appropriate solutions.

Each element within the schematic plays a specific role, whether it’s a connector, switch, or sensor. Familiarity with common symbols and notations is essential, as they serve as a universal language among professionals in the field. Recognizing the flow of electricity through the various components helps in pinpointing malfunctions and ensuring optimal performance.

Furthermore, understanding the relationships between different parts can aid in diagnosing problems more efficiently. When a malfunction occurs, tracing the path of electrical current through the system allows for targeted repairs, reducing downtime and enhancing reliability. A thorough interpretation of these schematics ultimately contributes to the longevity and efficiency of the electrical system.

Using Diagrams for Troubleshooting Issues

Visual representations are invaluable tools when it comes to diagnosing and resolving mechanical problems. By providing a clear layout of components and their interconnections, these illustrations enable users to pinpoint malfunctions more efficiently, ultimately saving time and resources.

Identifying Faulty Components

By studying these visuals, one can easily identify which parts may be malfunctioning. Understanding the layout helps in isolating issues and aids in determining the best course of action for repair or replacement.

Streamlining the Repair Process

Utilizing these illustrations can significantly streamline the repair process. Having a reference allows for a systematic approach, ensuring that no steps are overlooked and that repairs are executed with precision.

Differences Between Marine and Industrial Models

When comparing various engine types, it’s essential to understand the distinct characteristics that set them apart. Each model is designed for specific environments and operational requirements, influencing performance, durability, and overall functionality.

Marine engines are engineered for aquatic applications, focusing on corrosion resistance and efficient cooling systems. These engines typically prioritize low-end torque to handle varying loads and conditions while maintaining stability on water.

In contrast, industrial engines are built for terrestrial use, often emphasizing high power output and longevity under continuous heavy-duty operation. They are designed to endure harsh conditions, with a focus on fuel efficiency and ease of maintenance.

Ultimately, understanding these differences allows for informed decisions regarding engine selection, ensuring optimal performance in the intended application.

Maintaining Your Volvo Penta Equipment

Proper upkeep of your marine machinery is essential for optimal performance and longevity. Regular maintenance helps prevent unexpected failures and ensures that your equipment runs smoothly during critical moments on the water. Understanding the basic principles of care and upkeep will enable you to enjoy a seamless experience with your vessel.

Routine Inspections

Conducting frequent evaluations is vital for identifying potential issues early. Look for signs of wear and tear, such as corrosion or leaks, and address them promptly to avoid more significant problems down the line. Documenting your findings can help track performance over time.

Scheduled Servicing

Adhering to a servicing schedule is crucial for maintaining functionality. Ensure that all fluids are changed regularly, filters are replaced, and components are adjusted as needed. Engaging a professional service for complex tasks can enhance reliability and safety while using your machinery.