Comprehensive Guide to Volvo Sterndrive Parts Diagram

In the world of aquatic machinery, the interplay between various elements is crucial for optimal performance and reliability. This section delves into the intricate components that contribute to the functionality of marine propulsion systems. By examining these elements, one can gain valuable insights into their design and operational significance.

Visual representations serve as essential tools for understanding how different parts interact within these complex systems. They allow enthusiasts and technicians alike to grasp the arrangement and relationships among components, ensuring effective maintenance and repair processes.

Moreover, exploring these illustrations not only aids in troubleshooting but also enhances the overall comprehension of how these sophisticated mechanisms operate. A well-structured overview of the assembly can facilitate smoother navigation through the intricacies of marine engineering.

Understanding Volvo Sterndrive Systems

The operation of marine propulsion systems is essential for effective vessel performance. These systems integrate several components to ensure smooth movement through water, providing both efficiency and control. A deeper comprehension of these mechanisms reveals their complexities and the importance of each element in achieving optimal functionality.

Key Components and Their Functions

Each unit consists of vital elements that work in harmony. The primary assembly includes a drive unit, which is crucial for translating engine power into thrust. The propeller plays a significant role in generating movement, while the transmission allows for speed variations and directional changes. Understanding the interplay of these components is vital for maintaining peak performance.

Maintenance and Troubleshooting

Regular upkeep of these systems is essential for longevity and reliability. Routine inspections and timely replacements of wear-prone components can prevent more significant issues. When problems arise, recognizing the signs and knowing how to address them can save time and resources, ensuring that the vessel remains seaworthy.

Ultimately, mastering the intricacies of marine propulsion assemblies empowers operators to enhance their craft’s performance, ensuring enjoyable and safe voyages.

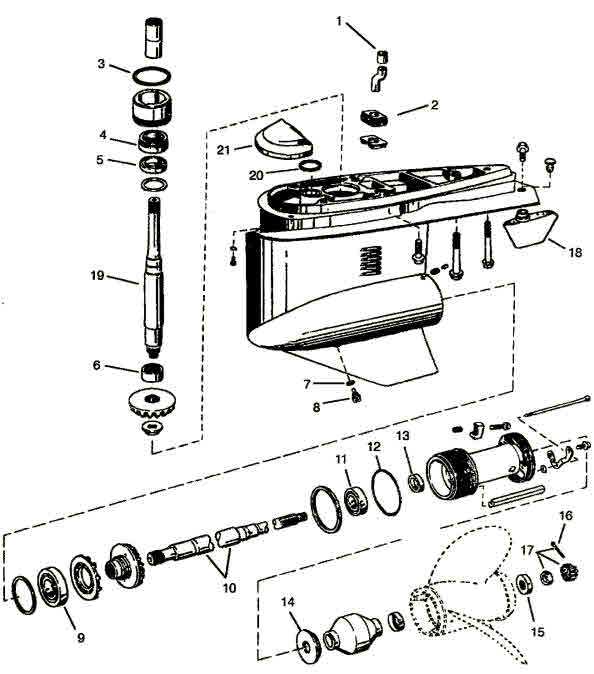

Components of Volvo Sterndrive Units

The efficient functioning of marine propulsion systems relies on a variety of integral elements that work in harmony. Each component plays a crucial role in ensuring smooth operation and reliability on the water. Understanding these elements is essential for maintenance and troubleshooting, contributing to the overall performance and longevity of the unit.

Propeller: The propeller is one of the most visible parts, converting rotational energy into thrust. Its design and material significantly impact efficiency and maneuverability.

Drive Shaft: This component transmits power from the engine to the propeller. Its durability is vital, as it endures high torque and stress during operation.

Gearbox: The gearbox facilitates the proper transfer of power and allows for gear changes. This component is crucial for adapting to varying water conditions and optimizing performance.

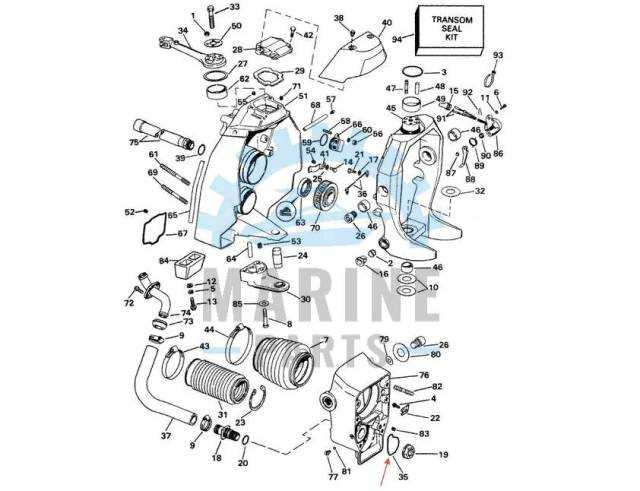

Transom Assembly: This structure connects the propulsion system to the hull, providing support and stability. It also houses several important features, including mounting points and seal systems.

Trim Mechanism: The trim system adjusts the angle of the propulsion unit, enhancing performance and fuel efficiency. Proper calibration of this mechanism is key for navigating different water conditions.

Cooling System: Effective temperature regulation is essential to prevent overheating. The cooling system ensures that the engine and other components operate within safe temperature ranges.

Electrical Components: Various electrical systems control functions such as ignition and monitoring. These parts are integral for the safe and efficient operation of the unit.

By familiarizing oneself with these critical elements, operators can enhance the reliability and performance of their marine propulsion systems, ensuring enjoyable and safe voyages.

Importance of Maintenance for Sterndrives

Regular upkeep is essential for ensuring the longevity and efficiency of marine propulsion systems. Neglecting routine care can lead to a decline in performance and potential failure, resulting in costly repairs and downtime. A proactive approach not only enhances functionality but also contributes to safety on the water.

Preventive measures play a crucial role in maintaining these systems. By routinely checking components for wear and tear, operators can identify issues early and address them before they escalate. This vigilance helps to minimize unexpected breakdowns and maintain optimal performance.

Furthermore, routine inspections can significantly extend the lifespan of the equipment. By adhering to a consistent maintenance schedule, owners can ensure that their systems operate smoothly and efficiently, providing peace of mind during voyages. The benefits of regular attention far outweigh the effort involved, making it a wise investment for any marine enthusiast.

Common Issues with Volvo Sterndrive Parts

When it comes to marine propulsion systems, understanding the typical challenges associated with components is essential for maintenance and optimal performance. Various mechanical elements can experience wear and tear, leading to operational difficulties. Identifying these issues early can save both time and money for vessel owners.

Frequent Mechanical Failures

One of the primary concerns is the degradation of mechanical seals and bearings. Over time, exposure to water and environmental factors can lead to corrosion and subsequent failure. This often results in leaks, which may compromise the entire system. Regular inspections can help detect these problems before they escalate.

Electrical and Control System Glitches

Another area prone to issues involves the electrical components that manage functionality. Faulty wiring or failing sensors can disrupt the control mechanisms, leading to erratic performance. Ensuring that all connections are secure and components are regularly tested can prevent unexpected malfunctions.

Proactive maintenance is key to extending the lifespan of your marine propulsion system. By staying vigilant and addressing common issues promptly, you can ensure a smoother and safer boating experience.

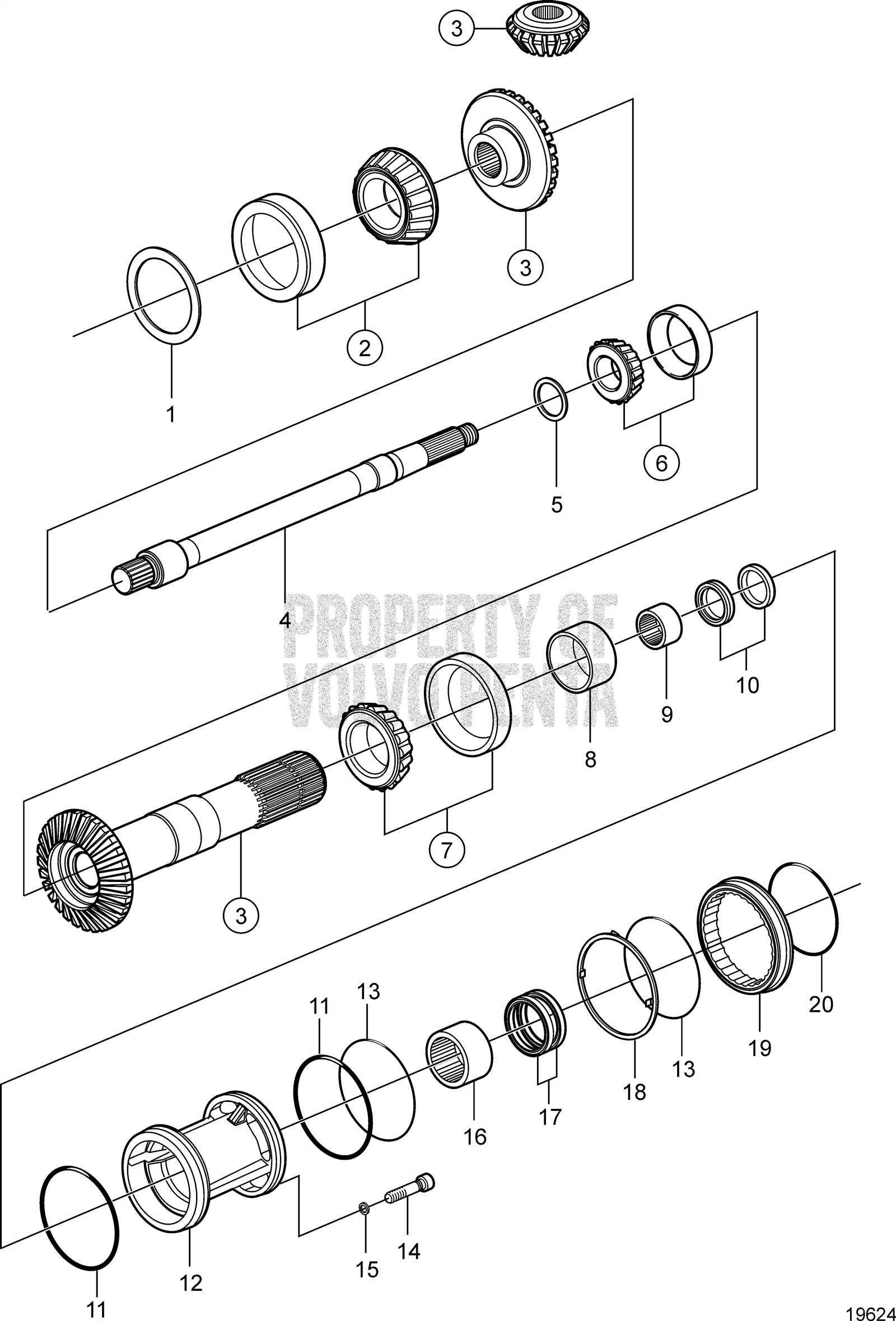

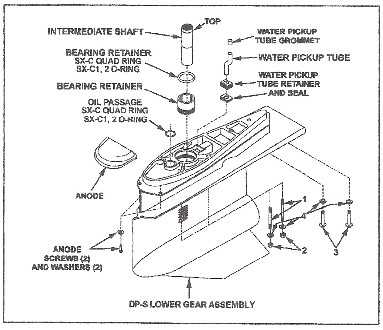

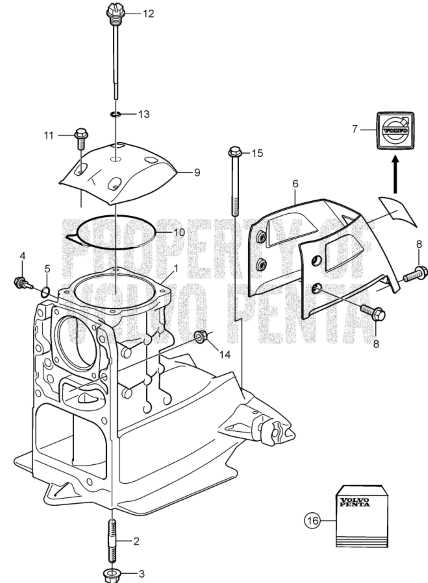

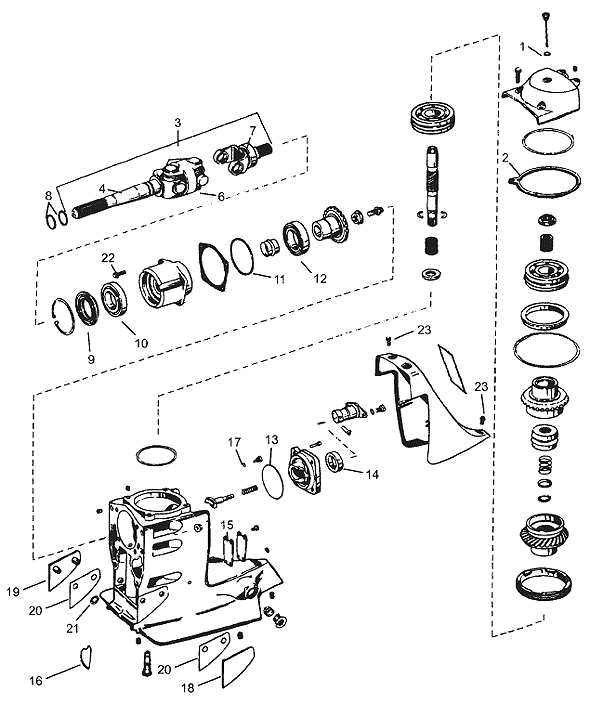

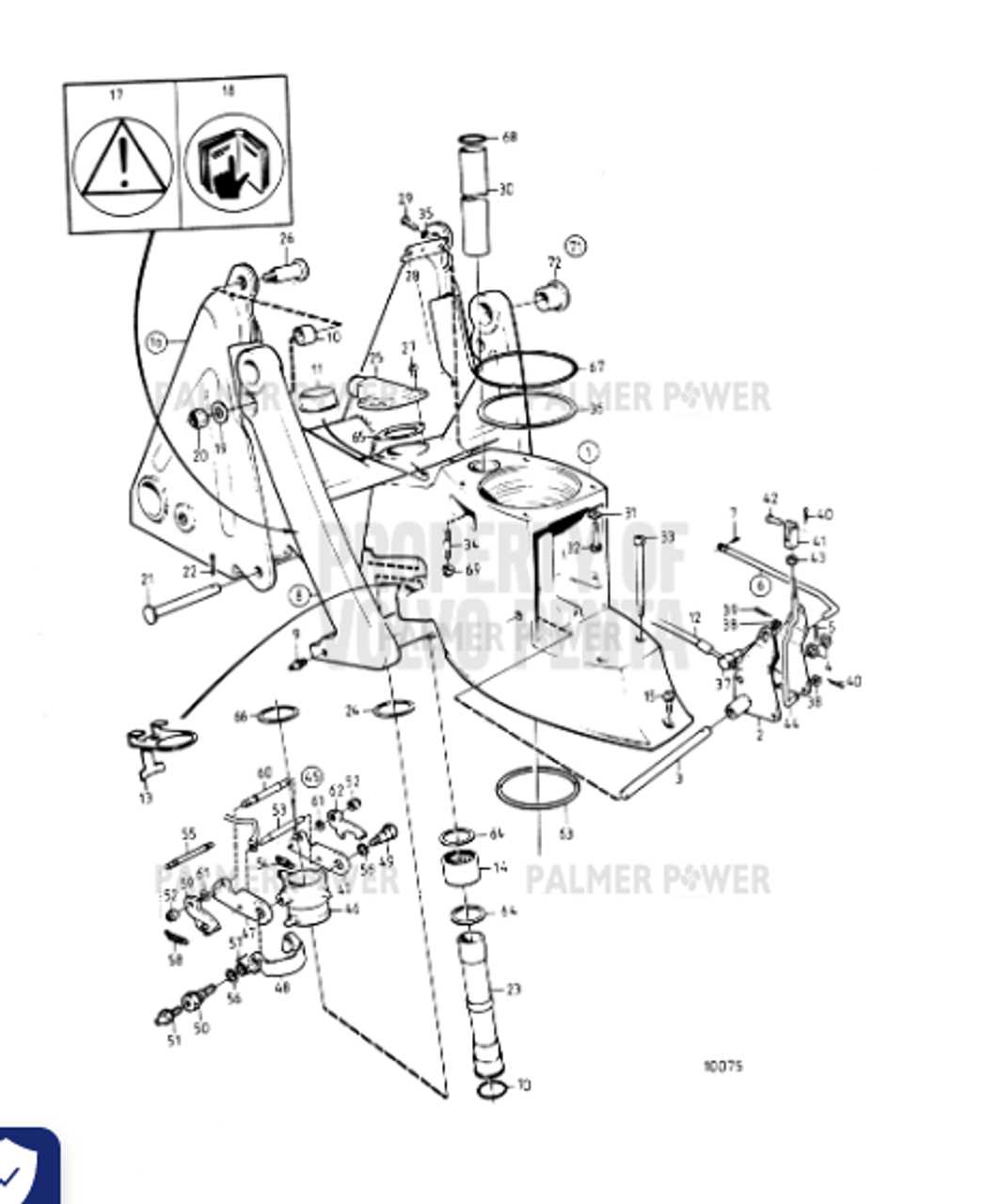

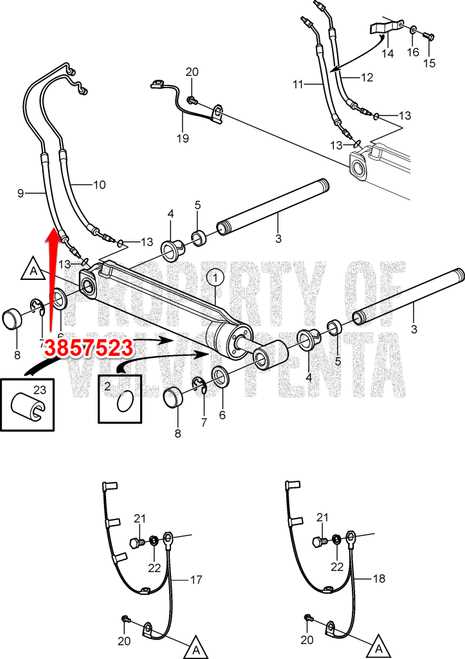

How to Read Sterndrive Diagrams

Understanding technical illustrations related to marine propulsion systems can be a daunting task. However, with the right approach, you can easily navigate these visuals to identify various components and their functions. This section provides insights on effectively interpreting these schematics.

Here are some key elements to consider when analyzing these illustrations:

- Symbols and Icons: Familiarize yourself with the common symbols used to represent different parts. Each symbol corresponds to a specific component, making it easier to identify them quickly.

- Lines and Arrows: Pay attention to the lines connecting different elements. Solid lines typically represent physical connections, while dashed lines may indicate functional relationships or fluid pathways.

- Labels: Look for textual descriptions accompanying each symbol. These annotations often provide essential information about the component, including part numbers and specifications.

- Color Codes: Some illustrations utilize color coding to distinguish between various systems or types of components. Understanding this color scheme can aid in faster identification.

By focusing on these aspects, you can enhance your ability to interpret technical visuals accurately. This skill is essential for anyone involved in maintenance or repairs of marine propulsion systems.

Identifying Parts in the Diagram

Understanding the components depicted in a technical illustration is essential for effective maintenance and troubleshooting. Each element serves a specific function, contributing to the overall performance of the system. By familiarizing yourself with the various symbols and representations, you can streamline repairs and enhancements.

First, start by examining the legend or key that often accompanies these visuals. This section provides critical insights into the meaning of each symbol, ensuring you can accurately identify what each part does. Pay attention to the color coding as it may indicate different materials or functions, which is crucial for selecting the right replacement components.

Next, focus on the layout of the illustration. Parts are typically arranged to reflect their physical relationships and assembly order. Recognizing these spatial arrangements can help in understanding how to approach disassembly or reassembly tasks efficiently. Look for groupings that might suggest a common functionality, making it easier to assess the system’s operation.

Lastly, consider referencing supplementary documentation that can provide further clarification on specific elements. Manuals and technical guides often include detailed descriptions that enhance your understanding of each component’s role. This knowledge empowers you to make informed decisions regarding repairs or upgrades.

Replacement Parts for Volvo Sterndrives

When it comes to maintaining marine propulsion systems, having access to high-quality components is essential. Proper functioning of these mechanisms ensures reliability and performance on the water. Understanding the different elements that may require replacement can help boat owners keep their vessels in optimal condition.

Common Components Needing Replacement

Various components within the drive system may wear out over time due to regular use and exposure to harsh marine environments. Among these, seals, bearings, and shafts are critical for the smooth operation of the propulsion system. Regular inspection and timely replacement of these elements can prevent more extensive damage and costly repairs.

Choosing the Right Components

When selecting new elements, it’s important to consider compatibility and quality. OEM (Original Equipment Manufacturer) components are often recommended, as they are specifically designed for the system, ensuring a perfect fit and reliable performance. Additionally, aftermarket options may provide cost-effective alternatives but require careful evaluation to ensure they meet necessary standards.

Tools Needed for Sterndrive Repairs

When undertaking maintenance or repairs on your marine propulsion system, having the right tools at hand is essential for ensuring efficiency and precision. A well-equipped toolbox can make the difference between a smooth operation and a frustrating experience.

Here’s a list of essential tools you should consider for your repair tasks:

- Socket Set: A comprehensive socket set will help you tackle various fasteners with ease.

- Wrenches: Both standard and adjustable wrenches are necessary for gripping and turning nuts and bolts.

- Screwdrivers: A variety of screwdrivers, including flathead and Phillips, will be required for different screw types.

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications.

- Propeller Puller: Ideal for removing the propeller without causing damage.

- Pliers: Needle-nose and slip-joint pliers can be invaluable for gripping and manipulating small components.

- Oil Filter Wrench: Specifically designed for easy removal of oil filters.

- Multimeter: A crucial tool for diagnosing electrical issues in your system.

- Cleaning Supplies: Brushes, rags, and solvents for keeping parts free from debris and corrosion.

- Safety Gear: Always prioritize safety with gloves, goggles, and other protective equipment.

Having these tools ready will not only facilitate repairs but also enhance your confidence in managing your vessel’s maintenance needs.

Step-by-Step Repair Procedures

Repairing marine propulsion systems requires a methodical approach to ensure optimal performance and longevity. This section outlines a series of procedures that can help you navigate the repair process efficiently, focusing on common components and potential issues.

Preparation and Safety

Before beginning any repair work, proper preparation is essential to ensure safety and effectiveness. Follow these initial steps:

- Gather all necessary tools and replacement components.

- Ensure that the workspace is clean and organized.

- Disconnect the battery and drain any fluids to prevent spills.

- Wear appropriate safety gear, including gloves and goggles.

Repair Steps

Follow these systematic steps to address common issues:

- Inspection: Examine the unit for visible damage, corrosion, or leaks. Take note of any abnormal wear.

- Disassembly: Carefully disassemble the unit, documenting each step. Keep track of all screws and components.

- Cleaning: Clean all parts thoroughly to remove debris, salt, and corrosion. Use a suitable cleaner for each material.

- Replacement: Replace worn or damaged components with new ones, ensuring compatibility.

- Reassembly: Follow your documentation to reassemble the unit, ensuring that all parts are secure.

- Testing: Reconnect the battery and conduct a thorough test to verify functionality. Check for leaks and unusual noises.

By adhering to these structured procedures, you can effectively manage repairs and enhance the reliability of your marine propulsion system.

Tips for Troubleshooting Sterndrive Problems

Tackling issues with marine propulsion systems can be challenging, but understanding common symptoms and their causes is essential for effective resolution. This guide offers practical insights to help you identify and rectify common complications that may arise during operation.

Common Symptoms and Their Causes

One of the first steps in troubleshooting is recognizing the signs of malfunction. Unusual noises, vibration, or difficulty in shifting gears may indicate underlying issues. Inspecting the fluid levels and checking for leaks can reveal problems with seals or pumps. Additionally, abnormal temperature readings may suggest blockages or cooling system failures.

Diagnostic Steps to Take

Begin with a visual inspection of the external components. Look for signs of wear or damage, particularly in the hoses and connections. Next, perform a functionality test to assess the response of the control systems. Using diagnostic tools can provide valuable data on system performance, aiding in pinpointing the source of the problem. Always refer to the manufacturer’s specifications for guidance on proper maintenance and repairs.

Resources for Volvo Sterndrive Owners

For enthusiasts and operators of aquatic vessels equipped with specific propulsion systems, having access to reliable information and quality resources is essential for maintaining performance and longevity. This section highlights various avenues to enhance knowledge and ensure smooth operation of your marine equipment.

Online Forums and Communities

Engaging with fellow boaters can provide invaluable insights and support. Online platforms offer a space for sharing experiences, troubleshooting issues, and discussing upgrades.

Manufacturer Websites and Manuals

Accessing official websites allows owners to find technical manuals, maintenance guides, and service bulletins. These resources are crucial for understanding the intricacies of your system and ensuring adherence to best practices.

| Resource Type | Description | Link |

|---|---|---|

| Online Forums | Communities for discussion and troubleshooting | boatingforum.com |

| Technical Manuals | Official documentation for maintenance and service | marine-manuals.com |

| Parts Retailers | Suppliers for high-quality components | boatparts.com |

Choosing Quality Aftermarket Parts

When it comes to maintaining and upgrading your watercraft, selecting high-quality replacement components is essential. The right choice can significantly enhance performance and longevity, ensuring your investment is well-protected. Below are key considerations to keep in mind when seeking alternatives to original equipment.

- Research the Brand: Look for manufacturers with a solid reputation. Reviews and testimonials can provide insight into their reliability and product performance.

- Material Quality: Evaluate the materials used in construction. High-grade materials often result in better durability and efficiency.

- Compatibility: Ensure that the components you choose are compatible with your specific model. Mismatched items can lead to malfunctions and additional costs.

- Warranty and Support: Opt for products that come with a warranty. This indicates the manufacturer’s confidence in their offerings and provides you with peace of mind.

- Price vs. Value: While it can be tempting to go for the cheapest option, consider the long-term value. Investing slightly more in a quality item can save you from frequent replacements.

By focusing on these factors, you can make informed decisions that enhance the performance and reliability of your vessel.

FAQs About Volvo Sterndrive Systems

This section addresses common inquiries regarding marine propulsion systems, focusing on their components, functionality, and maintenance. Understanding these aspects can enhance your boating experience and ensure optimal performance.

Common Questions

- What are the main components of a marine propulsion system?

- Engine

- Transmission

- Drive unit

- Propeller

- How can I improve the performance of my system?

- Regular maintenance

- Proper propeller selection

- Monitoring engine performance

- What should I do if I experience unusual noises?

- Inspect for loose components

- Check fluid levels

- Consult a professional technician

Maintenance Tips

- Perform routine inspections every season.

- Replace worn or damaged components promptly.

- Keep the drive unit clean and free of debris.

- Monitor fluid conditions and levels regularly.