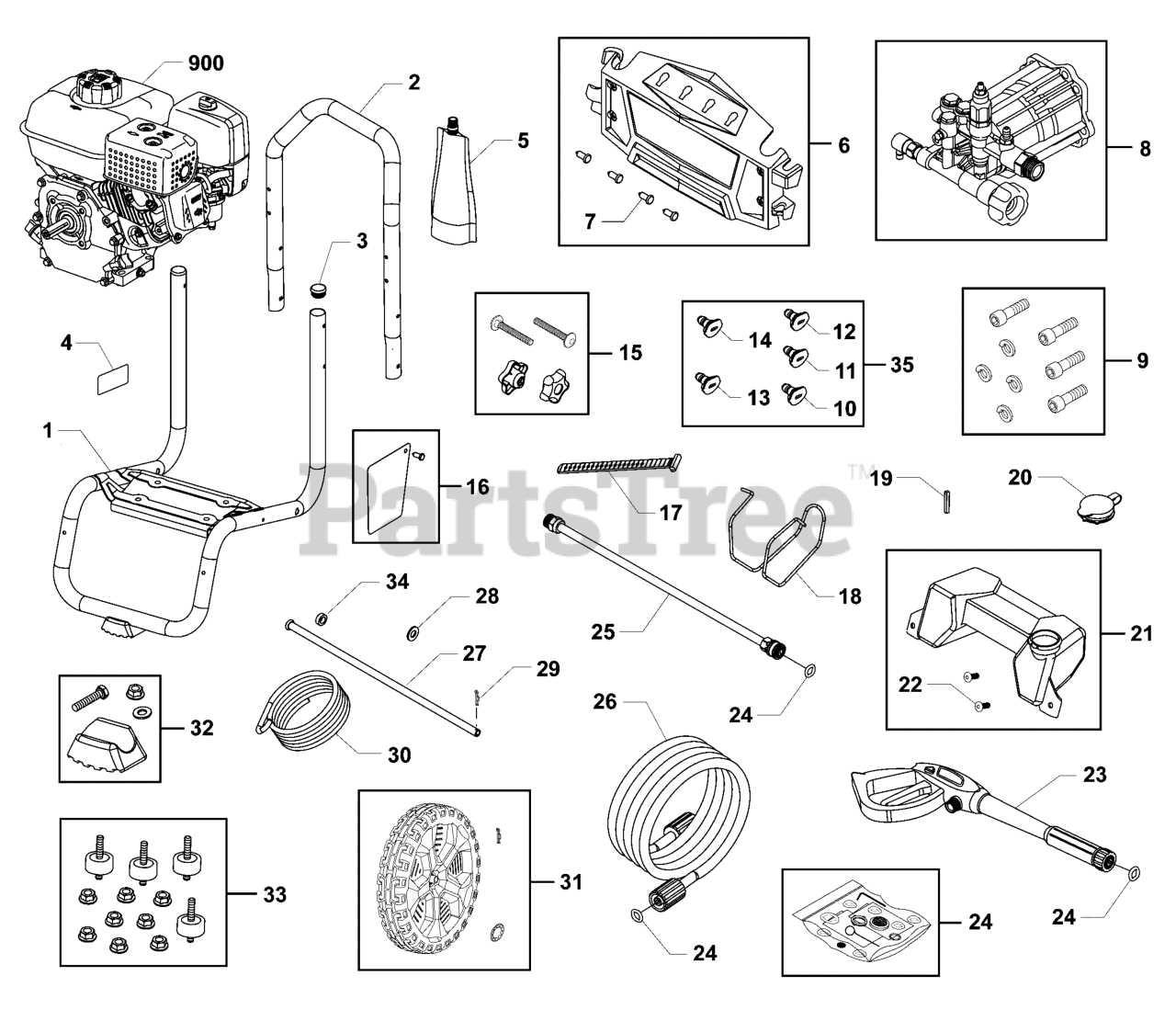

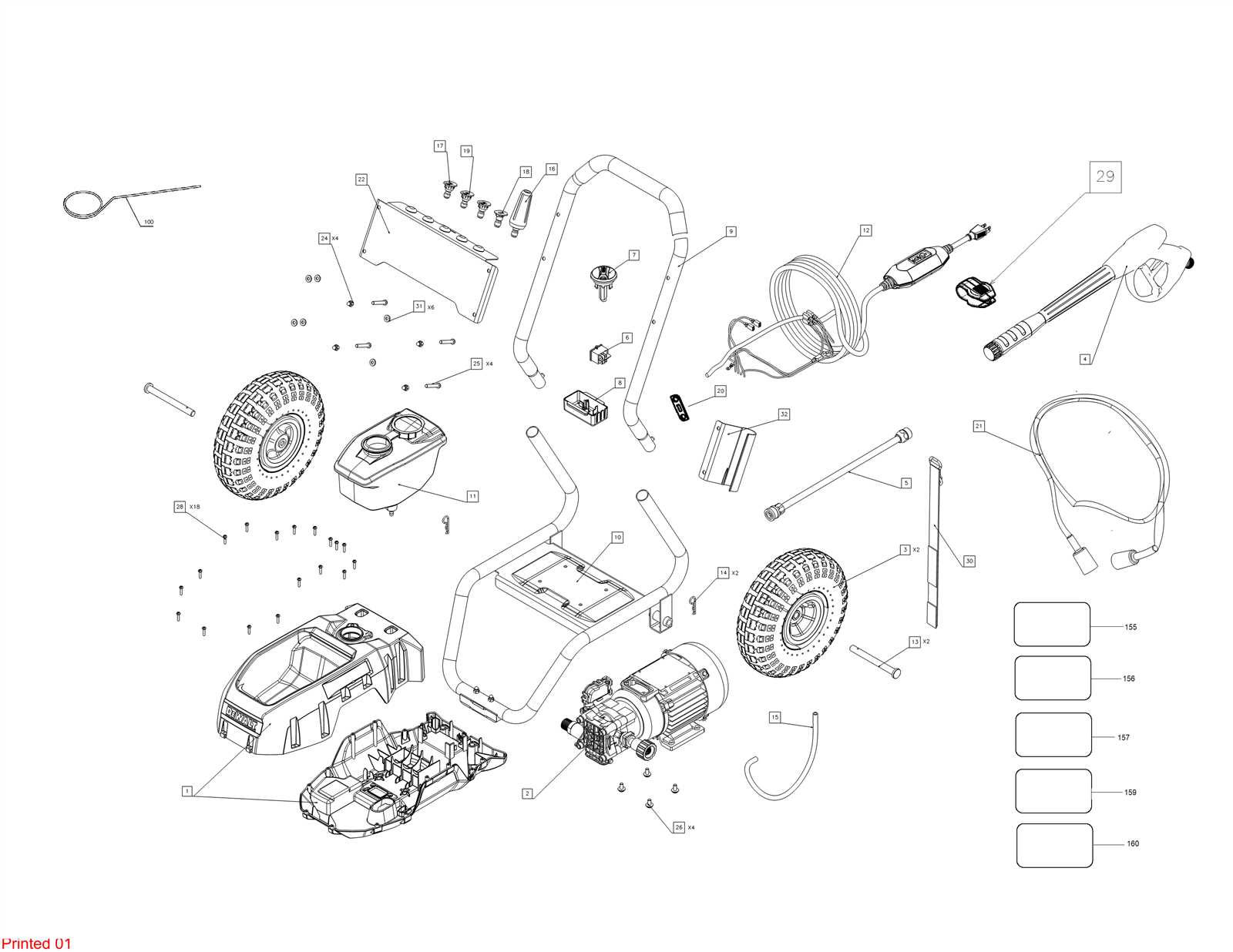

Dewalt Pressure Washer Parts Diagram Overview

Maintaining outdoor equipment can often seem daunting, especially when it comes to comprehending the various elements that make up a machine. A thorough grasp of how these components interact is crucial for effective upkeep and troubleshooting. By visualizing the configuration of each piece, users can streamline their maintenance processes and enhance the longevity of their devices.

Visual aids play a vital role in this understanding, providing a clear representation of how different parts fit together and function. By examining a comprehensive layout, one can identify key sections and their roles in the overall operation. This knowledge is not only beneficial for routine care but also empowers users to make informed decisions about repairs and replacements.

Additionally, familiarity with the essential elements and their respective placements fosters confidence in handling the equipment. Users who can navigate the intricacies of their tools are better equipped to tackle challenges that arise, ensuring that their outdoor tasks are completed efficiently and effectively. Engaging with this material paves the way for a deeper appreciation of machinery and its inner workings.

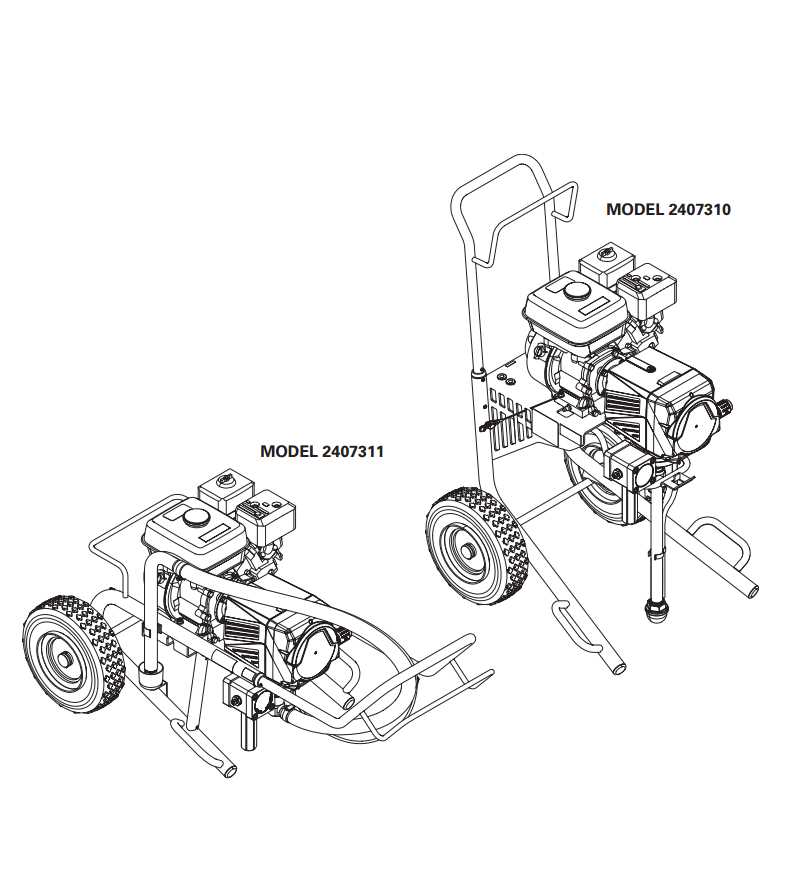

Dewalt Pressure Washer Overview

This section provides a comprehensive look at a well-known brand’s cleaning equipment designed for various outdoor tasks. These machines are built to deliver exceptional performance, making them a favorite among homeowners and professionals alike. Understanding their features and components can enhance your experience and ensure efficient operation.

Key Features

These cleaning units are typically equipped with powerful motors, high-capacity tanks, and versatile nozzles. The combination of high water flow and adjustable pressure settings allows users to tackle a range of cleaning challenges, from delicate surfaces to tough grime. Additionally, many models offer convenient mobility options, making it easier to navigate different areas.

Maintenance and Care

Proper upkeep is essential for longevity and optimal functionality. Regular checks on hoses, connections, and filters can prevent common issues and ensure smooth operation. Investing time in understanding the internal structure of these devices will empower users to troubleshoot minor problems effectively. Knowledge of the essential components can significantly enhance the overall performance and lifespan of the equipment.

Importance of Understanding Parts Diagram

Grasping the intricacies of assembly schematics is crucial for efficient maintenance and repair. A clear visual representation aids in recognizing components and their relationships, ultimately enhancing the longevity and performance of any machinery.

Familiarity with these schematics offers several benefits:

- Improved Troubleshooting: Quickly identify malfunctioning components, reducing downtime.

- Efficient Repairs: Understand the assembly process, making it easier to replace or fix specific elements.

- Cost Savings: Avoid unnecessary service calls by addressing issues independently.

- Enhanced Safety: Recognize critical parts that affect operational safety, minimizing risks during use.

In summary, a solid understanding of these illustrations empowers users to maintain their equipment effectively, ensuring optimal functionality and extending service life.

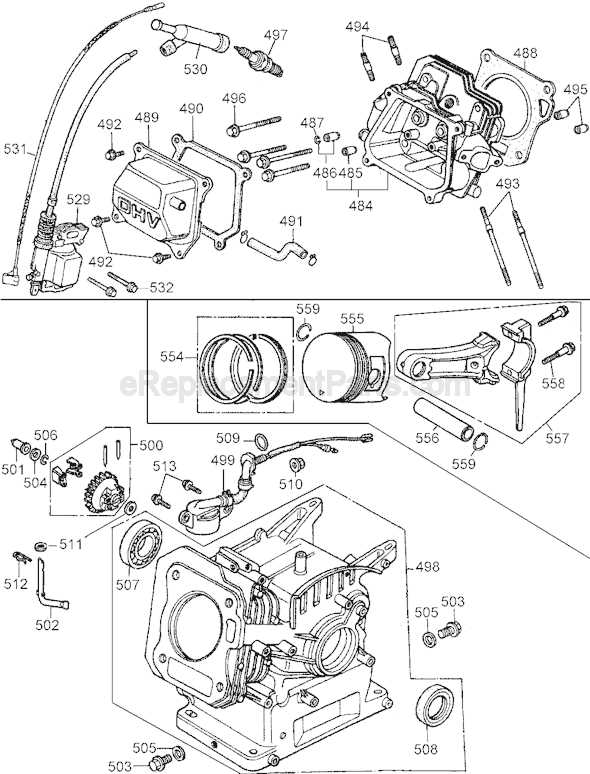

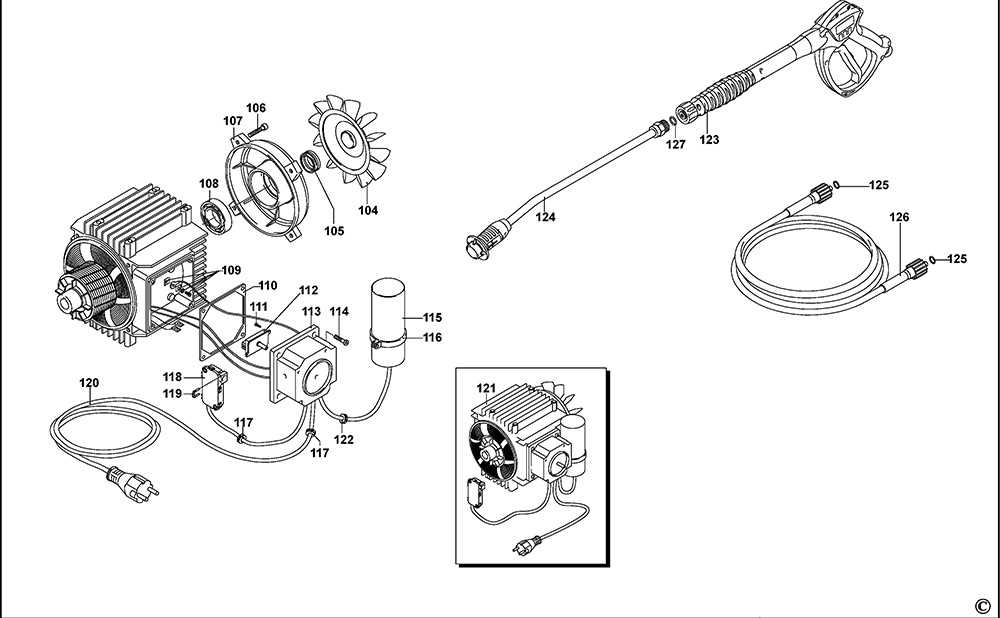

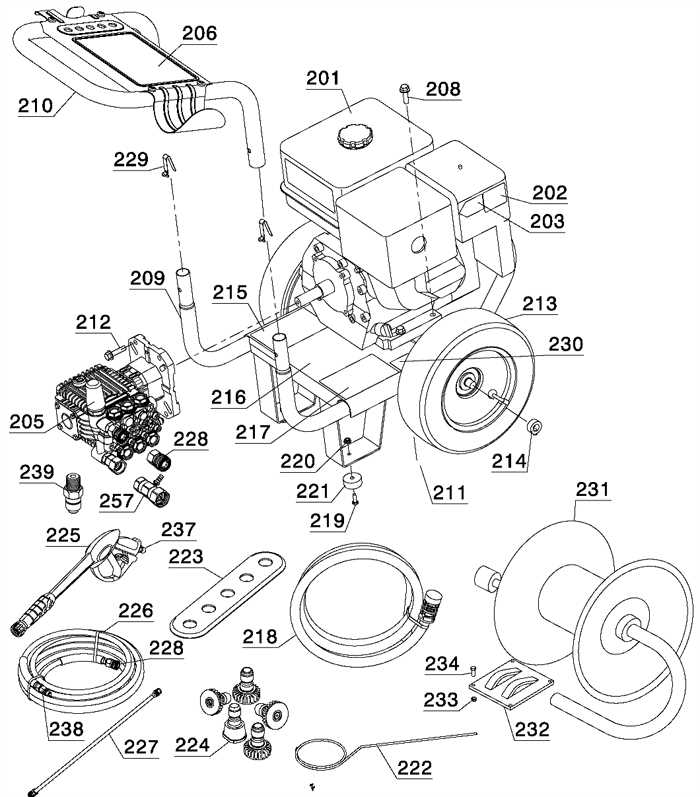

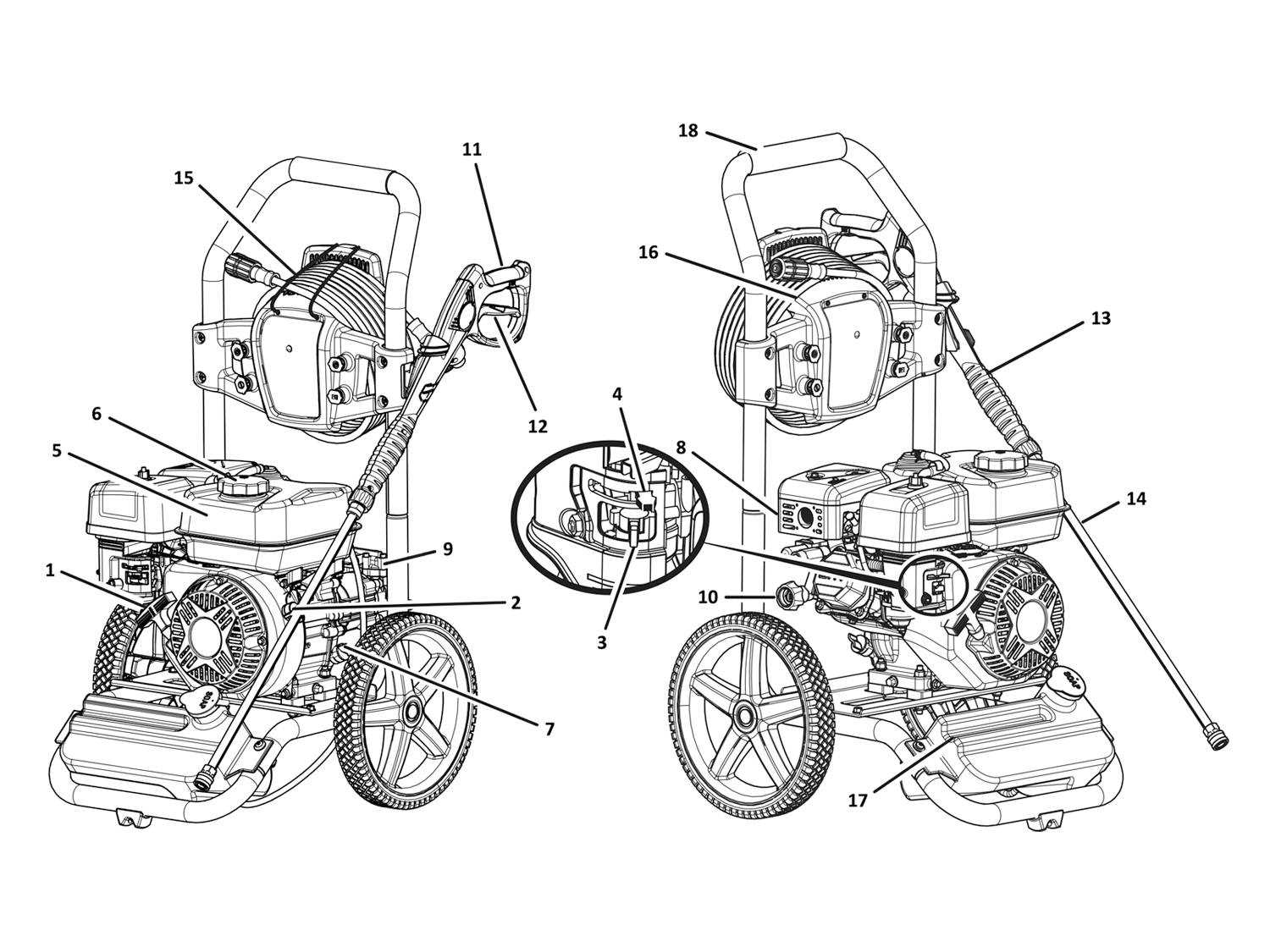

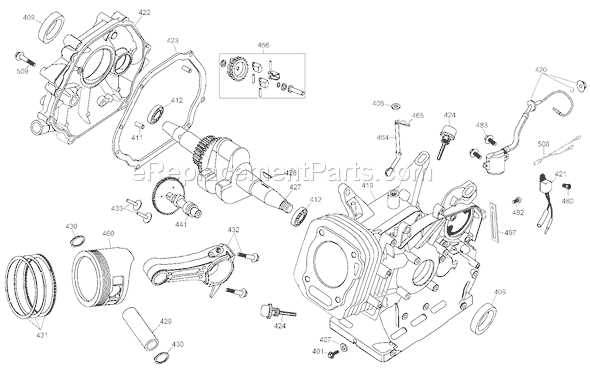

Main Components of Dewalt Pressure Washers

Understanding the essential elements of these cleaning machines can enhance your experience and efficiency during use. Each component plays a crucial role in ensuring optimal performance and durability. Familiarizing yourself with these key parts will help you maintain and troubleshoot your device effectively.

Key Elements

- Motor: The heart of the machine, responsible for providing the necessary power to operate various functions.

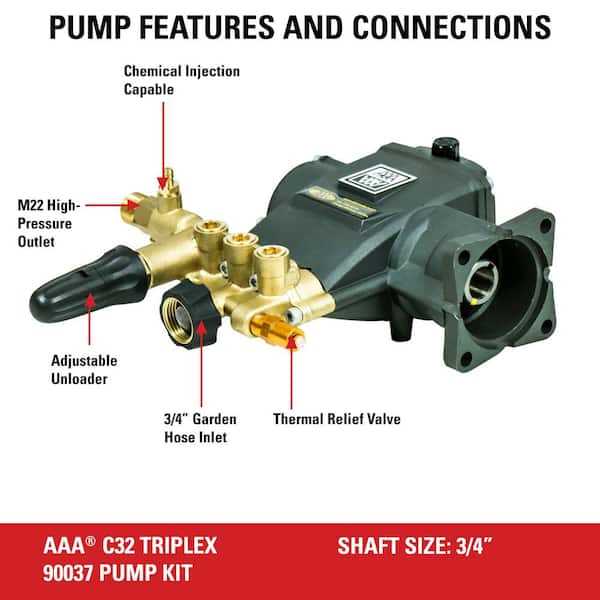

- Pump: This component generates the high-pressure flow needed to propel water through the nozzle, facilitating thorough cleaning.

- Frame: The structural base that houses all components, offering stability and support during operation.

- Hose: A flexible conduit that transports water from the source to the nozzle, available in various lengths for versatility.

- Nozzle: The attachment that controls the spray pattern, allowing users to adjust the intensity of the water stream.

- Trigger: The control mechanism for activating the flow of water, providing ease of use and safety.

Additional Features

- Wheels: Designed for mobility, making it easy to transport the machine across different surfaces.

- Water Inlet: The entry point for water, typically featuring filters to prevent debris from entering the system.

- Accessory Storage: Compartments or hooks that facilitate the organization of additional tools and attachments.

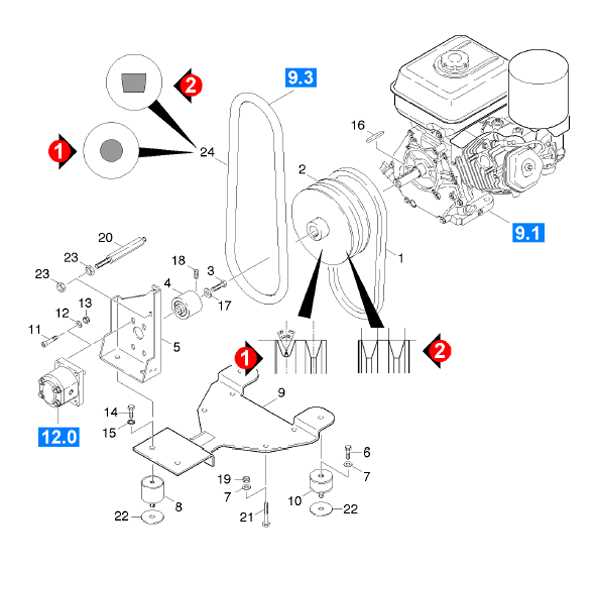

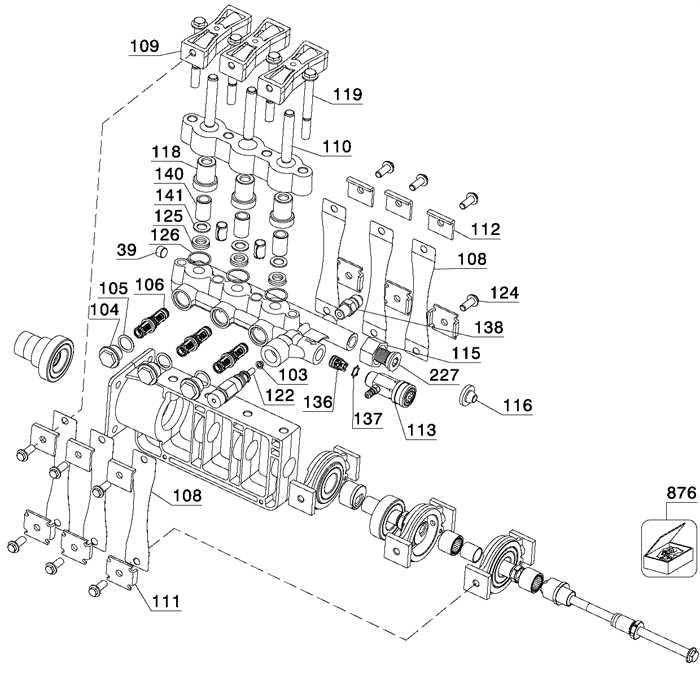

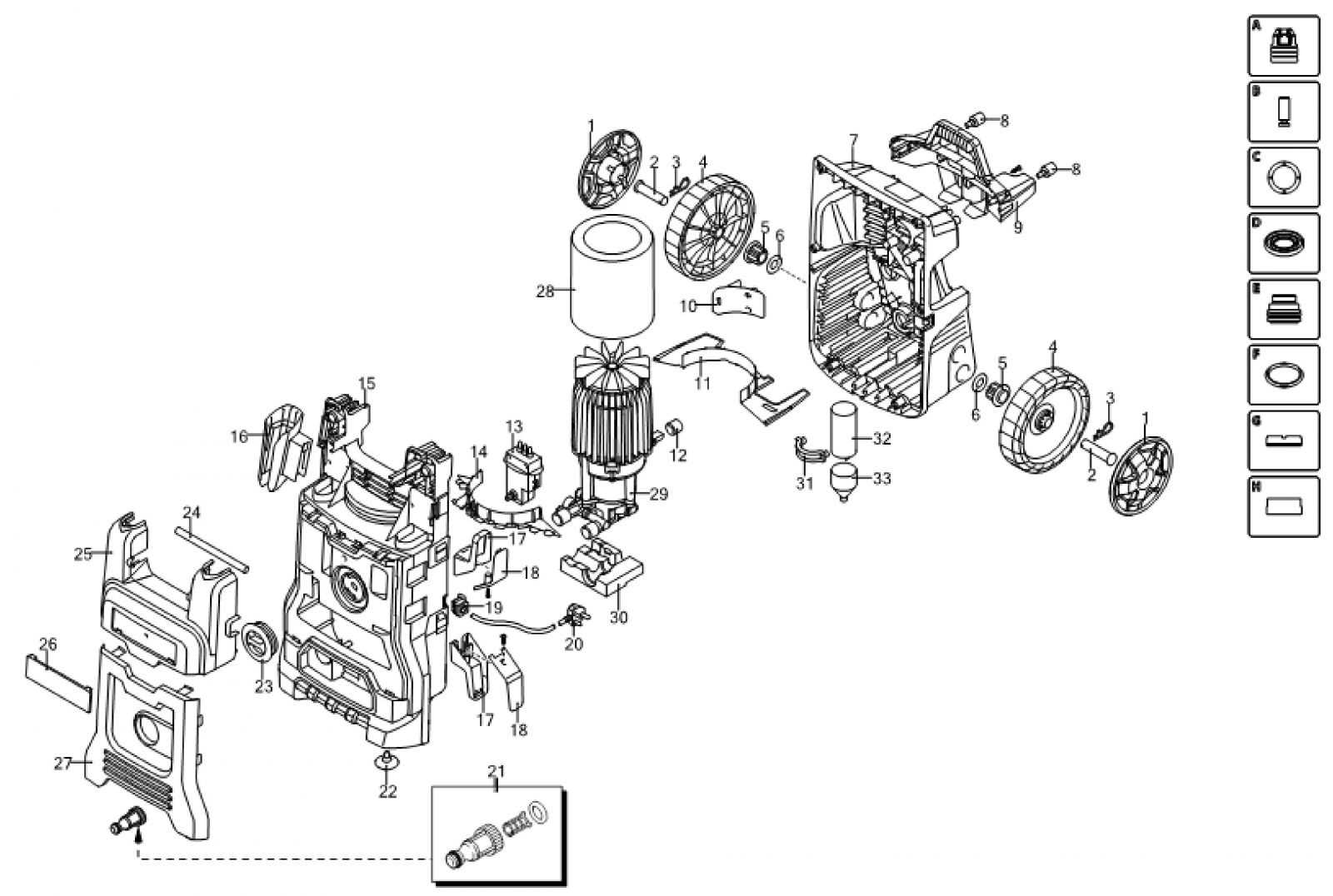

How to Read the Parts Diagram

Understanding a component schematic is essential for effective maintenance and repairs of your equipment. These visual representations simplify the identification and organization of various elements, ensuring that you can efficiently locate and replace any necessary components.

Identifying Key Features

When examining a component layout, focus on these critical aspects:

- Labels: Each item is typically labeled with a part number or description, aiding in quick identification.

- Sections: The layout may be divided into sections based on functionality, making it easier to find related components.

- Connections: Arrows or lines often indicate how parts connect or interact, which is crucial for understanding assembly.

Using the Diagram for Repairs

To effectively utilize the schematic during repairs, follow these steps:

- Identify the component that needs attention using the labels.

- Refer to the schematic to understand how the component fits within the assembly.

- Check the connections and any associated parts that may also require maintenance.

- Gather the necessary replacements based on the identified part numbers.

- Proceed with disassembly and replacement, following the reverse order of the schematic if applicable.

By mastering the art of reading these visuals, you can enhance your repair skills and ensure your equipment remains in top condition.

Common Issues with Pressure Washer Parts

Understanding the frequent problems that can arise with various components of cleaning equipment is essential for effective maintenance and troubleshooting. Many users encounter similar challenges that can hinder performance and efficiency. Recognizing these issues can lead to quicker resolutions and prolonged lifespan of the machinery.

One of the most common problems involves leaks, which can occur at connection points or within the hoses. These leaks not only reduce the overall effectiveness but can also lead to water waste. Another frequent issue is the buildup of debris, which can clog filters and nozzles, affecting the flow of liquid and the intensity of the spray. Regular cleaning and inspections can help mitigate this problem.

Additionally, wear and tear on seals and gaskets is a notable concern. Over time, these components can deteriorate, leading to diminished performance and potential breakdowns. It’s crucial to monitor the condition of these items and replace them as needed to ensure optimal operation.

Furthermore, issues related to the motor or engine can arise, such as starting difficulties or unusual noises. These symptoms often indicate deeper mechanical problems that should be addressed promptly. Regular maintenance checks can help identify such issues early, preventing more significant repairs down the line.

By staying vigilant about these common challenges, users can enhance the reliability and functionality of their cleaning equipment, ensuring it operates smoothly and efficiently over time.

Identifying Wear and Tear Signs

Recognizing the indicators of deterioration is crucial for maintaining equipment efficiency and longevity. Various components may exhibit signs of wear that can affect overall performance. Being attentive to these signs helps ensure optimal functioning and prevents potential breakdowns.

Common signs of degradation include unusual noises, leaks, and reduced efficiency during operation. Identifying these issues early can save time and costs associated with extensive repairs. Regular inspection and maintenance can prolong the life of essential components.

| Indicator | Possible Causes | Recommended Actions |

|---|---|---|

| Unusual Noises | Loose fittings or damaged parts | Tighten connections; replace faulty components |

| Fluid Leaks | Worn seals or cracks | Inspect seals; replace damaged parts |

| Decreased Performance | Clogged filters or worn nozzles | Clean filters; replace nozzles as necessary |

| Overheating | Poor ventilation or clogged vents | Ensure adequate airflow; clean vents regularly |

By regularly monitoring these signs, users can effectively manage the condition of their equipment, ensuring it operates smoothly and efficiently.

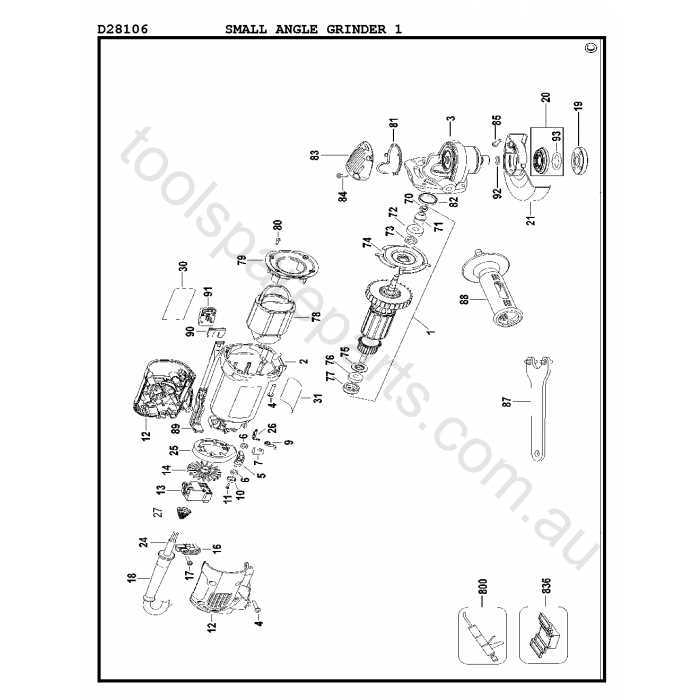

Replacement Parts for Dewalt Models

When it comes to maintaining your equipment, understanding the components that may require substitution is essential. Quality performance often hinges on the reliability of individual elements. This section delves into the essential replacements that ensure your tools operate smoothly and efficiently.

Common Components Needing Replacement

Throughout the lifespan of your equipment, certain elements may wear out or become damaged. Hoses, nozzles, and filters are among the most frequently replaced items. Regular inspection can help identify these parts before they lead to significant performance issues. Keeping spares on hand can save time and effort, allowing for quick maintenance when necessary.

Choosing Quality Alternatives

When selecting new components, it’s important to prioritize quality. Opting for reputable brands ensures that your replacements will not only fit correctly but also withstand the rigors of use. Compatibility with your existing machinery is crucial; always check specifications before making a purchase. Investing in high-quality replacements can extend the lifespan of your tools and enhance their overall performance.

Where to Find Authentic Components

Locating genuine elements for your equipment is crucial for optimal performance and longevity. Authentic components ensure that your machine operates efficiently, maintaining the quality and reliability expected from a reputable brand.

Authorized Retailers are the primary source for genuine items. Visiting a licensed distributor guarantees that you receive products that meet the manufacturer’s specifications. Check the brand’s official website for a list of approved sellers in your area.

Online Marketplaces can also provide a variety of options, but caution is essential. Always verify the seller’s credentials and look for reviews to ensure the authenticity of the components being offered. Reputable platforms often have filters that allow you to choose verified products.

Local Repair Shops may carry authentic parts or be able to order them directly from the manufacturer. These businesses often have a wealth of knowledge and can provide advice on the best components for your specific needs.

Ultimately, investing time in sourcing legitimate items not only enhances the performance of your equipment but also extends its lifespan, providing peace of mind for years to come.

Maintenance Tips for Longevity

To ensure the long-lasting performance of your cleaning equipment, regular upkeep is essential. Simple preventive measures can significantly extend the lifespan and efficiency of your machine, minimizing the need for costly repairs and replacements.

1. Regular Cleaning: Keep the exterior and interior components free from debris and dirt. A clean machine operates more efficiently and reduces wear on essential elements.

2. Check for Wear: Frequently inspect hoses, nozzles, and other attachments for signs of damage or deterioration. Addressing these issues promptly can prevent further complications.

3. Proper Storage: Store your equipment in a dry, sheltered area to protect it from the elements. This will help prevent rust and corrosion, which can compromise performance.

4. Fluid Maintenance: Regularly check and replace fluids according to the manufacturer’s guidelines. Keeping the internal components lubricated is vital for smooth operation.

5. Follow Usage Guidelines: Adhere to the recommended usage practices and pressure settings. Overworking your machine can lead to premature failure and inefficiency.

6. Seasonal Checks: At the start of each season, conduct a thorough inspection and maintenance routine. This proactive approach can help identify any potential issues before they become significant problems.

Implementing these maintenance practices will not only enhance the performance of your cleaning device but also ensure it remains a reliable tool for years to come.

Upgrading Your Pressure Washer Parts

Enhancing the components of your cleaning equipment can significantly improve its performance and longevity. By focusing on key elements, you can transform a standard device into a more efficient tool, capable of tackling a wider range of tasks with ease. Upgrading not only boosts functionality but also ensures that your machinery operates at its best, providing better results with less effort.

Choosing Quality Components

Selecting high-quality replacements is crucial for maximizing efficiency. Look for durable materials that withstand wear and tear, ensuring your equipment remains reliable over time. Researching reputable brands can help you identify parts that not only fit perfectly but also offer improved performance compared to the original components.

Benefits of Regular Upgrades

Regularly updating your equipment’s components can lead to several advantages. Enhanced efficiency often results in lower energy consumption, saving you money in the long run. Additionally, improved functionality allows for quicker and more effective cleaning, making your tasks less time-consuming. Embracing upgrades ultimately contributes to a more satisfying and productive experience.

Understanding Pressure Washer Accessories

In the realm of outdoor cleaning, the effectiveness of a machine can be significantly enhanced by various additional tools and components. These accessories play a crucial role in optimizing performance and expanding functionality, allowing users to tackle a diverse range of tasks with ease.

Types of Accessories

Several types of attachments are available, each designed to address specific cleaning needs. Nozzles are among the most important, offering different spray patterns to accommodate various surfaces. Surface cleaners provide an efficient way to clean large areas uniformly, while extension wands enable access to high or hard-to-reach spots without the need for ladders. Additionally, foam cannons can enhance the cleaning process by delivering detergent more effectively.

Benefits of Using Accessories

Utilizing these additional tools not only improves efficiency but also extends the lifespan of the main unit. By choosing the right attachments, users can minimize wear and tear on the primary equipment. Furthermore, accessories can make challenging tasks easier, allowing for a more thorough and enjoyable cleaning experience.

DIY Repairs vs. Professional Services

When it comes to fixing household equipment, homeowners often face a choice: tackle the repairs themselves or hire a specialist. Each approach has its benefits and drawbacks, depending on various factors such as skill level, complexity of the issue, and time constraints. Understanding these differences can help in making an informed decision that suits one’s needs.

Advantages of DIY Repairs

Engaging in self-repairs can be a rewarding experience. Not only does it provide an opportunity to learn new skills, but it can also save money that would otherwise go towards labor costs. Many find satisfaction in successfully resolving issues without external help. Furthermore, DIY repairs can be quicker, as there is no need to wait for an appointment with a technician.

Benefits of Hiring Professionals

On the other hand, opting for professional assistance ensures that the work is done by someone with expertise. This can be crucial for complicated problems that require specialized knowledge or tools. Professionals often provide warranties on their services, offering peace of mind. Additionally, using a trained technician can prevent potential mistakes that might arise from inexperience.

| Aspect | DIY Repairs | Professional Services |

|---|---|---|

| Cost | Generally lower | Higher due to labor fees |

| Time | Can be faster if knowledgeable | May require scheduling |

| Expertise | Varies by individual | High and specialized |

| Warranty | None typically | Often includes warranty |