Understanding the Honda GC190 Pressure Washer Pump Parts Diagram

When it comes to maintaining outdoor spaces, having a reliable cleaning apparatus is essential. These machines consist of various elements that work in unison to deliver effective results. Knowing the configuration of these components can greatly enhance your ability to troubleshoot and perform necessary maintenance.

Identifying the different sections of the cleaning device is crucial for anyone looking to optimize performance. Each segment serves a unique function, contributing to the overall efficiency of the system. By familiarizing yourself with these components, you can ensure that your equipment operates at its best.

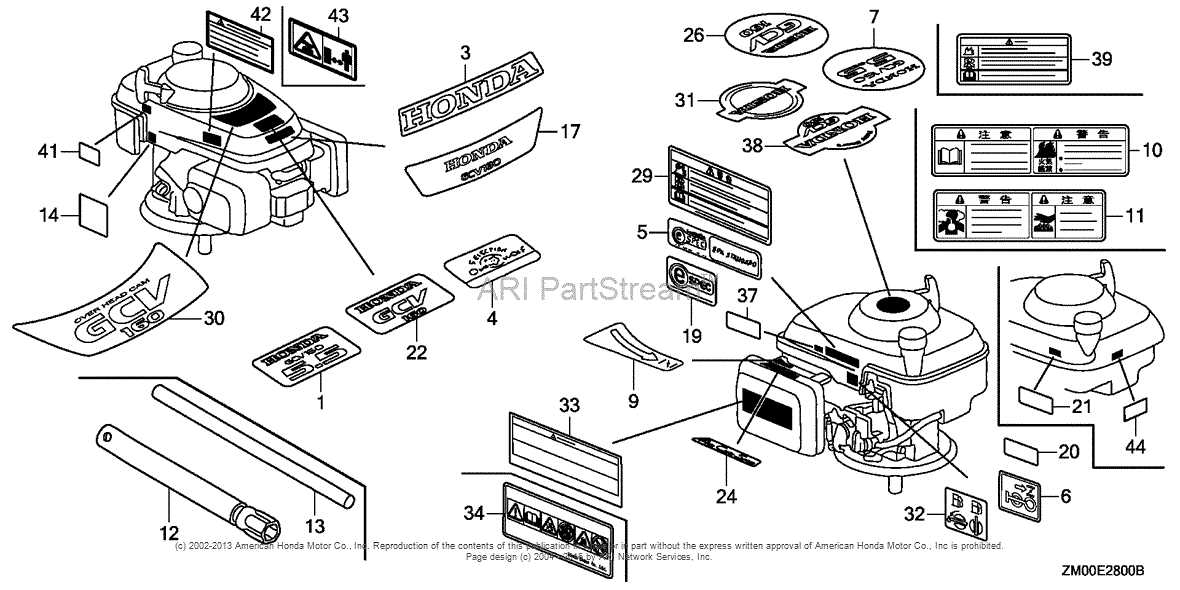

In this article, we will explore a detailed illustration showcasing the intricate arrangement of the various elements within this specific cleaning machine. Understanding how each piece fits into the larger system will empower users to conduct repairs and upgrades more effectively.

Understanding the Honda GC190 Pump

This section provides insights into the components and functions of a specific type of mechanical device designed for fluid movement. It plays a crucial role in enhancing efficiency and ensuring optimal performance during usage. By exploring its various elements, users can better appreciate how each part contributes to the overall effectiveness of the system.

Key Components

Familiarizing oneself with the essential elements of this equipment allows for improved maintenance and troubleshooting. Each component has a distinct purpose, working in harmony to deliver high performance. Below is a summary of the primary components involved:

| Component | Function |

|---|---|

| Housing | Encloses and protects internal parts while providing structural integrity. |

| Impeller | Generates fluid movement through rotation, creating pressure for effective operation. |

| Seals | Prevent leaks and maintain internal pressure, ensuring smooth functionality. |

| Valves | Control the flow of the liquid, allowing for precise operation based on user requirements. |

Importance of Regular Maintenance

To ensure longevity and reliability, routine care and inspection of this device are essential. Proper upkeep not only enhances performance but also minimizes the risk of malfunction. Being aware of the components and their functions empowers users to identify potential issues early and address them promptly.

Key Components of Pressure Washer Pumps

The effectiveness of a high-pressure cleaning device relies heavily on its essential elements. Understanding these components can enhance maintenance and ensure optimal performance during operation. Each part plays a crucial role in generating and directing water flow, impacting efficiency and cleaning capability.

Critical Elements of Operation

Among the most vital components are the cylinder and the piston. The cylinder houses the piston, which moves back and forth to create pressure. This movement compresses the water, facilitating a high-force output necessary for effective cleaning. Additionally, the valves regulate water intake and release, ensuring a steady flow during operation.

Additional Supporting Components

Other important parts include the gearbox, which connects the motor to the piston mechanism, and the seal assembly, responsible for preventing leaks and maintaining pressure integrity. The intake filter is another critical feature, preventing debris from entering the system and ensuring longevity and reliability.

How to Read Parts Diagrams

Understanding schematic representations of components is essential for effective maintenance and repair. These illustrations serve as visual guides, enabling users to identify individual elements and comprehend their interrelationships. By mastering the art of interpreting these visuals, you can streamline your repair processes and enhance your overall knowledge of machinery.

Key Elements of Diagrams

- Labels: Each component is typically marked with a unique identifier. Familiarize yourself with these labels to easily locate parts.

- Legend: Many diagrams include a legend explaining symbols and colors used. Refer to this to clarify any uncertainties.

- Connections: Look for lines indicating how components are linked. Understanding these connections is crucial for troubleshooting.

Steps for Effective Reading

- Start with the Overview: Before diving into details, glance at the entire illustration to get a general sense of layout.

- Focus on Sections: Break down the diagram into manageable sections to avoid feeling overwhelmed.

- Cross-Reference with Manuals: Use accompanying literature to gain deeper insights into the function and maintenance of each component.

- Take Notes: Jot down any questions or observations as you study the representation, helping reinforce your understanding.

Common Issues with GC190 Pumps

When dealing with outdoor cleaning equipment, users may encounter various challenges that hinder performance. Understanding these issues is essential for effective maintenance and troubleshooting. Several common problems can arise, impacting efficiency and functionality, often stemming from wear and tear, improper use, or lack of regular upkeep.

Loss of Pressure

One frequent issue is a noticeable drop in output force. This can be attributed to several factors, such as blocked hoses or fittings, which restrict fluid flow. Additionally, worn seals may lead to leaks, further diminishing operational strength. Regularly inspecting connections and replacing worn components can help restore optimal performance.

Unusual Noises

Another concern is the emergence of strange sounds during operation. These noises can signal underlying mechanical problems, such as misalignment or insufficient lubrication. Addressing these symptoms promptly is crucial, as neglect may result in more significant damage. Routine maintenance checks, including lubrication and part alignment, are vital for preventing these issues.

Maintenance Tips for Longevity

Proper upkeep is essential to ensure the extended lifespan of your outdoor cleaning equipment. Regular maintenance not only enhances performance but also prevents costly repairs and unexpected breakdowns. By following a few straightforward practices, you can keep your machinery running smoothly for years to come.

Regular Inspection

Consistent checks on your equipment are vital. Look for any signs of wear or damage, especially on seals and hoses. Addressing small issues promptly can prevent them from escalating into major problems. Additionally, ensure all connections are secure to maintain optimal functionality.

Cleanliness is Key

Keeping your device clean is crucial. After each use, remove any debris and residue that may accumulate. Using a soft cloth and mild detergent can help maintain the exterior, while checking internal components periodically ensures they are free from buildup. This practice not only preserves the equipment’s appearance but also its efficiency.

Replacement Parts Availability and Sources

When it comes to maintaining equipment, finding the right components is essential for optimal performance. Users often seek reliable sources for high-quality replacements to ensure longevity and efficiency. Various options are available, catering to different needs and preferences.

Local Retailers: Many individuals prefer to visit local stores that specialize in outdoor equipment or machinery. These establishments often stock a range of components, allowing for immediate purchase and expert advice. It’s beneficial to call ahead to confirm availability.

Online Marketplaces: The internet provides a vast selection of retailers offering components. Websites dedicated to machinery parts can be particularly useful, providing detailed descriptions and customer reviews. This option often allows for competitive pricing and convenient home delivery.

Manufacturer Websites: Official manufacturer websites can be an excellent source for original components. These sites typically ensure authenticity and compatibility, which is crucial for maintaining equipment integrity.

Second-Hand Options: For those on a budget, second-hand marketplaces may offer viable solutions. However, it’s important to verify the condition and compatibility of used items before making a purchase.

In summary, there are multiple avenues for sourcing necessary components, each with its advantages. Careful consideration of these options can lead to effective maintenance and enhanced performance of your machinery.

Tools Needed for Pump Repairs

Repairing mechanical components requires a specific set of instruments to ensure efficiency and precision. Whether you’re addressing minor issues or conducting a thorough overhaul, having the right tools on hand can significantly ease the process and improve outcomes.

Essential Tools

- Wrenches: A variety of sizes will help you tackle different bolts and fittings.

- Screwdrivers: Both flathead and Phillips types are necessary for various screws.

- Socket Set: Useful for removing and installing nuts and bolts quickly.

- Pliers: Ideal for gripping and manipulating components.

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications.

Additional Equipment

- Sealant: Essential for preventing leaks in joints and connections.

- Cleaning Supplies: Brushes and solvents help in removing debris and buildup.

- Replacement Seals and O-rings: Necessary for maintaining proper function and preventing leaks.

- Safety Gear: Gloves and goggles are important for personal protection during repairs.

Step-by-Step Repair Process

Repairing equipment can seem daunting, but with a clear approach, it becomes manageable. This section outlines a systematic method to identify issues, gather necessary tools, and execute repairs effectively.

-

Identify the Issue:

- Observe the symptoms and take note of any unusual sounds or leaks.

- Refer to the manual for troubleshooting tips specific to the model.

-

Gather Tools and Materials:

- Collect necessary tools, including wrenches, screwdrivers, and pliers.

- Ensure you have replacement components ready for installation.

-

Disassemble the Unit:

- Carefully remove the outer casing to access internal components.

- Keep screws and small parts organized to avoid misplacement.

-

Inspect Components:

- Check each part for wear, cracks, or other damage.

- Compare damaged parts with new ones to confirm replacements.

-

Replace Damaged Parts:

- Remove old components and install the new ones according to the manual.

- Ensure all connections are secure and properly aligned.

-

Reassemble the Unit:

- Carefully put the casing back in place, securing all screws.

- Double-check that everything is reassembled correctly.

-

Test the Equipment:

- Run the device briefly to check for any leaks or unusual noises.

- Observe the functionality to ensure everything operates smoothly.

Following these steps can significantly enhance your repair efficiency and ensure your equipment runs optimally.

Identifying Wear and Tear Signs

Regular maintenance is essential for any mechanical device, as it ensures optimal performance and longevity. Recognizing the signs of degradation can prevent minor issues from escalating into major failures. By being vigilant and knowledgeable, users can effectively address potential problems before they affect functionality.

Visual Inspections are the first step in identifying wear. Look for cracks, corrosion, or any unusual discoloration on components. These physical changes often indicate that parts are nearing the end of their lifespan and may require replacement.

Additionally, auditory cues can provide insight into the condition of the equipment. Unusual sounds such as grinding or rattling may suggest that internal components are not functioning correctly and could be suffering from excessive wear.

Performance changes are another crucial indicator. If the machinery is not operating as efficiently as before or is producing inconsistent results, it may be a sign that certain parts are beginning to fail. Monitoring these variations can help in diagnosing underlying issues early.

Finally, leaks are a common symptom of wear. Fluid escaping from seals or connections can lead to further complications if not addressed promptly. Regularly checking for any signs of leakage is essential to maintain the integrity of the system.

Benefits of Regular Maintenance

Consistent upkeep of equipment is essential for ensuring optimal performance and longevity. By prioritizing maintenance, users can significantly reduce the risk of unexpected failures and enhance overall efficiency.

Improved Performance

- Regular checks can identify potential issues before they escalate.

- Well-maintained machines operate at peak efficiency, saving time and energy.

- Proper care ensures consistent output quality, meeting user expectations.

Cost Savings

- Preventive maintenance minimizes repair costs associated with major breakdowns.

- Extended lifespan of equipment reduces the need for premature replacements.

- Increased efficiency often leads to lower operational costs over time.

Upgrading Your Pressure Washer Setup

Enhancing your cleaning equipment can significantly boost efficiency and performance. By incorporating high-quality components and accessories, you can achieve better results and extend the lifespan of your device. Here are some key areas to focus on when considering upgrades.

1. Evaluate Your Current Equipment

Before making any changes, assess the existing tools and their capabilities. Identify the limitations and areas where improvements are needed. Consider the following:

- Cleaning power

- Durability

- Ease of use

- Maintenance requirements

2. Recommended Upgrades

Once you’ve evaluated your setup, you can explore specific enhancements that align with your cleaning tasks:

- High-Performance Nozzles: Different nozzles provide varying spray patterns and pressure levels, allowing for customized cleaning.

- Replacement Components: Upgrading worn-out seals and hoses can improve functionality and prevent leaks.

- Detergent Systems: Incorporating a better soap application system enhances cleaning effectiveness, especially for tough stains.

- Safety Features: Adding safety mechanisms can help prevent accidents and ensure a smoother operation.

By making thoughtful upgrades, you can transform your cleaning setup into a more powerful and efficient tool, leading to better results and a more satisfying experience.

Comparing GC190 with Other Models

This section focuses on the differences and similarities between various engine types in the market, specifically examining one popular model alongside its counterparts. Understanding these distinctions helps users make informed decisions based on their specific needs and preferences.

Performance Metrics

When evaluating engine performance, several key metrics come into play. These include horsepower, torque, and fuel efficiency. Here’s a comparison of selected models based on these parameters:

| Model | Horsepower | Torque (lb-ft) | Fuel Efficiency (mpg) |

|---|---|---|---|

| Model A | 5.5 | 10.0 | 30 |

| Model B | 6.0 | 12.0 | 28 |

| Model C | 5.0 | 9.5 | 32 |

User Applications

Different engine models cater to various applications, from light residential tasks to heavy-duty commercial use. Users should consider how each model’s specifications align with their intended applications to ensure optimal performance and efficiency.