Understanding the Husky Power Washer Parts Diagram for Easy Maintenance

In the realm of outdoor maintenance, having a clear grasp of the various elements that constitute your cleaning apparatus is essential. Each component plays a vital role in ensuring optimal performance and longevity of the device. By familiarizing yourself with these elements, you can enhance your cleaning efficiency and address any issues that may arise during usage.

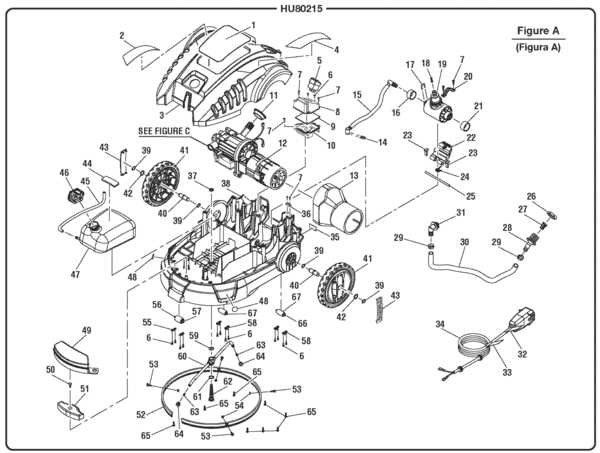

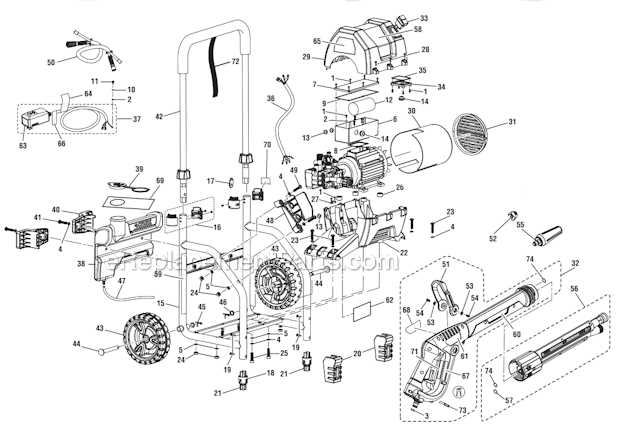

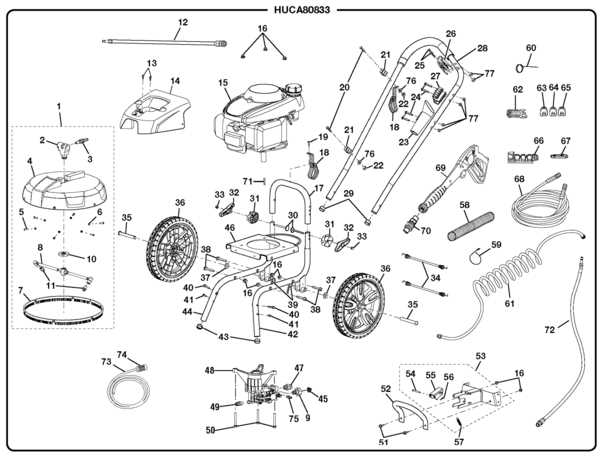

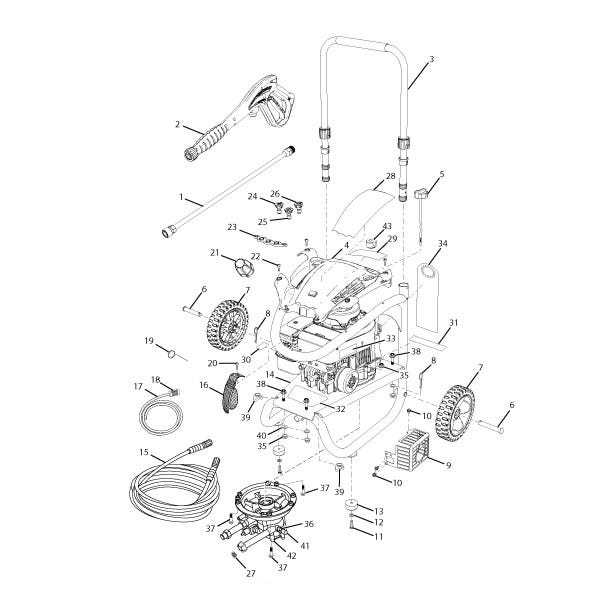

Visual aids can greatly assist in identifying and understanding the function of each section within the equipment. These representations not only simplify the repair process but also help in the assembly and disassembly of the unit. Whether you are a novice or an experienced user, having access to detailed illustrations can empower you to tackle maintenance tasks confidently.

Additionally, knowing the specific features and mechanisms at play allows for better decision-making when it comes to replacements or upgrades. Investing in high-quality components can lead to improved effectiveness and durability, ensuring that your cleaning sessions yield the best results possible. By delving into the intricacies of your device, you position yourself to achieve greater satisfaction in your outdoor cleaning endeavors.

Understanding Husky Power Washers

In the realm of outdoor cleaning tools, certain models stand out due to their reliability and efficiency. These machines are designed to tackle a variety of tasks, from removing dirt and grime from surfaces to restoring the appearance of patios and vehicles. Understanding the inner workings and components of these devices is essential for optimal performance and maintenance.

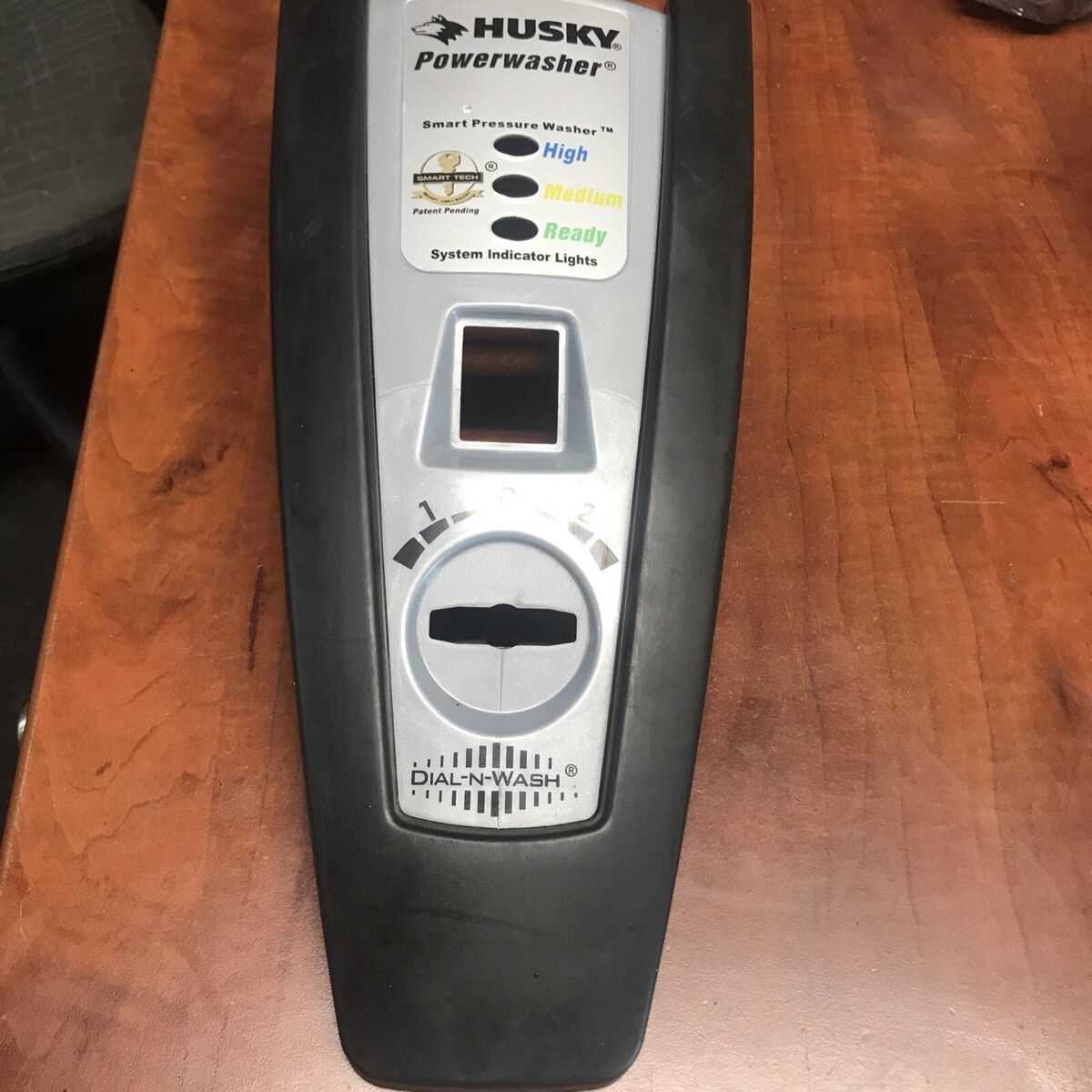

Key features often include adjustable pressure settings, various nozzle options, and durable construction materials that enhance longevity. Users benefit from the versatility these machines offer, allowing them to handle both light and heavy-duty cleaning tasks effectively.

To delve deeper into their functionality, one must consider the role of each component, ensuring they are aware of how to maintain and replace them when necessary. This knowledge leads to the ultimate cleaning experience, maximizing efficiency and extending the lifespan of the equipment.

Key Components of Power Washers

Understanding the essential elements that contribute to efficient cleaning equipment can greatly enhance performance and longevity. Each component plays a vital role in delivering the ultimate cleaning experience, ensuring that surfaces are effectively treated and restored.

Motor: The heart of the machine, it provides the necessary energy to drive the system. A powerful motor enables optimal pressure and flow rates, crucial for tackling tough grime.

Pump: This unit pressurizes the water, allowing it to be expelled forcefully through the nozzle. High-quality pumps are designed for durability and consistent performance, affecting the overall efficiency of the equipment.

Nozzle: Different nozzle types adjust the spray pattern and pressure, making it versatile for various cleaning tasks. Choosing the right nozzle can significantly impact the effectiveness of the cleaning process.

Hoses: These flexible tubes transport water from the source to the nozzle. Durable hoses can withstand high pressure and prevent leaks, ensuring a steady flow during operation.

Trigger Gun: This component allows users to control the water flow easily. A well-designed trigger gun offers comfort and reduces fatigue, enhancing the user experience during extended cleaning sessions.

Importance of Proper Maintenance

Neglecting maintenance can result in reduced efficiency, increased wear and tear, and safety hazards. Implementing a structured maintenance plan can save time and resources while ensuring that the equipment operates smoothly. Below is a summary of key benefits associated with proper maintenance:

| Benefit | Description |

|---|---|

| Enhanced Longevity | Regular servicing extends the life of the equipment, reducing the need for frequent replacements. |

| Improved Efficiency | Well-maintained machines perform better, ensuring optimal output and productivity. |

| Cost Savings | Preventive measures minimize the risk of major repairs, leading to lower overall costs. |

| Safety Assurance | Regular inspections help identify potential hazards, promoting a safer working environment. |

| Environmental Responsibility | Proper maintenance reduces emissions and waste, contributing to environmental conservation. |

Common Parts and Their Functions

This section explores various components commonly found in cleaning machines, highlighting their essential roles in ensuring optimal performance. Understanding these elements can enhance the user experience and facilitate maintenance.

| Component | Function |

|---|---|

| Motor | Powers the unit, providing the necessary force for operation. |

| Pump | Increases pressure to deliver a high-velocity stream of liquid. |

| Trigger Gun | Controls the flow of liquid; users can start and stop as needed. |

| Hose | Transports the liquid from the machine to the nozzle. |

| Nozzle | Modifies the spray pattern, allowing for different cleaning techniques. |

Reading a Parts Diagram Effectively

Understanding the layout of an assembly is crucial for anyone looking to perform maintenance or repairs. A well-structured visual representation can simplify the process, making it easier to identify components and their relationships. This knowledge can ultimately enhance efficiency and accuracy in repairs.

Key Elements to Focus On

- Labels: Pay attention to the names and numbers assigned to each component.

- Connections: Note how different pieces interact or connect with one another.

- Legends: Utilize any accompanying legends to decipher symbols or color codes.

Steps to Effective Reading

- Begin by familiarizing yourself with the overall layout.

- Identify and list the components required for your task.

- Trace connections to understand the assembly process.

- Refer back to the visual as needed during repairs.

Identifying Wear and Tear

Understanding the signs of deterioration is crucial for maintaining equipment efficiency and longevity. Regular inspection can help you catch issues before they escalate, ensuring optimal performance during usage.

Common Indicators

Look out for the following signs that may indicate components are nearing the end of their lifespan:

| Indicator | Description |

|---|---|

| Cracks | Visible fractures on surfaces that can lead to leaks or failure. |

| Rust | Corrosion that compromises structural integrity and can affect functionality. |

| Worn Edges | Rounded or frayed edges on components indicating excessive use. |

Maintenance Tips

Regular cleaning and timely replacement of damaged components can significantly enhance the lifespan of your equipment. Always consult the manufacturer’s guidelines for specific maintenance recommendations.

Replacement Parts: When to Buy

Understanding when to invest in new components for your equipment can significantly enhance its longevity and efficiency. Recognizing signs of wear and tear is essential to maintain optimal performance.

Monitor Performance: If you notice a decline in effectiveness or unusual noises, it may be time to consider new components. Addressing issues early can prevent more costly repairs later.

Regular Inspections: Conducting routine checks can help identify parts that are nearing the end of their lifespan. Look for signs of damage, such as cracks or excessive rust.

Usage Frequency: The more frequently you utilize your equipment, the sooner components may need replacement. Tailoring your replacement schedule to your usage can ensure reliability.

Manufacturer Recommendations: Always refer to the guidelines provided by the manufacturer. They often suggest timelines for replacement based on typical usage scenarios.

DIY Repair Tips for Owners

Maintaining your equipment can save you time and money, allowing you to tackle minor issues before they escalate. With a bit of knowledge and the right tools, you can perform basic repairs yourself, ensuring that your device operates smoothly and efficiently. This guide offers practical tips to help you navigate common challenges and enhance your repair skills.

Understanding Common Issues

Familiarize yourself with frequent problems that may arise. From leaks to low performance, recognizing symptoms early can make all the difference. Conducting a quick visual inspection and listening for unusual sounds can help identify potential faults. Keep a notebook to track any irregularities you observe over time.

Essential Tools and Techniques

Having the right tools is crucial for effective repairs. A basic toolkit should include wrenches, screwdrivers, and pliers. Additionally, consider investing in a multimeter to check electrical components. When working on your equipment, ensure you follow safety protocols; disconnect power sources and wear protective gear. For tasks such as cleaning or replacing components, refer to your owner’s manual for guidance on proper disassembly and reassembly.

Remember that patience is key. Take your time, and don’t hesitate to seek online resources or forums for advice if you encounter difficulties. With practice, you’ll gain confidence in your repair abilities, making you a more self-sufficient owner.

Safety Precautions During Repairs

When undertaking maintenance on any equipment, ensuring safety is paramount. Taking the necessary precautions not only protects the individual performing the work but also safeguards the tools and machinery involved. Understanding the potential hazards and preparing accordingly can significantly reduce the risk of accidents.

Always wear protective gear, such as gloves and safety glasses, to shield yourself from injuries. Sturdy footwear can also prevent slips and falls during the repair process.

Before starting any repair, disconnect the power source to avoid accidental activation. This step is crucial in preventing unexpected injuries while handling components. Review the manufacturer’s manual to familiarize yourself with the device and follow recommended guidelines.

Keep your workspace organized and free of clutter. A tidy environment reduces the risk of tripping or losing tools, which can lead to dangerous situations. Ensure proper ventilation when working with solvents or cleaning agents to avoid inhaling harmful fumes.

Finally, if you encounter any issues beyond your expertise, consult a professional. Seeking assistance can prevent further damage and ensure safety during complex repairs.

Finding Genuine Husky Parts Online

When it comes to maintaining and repairing your equipment, sourcing authentic components is crucial for ensuring longevity and optimal performance. The online marketplace offers a myriad of options, but not all sources guarantee quality. This section will guide you on how to effectively locate legitimate items for your machinery, ensuring your investment remains protected.

Identifying Reliable Retailers

To begin your search, focus on well-established retailers known for their credibility. Look for customer reviews and ratings that highlight the reliability of their offerings. Websites with detailed product descriptions and clear return policies often indicate a trustworthy source. Additionally, consider authorized dealers who specialize in your equipment’s brand, as they typically stock genuine merchandise.

Utilizing Manufacturer Resources

Another effective approach is to visit the manufacturer’s official website. Most manufacturers provide a list of authorized retailers or an online shop where you can purchase original components directly. Utilizing these resources not only ensures authenticity but often provides access to exclusive deals or warranties.

Remember that investing time in finding authentic components will pay off in the long run, enhancing the reliability and efficiency of your machinery.

Comparing Models: Which One Fits?

When selecting a cleaning machine, understanding the various options available is crucial for making an informed choice. Different models cater to unique needs, and identifying the right fit can enhance your experience and efficiency.

- Assess the intended use: Determine if your tasks are light, medium, or heavy-duty.

- Consider power source: Electric or gas options can significantly affect performance.

- Evaluate mobility: Look for features like wheels or handles for easier transport.

- Review accessories: Compatibility with various attachments can enhance versatility.

Ultimately, comparing specifications and user reviews can lead to the best decision for your requirements.

Understanding Warranty and Support

Grasping the essentials of protection and assistance services is crucial for maximizing the longevity and efficiency of your equipment. Knowing what is covered under warranty and the resources available for troubleshooting can enhance your overall experience and safeguard your investment.

Coverage Details

Warranties typically outline the specific components and issues that are protected. Familiarizing yourself with these details ensures you know when to seek support and what remedies are available in case of defects or failures.

Accessing Support Services

Effective customer service channels are vital for resolving inquiries and obtaining technical help. Utilize official resources, such as manuals and online platforms, to find assistance and connect with professionals when needed.

Best Practices for Long-lasting Equipment

Ensuring the durability and efficiency of your tools involves a combination of proper maintenance, thoughtful usage, and proactive care. By adhering to key strategies, you can significantly extend the lifespan of your devices, allowing them to perform optimally for years.

| Practice | Description |

|---|---|

| Regular Cleaning | Remove dirt and debris after each use to prevent buildup. |

| Routine Inspections | Check for wear and tear to address issues early on. |

| Proper Storage | Store in a dry, cool place to avoid damage from moisture. |

| Follow Manufacturer Guidelines | Adhere to recommended maintenance schedules and instructions. |

| Use Suitable Accessories | Utilize compatible tools and attachments to prevent malfunctions. |