Understanding Kenmore Washer Diagram Parts for Effective Maintenance

In the world of household devices, a clear grasp of their internal mechanisms can significantly enhance your troubleshooting skills. Each unit consists of various elements that work together to ensure optimal functionality. Familiarity with these components not only aids in maintenance but also empowers users to make informed decisions when issues arise.

Exploring the intricate network of machinery and circuitry reveals how each segment contributes to the overall performance. From the essential drive systems to intricate control panels, recognizing the roles of these features can simplify repairs and enhance efficiency. Knowledge of these intricate systems transforms the daunting task of appliance upkeep into a manageable endeavor.

Whether you’re seeking to perform routine checks or address specific malfunctions, understanding the layout and function of each component is invaluable. This insight paves the way for a more confident approach to home appliance care, allowing for quicker resolutions and a more reliable performance over time.

Understanding Kenmore Washer Components

Exploring the various elements of laundry appliances can enhance your maintenance skills and troubleshooting abilities. Each component plays a crucial role in ensuring efficient operation and longevity of the machine.

Key elements include:

- Drive Mechanism

- Water Inlet Valve

- Control Panel

- Drain Pump

- Agitator

Understanding these features helps in identifying potential issues and making informed decisions regarding repairs and replacements.

Key Parts of Kenmore Washers

This section explores the essential components found in household cleaning appliances, highlighting their roles and functions. Understanding these elements can enhance maintenance and improve efficiency in daily use.

Drum and Agitator

The drum is the central container where clothing is placed, while the agitator, often situated within the drum, facilitates the movement of items during the cleaning cycle, ensuring effective dirt removal.

Control Panel and Motor

The control panel allows users to select settings, manage cycles, and monitor operations. The motor drives the drum and agitator, powering the entire process for optimal performance.

Functionality of the Agitator

The agitator plays a crucial role in the cleaning process by creating movement within the drum. This motion ensures that the fabrics are thoroughly soaked and scrubbed, allowing detergent to penetrate and lift dirt effectively.

When in operation, the agitator moves back and forth, generating a dynamic flow of water that enhances the interaction between the items being laundered and the cleansing solution. Its design is engineered to maximize the efficiency of this action, ensuring that even heavily soiled garments receive the attention they need.

Moreover, the agitator’s ability to rotate at different speeds contributes to a varied washing cycle, accommodating different fabric types and soil levels. This adaptability is vital for achieving optimal cleaning results while minimizing damage to delicate materials.

Exploring the Spin Basket Design

The spin basket is a crucial component that significantly influences the efficiency and effectiveness of laundry processes. Its design impacts the ability to extract water from garments, ensuring they come out drier and ready for the next stage. Understanding its structure can help users appreciate how this element contributes to overall performance.

| Feature | Description |

|---|---|

| Material | Typically made from durable plastics or stainless steel for longevity. |

| Shape | Cylindrical design maximizes space and promotes efficient water removal. |

| Perforations | Small holes allow for optimal drainage while retaining garments. |

| Balance | Engineered to maintain stability during high-speed rotations. |

Role of the Water Pump

The water pump serves a critical function in the appliance’s operation, ensuring the efficient circulation and removal of liquid during various cycles. Its performance directly impacts the effectiveness of cleaning and draining processes, making it an essential component for optimal functioning.

Essentially, the pump works by drawing in water, allowing it to flow through different stages of the cycle, and subsequently expelling it at the right times. This not only helps maintain the right water levels but also facilitates thorough rinsing and prevents overflow.

Additionally, the water pump is designed to withstand varying pressures and resist wear over time, contributing to the appliance’s longevity. A well-functioning pump ensures that the appliance operates smoothly, thus enhancing overall user satisfaction.

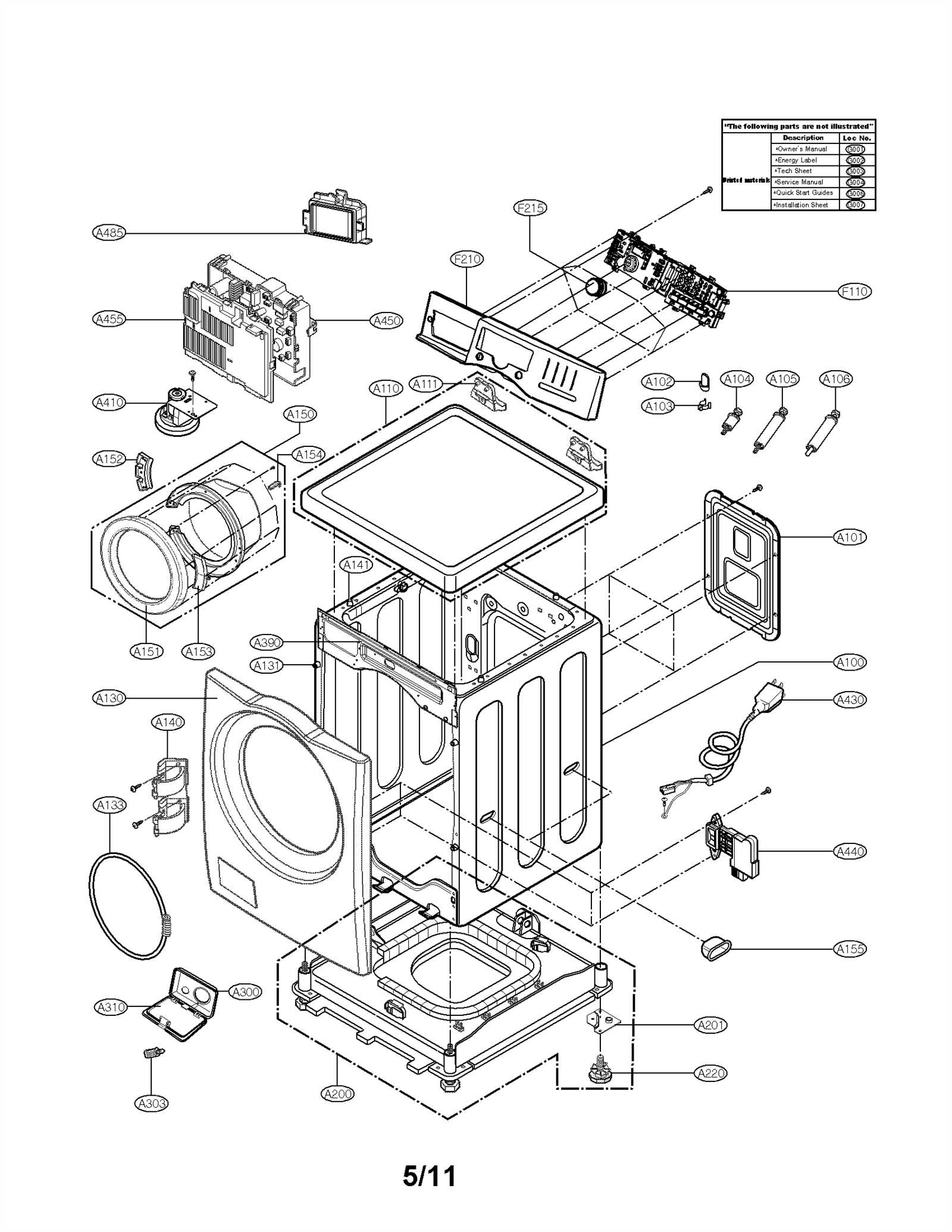

Electrical System Overview

The electrical framework in modern appliances plays a crucial role in their functionality and efficiency. Understanding its components and interactions can enhance troubleshooting and maintenance efforts.

This section delves into the various elements that make up the electrical system, highlighting their ultimate significance:

- Power Supply: The primary source that energizes the system.

- Circuitry: Pathways that facilitate the flow of electricity.

- Control Board: The brain that manages operations and user inputs.

- Sensors: Devices that monitor conditions and provide feedback.

- Connectors: Points where components interlink, ensuring continuity.

Understanding each of these components helps in identifying issues and optimizing performance, leading to a more efficient appliance experience.

Identifying the Control Panel Layout

Understanding the arrangement of the control interface is crucial for effective operation and troubleshooting. Familiarity with the various buttons, dials, and indicators can significantly enhance user experience and ensure optimal functionality. This section will guide you through the common components found on the control panel and their respective roles.

| Component | Description |

|---|---|

| Power Button | Activates or deactivates the machine. |

| Cycle Selector | Allows the user to choose the desired operational mode. |

| Temperature Control | Adjusts the water temperature for various settings. |

| Start/Pause Button | Initiates the chosen cycle or pauses it as needed. |

| Indicator Lights | Provide visual feedback on the current status of the machine. |

| Timer Display | Shows the remaining time for the current cycle. |

Recognizing these elements will aid in navigating the functionalities and troubleshooting any issues that may arise during use. Each feature plays a significant role in the overall efficiency of the device.

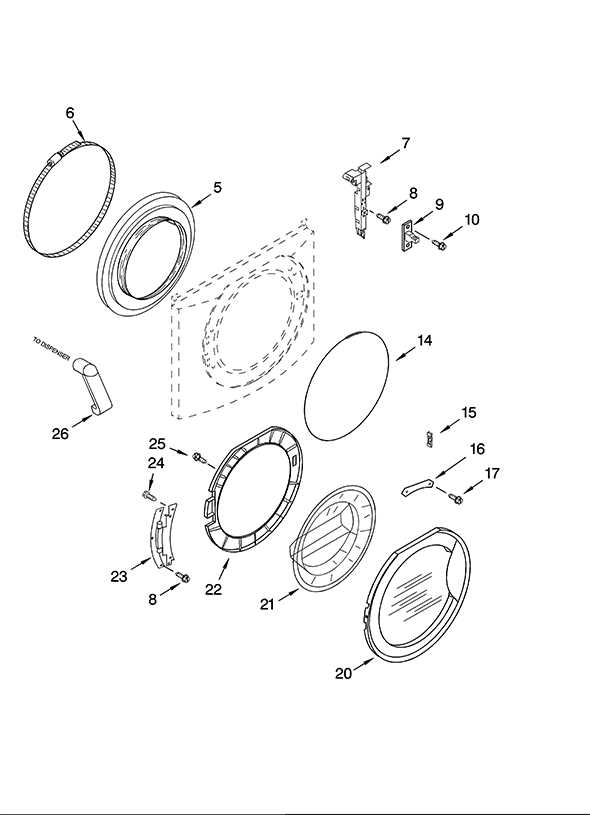

Importance of the Door Lock Mechanism

The door lock mechanism plays a crucial role in ensuring the safe and efficient operation of laundry appliances. This component not only secures the door during cycles but also prevents any accidents that could occur if the door were to open unexpectedly. Understanding its significance can enhance the overall user experience and prolong the lifespan of the appliance.

Safety Features

One of the primary functions of the door locking system is to maintain safety. By preventing the door from opening while the appliance is in use, it minimizes the risk of water spills and potential injuries. Users can operate their machines with confidence, knowing that the risk of accidents is greatly reduced.

Operational Efficiency

In addition to safety, the locking mechanism contributes to the overall efficiency of the appliance. When the door is securely closed, it ensures proper pressure and temperature are maintained within the unit. This leads to optimal cleaning results and energy efficiency, making the appliance not only safer but also more effective in its function.

In summary, the door lock mechanism is a vital component that enhances both safety and performance, making it an essential aspect of any laundry appliance’s design.

Maintenance of the Drain Hose

Regular care of the drainage tube is crucial for optimal functioning and longevity of your appliance. Proper maintenance prevents clogs and ensures efficient water flow, reducing the risk of leaks and damage.

Common Issues

- Clogs caused by debris or lint buildup

- Kinks that restrict water flow

- Improper installation leading to leaks

Maintenance Tips

- Inspect the hose regularly for signs of wear or damage.

- Clear any blockages by detaching the hose and rinsing it with water.

- Ensure the hose is properly secured and positioned to avoid kinks.

- Replace the hose every few years to maintain efficiency.

Understanding the Filter System

The filter system in laundry appliances plays a crucial role in maintaining efficiency and ensuring the longevity of the machine. This mechanism is designed to capture debris, lint, and other particles that can interfere with the washing process. Understanding how this system operates can help users troubleshoot issues and enhance the overall performance of their equipment.

Functionality of the Filter

The primary function of the filter is to prevent unwanted materials from circulating through the appliance. When clothing is washed, tiny fibers and residues are released. A well-maintained filter traps these elements, allowing clean water to circulate effectively. Regular inspection and cleaning of the filter can prevent blockages that may lead to poor washing results or even mechanical failures.

Maintenance Tips

To keep the filter functioning optimally, it’s essential to follow a few simple maintenance steps. Regularly check the filter for accumulated debris, and clean it according to the manufacturer’s recommendations. Replacing the filter at specified intervals can also ensure that the system continues to operate efficiently, ultimately enhancing the performance and lifespan of the appliance.

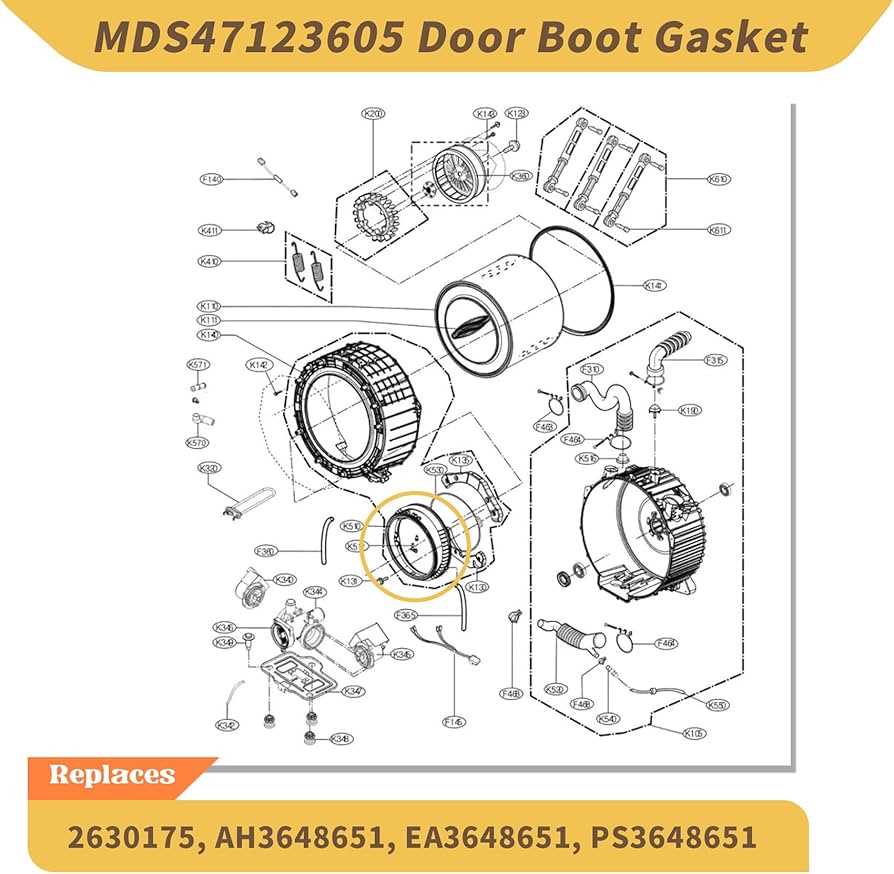

Diagram Analysis of the Tub Assembly

The tub assembly is a critical component that plays a vital role in the overall functionality of the appliance. Understanding its structure and interaction with other elements can enhance performance and longevity. This section will explore the key features and relationships within this assembly.

Central Role: The tub serves as the primary container for items during operation, facilitating movement and water circulation. Its design is engineered to maximize efficiency and minimize wear over time.

Components Overview: Essential elements include the outer tub, inner drum, and support brackets. Each part contributes uniquely to stability and functionality, ensuring that the system operates smoothly under various conditions.

Material Considerations: The materials used in the construction of the tub assembly are critical for durability and resistance to corrosion. Understanding these materials can aid in maintenance and replacement decisions.

Assembly Connections: Proper alignment and connection to the motor and pump are essential for optimal operation. Any misalignment can lead to inefficiencies and potential damage.

Overall, a thorough analysis of the tub assembly reveals its importance in achieving the ultimate performance of the entire system, highlighting the need for careful attention during maintenance and troubleshooting.

Common Issues with Washer Parts

Understanding the frequent challenges associated with laundry appliances can significantly enhance their efficiency and longevity. Many users encounter various malfunctions that stem from different components, often leading to frustration and decreased performance.

One prevalent problem is the accumulation of debris in filters, which can hinder functionality and cause leaks. Regular cleaning can mitigate this issue and improve water flow.

Another common concern is noise during operation, often resulting from worn-out bearings or misalignment. Identifying the source of the sound is crucial for timely repairs.

Moreover, electrical malfunctions can disrupt normal cycles, often caused by faulty wiring or circuit issues. It’s essential to ensure all connections are secure and functioning properly.

Lastly, wear and tear on rubber seals can lead to significant leaks, affecting both performance and safety. Regular inspections can help detect these issues early.

Replacing Kenmore Washer Components

Maintaining your laundry appliance’s efficiency often requires a deep dive into its inner workings. Understanding how to swap out various elements can extend its lifespan and enhance performance. This guide provides essential insights for successfully changing out components, ensuring that your machine continues to function at its best.

Identifying the Right Component: Before beginning any replacements, it’s crucial to accurately identify the part that needs attention. This may involve troubleshooting common issues or consulting a reference for the correct component name and function.

Preparation for Replacement: Gather the necessary tools and new components before starting the process. This preparation will streamline your efforts and minimize the risk of errors during installation.

Step-by-Step Replacement: Follow a systematic approach to remove the faulty part, ensuring that all connections are carefully detached. Once the old component is out, install the new one with attention to detail, securing it properly to prevent future issues.

Final Checks: After installation, it’s important to run a test cycle to ensure everything operates smoothly. Monitor for any unusual sounds or leaks, which may indicate that further adjustments are needed.