Understanding the Landa Pressure Washer Parts Diagram

For anyone involved in maintenance or operation of high-performance cleaning machines, grasping the intricacies of each element is essential. Knowing how these components fit together not only enhances efficiency but also extends the lifespan of the equipment.

In this guide, we will explore the various essential elements that contribute to optimal functionality. Each component plays a pivotal role, and understanding their arrangement can lead to better troubleshooting and maintenance practices.

Moreover, an in-depth look at these components will enable users to make informed decisions when it comes to repairs or upgrades. Let’s delve into the specifics and uncover the ultimate insights to keep your equipment running smoothly.

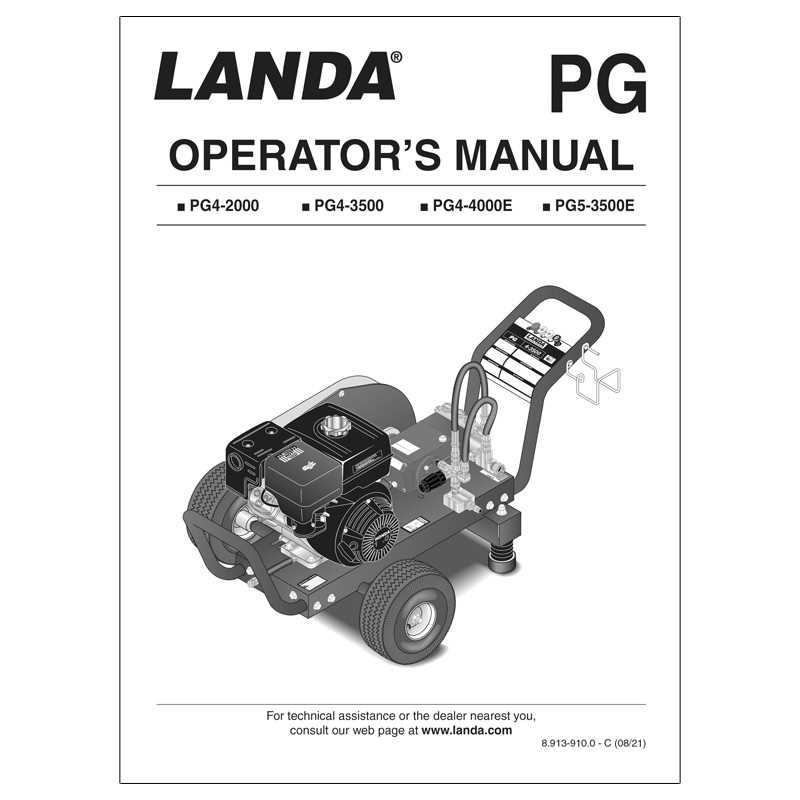

Landa Pressure Washer Overview

This segment provides an insight into a specific type of cleaning equipment designed for efficiency and effectiveness. These machines are tailored to tackle tough grime and dirt, making them essential for both commercial and residential applications.

Features of this cleaning apparatus include high-performance motors and specialized nozzles that enhance water flow and pressure. Users can expect versatility in usage, from light cleaning tasks to heavy-duty jobs.

Maintenance is crucial for optimal functioning; regular checks and replacements can extend the lifespan of the machine. Understanding the components will aid in troubleshooting and ensuring consistent performance.

In summary, this equipment stands out due to its robust design and capability, making it an ultimate choice for those seeking effective cleaning solutions.

Understanding Pressure Washer Components

Grasping the elements of a cleaning machine is essential for effective maintenance and operation. Each component plays a crucial role in delivering powerful performance, ensuring that tasks are completed efficiently. By familiarizing yourself with these individual parts, you can enhance the functionality and longevity of the equipment.

At the heart of this machinery lies the motor, which provides the necessary energy to drive the entire system. The pump, another vital element, generates the flow and pressure of the fluid, enabling it to tackle tough stains. Additionally, the nozzle serves to control the spray pattern, allowing users to adjust for different cleaning needs.

Other significant components include hoses, which transport the cleaning solution, and connectors that ensure a secure fit between parts. Regular inspection and understanding of these elements can lead to improved performance and a more satisfying cleaning experience.

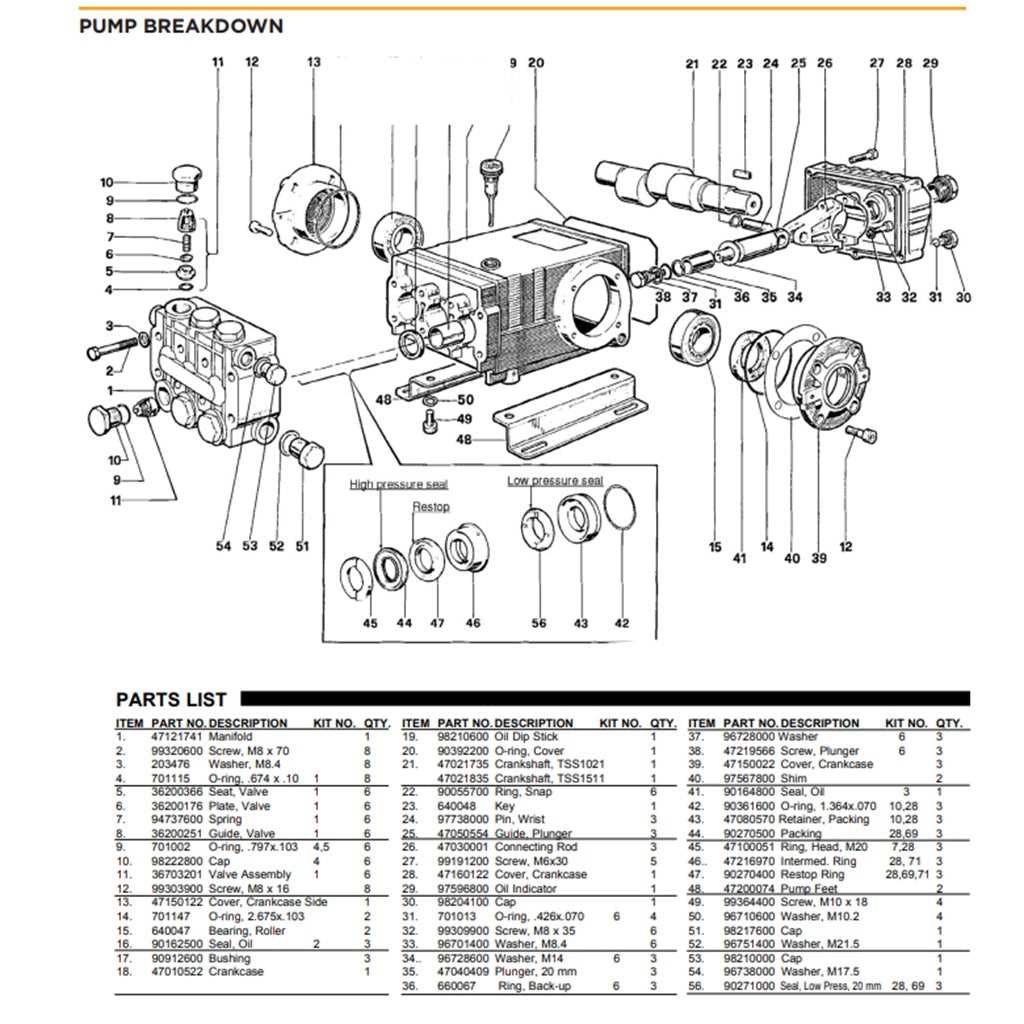

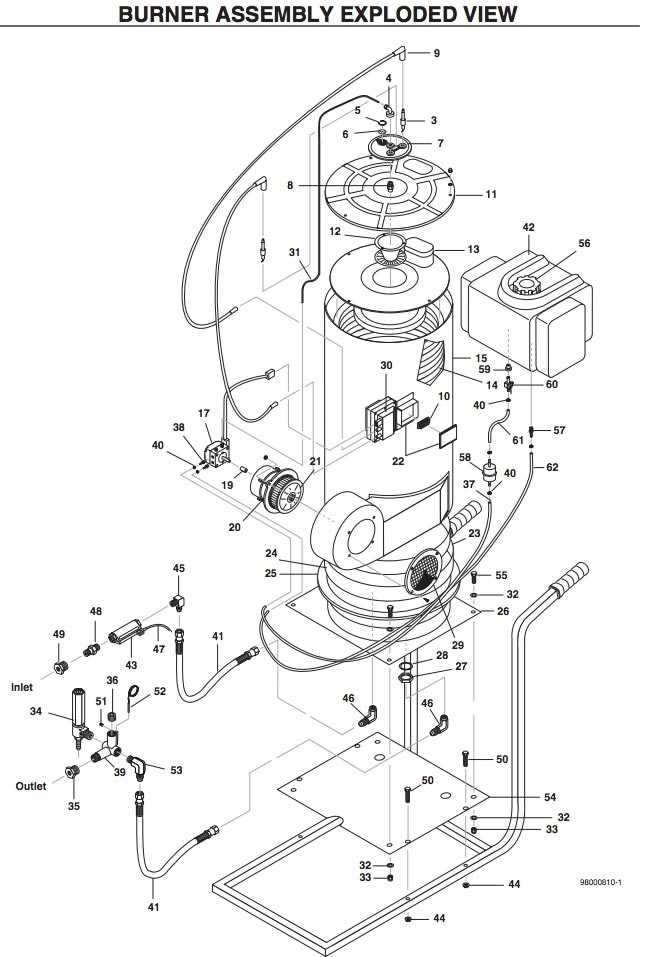

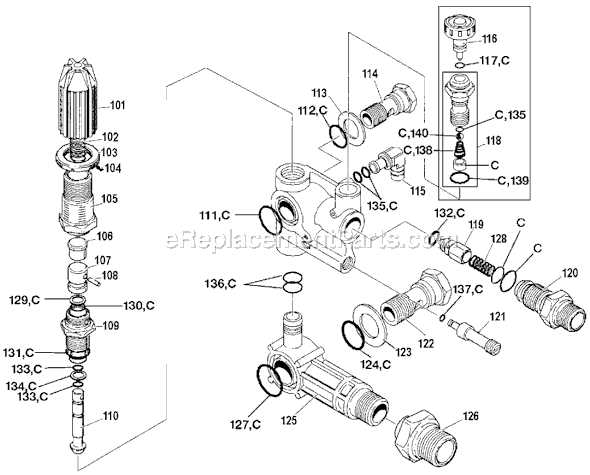

Importance of a Parts Diagram

A comprehensive visual representation of components serves as an essential tool for understanding the intricacies of machinery. It not only aids in identification but also enhances maintenance efficiency, ensuring that each element can be easily located and serviced. Such clarity is crucial for both novice and experienced users alike.

Moreover, having an accurate representation allows for quicker troubleshooting and repairs, minimizing downtime. When a malfunction occurs, the ability to quickly reference the layout can lead to immediate action and resolution.

Ultimately, a well-structured visual guide fosters confidence in handling equipment, empowering users to perform tasks with greater precision and safety. This leads to prolonged equipment lifespan and optimal performance, highlighting the significance of having a reliable reference at hand.

Key Components of Landa Models

Understanding the essential elements of these cleaning machines is crucial for optimal performance and maintenance. Each model is designed with specific features that contribute to its efficiency and effectiveness in various cleaning tasks. This section highlights the main components that play a vital role in the functionality of these units.

The motor serves as the powerhouse, converting electrical energy into mechanical energy to drive the entire system. This is typically coupled with a pump, which is responsible for generating the necessary flow and pressure for effective cleaning. The quality of both the motor and pump significantly impacts the machine’s performance.

Another key element is the nozzle, which directs the flow of water and determines the intensity of the spray. Various nozzle types are available, allowing users to adjust the cleaning process based on specific requirements. Additionally, the hose facilitates mobility and reach, ensuring that users can access hard-to-reach areas without hassle.

Moreover, the frame provides structural integrity and support, housing all components securely. Features such as wheels or handles enhance portability, making it easier to transport the unit from one location to another. Understanding these components helps users make informed decisions regarding maintenance and repairs, ultimately prolonging the lifespan of the equipment.

How to Read the Diagram

Understanding technical illustrations can significantly enhance your ability to maintain and repair equipment. These visuals serve as a roadmap, guiding you through various components and their interconnections. Familiarizing yourself with the symbols and notations used in these representations is essential for effective interpretation.

Begin with the Legend: Most illustrations include a legend or key that explains the symbols used. This section is crucial, as it provides insight into what each symbol represents, ensuring you can accurately identify the parts.

Identify Components: As you analyze the visual, take note of the different sections. Components are typically grouped based on their functionality or location within the system. Understanding these groupings can help you visualize how each piece interacts with others.

Follow the Flow: Many technical illustrations show the flow of materials or energy through the system. Pay attention to arrows and lines, which indicate movement and connections. This will help you understand the operational dynamics at play.

Look for Annotations: Additional notes or annotations may accompany the visual. These can provide valuable context or specific instructions regarding assembly, disassembly, or troubleshooting. Don’t overlook these details, as they often contain critical information.

By mastering these aspects, you’ll be better equipped to interpret the visual effectively, facilitating smoother maintenance and repair processes.

Common Issues and Repairs

Understanding frequent problems can significantly enhance the longevity and performance of your cleaning equipment. This section outlines typical challenges users face and offers solutions to restore optimal functionality.

Identifying Performance Issues

One common challenge is reduced cleaning efficiency. This often results from clogs in the system. Regularly checking for obstructions and cleaning filters can greatly improve performance. If the issue persists, examining the motor and connections might reveal deeper faults.

Leaking Components

Leaks can also be a major concern, often stemming from worn seals or loose fittings. Inspecting these areas and replacing damaged seals can prevent further issues. Always ensure that all connections are tight to minimize fluid loss.

Where to Find Replacement Parts

Locating the necessary components for your cleaning equipment can seem daunting, but various resources simplify the process. From authorized retailers to online platforms, understanding where to seek these items is crucial for efficient maintenance.

Authorized Dealers

One of the most reliable sources for acquiring new components is through authorized dealers. They offer genuine products, ensuring compatibility and performance. Additionally, these dealers often provide expert advice on installation and care.

Online Marketplaces

Many consumers turn to online marketplaces for convenience and a wider selection. Websites like eBay and Amazon feature numerous listings, allowing you to compare prices and read reviews. However, ensure you verify the seller’s credibility to avoid counterfeit goods.

Whether opting for local dealers or online shops, thorough research will lead you to the best solutions for your equipment needs.

Benefits of Original Parts

Using authentic components in your equipment ensures optimal performance and longevity. Original parts are designed specifically for the system, offering unmatched reliability and efficiency that generic alternatives often lack.

| Advantage | Description |

|---|---|

| Quality Assurance | Authentic components are subjected to rigorous testing, ensuring they meet high standards. |

| Perfect Fit | Original parts are engineered for seamless integration, minimizing the risk of malfunction. |

| Warranty Protection | Using genuine components often keeps warranties intact, protecting your investment. |

| Enhanced Safety | Original parts are designed to operate safely, reducing the likelihood of accidents. |

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your cleaning equipment involves regular upkeep and mindful practices. By following a few essential guidelines, you can significantly extend the lifespan of your machine while maintaining optimal performance.

Regular Inspection

Consistent evaluation of your device is crucial. Check for wear and tear on hoses, connections, and other components. Addressing minor issues promptly can prevent them from escalating into costly repairs.

Proper Cleaning Techniques

After each use, thoroughly clean the equipment to remove any residue. This not only maintains its appearance but also prevents buildup that could hinder functionality. Regularly flushing out any internal systems ensures that debris does not accumulate, keeping everything running smoothly.

Identifying Specific Parts by Model

Understanding the unique components of any cleaning machine is essential for effective maintenance and repairs. Each model has distinct features, and recognizing these can greatly enhance operational efficiency.

To pinpoint specific elements, start by consulting the manufacturer’s documentation that corresponds to your model. This documentation typically includes comprehensive lists and descriptions that simplify the identification process. Utilizing model numbers is crucial, as they serve as a reference for locating the right components and ensuring compatibility.

In addition, visual aids like schematics can provide clarity. By matching parts with their designated locations, users can better understand how each component interacts within the system, ultimately leading to improved functionality.

DIY Troubleshooting Techniques

When faced with equipment challenges, understanding some basic troubleshooting methods can save time and money. Engaging in hands-on diagnostics allows you to identify common issues without the need for professional intervention. By systematically assessing the situation, you can often rectify problems efficiently and effectively.

Identifying Common Issues

Begin by observing any unusual behavior or sounds. Check for leaks, irregular operation, or signs of wear. Documenting these observations will help pinpoint the source of the malfunction. Additionally, refer to user manuals or online resources to compare symptoms and potential solutions.

Basic Repair Techniques

Once you’ve narrowed down the issue, proceed with basic repair techniques. For instance, cleaning filters or connections can often resolve blockages. Replacing worn or damaged components is also crucial. Always ensure that tools and replacements are compatible with your equipment to avoid further complications. Regular maintenance is key to extending the lifespan of your machinery.

Enhancing Performance with Upgrades

Improving the efficiency and effectiveness of your cleaning equipment can significantly elevate your overall experience. By integrating high-quality enhancements, you can achieve superior results and extend the longevity of your machine.

Key Areas for Upgrades

- Improved Nozzles: Consider specialized nozzles that provide varying spray patterns for targeted cleaning.

- Enhanced Hoses: Opt for durable, flexible hoses that resist kinks and wear for better maneuverability.

- Powerful Motors: Upgrading to a more robust motor can boost performance and reduce cleaning time.

Benefits of Upgrading

- Increased Efficiency: Upgrades can lead to faster, more thorough cleaning processes.

- Cost Savings: Investing in quality components can lower maintenance and replacement costs over time.

- Versatility: Enhanced features allow for tackling a wider range of cleaning tasks effectively.

FAQs About Landa Pressure Washers

This section addresses common inquiries regarding high-performance cleaning equipment, helping users better understand their functionality, maintenance, and troubleshooting. Below are frequently asked questions that can assist both novice and experienced operators in maximizing the efficiency of their machines.

Common Questions

| Question | Answer |

|---|---|

| What type of fuel is recommended? | Using high-quality gasoline is essential for optimal performance. Always refer to the manufacturer’s guidelines for specific recommendations. |

| How often should maintenance be performed? | Regular maintenance is advised every 50 hours of operation or at least once a season to ensure longevity and efficiency. |

| What should I do if my machine won’t start? | Check fuel levels, battery connections, and ensure that all switches are in the correct position. If issues persist, consult a professional technician. |

| Can I use detergents with my equipment? | Yes, but it’s crucial to use detergents specifically designed for high-performance systems to prevent damage and ensure effective cleaning. |

Maintenance Tips

To prolong the lifespan of your equipment, always follow recommended maintenance practices, including regular inspections, cleaning, and prompt repairs. This proactive approach can save time and money in the long run.