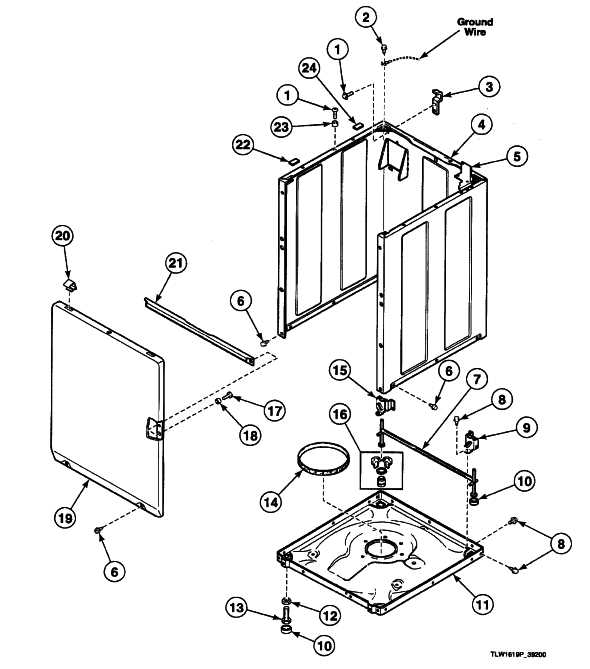

Parts Diagram for Speed Queen Commercial Washers

In the realm of laundry solutions, understanding the intricacies of your machine is essential for efficient operation. This section aims to provide insights into the various elements that make up these essential appliances, highlighting their functions and interconnections. A comprehensive grasp of these components can significantly enhance maintenance practices and prolong the lifespan of the equipment.

Each component plays a vital role in ensuring the smooth functioning of the system. By familiarizing oneself with the arrangement and purpose of these elements, operators can identify potential issues swiftly and implement necessary repairs or adjustments. This knowledge serves as a foundation for troubleshooting and effective upkeep, ultimately leading to better performance and reliability.

Understanding Speed Queen Washers

This section delves into the essential features and functionalities of a renowned brand of laundry appliances. These machines are designed for durability and efficiency, making them a popular choice in various settings, including residential and professional environments. Familiarity with their components and operation can significantly enhance user experience and maintenance.

Key Features

- Durability: Built to withstand heavy use, ensuring long-lasting performance.

- Efficiency: Engineered to optimize water and energy consumption, reducing overall costs.

- User-Friendly Controls: Intuitive interface allows for easy operation and programming of cycles.

Common Components

- Drum: The main chamber where laundry is placed, designed for effective cleaning.

- Agitator: A crucial element that facilitates the movement of clothes for thorough washing.

- Pump: Responsible for draining water from the drum after each cycle.

- Control Panel: The interface where users select washing settings and monitor progress.

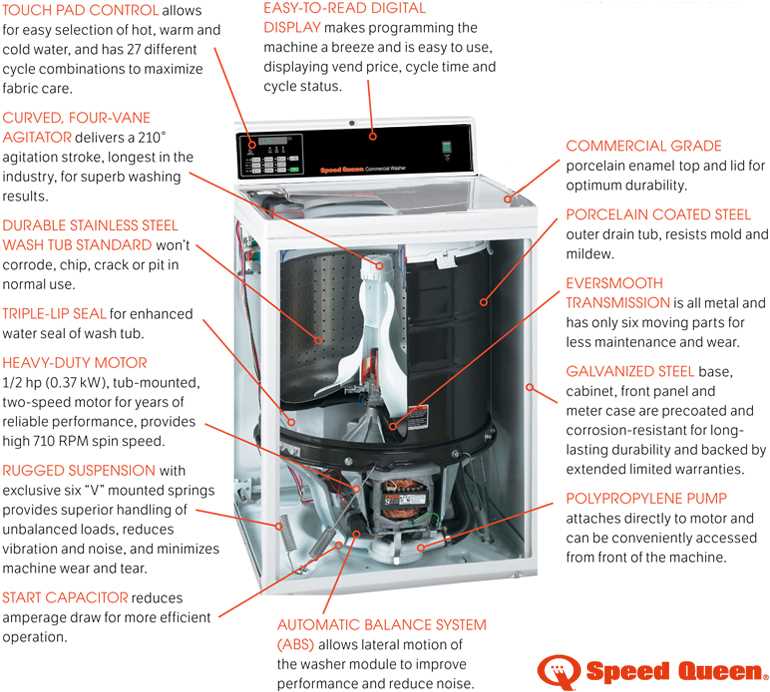

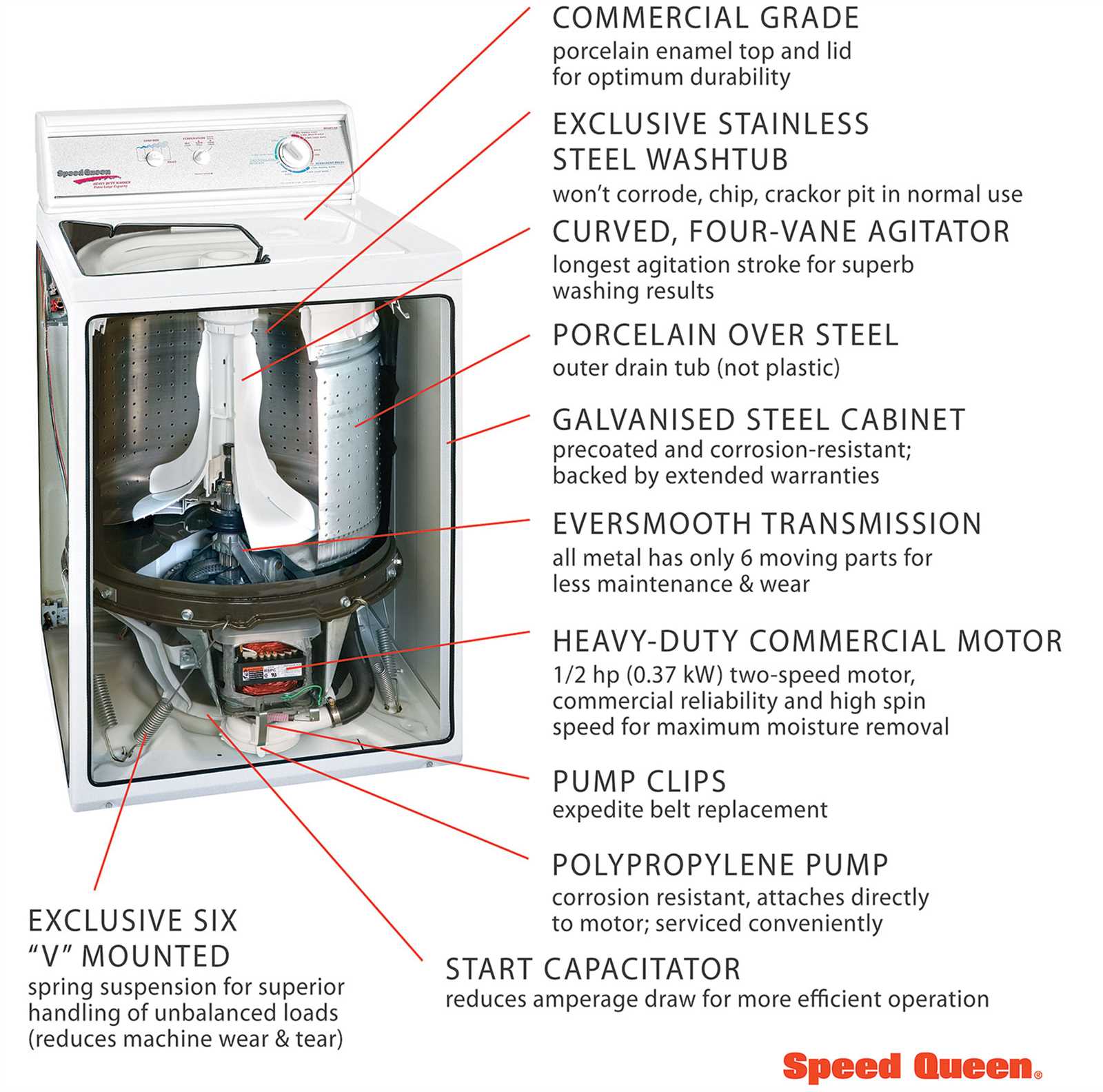

Key Components of Speed Queen Machines

The functionality and efficiency of laundry equipment depend significantly on its essential elements. Understanding these fundamental components is crucial for anyone involved in the maintenance or operation of such machinery. Each part plays a vital role in ensuring optimal performance and longevity.

Among the primary elements, the motor stands out as the powerhouse of the appliance, driving various operations. Another critical component is the drum, which facilitates the movement and rotation of the laundry, ensuring thorough cleaning. Additionally, the control panel provides users with the ability to adjust settings and monitor cycles, enhancing user experience.

Furthermore, the water inlet valve is essential for regulating water flow into the unit, while the drain pump effectively removes used water after each cycle. The suspension system is also noteworthy, as it minimizes vibrations during operation, contributing to the machine’s stability and quiet performance.

Each of these components contributes to the overall efficiency and effectiveness of the laundry system. Proper maintenance and understanding of these parts can lead to improved performance and extended lifespan of the equipment.

Functionality of Washer Parts

The essential components of a laundry appliance work in harmony to ensure effective cleaning and efficient operation. Each element plays a crucial role in the overall functionality, contributing to the seamless process of garment care. Understanding how these elements interact can enhance the performance and longevity of the machine.

Key Components and Their Roles

Each individual component has a specific function, from initiating the wash cycle to rinsing and spinning. The motor, for instance, drives the drum, facilitating the rotation necessary for agitating the contents. The pump is responsible for moving water in and out of the appliance, while the control panel allows users to select desired settings, providing ease of operation.

Importance of Maintenance

Regular upkeep of these components is vital for optimal functionality. Neglecting any part can lead to inefficiencies or malfunctions, ultimately affecting cleaning results. By ensuring that all elements are in good working order, users can maximize the effectiveness of their laundry appliance.

Common Issues with Washer Parts

When dealing with laundry appliances, it’s not uncommon to encounter a variety of challenges related to their components. Understanding these frequent problems can assist users in identifying issues early on and maintaining optimal functionality. Below are some typical concerns that may arise, which can impact the overall performance of these machines.

1. Leaks and Drips

One of the most prevalent issues faced is water escaping from the unit. This can often be attributed to worn-out seals or damaged hoses. Regular inspection and timely replacement of these components are essential to prevent water damage and maintain efficiency.

2. Noisy Operation

Unusual sounds during operation can indicate various underlying problems. Noises such as banging or grinding may suggest that certain elements are misaligned or need lubrication. Addressing these concerns promptly can help avoid further damage and extend the lifespan of the appliance.

Maintaining awareness of these common challenges is crucial for effective upkeep and ensures the longevity of the machine’s functionality.

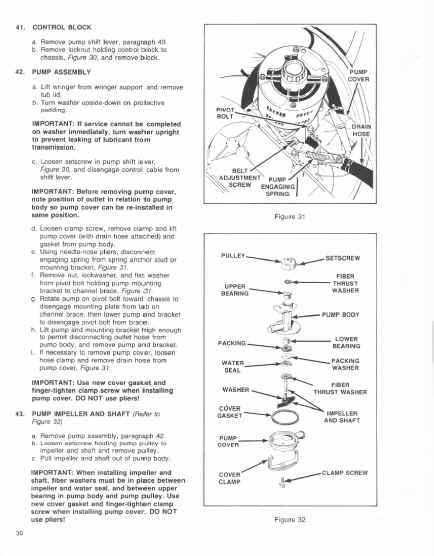

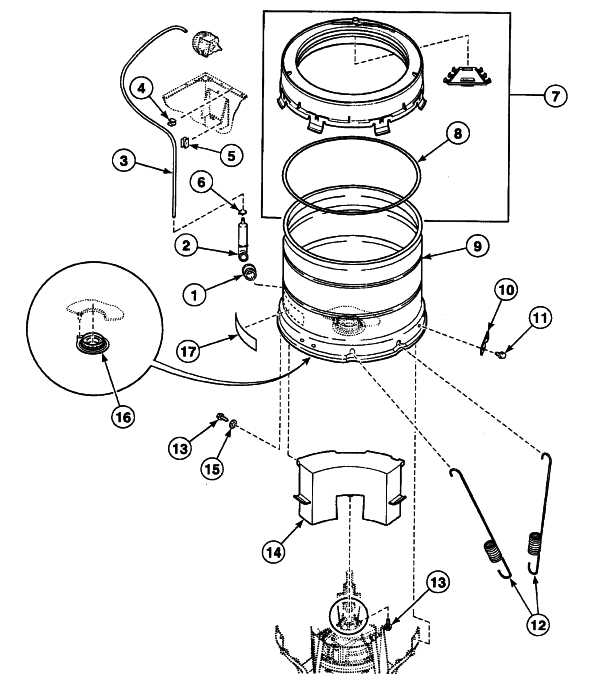

How to Identify Parts on Diagrams

Understanding how to recognize components on visual representations is essential for effective maintenance and repair. Each symbol or label has a specific meaning that correlates with physical elements. Familiarity with these identifiers aids in troubleshooting and ensures that replacements or adjustments are carried out correctly.

Familiarization with Symbols

Different illustrations utilize various symbols to denote specific components. It is crucial to become acquainted with these symbols and their meanings. Many resources provide a key or legend, which serves as a helpful guide. Regularly referring to these legends will enhance your ability to identify parts quickly and accurately.

Cross-Referencing with Manuals

Utilizing instructional manuals alongside visual representations can provide clarity. Manuals often include detailed explanations and additional context for each component. By cross-referencing the manual with the illustration, users can gain a comprehensive understanding of how parts function together and identify the correct replacements when needed.

Maintenance Tips for Long-lasting Performance

Regular upkeep is essential for ensuring the durability and efficiency of your appliance. Implementing a few straightforward practices can significantly extend its lifespan and maintain optimal functionality. Below are several key strategies that will help you achieve this goal.

Routine Cleaning

Maintaining cleanliness is crucial for any appliance. Accumulated dirt and debris can hinder performance and lead to premature wear. Here are some cleaning tips:

- Wipe down the exterior regularly to remove dust and grime.

- Check and clean the drum after every use to prevent buildup.

- Ensure that all filters are cleared of lint and obstructions.

Regular Inspections

Frequent checks can help you identify potential issues before they escalate. Consider these inspection practices:

- Examine hoses for signs of wear or leaks.

- Test electrical connections to ensure they are secure.

- Monitor the performance during each cycle to spot irregularities.

By following these maintenance tips, you can enhance the longevity of your appliance and ensure it operates efficiently for years to come.

Ordering Replacement Parts Efficiently

Acquiring necessary components for equipment maintenance is crucial for ensuring optimal functionality. To streamline the process, it is important to adopt effective strategies that enhance the experience of procuring replacements. By following these guidelines, individuals can minimize delays and avoid unnecessary costs.

Research and Identify Components

Begin by thoroughly investigating the specific components needed for your equipment. Use online resources, manuals, or even seek assistance from professionals to identify the exact specifications. Understanding the precise requirements will help in locating the right substitutes without confusion.

Utilize Trusted Suppliers

Engage with reputable suppliers who specialize in providing quality replacements. Establishing a relationship with reliable vendors ensures access to authentic components and timely delivery. Moreover, inquire about any warranties or return policies to safeguard your investment.

Tools Needed for Parts Replacement

When undertaking the task of replacing components in laundry equipment, having the appropriate instruments at your disposal is essential. This ensures not only a smooth process but also enhances safety and efficiency during maintenance tasks.

Common tools you may require include a standard screwdriver set, pliers, and a socket wrench for loosening and tightening fasteners. Additionally, a multimeter can be invaluable for checking electrical connections and diagnosing potential issues. It is also advisable to have a flashlight on hand to illuminate dark spaces within the machine.

Having a workbench or a clean, organized area where you can lay out your tools and the components you will be replacing can significantly streamline your workflow. Always remember to consult the manufacturer’s recommendations for any specific tools that may be required for your particular model.

Exploring Different Models and Variants

In the realm of laundry appliances, various designs and iterations cater to diverse needs and preferences. Understanding the differences among these variations can enhance efficiency and optimize performance in both residential and professional settings.

Each model boasts unique features tailored to specific user requirements. Here are some common categories to consider:

- Residential Units: These models are designed for home use, focusing on user-friendliness and energy efficiency.

- Heavy-Duty Options: Built to withstand rigorous usage, these variants are ideal for settings with high laundry demands.

- Compact Designs: Perfect for limited spaces, these units combine functionality with a smaller footprint.

- Smart Technology Models: Equipped with advanced features, these appliances allow for remote control and monitoring through mobile applications.

Exploring these options will enable users to select the most suitable machine for their specific laundry needs. Familiarity with the distinct characteristics of each variant ensures informed decision-making and optimal satisfaction.

Customer Support and Resources

When it comes to maintaining your equipment, having access to reliable assistance and valuable resources is essential. Support services play a vital role in ensuring that users can resolve any issues they encounter effectively and efficiently. This section provides an overview of the various support options and helpful materials available to users.

Assistance Channels

Users can access a range of assistance channels to address their inquiries and concerns. These include phone support, email communication, and live chat services. Each channel offers unique benefits, allowing individuals to choose the method that best fits their needs. Whether you require immediate help or prefer to send a detailed request, these channels are designed to facilitate swift and effective resolutions.

Helpful Resources

In addition to direct support, users can benefit from an array of informative resources. Manuals, troubleshooting guides, and video tutorials serve as valuable tools for understanding the operation and maintenance of your equipment. These resources not only help to enhance your knowledge but also empower you to tackle minor issues independently, saving time and resources in the long run.

Benefits of Using Authentic Parts

Utilizing genuine components in your equipment can significantly enhance its performance and longevity. Authentic elements are specifically designed to meet the exact specifications of the machinery, ensuring optimal functionality. This commitment to quality not only supports the operational efficiency of your appliance but also helps maintain its overall value over time.

Quality Assurance

One of the primary advantages of choosing original components is the assurance of superior quality. These elements undergo rigorous testing and adhere to strict manufacturing standards, providing confidence that they will perform reliably. By investing in authentic components, you minimize the risk of malfunctions and ensure your equipment operates smoothly.

Long-Term Cost Savings

While genuine components may initially appear more expensive than generic alternatives, they often lead to substantial long-term savings. Authentic parts typically last longer and require less frequent replacement, reducing overall maintenance costs. Additionally, their reliable performance decreases the likelihood of breakdowns, which can be costly in terms of repairs and downtime.