Honda GX120 Water Pump Parts Diagram Explained

When it comes to maintaining the efficiency of your machine, having a clear understanding of its inner workings is essential. Each element plays a critical role in the overall functionality, and knowing how they interact can help prevent issues before they arise. This guide will delve into the specifics of one such model, providing insight into its essential elements.

In this exploration, we will break down the intricate assembly of the device, highlighting the various components that contribute to its performance. By familiarizing yourself with these individual parts, you can better appreciate their functions and the importance of regular maintenance. The visual representation of these elements will serve as a valuable reference point for both novice users and experienced operators alike.

Equipped with this knowledge, you can approach repairs and maintenance tasks with confidence. Understanding each component not only aids in troubleshooting but also enhances your overall experience with the machine. Whether you are looking to replace a worn piece or simply gain a deeper understanding of your equipment, this detailed examination will guide you through the process.

Understanding Honda GX120 Water Pump

This section explores the essential components and functioning of a specific fluid transfer machine, highlighting its design and operational aspects. By examining its structure, users can gain insights into maintenance and troubleshooting, ensuring optimal performance over time.

Key Components

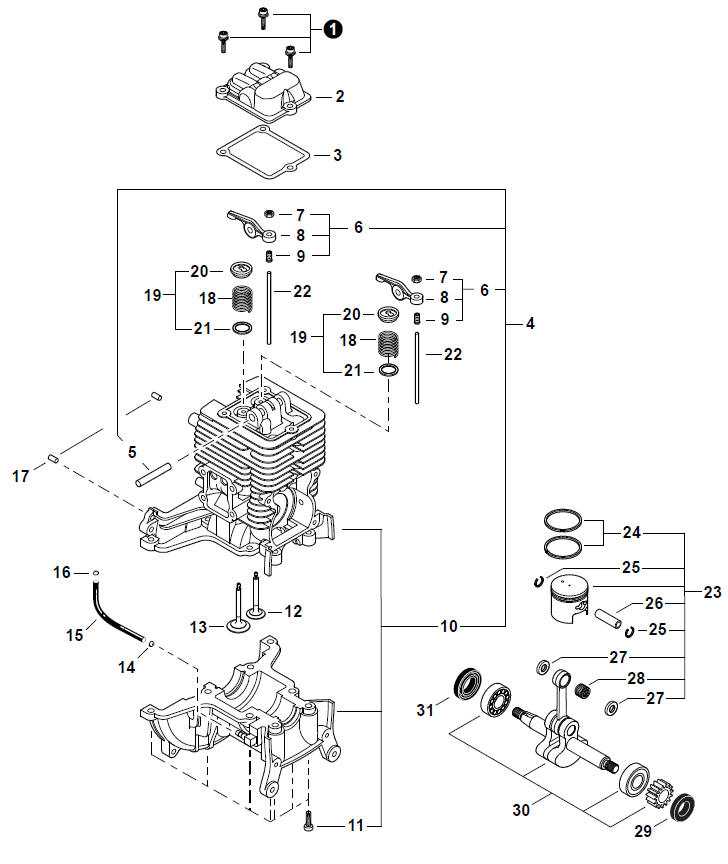

The main elements of this device include the engine, impeller, and housing. Each part plays a crucial role in the overall efficiency and effectiveness of the system. A comprehensive understanding of these components aids in both regular upkeep and effective repairs.

Operational Insights

Efficiency in operation depends on various factors, including the arrangement of components and the quality of materials used. Regular inspection and timely replacement of worn elements can significantly enhance the longevity and reliability of the machine.

| Component | Description |

|---|---|

| Engine | Powers the unit, converting fuel into mechanical energy. |

| Impeller | Responsible for moving the fluid through the system. |

| Housing | Encases the internal mechanisms, providing protection and structure. |

Key Components of the Water Pump

Understanding the essential elements of this device is crucial for efficient operation and maintenance. Each component plays a significant role in ensuring optimal performance and reliability, contributing to the overall functionality of the system.

The engine serves as the powerhouse, generating the necessary force. Coupled with the impeller, it moves fluid effectively, creating the required pressure. Additionally, the casing protects internal parts and aids in directing the flow, while seals prevent leaks and ensure durability. Filters are vital for maintaining cleanliness, preventing debris from entering the system, and extending its lifespan.

Regular inspection and knowledge of these key components can enhance efficiency and reduce potential issues, ultimately leading to a more effective performance.

Importance of a Parts Diagram

A detailed visual representation of components is essential for anyone involved in maintenance or repair tasks. Such illustrations provide clarity, making it easier to identify each piece and understand how they interact within a system. When faced with a malfunction or the need for upgrades, having a comprehensive guide is invaluable.

Enhancing Understanding

Visual aids not only simplify the assembly process but also enhance overall comprehension. By showcasing the relationship between various elements, users can gain insights into the function and purpose of each part. This leads to more effective troubleshooting and informed decision-making.

Facilitating Efficient Repairs

When performing repairs, quick access to a well-organized visual guide can significantly reduce downtime. Knowing the exact location and arrangement of each component allows technicians to work swiftly and accurately. Moreover, this resource can prevent errors, ensuring that every piece is correctly replaced or adjusted, ultimately extending the lifespan of the equipment.

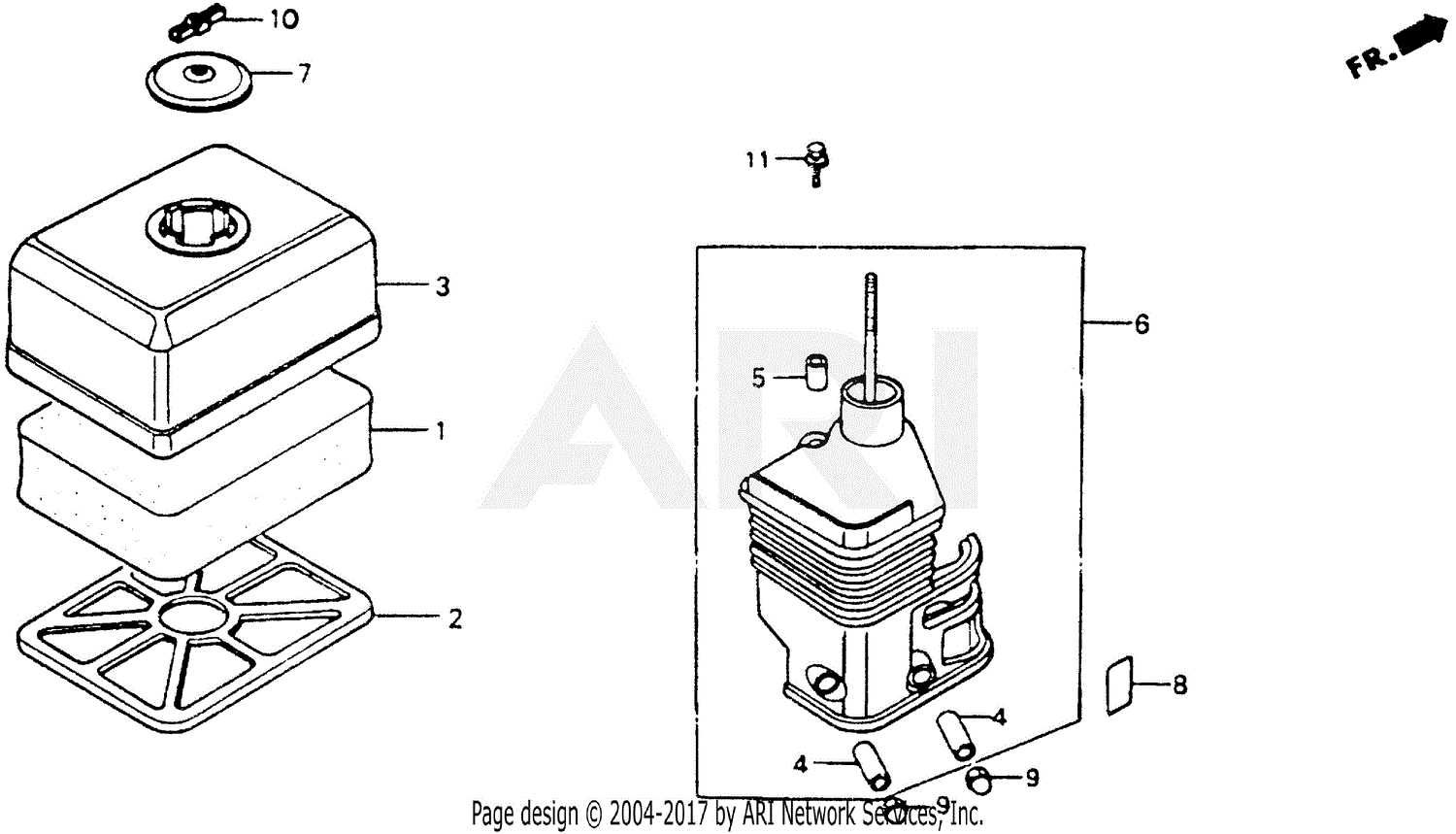

How to Read a Parts Diagram

Understanding an illustration of components is essential for effective maintenance and repair. This visual guide offers a structured way to identify and locate individual elements within a complex assembly. By familiarizing yourself with the symbols and notations, you can navigate the layout more efficiently.

Identifying Symbols and Labels

Every illustration contains specific icons and text that denote various elements. Familiarizing yourself with these symbols is crucial. They often include numbers or letters that correspond to a list of items, making it easier to find what you need.

Following the Assembly Sequence

Pay attention to the order in which components are arranged. This sequence often reflects how they fit together in the actual setup. Recognizing this flow can greatly simplify the reassembly process after repairs or replacements.

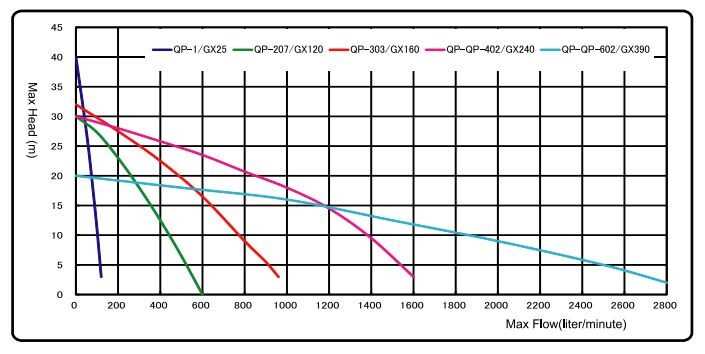

Common Issues with Water Pumps

In any system that involves fluid movement, various challenges can arise that affect efficiency and performance. Understanding these common problems is essential for maintaining optimal operation and ensuring longevity. This section explores typical malfunctions and their potential solutions.

| Issue | Description | Possible Solutions |

|---|---|---|

| Overheating | Excessive heat can cause damage to internal components and lead to failures. | Check for blockages, ensure proper cooling mechanisms are in place, and monitor fluid levels. |

| Leaks | Fluid escaping from joints or seals can reduce efficiency and create hazards. | Inspect seals and gaskets for wear; replace any damaged components promptly. |

| Noisy Operation | Unusual sounds may indicate mechanical issues or misalignment. | Examine for loose parts or misaligned components and tighten or realign as necessary. |

| Poor Performance | Insufficient flow or pressure can impact overall effectiveness. | Evaluate intake and discharge areas for blockages; clean or clear as needed. |

| Corrosion | Degradation of materials can weaken structures and lead to failure. | Use corrosion-resistant materials and perform regular inspections for early detection. |

Maintaining Your Honda GX120

Regular upkeep is essential for ensuring longevity and optimal performance of your equipment. Proper care not only enhances efficiency but also prevents unexpected breakdowns. This guide will explore key practices to keep your machine running smoothly.

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Check Oil Levels | Every 20 hours | Use recommended oil type for best results. |

| Clean Air Filter | Every 50 hours | Replace if damaged or heavily soiled. |

| Inspect Fuel System | Before each use | Ensure no leaks or blockages are present. |

| Examine Hoses and Connections | Monthly | Look for wear and tighten any loose fittings. |

Replacement Parts Availability

Access to essential components is crucial for maintaining the efficiency and longevity of your machinery. Finding reliable sources for these elements can enhance performance and reduce downtime. Understanding where to locate high-quality replacements is key for any operator looking to ensure their equipment runs smoothly.

Where to Find Components

Numerous retailers specialize in supplying essential items for various machines. Online marketplaces often provide a wide selection, allowing users to compare prices and specifications easily. Additionally, local suppliers may offer personalized service, ensuring that you acquire the right components for your specific needs.

Quality and Compatibility

When seeking replacements, it’s vital to prioritize both quality and compatibility. OEM options usually guarantee a perfect fit and reliable performance, while aftermarket choices can offer cost-effective alternatives. Always verify compatibility with your model to avoid unnecessary complications and ensure optimal functioning.

Identifying Each Component Easily

Understanding the individual elements of a machinery unit can significantly enhance your maintenance skills and efficiency. Recognizing each part by its function and appearance simplifies troubleshooting and repairs, allowing for a smoother operational experience. Familiarity with the components will empower users to handle issues promptly, ensuring the device performs optimally.

Key Elements and Their Functions

Each segment serves a unique purpose within the assembly. For instance, the primary component is responsible for generating power, while others aid in directing flow and managing pressure. By studying the layout and roles of these elements, you can easily pinpoint where problems may arise and take corrective actions swiftly.

Visual Identification Tips

To assist in quick recognition, consider creating a reference guide featuring labeled illustrations or photographs of each piece. Color coding components can also be an effective method for distinguishing between various types. Additionally, employing simple mnemonics can aid in memorizing the arrangement and functions, facilitating quicker repairs and maintenance tasks.

Tools Needed for Repairs

Effective maintenance requires a selection of essential instruments to ensure successful repairs. Having the right tools on hand can significantly simplify the process and enhance overall efficiency.

- Socket Set

- Wrench Set

- Screwdriver Set

- Pliers

- Torque Wrench

- Adjustable Wrench

Additionally, certain specialized tools may be beneficial for more complex tasks:

- Fuel Line Tool

- Seal Puller

- Diagnostic Tester

Being well-equipped will ultimately lead to smoother repairs and extended longevity of the equipment.

Step-by-Step Assembly Guide

This section provides a comprehensive walkthrough for assembling the equipment effectively and efficiently. By following these organized steps, you will ensure a smooth installation process and optimal performance of the unit.

Step 1: Preparation

Before beginning assembly, gather all necessary tools and components. Ensure you have a clean workspace to facilitate an orderly process.

Step 2: Base Installation

Start by securing the base structure. Align the components accurately and use the appropriate fasteners to secure them tightly. This foundation is crucial for stability.

Step 3: Connecting the Engine

Carefully attach the engine to the assembled base. Make sure to follow the alignment marks, and ensure all connections are snug to prevent any movement during operation.

Step 4: Assembly of the Delivery System

Next, install the delivery components. This step involves connecting the necessary pipes and hoses. Ensure that all seals are tight to avoid leaks, and double-check the fittings for security.

Step 5: Final Adjustments

After all major components are in place, inspect the entire assembly. Look for any loose parts or misalignments. Make the necessary adjustments to guarantee everything is functioning properly.

Step 6: Testing

Once the assembly is complete, perform a thorough test. This will help identify any issues before the equipment is put into regular use. Monitor for performance and ensure everything operates smoothly.

By adhering to these steps, you can achieve a successful assembly that will enhance the efficiency and longevity of your equipment.

Understanding Water Pump Operation

This section explores the fundamental principles that govern the functionality of fluid-moving machinery, focusing on the essential components and their interactions. By examining these mechanisms, one can appreciate the efficiency and reliability of these devices in various applications.

| Component | Function |

|---|---|

| Motor | Drives the mechanism, providing the necessary energy to initiate fluid movement. |

| Impeller | Transforms rotational energy into kinetic energy, propelling the liquid forward. |

| Volute | Guides the flow, converting kinetic energy into pressure to enhance efficiency. |

| Seal | Prevents leakage, ensuring the integrity of the system and minimizing loss of fluid. |

| Inlet/Outlet | Facilitates entry and exit of the liquid, maintaining a continuous flow. |

Understanding these elements provides insight into how they work together to achieve optimal performance and address various challenges in fluid transfer tasks.

Safety Precautions for Repairs

When engaging in maintenance or fixing machinery, ensuring safety is paramount. Proper precautions can prevent accidents and injuries, fostering a secure environment for both the technician and equipment.

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear.

- Disconnect power sources before starting any repair work to avoid electric shock.

- Work in a well-ventilated area to prevent inhalation of harmful fumes.

- Keep your workspace organized to minimize the risk of accidents caused by clutter.

- Use tools that are in good condition and specifically designed for the task at hand.

Adhering to these guidelines not only enhances personal safety but also ensures that the machinery functions optimally after repairs.

Resources for Further Learning

Expanding your knowledge about machinery maintenance and repair can greatly enhance your skills and understanding. This section provides valuable materials and references to help you explore various aspects related to the functioning and upkeep of engines.

| Resource Type | Description | Link |

|---|---|---|

| Online Forums | Engage with community experts to share insights and troubleshooting techniques. | Visit Forum |

| Instructional Videos | Visual guides that cover assembly, disassembly, and maintenance procedures. | Watch Videos |

| Books | Comprehensive texts offering detailed information on engine mechanics. | Browse Books |

| Manufacturer Manuals | Official documentation detailing specifications and service guidelines. | Access Manuals |