Comprehensive Guide to Honda Water Pump Parts Diagram

The efficient operation of machinery often hinges on the intricate interplay of various elements. Gaining insight into these components can significantly enhance maintenance practices and overall functionality. In this exploration, we aim to highlight the crucial aspects that contribute to seamless performance.

Each individual piece plays a pivotal role, and understanding their specific functions can lead to improved reliability. By examining the configuration and relationships among these elements, users can make informed decisions regarding upkeep and repairs.

Whether you’re a seasoned technician or a novice enthusiast, delving into the structure of these components reveals the ultimate secrets behind effective operation. Grasping how they work together empowers users to achieve optimal results in their endeavors.

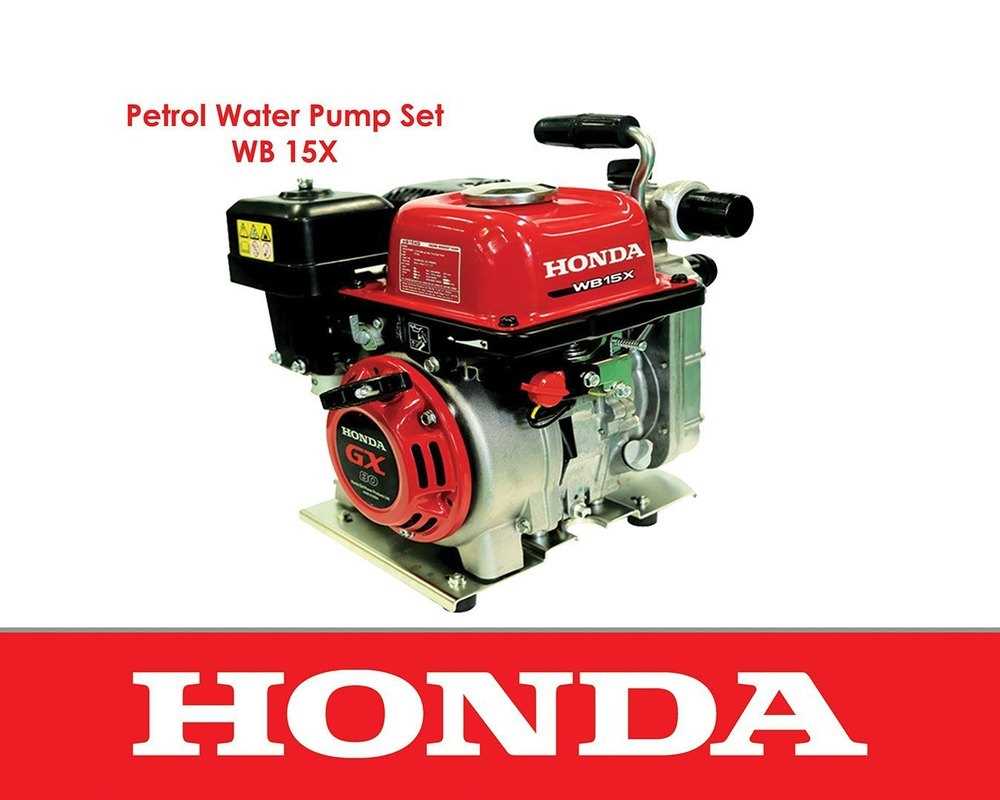

Understanding Honda Water Pumps

This section aims to explore the essential components and functions of a fluid circulation device, focusing on its significance in maintaining performance and efficiency in various applications. A deeper understanding of its inner workings can help users identify issues and ensure optimal operation.

Key Components

The core elements of this system include a motor, an impeller, and seals, each playing a critical role in the fluid movement process. Familiarity with these components enhances troubleshooting capabilities and maintenance practices.

| Component | Function |

|---|---|

| Motor | Drives the impeller, initiating fluid movement. |

| Impeller | Increases fluid velocity, directing it through the system. |

| Seals | Prevents leaks, maintaining system integrity. |

Maintenance Tips

Regular inspection of the key elements is vital for longevity. Cleaning and timely replacement of worn components can significantly enhance performance and prevent breakdowns.

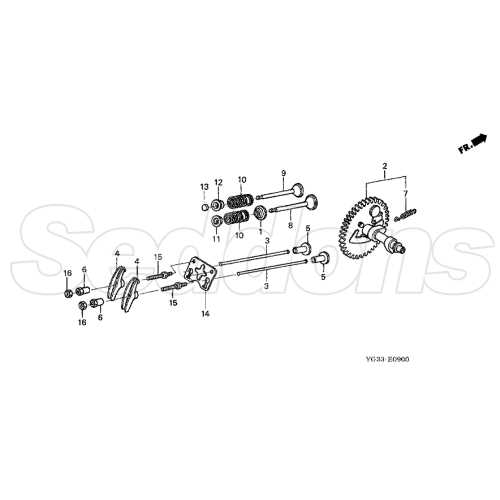

Key Components of Honda Water Pumps

This section explores the essential elements that contribute to the functionality and efficiency of these devices. Understanding these components allows users to grasp their roles and importance in the overall system.

Essential Elements

- Engine: Provides the necessary power for operation.

- Impeller: Moves fluid through the system, creating flow.

- Volute: Directs the fluid towards the discharge outlet.

- Seals: Prevent leaks and maintain pressure.

Supporting Features

- Strainer: Prevents debris from entering the system.

- Throttle: Controls the speed and flow rate.

- Fuel System: Ensures adequate energy supply for the engine.

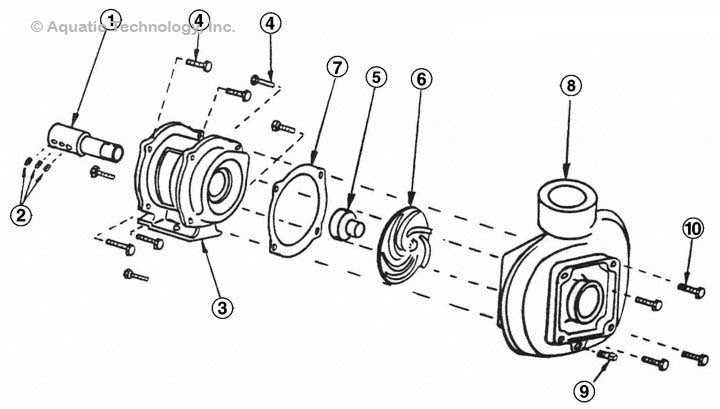

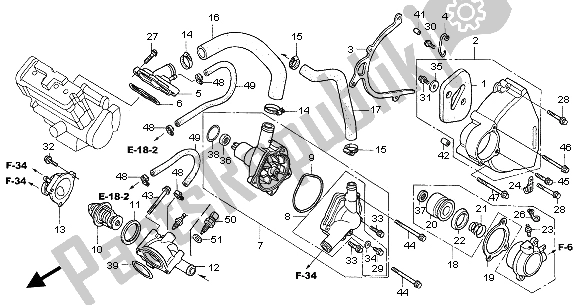

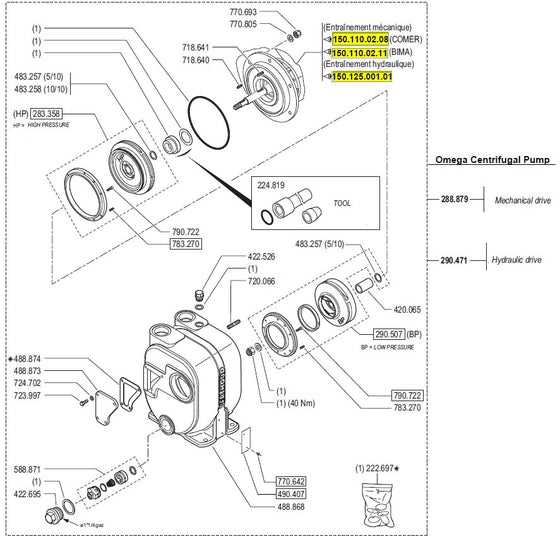

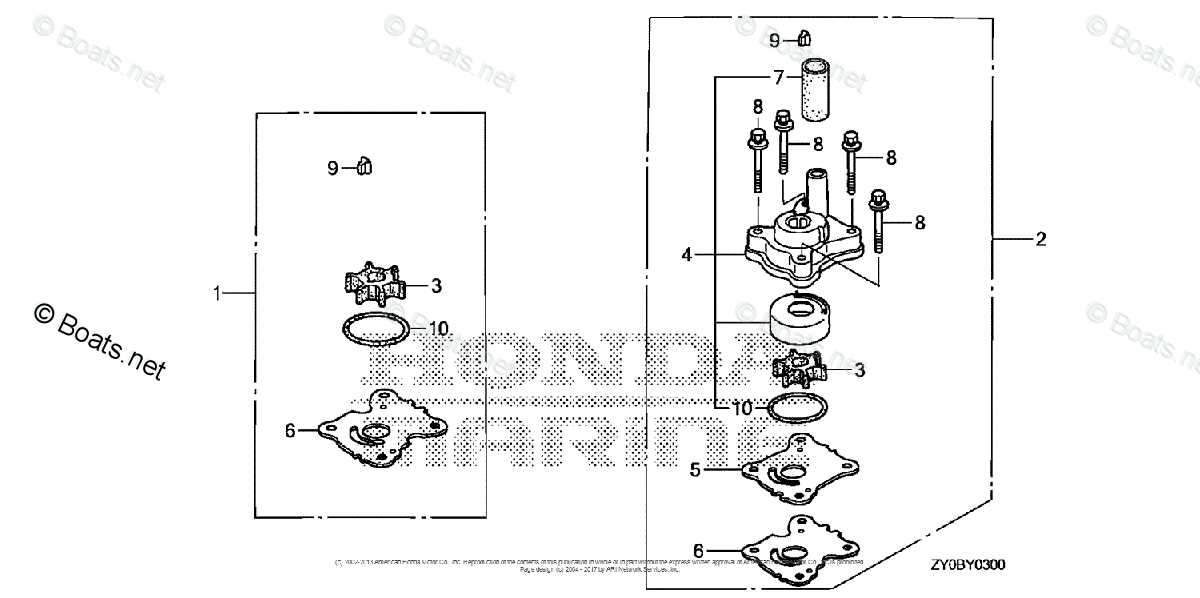

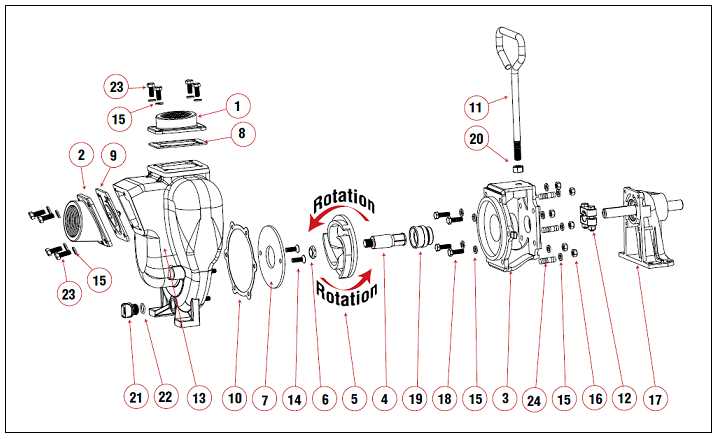

Importance of Water Pump Diagrams

Understanding the intricacies of mechanical systems is essential for efficient maintenance and repair. Visual representations serve as crucial tools, offering clarity and insight into the various components involved. This knowledge aids in identifying issues and implementing solutions effectively.

Clear visual guides provide a roadmap, enabling technicians to navigate complex assemblies with ease. They help in pinpointing the location of each component, ensuring that repairs are executed accurately and swiftly. Additionally, these illustrations enhance communication among professionals, fostering collaboration in troubleshooting processes.

Ultimately, utilizing visual aids streamlines the workflow, reduces the risk of errors, and enhances the longevity of the machinery. Investing time in understanding these guides can lead to better outcomes and increased efficiency in any mechanical project.

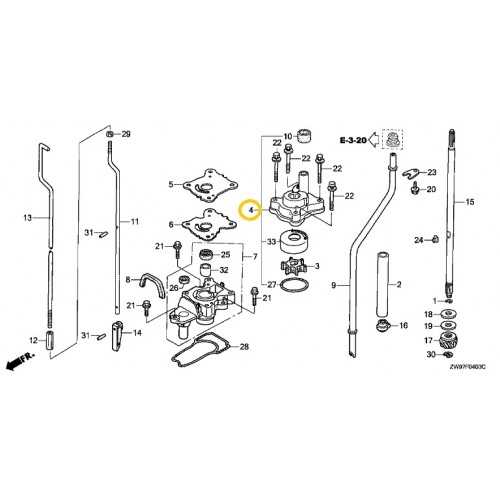

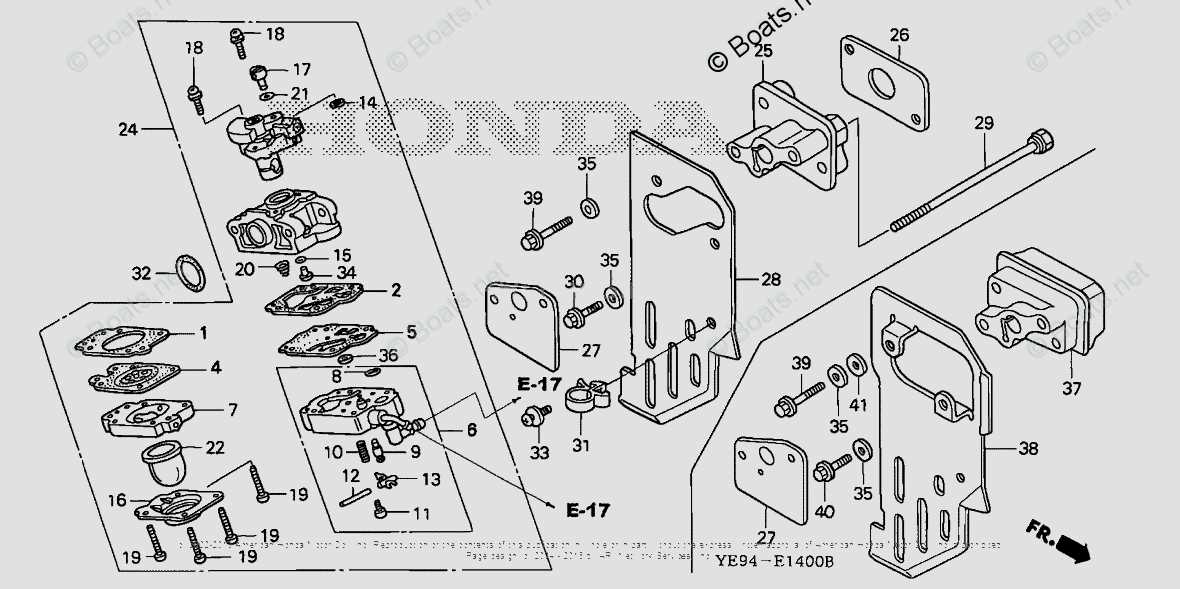

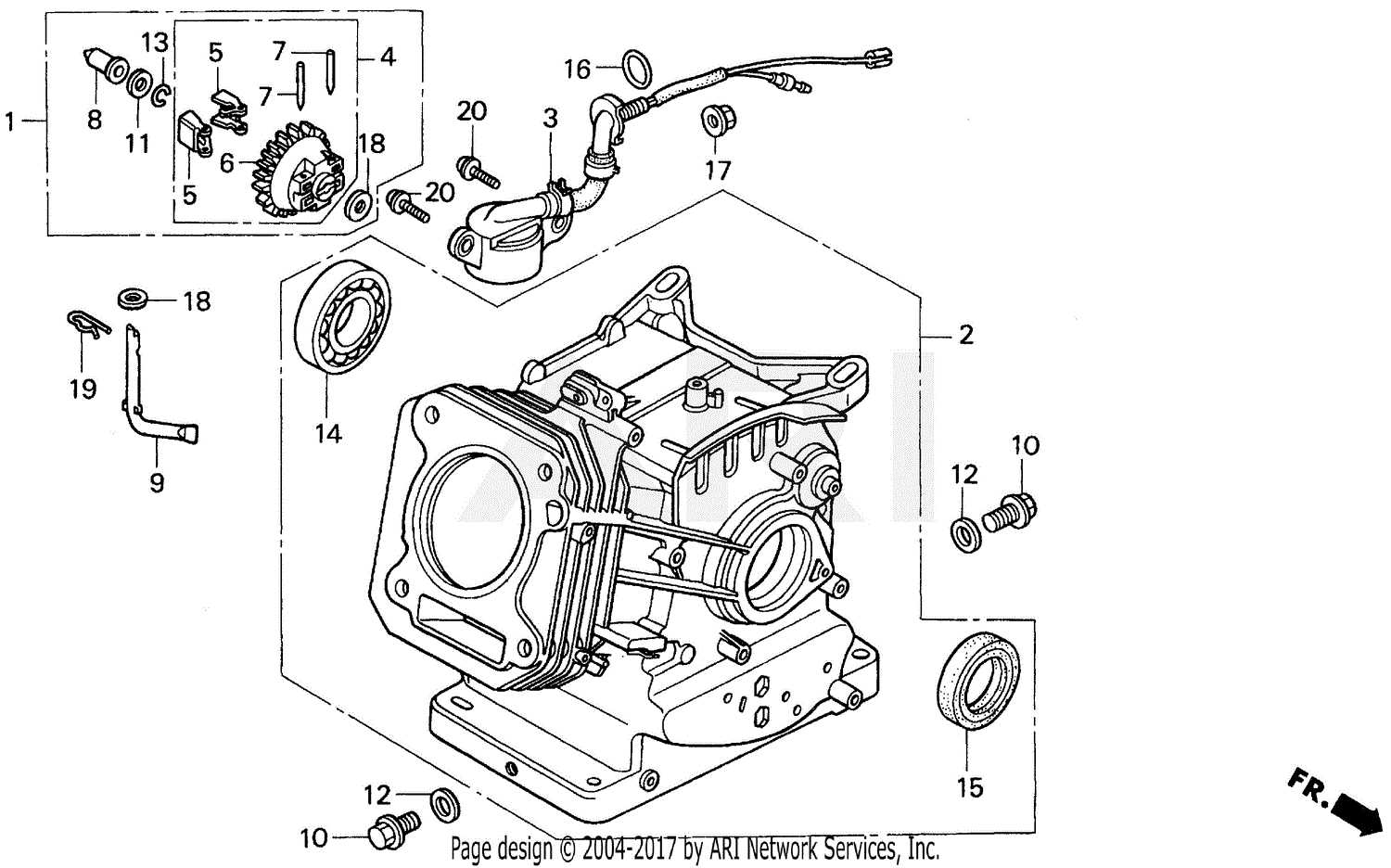

Identifying Parts in the Diagram

Understanding the components within a technical illustration is crucial for effective maintenance and repair tasks. This section aims to provide insights into recognizing and differentiating various elements depicted in the visual representation. Familiarity with these components will enhance troubleshooting and facilitate the assembly or disassembly processes.

Common Components and Their Functions

Each element within the illustration serves a specific purpose, contributing to the overall functionality of the system. Here is a brief overview of some common components:

| Component | Function |

|---|---|

| Impeller | Drives fluid movement within the system. |

| Seal | Prevents leakage of fluids, ensuring efficient operation. |

| Housing | Encloses the internal components and provides structural support. |

| Drive Shaft | Transfers rotational energy to the impeller. |

Tips for Accurate Identification

When examining the illustration, consider the following tips for accurate identification of each element:

- Refer to the accompanying labels or legends for clarification.

- Compare the components against actual parts for a better understanding.

- Note any distinguishing features, such as shape or size, that may aid in identification.

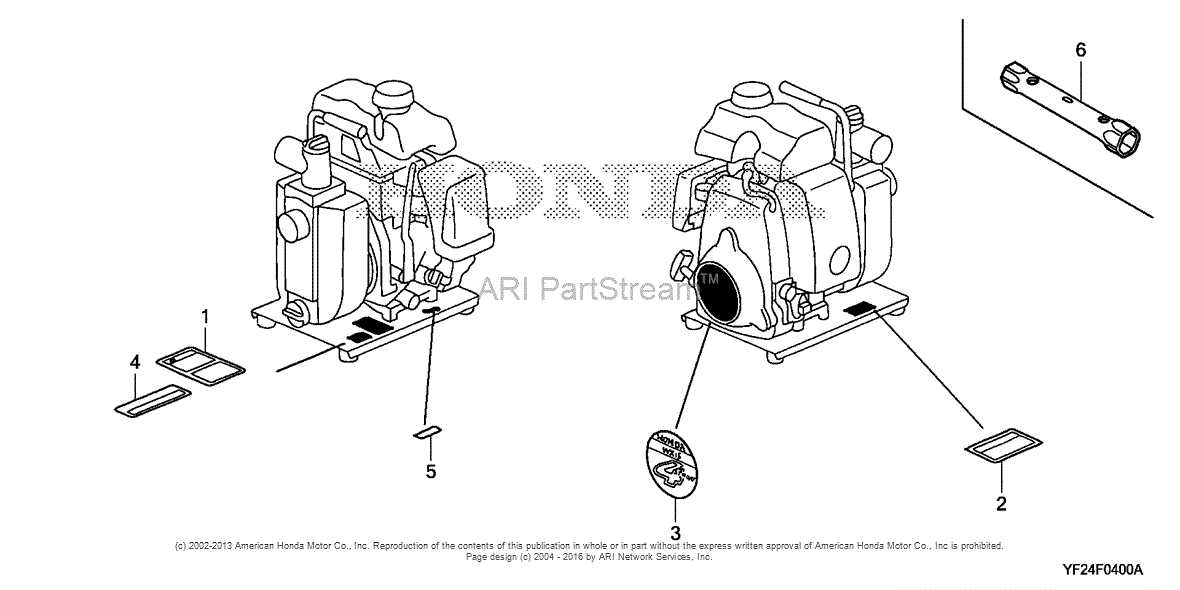

Common Honda Water Pump Models

This section provides an overview of widely used models known for their reliability and performance in fluid circulation. Understanding these variants is crucial for effective maintenance and repair, ensuring optimal functionality in various applications.

Popular Models

| Model Name | Specifications | Typical Uses |

|---|---|---|

| Model A | 1.5 HP, 2″ Inlet/Outlet | Construction, Agriculture |

| Model B | 2.0 HP, 3″ Inlet/Outlet | Irrigation, Industrial |

| Model C | 1.0 HP, 1.5″ Inlet/Outlet | Residential, Landscaping |

Key Features

Each model boasts distinct characteristics designed to meet specific requirements. Enhanced durability, ease of maintenance, and energy efficiency are common attributes that ensure longevity and effective operation in diverse environments.

How to Read Pump Diagrams

Understanding visual representations of mechanical assemblies is crucial for effective maintenance and repair. These illustrations provide insights into the components’ arrangement, functionality, and interactions within the system. By familiarizing yourself with the key elements, you can navigate these graphics with confidence.

Key Components

Each illustration typically includes symbols for various elements such as motors, seals, and impellers. Familiarize yourself with these icons to grasp their roles within the entire assembly. Labels often accompany these symbols, detailing specifications like dimensions and materials.

Reading the Flow Direction

Flow direction is essential for proper assembly and functionality. Look for arrows that indicate the movement of fluids, as these will guide you on how components interact. Understanding this aspect ensures the system operates efficiently and prevents potential issues. Take your time to analyze these indications before proceeding with any tasks.

Maintenance Tips for Water Pumps

Regular upkeep is essential for ensuring the longevity and efficiency of your machinery. Implementing a few simple strategies can prevent potential issues and enhance overall performance.

- Check for leaks regularly to avoid fluid loss.

- Inspect seals and gaskets for wear and replace them as needed.

- Clean any debris or build-up that could obstruct movement.

- Monitor operating temperatures to prevent overheating.

- Ensure all connections are secure to avoid vibrations.

By following these guidelines, you can significantly extend the lifespan and reliability of your equipment.

Diagnosing Pump Issues with Diagrams

Identifying problems in mechanical systems can often be a challenging task. Utilizing visual representations can greatly enhance the understanding of components and their interactions. By closely examining these illustrations, one can pinpoint malfunctions, assess conditions, and streamline troubleshooting processes.

Common Symptoms: Recognizing indicators such as unusual noises, leaks, or performance drops is crucial. Each symptom can correspond to specific components depicted in the visuals, aiding in efficient diagnostics.

Step-by-Step Analysis: Following a structured approach while referencing the illustrations helps in methodically assessing each section of the mechanism. This practice not only clarifies the areas needing attention but also reinforces overall comprehension of the system’s functionality.

Where to Find Replacement Parts

Finding suitable components for your machinery is crucial for maintaining efficiency and performance. There are several avenues you can explore to locate the right items for your needs.

- Authorized Dealers: Check with certified distributors who specialize in original equipment.

- Online Marketplaces: Websites like eBay and Amazon often have a variety of options from different sellers.

- Local Auto Stores: Visit nearby retail outlets that may carry compatible components.

- Salvage Yards: Explore junkyards for used parts that can be a cost-effective solution.

- Manufacturer Websites: Many brands provide resources for finding genuine items directly from their sites.

By utilizing these sources, you can ensure you find the ultimate components to keep your equipment running smoothly.

Comparing Honda Water Pumps to Others

When examining different models in the realm of fluid circulation machinery, it’s essential to evaluate their unique features and performance capabilities. While some brands stand out for their reliability and efficiency, others may offer alternative advantages that cater to specific user needs. This comparison aims to highlight these distinctions, enabling informed choices for various applications.

Performance and Efficiency

One key aspect to consider is the performance of each model. Some machines excel in high-output scenarios, providing robust flow rates ideal for heavy-duty tasks. Conversely, others might prioritize energy efficiency, ensuring lower operational costs over time. This balance between power and sustainability is crucial for users looking to maximize value.

Durability and Maintenance

Another vital factor is the durability of the equipment. Certain brands are renowned for their use of high-quality materials, resulting in longevity and reduced wear and tear. Maintenance requirements also vary; some models require frequent upkeep, while others are designed for minimal intervention. Understanding these aspects can significantly impact long-term satisfaction and reliability.

DIY Repairs Using Diagrams

Engaging in do-it-yourself repairs can be a rewarding experience, especially when utilizing visual aids to guide the process. These illustrations provide a clear representation of components, helping enthusiasts understand the assembly and disassembly of various systems. Whether for maintenance or troubleshooting, having access to these resources can simplify even the most complex tasks.

Understanding the Visual Aids

Visual guides serve as invaluable references, allowing individuals to grasp the layout of different elements. By studying these resources, one can identify potential issues, locate specific components, and determine the appropriate tools needed for repairs. This knowledge fosters confidence and encourages a hands-on approach.

Steps to Successful Repairs

To achieve successful repairs, start by carefully examining the visual materials. Follow each step methodically, ensuring all parts are accounted for and correctly aligned. Documenting the process can also be beneficial, providing a reference for future maintenance. With patience and attention to detail, even novice repairers can achieve professional results.

Benefits of Genuine Honda Parts

Using authentic components for your machinery ensures optimal performance and longevity. These products are designed specifically for your model, providing reliability and peace of mind. The distinction between genuine items and alternatives can significantly impact the efficiency of your equipment.

| Benefit | Description |

|---|---|

| Quality Assurance | Authentic components undergo rigorous testing for durability and reliability. |

| Perfect Fit | Designed to match specifications, reducing the risk of malfunctions. |

| Longer Lifespan | Genuine items often outlast aftermarket alternatives, saving you money in the long run. |

| Manufacturer Support | Access to customer service and warranties that come with authentic purchases. |

Upgrading Your Water Pump System

Enhancing your fluid circulation system can significantly improve efficiency and performance. Upgrades can lead to better reliability and longevity, ensuring that your setup meets current demands and standards.

Benefits of Upgrading

- Increased Efficiency: Modern components often provide better energy consumption rates.

- Enhanced Durability: New materials and designs can withstand wear and tear more effectively.

- Improved Performance: Upgrading can lead to better flow rates and pressure management.

- Compatibility: New systems may offer better integration with existing technology.

Key Considerations

- Evaluate Current System: Assess the performance and identify areas needing improvement.

- Select Quality Components: Choose reliable brands known for durability and efficiency.

- Installation: Ensure proper installation to avoid future issues.

- Maintenance Plan: Establish a routine to maintain the upgraded system for optimal performance.