Understanding Kangen Water Machine Components

Comprehensive filtration systems are designed to provide high-quality hydration through a sophisticated process that includes various components working in unison. Each of these elements plays a critical role in ensuring the efficiency and functionality of the device, offering users a reliable solution for their daily needs.

To fully appreciate the inner workings of such systems, it is essential to explore the specific elements involved and how they contribute to the overall performance. By analyzing the key components and their interactions, users can gain a clearer understanding of what makes these filtration devices so effective.

In the following sections, we will delve into the specific aspects of these systems, highlighting the essential elements that ensure optimal operation and reliability. This detailed overview will help users better understand the intricacies of these advanced devices.

Understanding Water Filtration Systems

Filtration systems are essential for ensuring the purity of liquids used in various applications. By removing impurities and contaminants, these systems contribute to enhancing the quality of the substance, making it safer for consumption or other uses. The efficiency and design of these systems vary depending on the specific purpose and environment in which they are implemented.

Key Components of Filtration Systems

Filtration systems are composed of various elements that work together to remove unwanted particles. Each component plays a critical role in the purification process, ensuring optimal results.

- Filters: Responsible for trapping larger particles and sediments.

- Membranes: Used to separate finer contaminants that may not

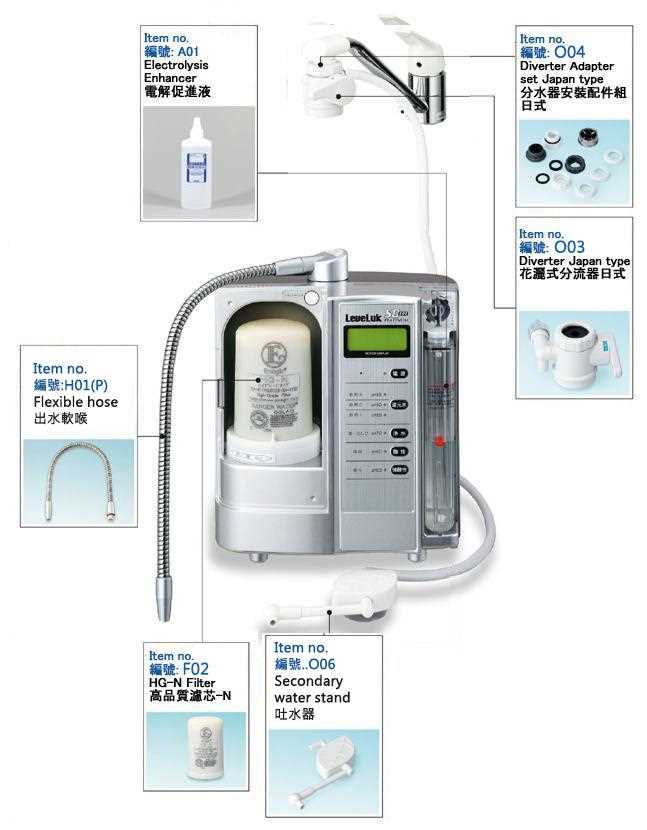

Components of a Water Ionizer

An ionizer designed for liquids operates through a series of essential internal elements that work together to modify the properties of the fluid. These components ensure the transformation process occurs efficiently, providing the desired outcome.

Electrolysis Chamber

This section is crucial for the ionization process, where the liquid is separated into different streams. The chamber contains several electrodes made of high-quality materials, typically platinum or titanium, which facilitate the necessary reactions.

- Application of a controlled electric current.

- Separation of positive and negative ions within the solution.

- Formation of byproducts that contribute to a cleaner result.

- Material Composition: The effectiveness of an electrode depends significantly on the materials used. Common materials include platinum and titanium due to their durability and conductivity.

- Functionality: Electrodes serve as the medium for electrical current, which is essential in the ionization process. Proper balance between positive and negative charges ensures efficiency.

- Maintenance: Over time, electrodes may degrade, affecting performance. Regular cleaning and replacement are key to sustaining functionality and extending the lifespan of the device.

Importance of pH Level Control

Maintaining the appropriate acidity or alkalinity in fluid systems is crucial for ensuring optimal functionality and health benefits. The balance of pH levels directly influences various chemical reactions and biological processes, making it essential for achieving desired outcomes in liquid solutions. Understanding the significance of regulating this parameter helps in maximizing efficiency and promoting well-being.

Impact on Health

Consistent pH management can significantly affect overall health. Fluids with balanced acidity support proper digestion and nutrient absorption. Furthermore, the right pH levels can enhance the body’s natural detoxification processes, leading to improved vitality and resilience against illnesses.

Effects on Equipment Performance

Proper pH regulation not only benefits personal health but also plays a vital role in preserving equipment longevity. Acidic or alkaline conditions can lead to corrosion or scaling, adversely affecting the performance and efficiency of devices. Regular monitoring and adjustment of pH levels ensure that systems operate smoothly and remain in optimal condition.

Adjusting Acidity with Internal Parts

Altering the pH level of liquids is essential for achieving desired health benefits. Various components within a system play a critical role in this process, ensuring that the acidity can be fine-tuned according to specific needs. Understanding these elements allows users to optimize their experience and enhance the overall effectiveness of the solution being produced.

Key Components Influencing pH Levels

Several internal elements are responsible for modifying the acidity. Each component serves a distinct function, contributing to the overall adjustment mechanism. Here are some of the primary parts that facilitate this process:

Component Function Electrodes Responsible for the ionization process, influencing pH levels. Filters Remove impurities, ensuring a more controlled environment for pH adjustment. Control Unit Monitors and regulates the overall process, allowing for precise modifications. Membranes Facilitate ion exchange, critical for achieving the desired acidity. Maintaining Optimal Acidity

To ensure the best results, regular maintenance of these components is necessary. By keeping the internal elements in optimal condition, users can consistently achieve their desired pH levels. Understanding the interplay of these components allows for better control and enhances the efficacy of the solution produced.

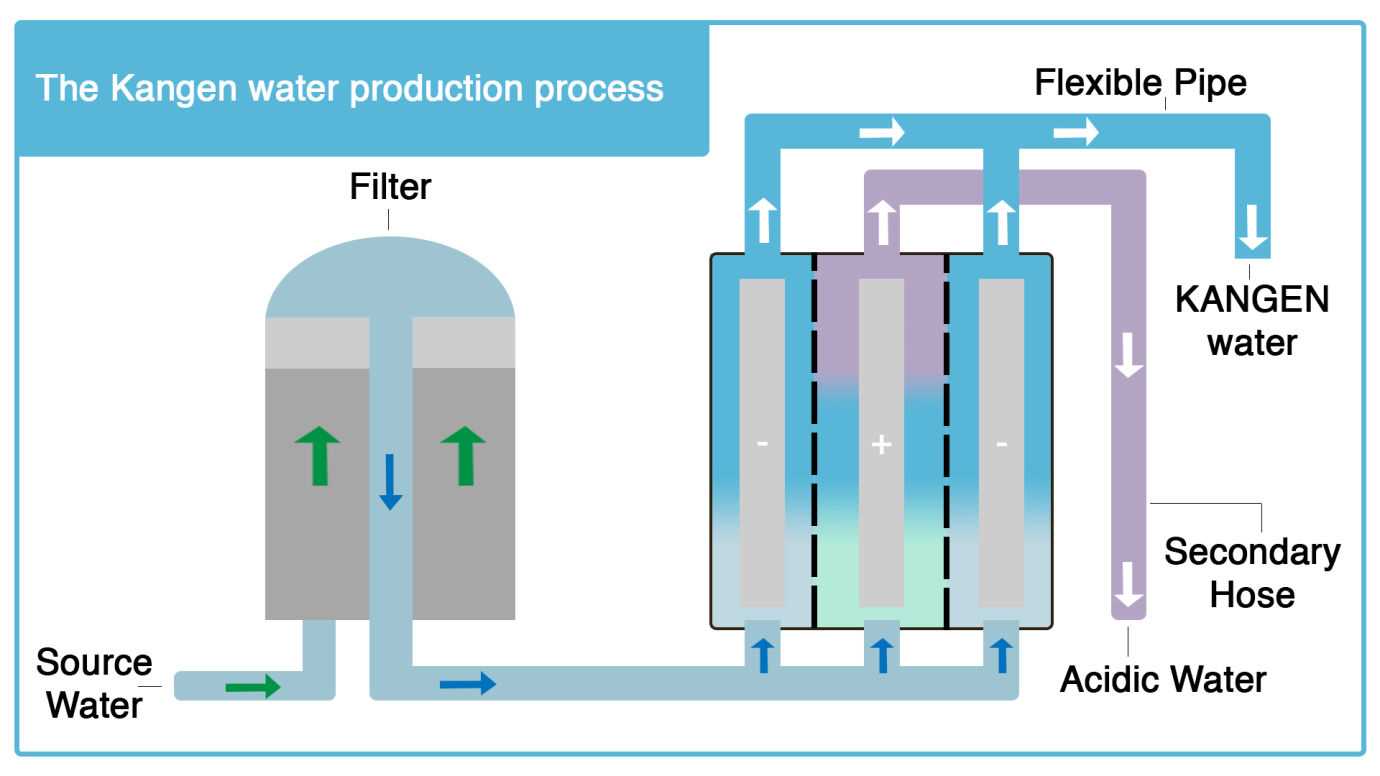

Water Flow Mechanism Explained

The process by which liquid travels through various components is essential for ensuring optimal performance and efficiency. Understanding this flow is vital for grasping how different elements work together to facilitate the effective transformation of fluid into its desired form.

At the core of this system lies a series of interconnected pathways and chambers designed to manage the flow. Each segment plays a specific role in directing the liquid, ensuring it undergoes the necessary treatments before reaching the final destination. Here are the key components involved:

- Intake Chamber: The initial entry point where the liquid is drawn in for processing.

- Filtration System: A critical stage that removes impurities and enhances quality.

- Electrolysis Cells: Specialized units that promote chemical changes through electrical currents.

- Distribution Network: A series of pathways that ensure even flow to various outlets.

- Outlet Port: The final exit point where the processed liquid is dispensed for use.

This intricate network not only ensures efficient delivery but also allows for modifications in treatment methods, enhancing the adaptability of the system to different needs.

Pipes and Valves Inside the Unit

The internal components of a filtration apparatus play a crucial role in ensuring fluid flows smoothly and efficiently throughout the system. Understanding the layout and function of these elements is essential for optimal operation and maintenance.

In this section, we will explore the key features and roles of pipes and valves found within the system:

- Pipes: These conduits are designed to transport liquids from one location to another. They come in various sizes and materials, each chosen based on the specific requirements of the setup.

- Valves: These mechanisms control the flow of liquid within the apparatus. They can be manually operated or automated, providing flexibility in managing the system’s operation.

Understanding the arrangement of pipes and valves helps in troubleshooting issues, performing repairs, and ensuring the longevity of the apparatus.

Here are some common types of valves you may encounter:

- Ball Valves: Known for their durability and ability to provide a tight seal, these valves are ideal for on/off control.

- Gate Valves: Typically used for fully opening or closing the flow, they offer minimal resistance when fully open.

- Check Valves: Designed to prevent backflow, these valves ensure that fluid flows in only one direction.

Proper knowledge of these components is vital for anyone involved in the operation and maintenance of the filtration unit.

Maintaining Longevity of Water Machines

Ensuring the extended lifespan of purification systems requires a combination of routine care and proper usage. Implementing straightforward maintenance practices can significantly enhance performance and efficiency, leading to prolonged functionality. Understanding the essential components and their roles will aid in effective upkeep.

Regular Cleaning is vital to prevent the accumulation of impurities and mineral deposits. Routine rinsing and deep cleaning sessions should be scheduled according to the manufacturer’s recommendations to maintain optimal performance. Using suitable cleaning solutions designed for specific components can enhance results.

Component Inspection plays a crucial role in identifying potential issues before they escalate. Periodically checking filters, hoses, and seals for wear and tear will help in early detection of problems, allowing for timely replacements or repairs. This proactive approach can save both time and money in the long run.

Optimal Usage involves adhering to the operational guidelines provided by the manufacturer. Avoiding excessive load or misuse can prevent premature wear. Additionally, understanding the quality of input sources ensures that the system operates efficiently, reducing stress on its components.

By prioritizing these maintenance strategies, users can enjoy enhanced performance and durability, ensuring that their purification systems serve them effectively for many years.

Common Parts That Need Replacing

Regular maintenance is essential for optimal performance and longevity of filtration systems. Certain components may wear out over time and require replacement to ensure the continued effectiveness of the unit.

Essential Components to Monitor

- Filters: These are critical for removing impurities. Depending on usage, they may need to be changed every few months.

- Electrodes: Integral for the ionization process, these may lose efficiency and require replacement to maintain proper functionality.

- O-rings: Often used to prevent leaks, these rubber seals can degrade and lead to water loss if not replaced regularly.

- Hoses: Flexible tubing can become brittle or clogged, necessitating periodic checks and replacements to ensure proper flow.

Indicators of Wear

- Reduced Flow Rate: A noticeable decrease in the output may indicate that filters or hoses are clogged.

- Unusual Odors or Tastes: These can signal that filtration components are no longer effective and should be replaced.

- Leaks: Water pooling around the unit may suggest that seals or O-rings have worn out and need attention.

Benefits of a Multi-Stage Filtration

A multi-stage filtration system offers a comprehensive approach to purifying liquids, ensuring the removal of a wide range of impurities. This method involves several distinct processes that work together to enhance the quality and safety of the final product. By employing various filtration techniques, users can achieve a higher level of cleanliness and taste.

- Enhanced Purity: Each stage targets specific contaminants, resulting in significantly cleaner liquid.

- Improved Taste: By eliminating undesirable substances, the overall flavor is notably enhanced, making it more enjoyable.

- Health Benefits: Reducing harmful microorganisms and pollutants can lead to better overall health outcomes.

- Increased Longevity: This system often prolongs the lifespan of appliances by preventing the buildup of harmful deposits.

- Cost-Effectiveness: Investing in a multi-stage system can lead to long-term savings by reducing the need for bottled alternatives.

Overall, a multi-stage filtration approach not only improves the quality of the liquid but also contributes to a healthier lifestyle and better tasting experiences.

How the Filtration Process Works

The filtration process involves multiple stages where various impurities and substances are removed from the liquid. This system ensures the liquid is purified and prepared for further use. Through a series of advanced mechanisms, unwanted particles are separated, leaving behind cleaner and healthier fluid.

Preliminary Stage: At the beginning, the liquid passes through a basic filter that traps larger particles such as sediment and debris. This ensures that the subsequent stages handle a more refined flow.

Advanced Filtration: In this phase, more complex filters are employed to target smaller impurities, such as chemical residues and harmful elements. These filters are designed to absorb or neutralize these unwanted substances effectively.

Final Refinement: The last stage is focused on fine-tuning the purity of the liquid. Any remaining particles are eliminated, and the resulting fluid is optimized for its intended purpose, ensuring safety and quality.

Key Filters and Their Functions

In any efficient purification system, filters play an essential role in ensuring the fluid is processed and free from impurities. Each type of filter within the system contributes to achieving optimal performance by targeting specific contaminants or enhancing overall quality. Below, we will explore the most common filters used in these systems and their distinct functionalities.

The Role of Electrolysis in Purification

Electrolysis plays a critical role in enhancing the quality of liquids through a chemical process that alters the properties of various substances. This method separates components based on their molecular structure, ensuring that the final output is cleaner and more refined.

The process involves an electric current that passes through the fluid, causing a reaction that helps to remove impurities and balance important elements. Below are some key steps that highlight how this method works:

By manipulating these molecular interactions, electrolysis is able to enhance the overall quality, providing a significant improvement over untreated options. This purification process ensures a more reliable and efficient outcome, making it a preferred method for producing higher-grade results

Essential Electrodes in Water Machines

Electrodes play a critical role in devices designed to modify the properties of liquids through ionization. These components are responsible for facilitating key reactions that impact the liquid’s composition, leading to desired effects. Understanding the role of these elements is crucial for maintaining optimal performance.