Understanding Rheem Water Softener Parts Diagram

In the realm of residential and commercial filtration solutions, the intricate interplay of various elements is crucial for optimal performance. A comprehensive comprehension of these components enables users to maintain and troubleshoot their systems effectively, ensuring longevity and efficiency.

Visual representations of these assemblies play a significant role in facilitating understanding. By examining the arrangement and function of each piece, individuals can better appreciate how they contribute to the overall functionality of the setup. Such insights can lead to more informed decisions regarding maintenance and upgrades.

Furthermore, having a clear grasp of the configuration can simplify the process of identifying potential issues. When users are familiar with the layout, they can pinpoint malfunctions more rapidly, saving time and resources in the long run. This knowledge empowers individuals to take charge of their systems, fostering a proactive approach to care and management.

Understanding Rheem Water Softeners

This section delves into the mechanics and functions of devices designed to enhance the quality of household liquids. These systems play a crucial role in eliminating unwanted minerals, resulting in improved efficiency and longevity of plumbing fixtures and appliances. A clear understanding of their components and operation can help users make informed decisions regarding maintenance and troubleshooting.

Key Components and Functionality

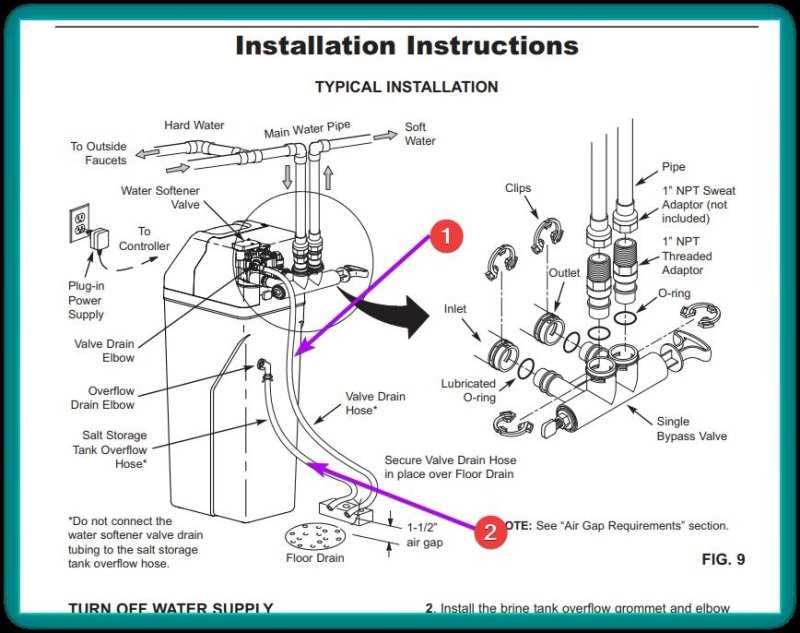

The main elements of these systems work in unison to provide optimal performance. Typically, they consist of a resin tank, brine tank, and a control unit. The resin tank is where the exchange process occurs, removing harmful ions. The brine tank contains the salt solution used for regeneration, while the control unit manages the entire operation, ensuring the system runs efficiently.

Maintenance and Troubleshooting

Regular upkeep is essential for ensuring longevity and effectiveness. Users should periodically check the salt levels in the brine tank and clean the resin to prevent buildup. If issues arise, such as reduced efficiency, examining the control unit and the resin tank is a crucial step. Understanding the internal workings can significantly ease the troubleshooting process.

Importance of Water Softening Systems

These systems play a crucial role in enhancing the quality of everyday life by addressing issues caused by mineral buildup in household systems. They help in preserving the longevity of plumbing, appliances, and fixtures, ultimately leading to cost savings and improved efficiency in various household operations.

Benefits for Household Appliances

Utilizing such systems can significantly extend the lifespan of appliances like dishwashers and washing machines. Reduced mineral deposits minimize wear and tear, allowing these devices to operate more efficiently. This efficiency not only conserves energy but also ensures that appliances perform optimally, enhancing their effectiveness in cleaning and functioning.

Improvement in Skin and Hair Health

The benefits extend beyond appliances; they also impact personal care. Individuals often notice softer skin and healthier hair when using treated resources. This is because the absence of harsh minerals allows for better lathering of soaps and shampoos, resulting in improved cleansing without the drying effects associated with untreated sources.

Key Components of Rheem Systems

Understanding the essential elements of these systems is crucial for effective maintenance and operation. Each component plays a significant role in ensuring optimal performance and longevity, making it important to recognize their functions and interconnections.

Control Unit: This is the brain of the system, responsible for managing the regeneration cycle and monitoring the overall efficiency. It ensures that the device operates at peak performance by adjusting settings based on usage patterns.

Resin Tank: This crucial container houses the resin beads that facilitate the ion exchange process. These beads attract and remove undesirable minerals from the incoming flow, thus enhancing the quality of the treated liquid.

Brine Tank: This component stores the salt solution necessary for regenerating the resin beads. Its proper functioning is vital to maintaining the effectiveness of the ion exchange process over time.

Distribution System: This network ensures that the treated liquid is evenly distributed throughout the household or facility. A well-designed distribution system enhances efficiency and minimizes pressure drops.

Bypass Valve: This feature allows users to divert the flow around the system when maintenance is required or during certain activities where treatment is not necessary. It provides flexibility and control over the treatment process.

Overflow Drain: This safety mechanism prevents flooding by directing excess liquid away from the system. It is an essential feature for safeguarding against potential leaks or overflows.

Recognizing the importance of these components helps users appreciate their roles and the overall efficiency of the systems, leading to better maintenance practices and prolonged service life.

Common Issues in Water Softeners

When it comes to systems designed to reduce mineral content, several challenges can arise that impact their effectiveness and efficiency. Understanding these common problems is crucial for maintaining optimal performance and prolonging the lifespan of the unit.

Frequent Problems

- Salt Bridges: A solid mass of salt can form in the brine tank, preventing proper dissolution and leading to inadequate regeneration cycles.

- Clogged Filters: Sediment and debris may accumulate in filters, reducing flow rates and overall functionality.

- Resin Bed Issues: The resin beads can become coated with oils or contaminants, decreasing their ability to exchange ions effectively.

Signs of Malfunction

- Inconsistent Water Quality: Fluctuations in hardness levels indicate potential system issues.

- Unusual Sounds: Grinding or hissing noises may suggest mechanical problems within the system.

- Low Pressure: A drop in water pressure can signal blockages or malfunctioning components.

Addressing these common issues promptly can help ensure a consistent supply of treated water and enhance the overall functionality of the system.

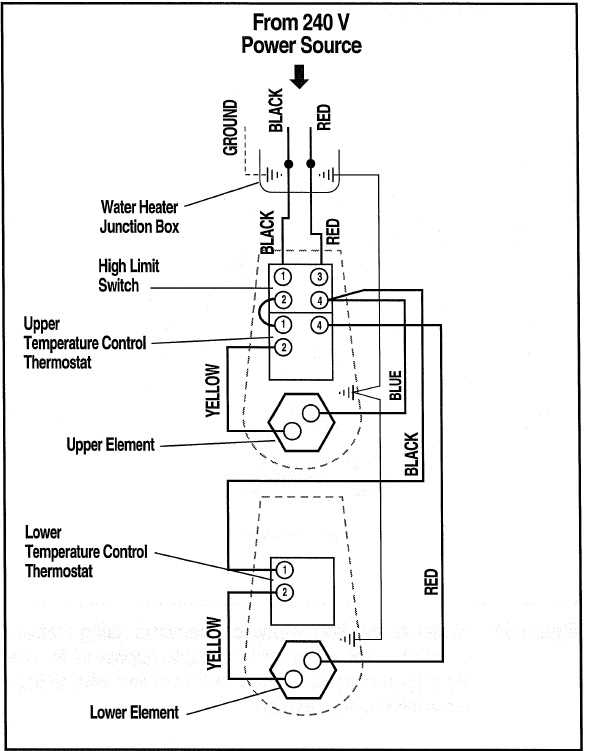

How to Read Parts Diagrams

Understanding technical illustrations is crucial for effective maintenance and repair tasks. These visual representations provide essential information about components and their interconnections, making it easier to identify issues and perform replacements. Familiarity with the layout and symbols used in these schematics enhances comprehension and accuracy during the repair process.

Here are some tips for interpreting these illustrations effectively:

| Tip | Description |

|---|---|

| 1. Familiarize with Symbols | Learn the common icons and notations used to represent various elements, as they vary between manufacturers. |

| 2. Follow the Flow | Pay attention to the flow direction indicated in the image, which can be essential for understanding the operation. |

| 3. Check for Labels | Look for labels that specify the names or functions of the parts, which can aid in quicker identification. |

| 4. Reference Numbers | Use reference numbers that link components to their descriptions in accompanying documentation for clarity. |

| 5. Practice with Real Examples | Engage with actual components while cross-referencing them with the schematic to build confidence and understanding. |

By mastering these techniques, you will be better equipped to navigate technical illustrations, leading to more efficient repairs and maintenance tasks.

Essential Parts for Maintenance

Regular upkeep of your system is crucial for ensuring optimal performance and longevity. Understanding the fundamental components involved can greatly aid in effective management and prompt troubleshooting when necessary. This knowledge allows for smoother operations and a reduction in potential issues.

Key Components

The core elements of your unit include a variety of mechanisms and accessories that work together seamlessly. Among these, the resin tank plays a vital role in ion exchange, while the control valve regulates the flow and timing of the process. Regular inspection and maintenance of these components can prevent operational hiccups.

Importance of Routine Checks

Consistent monitoring of these essential elements is vital for early detection of wear or damage. This proactive approach not only helps in maintaining efficiency but also extends the lifespan of your equipment. Additionally, keeping a close eye on components like the brine tank and the injector ensures that the entire system functions as intended, providing consistent results.

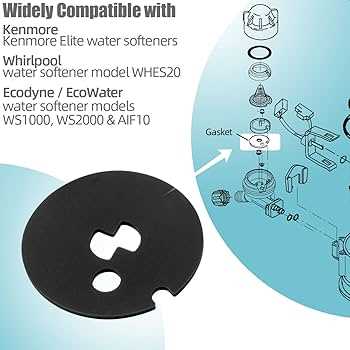

Replacement Parts Availability

Ensuring the optimal performance of your system often requires access to specific components. Availability of these essential elements can greatly influence maintenance and efficiency. It’s important to identify reliable sources for obtaining the necessary replacements when issues arise.

Numerous suppliers offer a range of components, ensuring that users can find what they need without hassle. Many retailers provide online platforms, making it convenient to browse and order the required items. Additionally, some manufacturers maintain a comprehensive catalog, allowing for easy identification and procurement of specific components.

When looking for replacements, consider verifying compatibility with your existing system. Reliable vendors often include detailed specifications, helping to ensure that the selected components meet your needs. Furthermore, checking for warranties or guarantees can provide added peace of mind during the purchasing process.

In conclusion, having access to a wide array of components is crucial for maintaining system efficiency. By leveraging various suppliers and ensuring compatibility, you can effectively manage any necessary replacements and enhance overall performance.

Understanding the Control Valve Function

The control valve plays a pivotal role in regulating the flow and treatment of fluids within a system. Its design and operation significantly influence the overall efficiency and effectiveness of the entire setup. This section explores the primary functions and importance of the control valve.

Key functions of the control valve include:

- Flow Regulation: It precisely adjusts the amount of liquid passing through, ensuring optimal performance.

- Pressure Management: The valve maintains consistent pressure levels, preventing damage to the system.

- Timing Control: It determines when to initiate or halt processes, enhancing operational efficiency.

Understanding these functions can aid in troubleshooting and maintenance, leading to improved longevity and reliability of the system. Here are some critical components of the control valve:

- Actuator: The mechanism that moves the valve to open or close it based on signals received.

- Body: The main structure that houses the internal components and facilitates flow.

- Seat and Disk: These parts create a seal to control fluid movement effectively.

In summary, the control valve is essential for managing the dynamics of fluid systems, and understanding its functions enhances both user experience and system performance.

Resin Tanks: Purpose and Maintenance

Resin tanks play a crucial role in various filtration systems, facilitating the removal of unwanted minerals and impurities from liquids. These vessels are designed to house specialized materials that enhance the quality of the treated fluid, ensuring it meets the desired standards for use in households and industries alike. Understanding their function and proper upkeep is essential for maintaining optimal performance and longevity.

Functionality of Resin Tanks

The primary function of resin tanks is to contain resin beads that interact with the fluid passing through. These beads possess the ability to attract and hold onto specific ions, effectively replacing them with more desirable alternatives. This ion exchange process is vital for reducing hardness and improving the overall quality of the fluid, making it safer and more efficient for various applications.

Maintenance Guidelines

Regular maintenance of resin tanks is essential to ensure they operate effectively. It involves periodic checks for any signs of wear or damage, as well as ensuring the resin remains functional. Cleaning the tank and replacing resin beads when necessary will help maintain efficiency. Additionally, monitoring the flow rate and pressure can provide insight into the tank’s performance, allowing for timely interventions if issues arise.

Brine Tanks and Their Role

Brine containers serve a crucial function in the process of mineral removal, enhancing the efficiency of the overall system. These units play a significant part in regenerating the essential elements required for optimal performance, ensuring a continuous supply of treated fluid. Understanding their components and operations can help in maintaining their effectiveness and longevity.

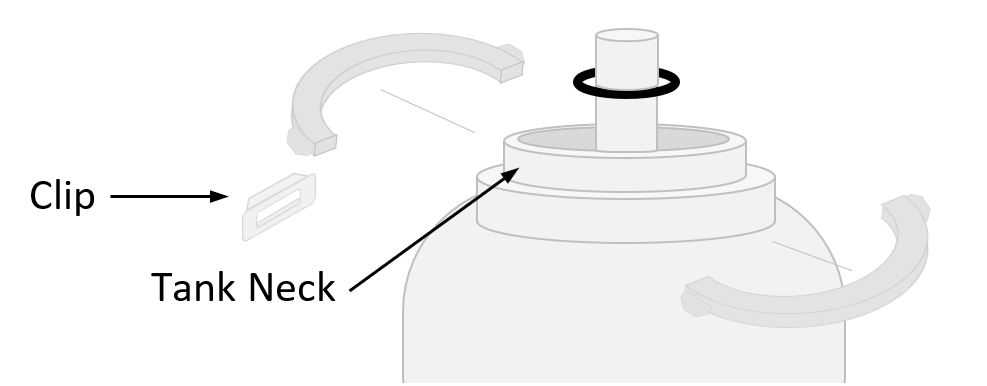

Components of Brine Tanks

- Salt Storage Area: The section where sodium chloride or other agents are stored for creating the brine solution.

- Brine Solution: A mixture of water and salt, crucial for the regeneration process.

- Level Control: Mechanisms to monitor and maintain the appropriate amount of solution within the tank.

- Drainage System: Allows for the expulsion of excess solution to prevent overflow.

Importance of Maintenance

- Regular Inspection: Checking for salt levels and ensuring no clogs are present.

- Cleaning: Removing any buildup or residues to promote efficiency.

- Replacing Parts: Identifying and substituting worn or damaged components promptly.

- Monitoring Performance: Keeping track of the system’s efficiency can prevent larger issues.

By understanding the pivotal role of brine tanks, users can better appreciate their maintenance and function, ensuring a smooth operation of the overall mineral reduction system.

Identifying Faulty Components

Recognizing malfunctioning elements within a system is crucial for maintaining optimal performance. Various indicators can signal issues, from unusual noises to inefficiencies in operation. Understanding these signs can help in pinpointing the source of problems, allowing for timely interventions.

Common symptoms include inconsistent output, where the expected results are not achieved, and strange sounds, such as grinding or hissing, which may indicate mechanical wear. Changes in pressure can also be a red flag, suggesting blockages or leaks in the system. Regular monitoring and awareness of these factors can facilitate early detection and resolution.

Additionally, inspecting the condition of seals and connections is essential, as these areas are prone to wear and can lead to significant disruptions. Discoloration or corrosion on components often points to deterioration that should be addressed immediately. Maintaining a routine check on these aspects can greatly enhance the longevity and efficiency of the system.

Tips for Troubleshooting Issues

When dealing with common challenges in your home system, it’s essential to approach the situation methodically. Understanding the potential causes of malfunctions can save time and resources, allowing you to restore functionality more efficiently.

Check the Power Supply: Ensure that the device is receiving adequate power. A simple inspection of the outlet and the power cord can reveal loose connections or faults that may be interrupting operation.

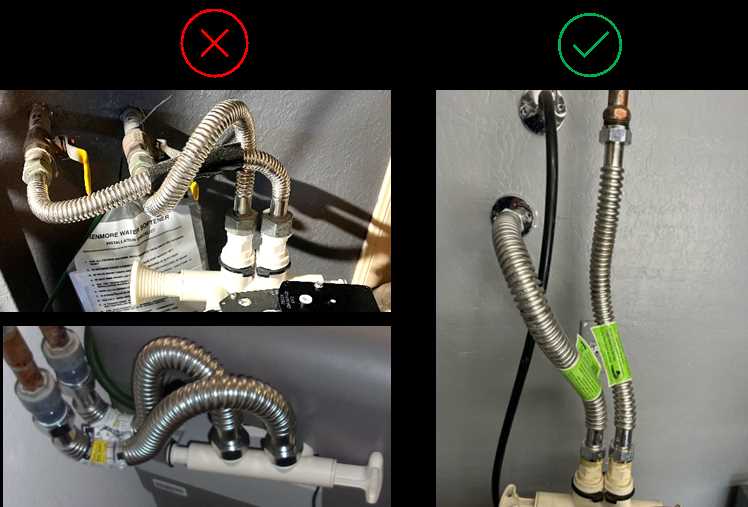

Inspect for Blockages: Regularly examine hoses and connections for any obstructions. Build-up or debris can impede the flow, leading to suboptimal performance.

Monitor Settings: Sometimes, the issue may stem from incorrect adjustments. Verify that all settings are aligned with the manufacturer’s recommendations for optimal functioning.

Perform a Visual Inspection: Look for any signs of wear, damage, or leaks. Identifying these problems early can prevent further complications.

Consult the Manual: The user guide often contains troubleshooting steps tailored to specific issues. Don’t overlook this resource for guidance on resolving problems.

Seek Professional Help: If the issue persists despite your efforts, consider reaching out to a qualified technician. Their expertise can pinpoint and address complex problems effectively.

DIY Repairs vs. Professional Help

When faced with maintenance challenges in your home, you often find yourself at a crossroads: should you tackle the issue yourself or enlist the help of a specialist? Both options have their advantages and drawbacks, and understanding these can help you make an informed decision.

Advantages of DIY Repairs

- Cost Savings: Taking on repairs yourself can significantly reduce labor costs.

- Skill Development: Engaging in hands-on work allows you to learn new skills and enhance your troubleshooting abilities.

- Convenience: You can set your own schedule, tackling repairs at your convenience without waiting for an appointment.

Benefits of Professional Assistance

- Expertise: Professionals bring a wealth of knowledge and experience, ensuring that issues are resolved correctly.

- Time Efficiency: Specialists often complete repairs more quickly, saving you time and hassle.

- Warranty Protection: Many professionals offer guarantees on their work, providing peace of mind in case of future problems.

Ultimately, the choice between DIY and professional help hinges on your confidence in handling repairs, the complexity of the issue, and your available resources. Evaluating these factors will guide you in making the best decision for your situation.