Understanding the Components of a Trailer Wheel Parts Diagram

In the realm of transportation, ensuring that all elements function harmoniously is paramount for safety and efficiency. This section delves into the intricate mechanisms involved in supporting heavy loads while maintaining stability on the road. Each segment plays a crucial role, contributing to the overall performance and durability of the system.

Identifying key elements can significantly enhance the understanding of how these systems operate. Knowledge of various functionalities allows for better maintenance and troubleshooting, ultimately leading to improved longevity and reliability. Awareness of these components empowers operators to make informed decisions regarding their upkeep.

Furthermore, a comprehensive grasp of these crucial aspects not only aids in preventing potential failures but also promotes a smoother towing experience. Emphasizing the interconnectivity of the various elements fosters a deeper appreciation for the engineering behind them, encouraging users to prioritize safety and efficiency in their operations.

Understanding Trailer Wheel Components

Grasping the various elements that contribute to the functionality of a transport unit is essential for both safety and performance. Each component plays a crucial role in ensuring smooth movement and stability, allowing for efficient load management and travel. By familiarizing oneself with these essential elements, users can make informed decisions about maintenance and upgrades.

Key Elements of the Assembly

The fundamental structure consists of several interconnected components. The outer casing, often made from durable materials, protects internal mechanisms and aids in overall performance. Inside, you’ll find assemblies designed to support heavy loads and facilitate smooth rotation. Understanding the relationship between these components helps in identifying potential issues before they become critical.

Maintenance and Care

Regular inspection of each individual component is vital for longevity and reliability. Pay attention to signs of wear, such as unusual noises or decreased performance. Lubrication and timely replacement of worn items can significantly extend the lifespan of the entire setup. Emphasizing proactive care can prevent costly repairs and enhance safety during operation.

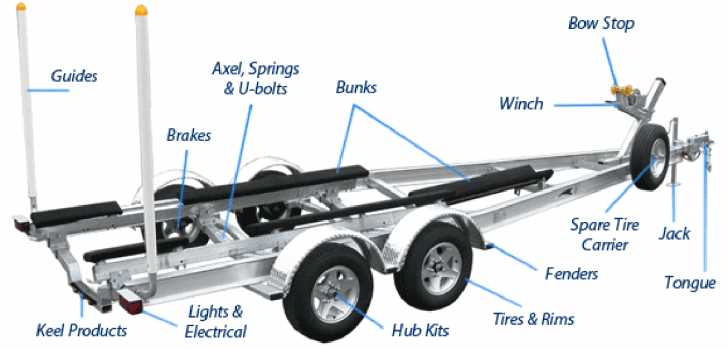

Essential Parts of Trailer Wheels

Understanding the fundamental components that contribute to the functionality of a towing setup is crucial for effective operation and maintenance. Each element plays a vital role in ensuring stability, safety, and efficiency while on the road.

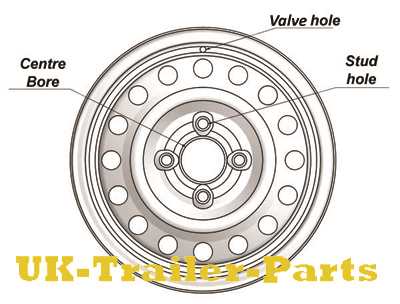

- Rim: The outer circular design that holds the tire in place and provides structural integrity.

- Tire: The rubber exterior that makes contact with the ground, offering traction and support for loads.

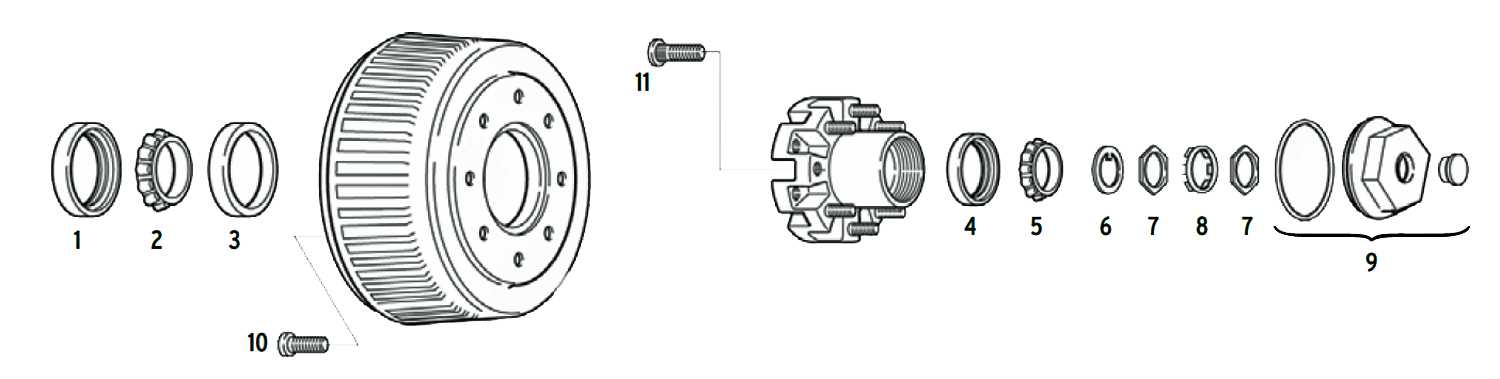

- Hub: The central part that connects the assembly to the axle, allowing for rotation and smooth movement.

- Bearing: This component reduces friction between moving parts, ensuring seamless rotation of the hub.

- Studs: These protrusions secure the rim to the hub, ensuring everything stays in place under various conditions.

- Nuts: Fasteners that hold the studs in position, providing a tight grip and enhancing safety.

- Axle: The main shaft that supports the load and facilitates the rotation of the hub and rim.

- Spacer: Used to adjust the distance between components, ensuring proper alignment and function.

Regular inspection and maintenance of these key components can greatly enhance the performance and longevity of the entire system, contributing to a safer towing experience.

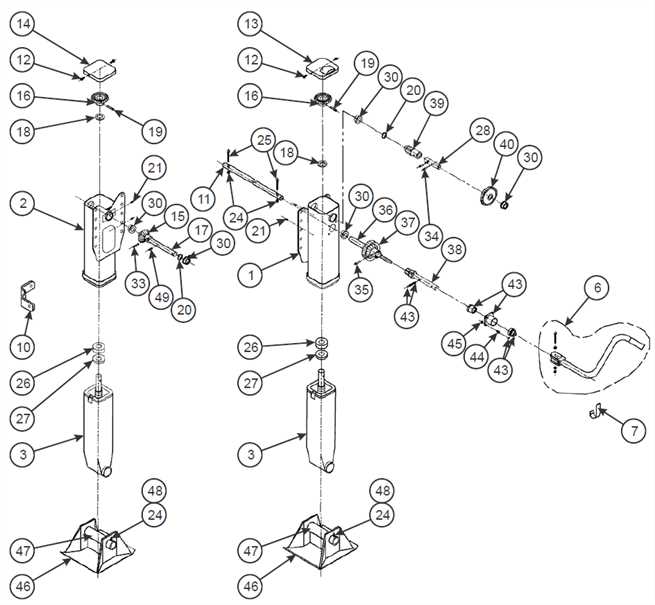

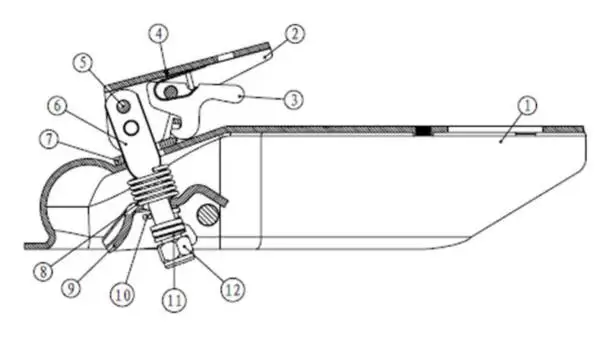

How to Read a Wheel Diagram

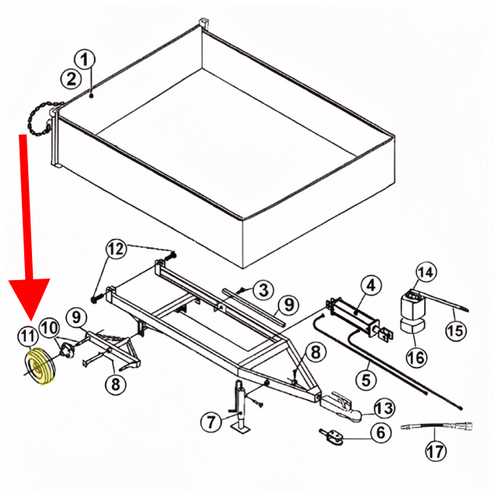

Understanding a schematic representation of a circular assembly is essential for effective maintenance and troubleshooting. Familiarity with the components and their arrangement can simplify repairs and enhance performance. Here’s how to navigate such illustrations effectively.

- Identify Key Components: Look for labels and symbols indicating various elements. Common parts may include hubs, bearings, and rims.

- Recognize the Layout: Diagrams often display parts in relation to one another. Note how they connect and interact within the system.

- Understand Measurements: Pay attention to any dimensions or scales provided. These can inform you about the size and compatibility of each element.

To further your comprehension, consider these additional tips:

- Study Legend or Key: If present, this section explains the symbols used, helping clarify the representation.

- Consult Manufacturer Resources: Official documentation often provides insights or specifications that enhance your understanding of the schematic.

- Practice with Real Examples: Hands-on experience with actual assemblies can reinforce your ability to interpret illustrations accurately.

By applying these strategies, you will become proficient in decoding visual representations, ultimately leading to better maintenance practices and enhanced operational efficiency.

Common Issues with Trailer Wheel Parts

Understanding the typical problems associated with components used for transport vehicles is essential for maintaining safety and performance. Many users encounter various difficulties that can lead to decreased efficiency and even hazardous situations if not addressed promptly.

One frequent issue is improper alignment, which can cause uneven wear and tear. This misalignment often stems from incorrect installation or damage to support structures. Regular checks can help prevent these complications.

Another common challenge involves brake system malfunctions. Over time, components may degrade, leading to decreased stopping power and increased stopping distances. Regular maintenance and timely replacements are crucial to ensure functionality and safety.

Additionally, corrosion is a significant concern, particularly in areas exposed to moisture and salt. This deterioration can weaken structural integrity and compromise performance. Protective coatings and regular inspections can mitigate these risks.

Finally, bearing failures are a prevalent issue, often caused by inadequate lubrication or excessive heat. Keeping a close eye on these elements and addressing them quickly can prevent costly repairs and ensure smooth operation.

Maintenance Tips for Trailer Wheels

Proper care and attention are essential for ensuring the longevity and performance of your vehicle’s rolling components. Regular maintenance not only enhances safety but also improves efficiency and prevents costly repairs. Here are some key practices to keep in mind.

Firstly, it’s vital to routinely inspect the rubber surfaces for signs of wear or damage. Look for cracks, bulges, or uneven tread patterns that may indicate a need for replacement. Maintaining optimal air pressure is equally important; under-inflation can lead to overheating, while over-inflation increases the risk of blowouts.

Additionally, check the connection points and bearings for signs of corrosion or excessive wear. Regular lubrication of moving parts is crucial to reduce friction and extend their lifespan. Ensure that all fasteners are securely tightened to prevent any loosening during travel.

Cleaning these components regularly can also prevent dirt and grime build-up, which may lead to premature wear. If your setup experiences frequent exposure to water or road salt, consider applying protective coatings to safeguard against rust and corrosion.

Lastly, keep an eye on alignment and balance, as misalignment can cause uneven wear and decrease stability. Scheduling periodic professional inspections will help catch any issues early, ensuring a smooth and safe journey every time.

Choosing the Right Wheel Size

Selecting the appropriate size for your rolling components is crucial for ensuring optimal performance and safety. The dimensions affect not only the handling and stability of the vehicle but also its load-bearing capacity. Understanding the nuances of size choices can greatly enhance your overall experience.

Factors to Consider

Several elements influence the decision on which size to choose. Among them are the type of terrain you plan to navigate, the overall weight of the load, and the compatibility with your existing framework. Each of these factors plays a significant role in determining the most suitable dimensions.

Size Comparison Table

| Size | Load Capacity | Best Use Case |

|---|---|---|

| 13 inches | 1,200 lbs | Light-duty use, paved surfaces |

| 14 inches | 1,500 lbs | Moderate loads, mixed terrain |

| 15 inches | 2,000 lbs | Heavy loads, off-road applications |

Ultimately, making an informed choice regarding dimensions will enhance safety and efficiency, contributing to a smoother journey. Take the time to evaluate your specific needs before making a selection.

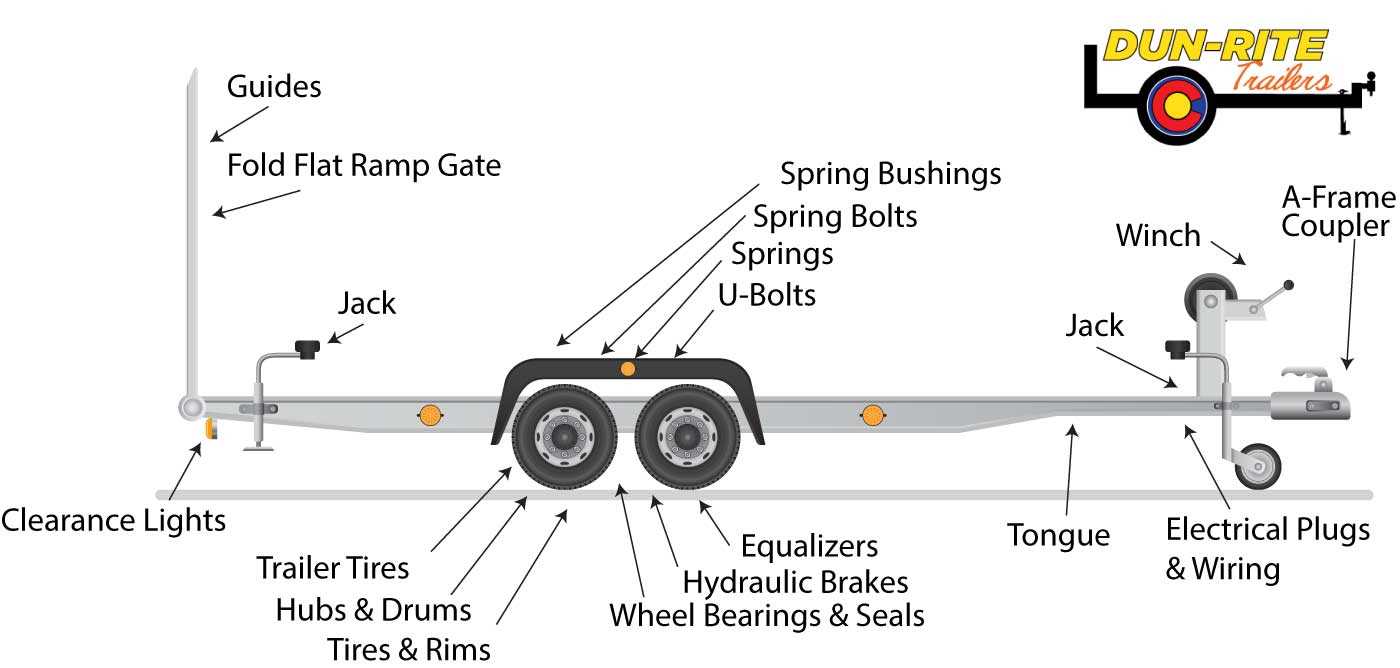

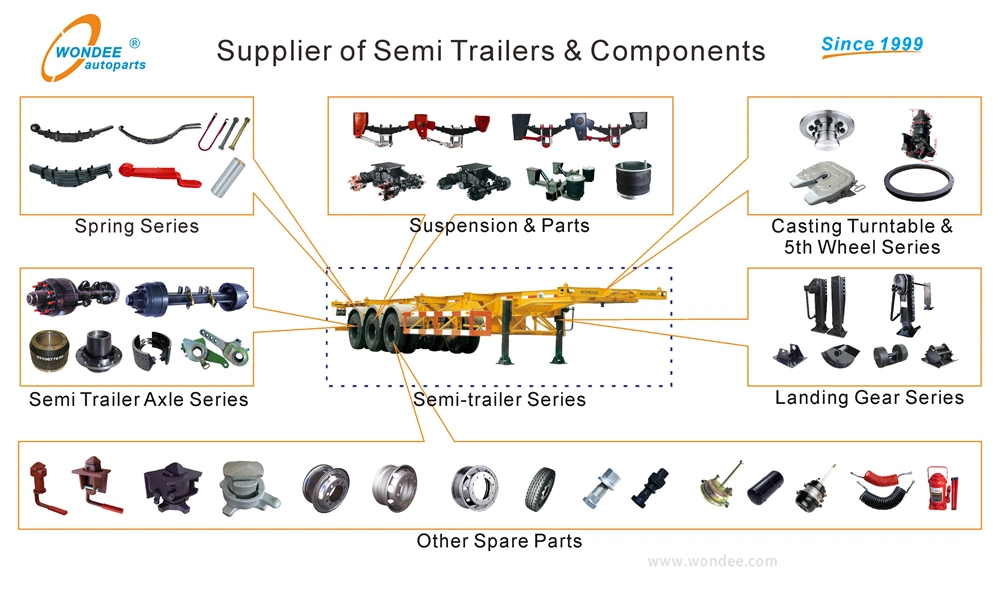

Types of Trailer Axles Explained

Understanding the various types of axles is essential for ensuring optimal performance and safety in towing applications. Each type serves a unique purpose and comes with distinct features, making them suitable for different loads and usage scenarios.

Here are the primary categories of axles commonly used in towing systems:

- Single Axles:

- Best for lighter loads

- Usually simpler in design

- Often used in smaller vehicles

- Dual Axles:

- Provides better weight distribution

- Improves stability and handling

- Commonly found in mid-range towing solutions

- Tandem Axles:

- Designed for heavier loads

- Offers superior support and durability

- Ideal for larger transport needs

- Drop Axles:

- Lowering the center of gravity

- Enhances stability when loaded

- Often used in specialized applications

When selecting an axle, consider factors such as the weight capacity, intended use, and desired maneuverability. Each type brings its own advantages, ensuring you can find the right fit for your specific requirements.

Brake Systems in Trailer Wheels

The effectiveness of a stopping mechanism is crucial for ensuring safety and stability during transportation. Various components work in unison to provide reliable deceleration and control. Understanding these systems can enhance performance and maintenance practices.

Types of Braking Mechanisms

There are several methods used to achieve efficient braking, each with its own unique characteristics:

- Electric Brakes: Utilize electromagnetic force to engage the braking system, providing smooth and controlled stopping.

- Hydraulic Brakes: Employ fluid pressure to activate the brakes, offering strong stopping power and reliability.

- Surge Brakes: Operate based on the inertia of the vehicle, activating automatically when a deceleration occurs.

Key Components of Braking Systems

Each braking method includes essential elements that contribute to overall functionality:

- Actuator: Responsible for initiating the braking action based on the chosen mechanism.

- Brake Shoes or Pads: Create friction against a surface to reduce speed.

- Backing Plate: Provides structural support for the components.

- Brake Lines: Facilitate the transfer of fluid in hydraulic systems.

Regular maintenance of these components ensures optimal performance and safety, significantly reducing the risk of failure during operation.

Importance of Wheel Bearings

Essential components play a crucial role in the performance and safety of any moving vehicle. Among these elements, certain mechanisms are pivotal for smooth operation and longevity. Understanding their significance can greatly enhance maintenance practices and overall efficiency.

Key Functions

These components serve several important functions:

- Facilitating smooth rotation, reducing friction.

- Supporting heavy loads, ensuring stability.

- Minimizing wear and tear on connected systems.

Consequences of Neglect

Failing to properly maintain these crucial elements can lead to serious issues, including:

- Increased friction, causing overheating.

- Premature wear on other vehicle components.

- Potential failure, leading to safety hazards.

Regular inspection and maintenance of these components are vital for optimal performance and safety in any transport application.

Exploring Different Tire Options

When it comes to selecting the right rubber for your vehicle, various factors come into play that can significantly influence performance and safety. Understanding the variety of available choices is crucial for making an informed decision that aligns with your specific needs.

Types of Rubber vary widely, with some designed for optimal grip on wet surfaces, while others excel in durability and wear resistance. For instance, all-season options offer a balanced performance, suitable for diverse weather conditions, whereas specialized variants, like mud or off-road types, are tailored for challenging terrains.

Additionally, tread patterns play a vital role in how a vehicle handles different environments. Aggressive treads can enhance traction in loose materials, whereas smooth designs often provide better fuel efficiency on paved roads. It’s essential to match the tread type to your typical driving conditions to ensure safety and performance.

Finally, load capacity is another critical consideration. Selecting a suitable option that can support the weight of your cargo while maintaining stability and control is paramount. Researching the specifications and understanding the implications of each choice will lead to a more effective selection.

Identifying Damage in Wheel Components

Recognizing harm in essential components is crucial for maintaining safety and performance. Regular inspections can prevent potential issues and ensure longevity. Understanding where to look and what to assess is fundamental for effective maintenance.

Common indicators of damage include:

- Cracks: Look for visible fractures on the surface.

- Wear: Excessive abrasion can compromise integrity.

- Corrosion: Rust or discoloration may indicate deterioration.

To systematically identify damage, consider the following steps:

- Perform a visual inspection, focusing on high-stress areas.

- Use a measuring tool to check for deformities or irregularities.

- Assess all connections and fittings for signs of loosening.

By adhering to these guidelines, one can effectively identify issues and maintain optimal function.

Upgrading Your Trailer Wheel Setup

Enhancing your vehicle’s rolling components can significantly improve performance, stability, and overall safety. Whether you’re a frequent traveler or an occasional user, investing in quality upgrades can transform your experience. By focusing on specific elements of the assembly, you can achieve better handling and a smoother ride.

First and foremost, consider the type of rims you are using. Upgrading to lightweight yet durable options can reduce overall weight and improve fuel efficiency. Additionally, selecting the right size is crucial for maintaining balance and ensuring compatibility with your current setup.

Another critical aspect is the selection of robust tires. Opt for designs that offer enhanced traction and durability, especially if you often traverse challenging terrains. The right tread pattern not only provides grip but also impacts the lifespan of your rolling components.

Lastly, don’t overlook the importance of high-quality bearings and fasteners. Upgrading these elements ensures smooth rotation and reduces the risk of mechanical failures. A reliable connection is vital for maintaining safety and performance during your journeys.

Safety Guidelines for Trailer Wheels

Ensuring the security and functionality of your transportation apparatus is crucial for safe journeys. Adhering to specific recommendations can prevent accidents and prolong the lifespan of your equipment. Here are essential considerations to keep in mind.

Regular Inspections: Conduct frequent evaluations of all components. Look for signs of wear, corrosion, or damage. Address any issues immediately to avoid potential hazards during use.

Proper Maintenance: Implement a consistent maintenance schedule. This includes cleaning, lubricating moving parts, and ensuring all connections are tight and secure. Regular upkeep is vital for optimal performance.

Load Management: Always adhere to the manufacturer’s guidelines regarding weight limits. Distributing the load evenly helps maintain balance and stability, reducing the risk of mishaps on the road.

Correct Inflation: Ensure that tires are inflated to the recommended pressure levels. Under-inflation or over-inflation can lead to blowouts or decreased handling efficiency, posing serious dangers.

Safe Parking Practices: When parking, ensure that your setup is on a stable surface. Utilize wheel chocks and engage the parking brake to prevent unintended movement.

By following these essential guidelines, you can significantly enhance safety during transit, ensuring a smoother and more secure experience on the road.