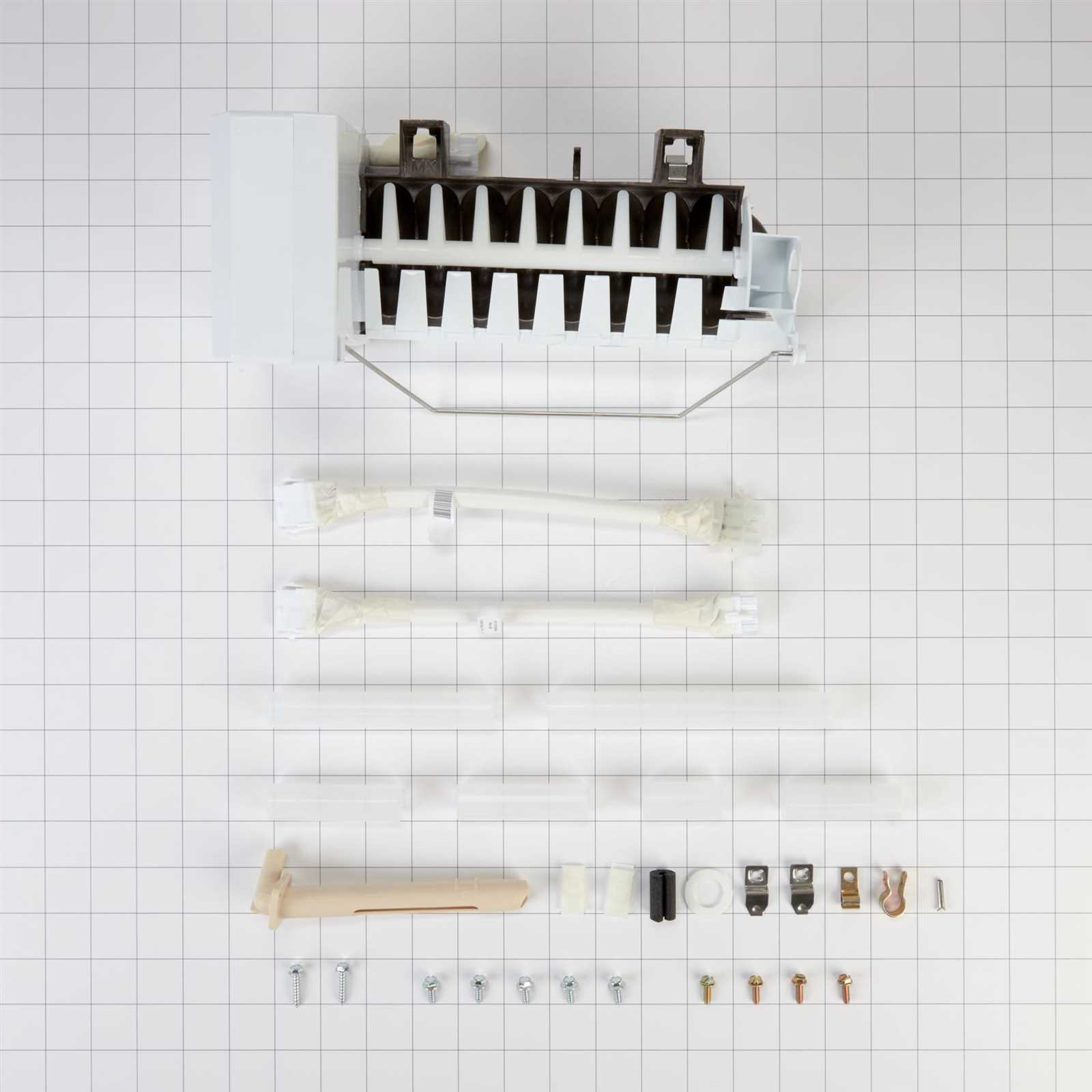

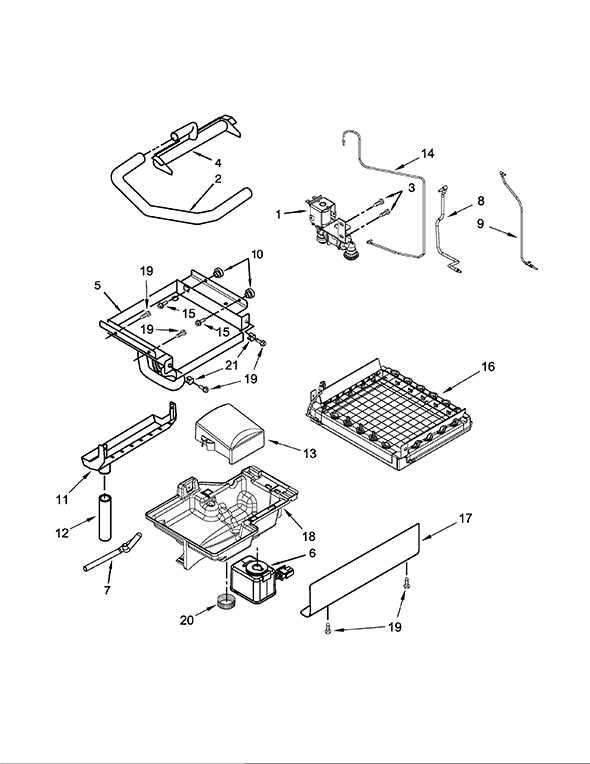

Whirlpool Ice Dispenser Parts Overview

Modern refrigeration units are equipped with complex mechanisms that help deliver convenience and efficiency. One of the standout features of these systems is their ability to provide various services without the need for manual labor. This function relies on an intricate assembly of elements designed to work seamlessly together, ensuring both ease of use and reliability.

To fully appreciate how these units operate, it’s essential to examine the core structures involved in delivering cooled refreshments directly to the user. Each piece plays a crucial role in maintaining the smooth operation of the system. From the internal mechanisms to the visible external controls, every part is engineered to contribute to a hassle-free experience.

By exploring the individual sections of the cooling unit’s mechanism, users can gain a deeper understanding of how these components interact to perform their designated tasks. This guide will walk you through the primary features and provide insight into how the entire system functions cohesively.

Whirlpool Ice Dispenser Overview

The cooling and delivery system found in modern kitchen appliances plays a crucial role in providing users with chilled solutions for various needs. These mechanisms are designed to offer a convenient and efficient way to access frozen elements without needing to open compartments repeatedly.

At the heart of this system, several components work together to ensure smooth performance. From collection units to motorized elements that move the frozen material to the front, every part is essential for maintaining overall functionality. Regular maintenance ensures long-lasting operation and reduces potential breakdowns.

Main Components of Ice Dispensers

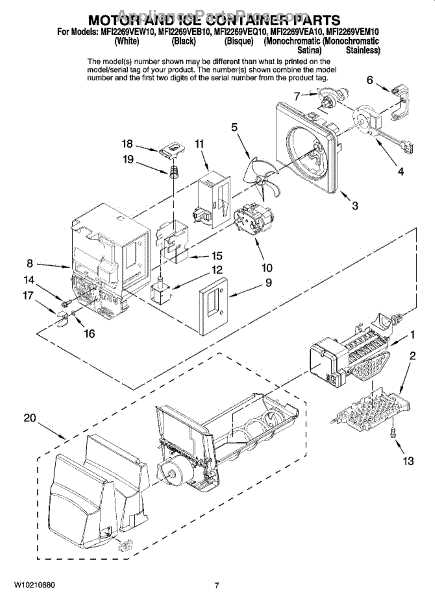

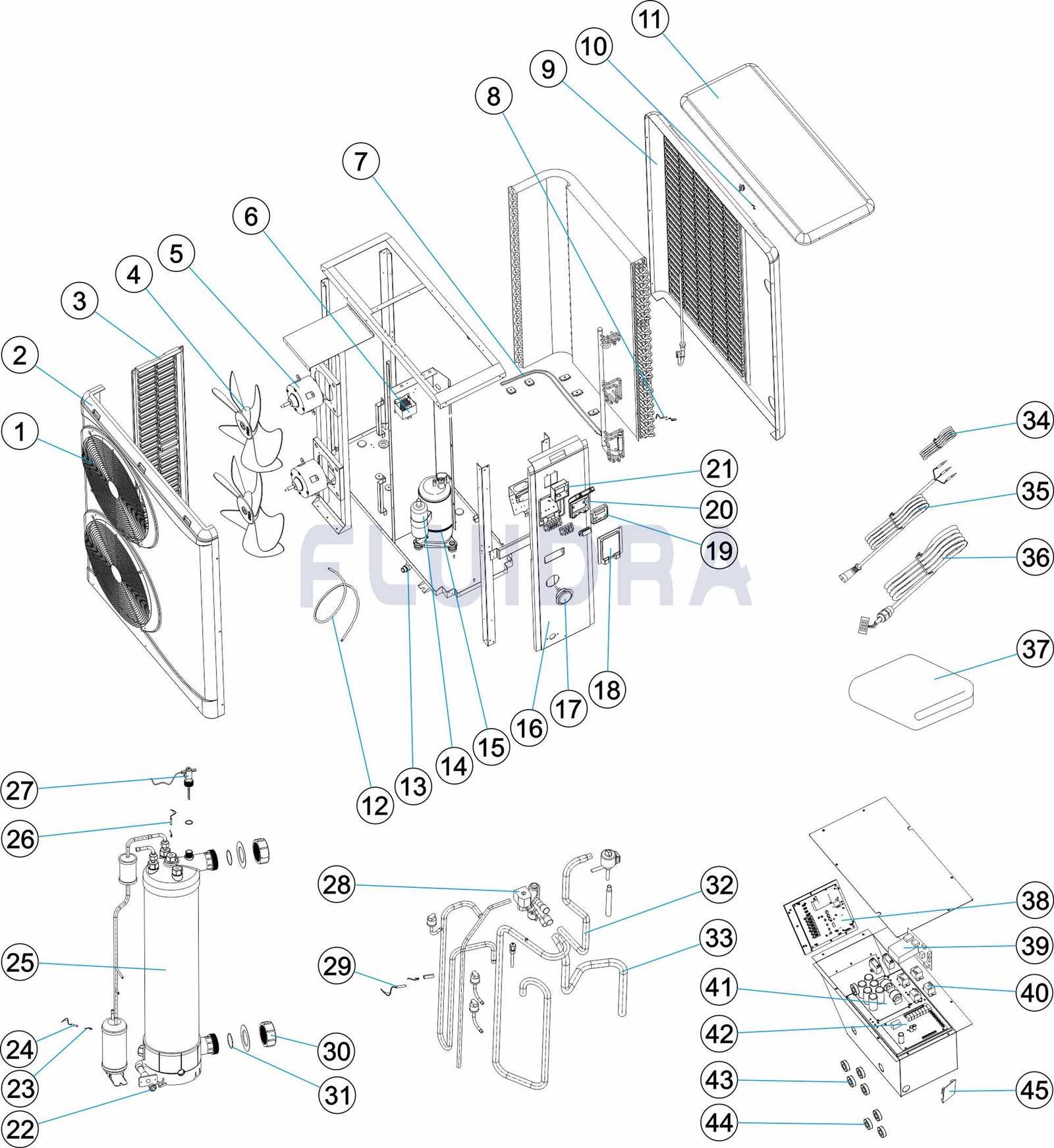

The system responsible for delivering frozen cubes consists of several essential elements that work together to provide efficient cooling and distribution. Each component plays a crucial role in ensuring smooth operation, and their coordination is key to maintaining functionality.

The primary elements include the mechanism responsible for producing the frozen cubes, storage units, and the transport assembly that facilitates the movement of the product. These components work in harmony, with each part contributing to the overall performance of the system.

Understanding how these elements interact helps in troubleshooting any potential issues and maintaining the system in optimal condition.

How the Ice Dispenser Works

Understanding the mechanics of a cooling unit’s delivery system can help identify how cold blocks are formed and moved through the machine. The process involves several key steps that ensure efficient functionality, from creating frozen cubes to channeling them to the user. The device operates automatically, with sensors and mechanisms working together to provide consistent performance.

At the heart of the system is a cooling chamber where liquid is frozen. Once the cubes are ready, they are stored in a special compartment until requested. The unit then activates a transport mechanism, moving the frozen material from storage to the serving point. Different levers and controls regulate this process, allowing smooth and timely delivery.

This entire setup relies on various interconnected components working together. Each part has a specific role, from freezing to dispensing. By maintaining the system regularly, the user can ensure continuous and reliable operation of this cooling device.

Common Issues with Ice Dispensers

Devices that distribute frozen cubes can occasionally run into problems that affect their efficiency. Whether it’s due to mechanical issues or blockages, these challenges often reduce performance and cause user frustration. It’s important to identify and resolve the root of the problem to restore functionality.

- Clogs in the mechanism: Blockages are a frequent issue, usually caused by frozen water or debris that prevents smooth operation.

- Malfunctioning motors: The motor responsible for pushing out the cubes can wear down over time, leading to inconsistent or no output.

- Stuck flaps or doors: The chute’s door may get stuck, either due to freezing or mechanical wear, preventing proper release of frozen items.

- Temperature fluctuations: Inconsistent freezing levels can cause build-up or melting, leading to performance issues.

- Sensor problems: Faulty sensors may misread commands, causing the machine to stop responding to user inputs.

By addressing these common issues, users can often restore their device’s functionality without needing major repairs.

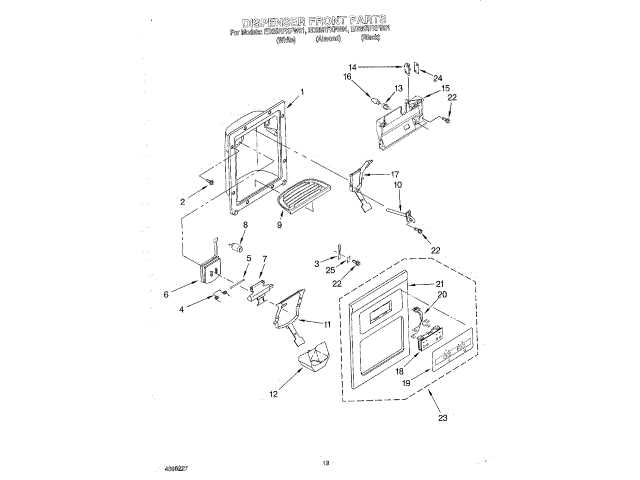

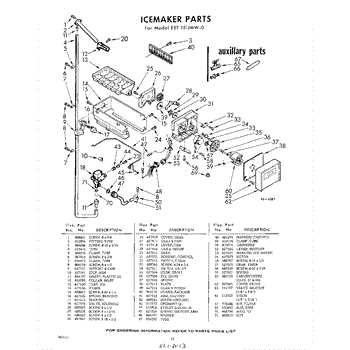

Identifying Key Parts of the Dispenser

Understanding the core elements of a cooling unit’s delivery mechanism can simplify troubleshooting and maintenance. Each component plays a distinct role in ensuring smooth operation, from moving chilled elements to controlling flow. Familiarity with these features allows for quick identification of issues and effective part replacement.

Primary Components and Their Functions

Several critical components work in tandem to provide efficient distribution. These include mechanical levers, electrical controls, and other supportive structures. Below is a concise guide to the main elements and their associated roles.

| Component | Description | Common Issues |

|---|---|---|

| Control Panel | Manages all operations through buttons and sensors, allowing users to select different settings. | Faulty buttons, unresponsive sensors. |

| Actuator | A lever or switch that initiates the release mechanism. | Loose connections, broken levers. |

| Motor Assembly | Powers the movement of internal components, enabling proper functionality. | Wear and tear, overheating. |

| Release Chute | Guides the output, ensuring that contents are dispensed cleanly and accurately. | Blockages, improper alignment. |

Maintenance Tips for Key Components

Regular inspection and cleaning of these components can prolong the lifespan of the mechanism. If any of the parts become worn or damaged, replacing them promptly is crucial to avoid larger malfunctions. Always consult a manual for detailed instructions specific to your model.

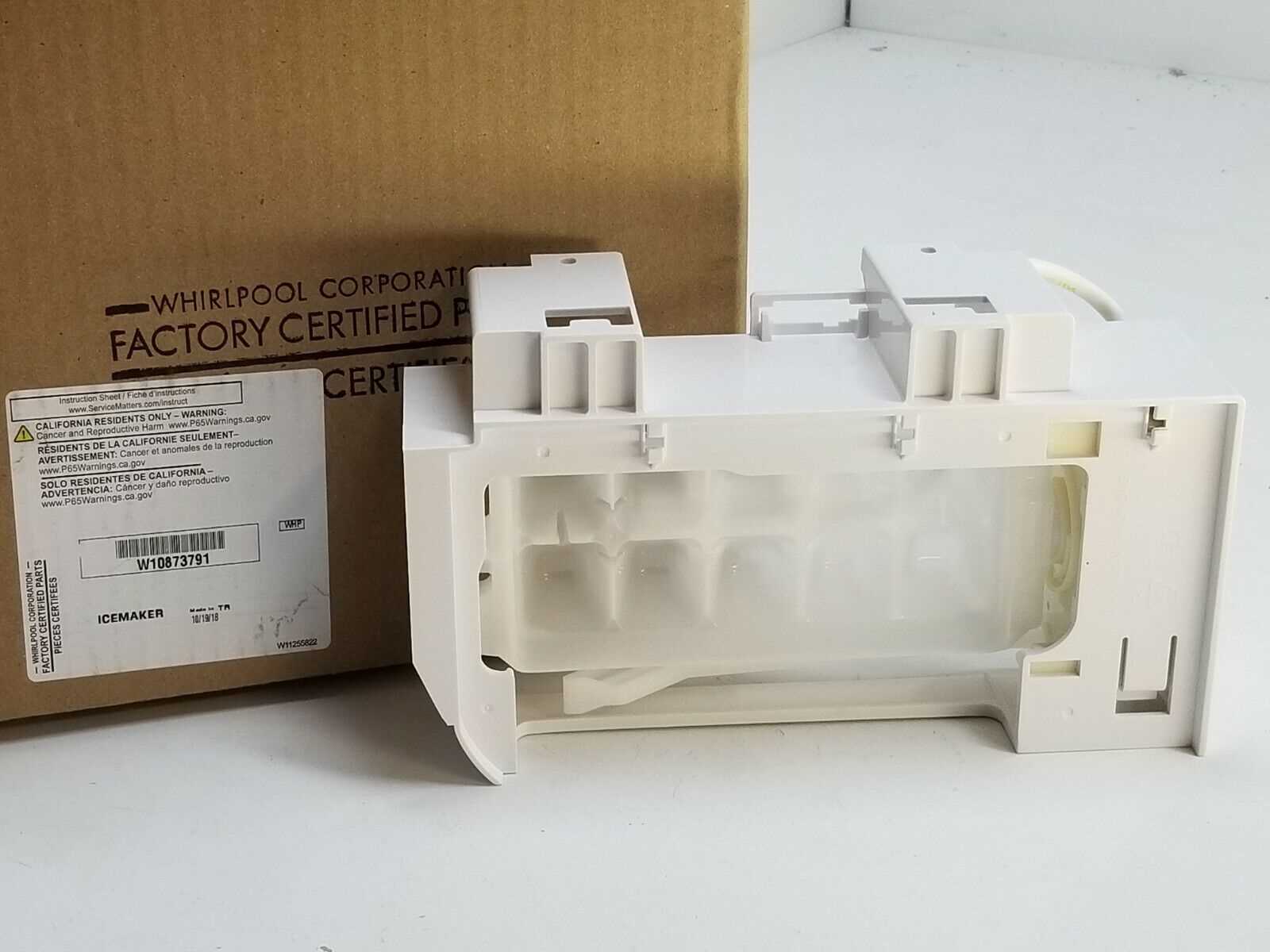

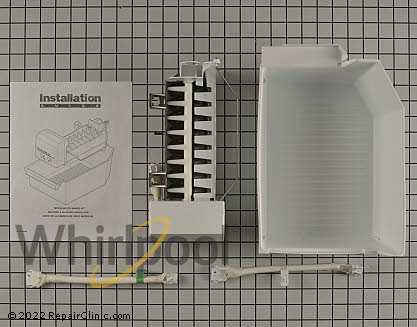

Replacing a Faulty Ice Maker Motor

When the cooling unit’s production mechanism fails, it can lead to disruptions in functionality. Identifying the malfunctioning component is crucial for restoring proper operation. This section will guide you through the process of replacing the motor responsible for producing frozen cubes.

Before beginning the replacement, ensure that you disconnect the appliance from its power source to avoid any electrical hazards. Gather the necessary tools, including a screwdriver and a replacement motor designed for your specific model.

Once you have everything prepared, access the compartment housing the motor. Remove any covers or panels that obstruct your view. Take note of how the existing motor is connected to the unit, as this will assist you in correctly installing the new one.

Disconnect the faulty motor from the wiring harness and remove it from its mounting. Carefully position the new motor in place, ensuring it aligns with the existing mounts. Reconnect the wiring harness, making sure each connection is secure and correctly positioned.

After everything is reassembled, restore power to the appliance and run a test cycle. Check for any unusual noises or malfunctions to confirm that the installation was successful. With the new motor in place, your cooling unit should function smoothly once again.

Understanding the Role of the Control Board

The control board serves as the brain of various home appliances, coordinating multiple functions to ensure efficient operation. It processes inputs from various sensors and manages the overall functionality, enabling users to interact seamlessly with the machine. Its design is crucial for maintaining optimal performance and reliability.

Key Functions of the Control Board

This component is responsible for interpreting user commands and translating them into actionable operations. It monitors different parts of the appliance and activates them as necessary, contributing to a smooth user experience. Some of its main functions include:

| Function | Description |

|---|---|

| Sensor Management | Collects data from various sensors to assess operational conditions. |

| Command Processing | Processes inputs from user interfaces and translates them into machine actions. |

| Component Activation | Controls the operation of motors, valves, and other essential elements. |

| Diagnostic Functions | Performs self-checks to identify any malfunctions or issues within the system. |

Importance of a Functional Control Board

A well-functioning control board is vital for the appliance’s longevity and efficiency. Any malfunction can lead to improper operations, resulting in user frustration and potential damage to the machine. Regular maintenance and timely replacements of this component are essential to ensure the appliance remains in top condition.

Maintaining the Water Inlet Valve

The water inlet valve is a crucial component in any refrigeration system, responsible for regulating the flow of water to various functions. Proper maintenance of this valve ensures optimal performance and longevity, preventing issues such as leaks or blockages that can disrupt operations.

Regular Inspections

Conducting regular inspections is essential to identify any signs of wear or malfunction. Look for any buildup of minerals or debris around the valve, as these can impede its function. Ensure that all connections are secure and free from leaks.

Cleaning Procedures

Periodically, it is important to clean the valve to maintain its efficiency. Disconnect the water supply and carefully remove the valve. Use a mixture of warm water and vinegar to dissolve any buildup, and gently scrub the surfaces with a soft brush. Rinse thoroughly before reinstalling.

Proactive maintenance of the water inlet valve not only enhances its functionality but also extends the life of the entire system. Staying attentive to these details can save time and reduce costs associated with repairs.

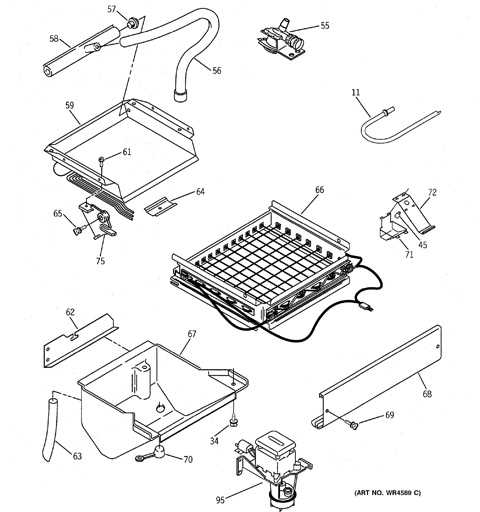

How to Replace the Auger Assembly

Replacing the auger mechanism in your appliance can significantly enhance its efficiency and functionality. This process involves removing the existing assembly and installing a new one to ensure proper operation.

Step 1: Begin by unplugging the appliance to ensure safety. This prevents any electrical hazards while you work.

Step 2: Open the door and remove any stored materials that may obstruct access to the assembly. This allows for a clear workspace.

Step 3: Locate the cover panel that protects the auger assembly. Remove the screws or fasteners securing this panel using a screwdriver or appropriate tool.

Step 4: Once the panel is removed, carefully detach the auger assembly from its mounting. Take note of how it is connected to facilitate easier installation of the new unit.

Step 5: Position the new auger assembly in place, ensuring it aligns correctly with the mounting points. Secure it with the appropriate fasteners.

Step 6: Replace the cover panel and secure it with screws. Double-check that everything is tightly fastened to prevent any movement.

Step 7: Plug the appliance back in and test its operation to confirm that the new assembly functions correctly. Monitor for any unusual sounds or issues during this initial test.

Following these steps will help ensure a successful replacement, restoring the appliance’s functionality and performance.

Fixing Ice Crusher Blade Problems

Maintaining the functionality of your cold beverage machine is essential for ensuring consistent performance. One common issue involves the blades responsible for shredding frozen cubes. Addressing these complications promptly can restore efficiency and improve the overall user experience.

To effectively troubleshoot and repair blade issues, follow these steps:

| Problem | Possible Causes | Solutions |

|---|---|---|

| Blades not spinning | Jammed ice, faulty motor | Clear any blockages and inspect the motor |

| Inconsistent crushing | Worn blades, misalignment | Replace worn components and align blades correctly |

| Excessive noise | Loose parts, damaged blades | Tighten all components and replace damaged blades |

By understanding these potential issues and their solutions, you can ensure that your machine continues to operate smoothly, providing perfectly crushed frozen delights whenever needed.