Understanding the Parts Diagram of Yamaha 2 Stroke Outboard Motors

Exploring the intricate workings of marine propulsion systems reveals a fascinating world of engineering and design. Each element plays a crucial role in ensuring optimal performance, efficiency, and reliability. Knowledge of these components not only enhances maintenance practices but also empowers enthusiasts and professionals alike to tackle repairs with confidence.

In this section, we will delve into the various elements that comprise a two-cycle engine, examining their functions and interconnections. Recognizing how each segment contributes to the overall operation can significantly improve one’s ability to troubleshoot issues and optimize performance. This exploration will illuminate the relationship between each part, fostering a deeper appreciation for the craftsmanship behind these powerful machines.

Whether you’re an experienced technician or a budding hobbyist, a thorough understanding of these components is essential. By familiarizing yourself with the configuration and role of each piece, you will be better equipped to maintain and enhance the functionality of your marine vessel. Let’s embark on this journey into the core of marine engineering.

Understanding Yamaha Outboard Motor Design

Exploring the intricacies of marine propulsion systems reveals a blend of engineering brilliance and practical functionality. Each element is meticulously crafted to ensure optimal performance, durability, and efficiency in aquatic environments.

Key components play a significant role in the overall structure:

- Powerhead: Houses the engine and essential systems, providing the necessary thrust.

- Lower Unit: Transmits power to the propeller while protecting the internal gears.

- Cooling System: Maintains optimal temperatures to prevent overheating during operation.

- Fuel Delivery System: Ensures a consistent flow of fuel to maximize efficiency and performance.

Understanding how these elements interact is crucial for effective maintenance and troubleshooting. A well-designed assembly not only enhances functionality but also contributes to the longevity of the unit.

- Regular inspections can prevent premature wear and tear.

- Proper lubrication is essential for smooth operation.

- Timely replacement of components can significantly enhance performance.

By delving into the design features, users can appreciate the technological advancements that facilitate seamless navigation and reliable operation in various marine conditions.

Key Components of 2-Stroke Motors

Understanding the essential elements of two-cycle engines is crucial for efficient operation and maintenance. These engines rely on a series of interconnected components that work harmoniously to deliver power and performance. Each part plays a specific role in the overall functionality, making them vital for seamless operation.

Main Elements

- Crankshaft

- Piston

- Connecting Rod

- Cylinder

- Fuel System

Supporting Components

- Ignition System

- Exhaust System

- Lubrication System

- Cooling System

Each of these components contributes to the ultimate performance and longevity of the engine, ensuring it meets the demands of various applications.

Benefits of 2-Stroke Technology

This technology offers a range of advantages that enhance performance and efficiency in various applications. Its design allows for a simpler construction and often leads to lighter equipment, making it ideal for specific environments.

Advantages

- Improved Power-to-Weight Ratio

- Fewer Moving Parts

- Ease of Maintenance

Efficiency and Performance

- Rapid Acceleration

- Higher RPMs

- Lower Initial Costs

Overall, this technology is valued for its combination of simplicity and power, making it a popular choice in many sectors.

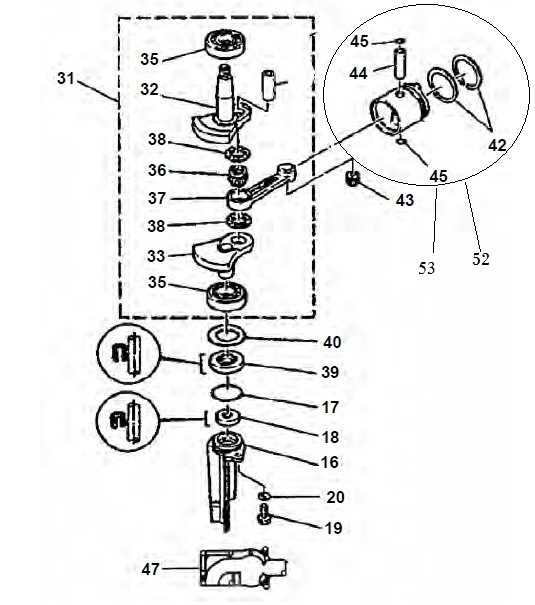

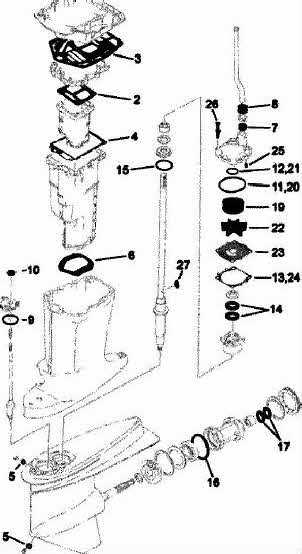

How to Read Motor Parts Diagrams

Understanding technical illustrations can enhance your ability to maintain and repair machinery. These visual representations provide essential information about components and their arrangements. By grasping the symbols and layout, you can efficiently identify and work with the various elements involved.

Familiarize yourself with the common symbols used in these illustrations. Each symbol typically represents a specific component, and knowing what they signify is crucial. Consult a legend if available, as it offers detailed descriptions of each part and its function.

Next, pay attention to the orientation of the illustration. Most diagrams will have a specific viewpoint, such as top-down or side view. Recognizing this perspective can help you understand how parts interact in three-dimensional space.

Lastly, take your time when analyzing the layout. Follow the connections and lines that link different components. This will give you insights into how systems operate together and the ultimate flow of energy or fluids through the assembly.

Essential Tools for Maintenance

Regular upkeep of your equipment is crucial for longevity and performance. To achieve optimal results, certain instruments are indispensable. Here’s a list of essential tools that will aid in maintaining your machine efficiently.

- Wrenches: For loosening and tightening various components.

- Screwdrivers: Essential for adjusting and securing parts.

- Pliers: Useful for gripping and manipulating small items.

- Socket Set: Provides versatility for different bolt sizes.

- Torque Wrench: Ensures proper tightening without damage.

Having the right tools not only simplifies the process but also enhances safety and effectiveness during maintenance tasks.

Common Parts Replacement Guide

This section provides a comprehensive overview of frequently replaced components for marine engines. Understanding which elements are subject to wear and tear can enhance performance and prolong the lifespan of your equipment.

Fuel Filter: Regularly checking and replacing the fuel filter is essential for maintaining clean fuel flow. A clogged filter can lead to poor engine performance and increased wear on internal components.

Impeller: The water pump impeller is crucial for cooling the engine. Over time, it can degrade, leading to overheating. Replacement every few years is advisable to ensure optimal cooling efficiency.

Spark Plugs: These small yet vital components ignite the fuel-air mixture in the combustion chamber. Worn or fouled spark plugs can cause misfires and decreased fuel efficiency. Regular replacement can improve starting and overall performance.

Battery: A reliable power source is necessary for smooth operation. Periodic testing and replacement of the battery will ensure that the engine starts reliably and operates without interruption.

Lower Unit Oil: Maintaining proper lubrication in the lower unit is critical. Regular oil changes can prevent costly damage from corrosion and wear, ensuring smooth operation of gears and bearings.

By keeping an eye on these essential components, you can ensure that your marine engine remains in peak condition, ready for any adventure on the water.

Identifying Yamaha Model Variations

Understanding the distinctions among various models is essential for effective maintenance and repair. Each variant showcases unique features and specifications that cater to different needs and performance requirements. By recognizing these differences, users can ensure they select the appropriate components for their specific model.

Key Characteristics to Observe

When examining a particular variant, focus on the engine size, configuration, and serial number. These elements often provide critical insights into the specific capabilities and design of the unit, allowing for a more informed selection of compatible accessories and enhancements.

Resources for Identification

Consulting manufacturer resources, manuals, and online forums can greatly assist in distinguishing between models. Engaging with communities dedicated to this topic can also facilitate knowledge-sharing, helping enthusiasts identify their equipment accurately.

Maintenance Tips for Longevity

Ensuring the extended life of your watercraft’s engine involves a consistent maintenance routine. Regular care not only enhances performance but also prevents costly repairs down the line. By following some essential practices, you can keep your equipment in optimal condition for years to come.

Regular Inspections

Performing routine checks is crucial. Focus on components such as fuel lines, filters, and electrical connections. Look for signs of wear and tear, and replace any damaged parts promptly to avoid further issues.

Proper Cleaning

Keeping the engine clean is vital for performance. Remove any debris or salt buildup after each use, especially if operating in marine environments. This prevents corrosion and ensures that all parts function smoothly.

| Maintenance Task | Frequency | Importance |

|---|---|---|

| Check oil levels | Before each use | Ensures proper lubrication |

| Inspect fuel quality | Monthly | Prevents engine issues |

| Clean air filter | Every 50 hours | Enhances airflow |

| Test battery condition | Seasonally | Avoids starting problems |

| Check spark plugs | Every 100 hours | Ensures efficient combustion |

Diagnosing Common Engine Issues

Identifying frequent problems in an engine can significantly enhance performance and longevity. By systematically analyzing symptoms, one can often pinpoint the root cause of malfunctions, allowing for effective remedies and preventative measures.

Here are some typical issues and their potential indicators:

| Issue | Possible Symptoms |

|---|---|

| Poor Starting | Difficulty igniting, unusual noises during cranking |

| Overheating | Excessive heat, warning lights activated |

| Inefficient Performance | Reduced speed, inconsistent power delivery |

| Unusual Sounds | Knocking, grinding, or sputtering noises |

| Fuel Leaks | Puddles under the unit, strong fuel odor |

Addressing these issues promptly can prevent more serious damage and ensure optimal functionality.

Performance Upgrades for Outboards

Enhancing the capabilities of marine engines can significantly improve efficiency and speed. By focusing on key modifications and high-quality components, enthusiasts can achieve a superior boating experience. Whether for recreational use or competitive racing, various upgrades can unleash the true potential of these powerful machines.

Engine Tuning

One of the most effective ways to boost performance is through engine tuning. Adjusting fuel mixtures, optimizing ignition timing, and upgrading exhaust systems can lead to improved acceleration and top speed. Custom tuning can tailor the engine’s output to meet specific demands, ensuring it runs at peak efficiency.

Propeller Selection

Choosing the right propeller is crucial for maximizing thrust and minimizing drag. Upgrading to a performance propeller can enhance handling and responsiveness, allowing for better control and maneuverability. Selecting the appropriate pitch and diameter can also contribute to improved fuel economy and overall performance.

Environmental Considerations for 2-Strokes

The environmental impact of certain engines is a crucial topic, especially regarding emissions and fuel efficiency. Understanding these effects can guide users in making informed decisions that align with sustainability goals.

Emissions and Pollution

Engines in question typically produce higher emissions compared to their four-cycle counterparts. Key points include:

- Increased hydrocarbon release

- Higher levels of carbon monoxide

- Potential for water contamination due to oil discharge

Improving Environmental Impact

To mitigate negative effects, consider the following strategies:

- Utilize cleaner fuels

- Regular maintenance to ensure optimal performance

- Invest in modern technology that meets environmental standards

Comparing Yamaha to Other Brands

When evaluating various manufacturers in the marine industry, it’s crucial to consider performance, reliability, and user satisfaction. Each brand brings unique features and technologies that cater to different preferences and needs. Understanding these distinctions can help consumers make informed decisions.

In terms of efficiency and durability, some competitors may offer similar specifications, but Yamaha often stands out with its innovative engineering and design. Users frequently highlight the smooth operation and longevity of Yamaha’s offerings, making it a favored choice among enthusiasts.

Price is another critical factor in this comparison. While some brands may provide lower initial costs, Yamaha’s reputation for quality can translate to lower maintenance expenses over time, providing greater value for investment. Moreover, the availability of service and support can vary, with Yamaha typically receiving high marks for customer service and accessibility of parts.

Ultimately, each brand has its strengths and weaknesses. By delving into specific models and customer feedback, prospective buyers can better understand how Yamaha stacks up against its competitors in meeting their individual requirements.

Resources for Further Learning

This section aims to provide a variety of tools and references for those eager to expand their understanding of two-cycle engines and their components. Whether you are a novice or a seasoned enthusiast, these resources can help deepen your knowledge and enhance your skills in maintenance and repair.

Online Tutorials and Videos

Platforms such as YouTube and specialized forums offer numerous instructional videos and tutorials. These resources can guide you through disassembly, reassembly, and troubleshooting, allowing you to see practical applications of the concepts discussed.

Books and Manuals

Consider investing in comprehensive manuals and books focused on engine mechanics. These texts often provide detailed explanations, diagrams, and troubleshooting tips, serving as an excellent reference for both learning and practical application.