Comprehensive Guide to Yamaha 115 Outboard Motor Parts Diagram

In the world of marine propulsion, having a clear understanding of engine components is essential for maintenance and repair. A well-organized visual representation can greatly aid in identifying each element, ensuring that boat enthusiasts can effectively manage their vessels. This guide provides a detailed overview of the intricate relationships between various engine parts, fostering a deeper comprehension of their functionalities.

Maintenance and care are crucial for the longevity and performance of any marine engine. Familiarity with the structure and layout of the components allows for more efficient troubleshooting and replacement procedures. By examining the interconnected parts, users can gain insights into how each contributes to overall performance and reliability.

Whether you’re a seasoned technician or a novice boater, having access to a thorough schematic can enhance your understanding of the mechanisms at play. This resource serves as a valuable tool for anyone looking to improve their skills and ensure their watercraft operates smoothly and efficiently.

Understanding Yamaha 115 Outboard Motor

This section delves into the intricate workings and components of a specific type of propulsion system commonly utilized in aquatic vehicles. Gaining a comprehensive understanding of its structure and function is essential for effective maintenance and optimal performance.

Key Components

To appreciate the efficiency and reliability of this propulsion system, it’s vital to familiarize yourself with its essential elements:

- Engine assembly

- Fuel system

- Ignition system

- Cooling system

- Exhaust system

- Propulsion mechanism

Maintenance Tips

Regular upkeep is crucial for ensuring longevity and peak operation. Consider these important practices:

- Check and replace the oil regularly.

- Inspect the fuel filter for blockages.

- Ensure the cooling system is free of debris.

- Examine the propeller for damage.

- Test electrical connections periodically.

By understanding the components and following maintenance guidelines, users can enhance the performance and reliability of their aquatic propulsion systems.

Key Components of Yamaha 115 Motor

Understanding the essential elements of an aquatic propulsion unit is crucial for optimal performance and maintenance. Each component plays a significant role in ensuring efficiency and reliability during operation.

Powerhead: This is the powerhouse of the unit, housing the engine and providing the necessary thrust for movement.

Gear Case: Positioned at the bottom, this element contains the gears that transfer power to the propeller, crucial for speed and maneuverability.

Propeller: The rotating blade that propels the vessel forward, its design and pitch greatly influence performance and handling.

Cooling System: This mechanism prevents overheating by circulating water around the engine, ensuring longevity and efficiency.

Fuel System: Responsible for delivering the right mixture of fuel and air, it directly impacts the engine’s performance and responsiveness.

Steering System: This allows for precise control of direction, enhancing the navigational capabilities of the vessel.

By delving into these fundamental components, users can achieve a deeper understanding of functionality and maintenance, ensuring the ultimate reliability on the water.

Importance of Motor Maintenance

Regular upkeep of marine engines is crucial for ensuring optimal performance and longevity. Neglecting maintenance can lead to a range of issues that not only affect efficiency but also compromise safety on the water.

Preventive care helps identify potential problems before they escalate into major failures. This proactive approach reduces repair costs and minimizes downtime, allowing for a smoother experience during use.

Furthermore, cleaning and inspection of components contribute significantly to maintaining efficiency. A well-maintained engine operates at its peak, providing reliable power when needed most.

Ultimately, prioritizing maintenance ensures that your equipment remains in top shape, enhancing both performance and safety. Embracing a routine check-up can make a significant difference in your overall experience.

Common Issues and Solutions

This section addresses frequent challenges encountered with marine propulsion systems and offers practical solutions for each issue. Understanding these problems can enhance performance and prolong the lifespan of your equipment.

-

Starting Difficulties:

Issues with ignition may arise due to battery failure or fuel supply problems. Check the battery connections and ensure the fuel tank is full and free of debris.

-

Overheating:

This can occur due to a blocked cooling system. Inspect the water intake and clean any obstructions to maintain optimal temperature.

-

Unusual Noises:

Strange sounds may indicate mechanical issues. Regularly check for loose components and ensure proper lubrication of moving parts.

-

Poor Performance:

If acceleration is sluggish, consider examining the propeller for damage and the fuel system for blockages.

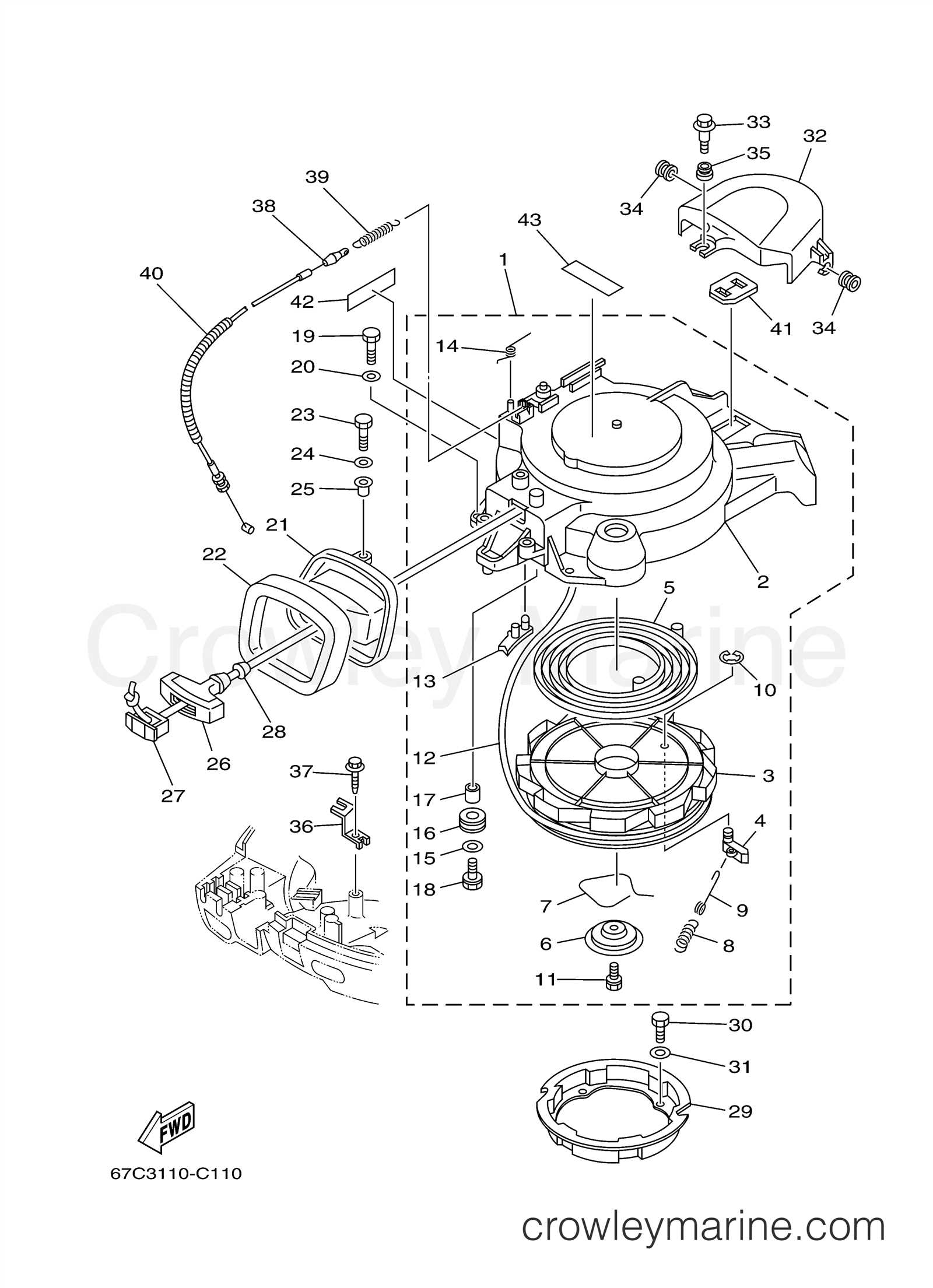

How to Read Parts Diagrams

Understanding visual representations of components is essential for anyone involved in maintenance or repair. These illustrations provide a detailed overview of various elements, helping users identify and locate specific items within a complex assembly. Mastering this skill can enhance efficiency and accuracy in any technical task.

Key Elements to Look For

- Labels: Each component is typically labeled with a unique identifier, making it easier to reference in discussions or when ordering replacements.

- Numbering System: A systematic numbering approach often accompanies the illustration, allowing users to match numbers with descriptions in accompanying documentation.

- Connection Points: Pay attention to how parts are connected. Understanding these relationships can aid in disassembly and reassembly.

Steps to Follow

- Start by familiarizing yourself with the overall layout of the illustration.

- Identify the labels and corresponding numbers for each component.

- Note any additional notes or symbols that provide further information about assembly or maintenance.

- Refer to the accompanying text for detailed descriptions and specifications.

Identifying Replacement Parts

Understanding how to pinpoint components for marine engines is essential for maintaining performance and longevity. Proper identification ensures compatibility and enhances the efficiency of repairs and upgrades.

When searching for specific elements, consider the following steps:

- Consult the owner’s manual for detailed specifications.

- Examine existing components for serial numbers or model identifiers.

- Utilize online resources or community forums for guidance on identification.

Additionally, familiarize yourself with common types of components, which include:

- Fuel systems

- Electrical assemblies

- Cooling mechanisms

- Propulsion elements

By following these guidelines, you can ensure that you obtain the correct items needed for maintenance or replacement, ultimately enhancing the reliability of your watercraft.

Tools Needed for Repairs

Effective repairs require a selection of essential instruments to ensure precision and efficiency. Familiarity with the right tools can significantly enhance the quality of your maintenance tasks, making the process smoother and more manageable.

Basic Hand Tools

Having a reliable set of hand tools is crucial. This includes wrenches, screwdrivers, and pliers, which are necessary for various adjustments and replacements. A good toolkit provides versatility and helps tackle a range of issues.

Specialized Equipment

In addition to standard tools, consider investing in specialized equipment. This may involve torque wrenches or compression gauges, which are vital for specific repairs. Such instruments enable you to delve deeper into complex tasks and achieve ultimate results.

Safety Tips for Motor Maintenance

Proper upkeep of your marine propulsion system is crucial not only for performance but also for ensuring your safety while on the water. By adhering to certain precautions and guidelines, you can prevent accidents and extend the lifespan of your equipment. This section highlights essential safety tips that every operator should follow during maintenance procedures.

Personal Protective Equipment

Always wear appropriate personal protective gear when performing maintenance tasks. This includes safety goggles to shield your eyes from debris, gloves to protect your hands from sharp components, and steel-toed boots to guard against heavy objects. Proper attire minimizes the risk of injury and promotes a safe working environment.

Work Environment Safety

Ensure that the maintenance area is well-ventilated and free from hazards. Keep flammable materials away from the workspace, and utilize tools that are in good condition. Regularly inspect your surroundings to identify potential risks such as slippery surfaces or clutter that could lead to accidents. A clean and organized environment is essential for safe and effective maintenance.

Where to Buy Genuine Parts

Finding authentic components for your marine equipment is essential for optimal performance and longevity. Utilizing original products ensures compatibility and reliability, preventing potential issues that can arise from using substandard alternatives. This section will guide you through the best sources for acquiring genuine replacements.

Authorized Dealers

- Visit local authorized dealerships that specialize in marine gear.

- Check for manufacturer-certified retailers online.

- Ensure the dealer offers a warranty on all items sold.

Online Marketplaces

- Look for reputable websites dedicated to marine supplies.

- Read customer reviews to gauge the reliability of the seller.

- Compare prices and check for return policies before making a purchase.

By sourcing components from these reliable avenues, you can maintain the integrity of your equipment and ensure safe and enjoyable experiences on the water.

Comparing Aftermarket vs. Original Parts

When maintaining machinery, the choice between replacement components can significantly impact performance and longevity. Users often face the dilemma of selecting between manufacturer-specific items and alternatives that may offer cost savings but vary in quality.

- Quality: Original components are typically manufactured to strict specifications, ensuring reliability. In contrast, aftermarket options may vary widely in quality.

- Cost: Aftermarket alternatives often come at a lower price, appealing to budget-conscious consumers. However, initial savings may not account for potential long-term issues.

- Availability: Original components may have limited availability, while alternatives can be easier to source, especially for older models.

- Warranty: Manufacturer-specific items usually come with a warranty, providing peace of mind that aftermarket parts may lack.

Ultimately, the decision hinges on individual priorities such as budget, performance, and reliability. Careful consideration of both options can lead to an informed choice that best meets the needs of the user.

Service Manual Resources Available

Accessing comprehensive documentation is crucial for effective maintenance and repair tasks. Various resources provide detailed instructions, specifications, and troubleshooting guidelines to ensure optimal performance and longevity of marine equipment.

Online Portals: Numerous websites offer downloadable manuals that cater to specific models, complete with illustrations and maintenance tips.

Printed Manuals: Many users prefer physical copies, which can be acquired through authorized dealers or online retailers, ensuring easy reference during service procedures.

Community Forums: Engaging with fellow enthusiasts in online forums can yield valuable insights, shared experiences, and sometimes even digital copies of service guides.

Videos: Platforms like YouTube feature a plethora of instructional videos, providing visual demonstrations that can complement written resources.

By leveraging these varied resources, individuals can delve deeper into maintenance practices, leading to more informed and efficient servicing efforts.