Understanding the Yamaha 15 HP Outboard Parts Diagram

When it comes to maintaining your small watercraft, having a clear understanding of its mechanical components is essential. Proper knowledge enables you to identify issues quickly and make informed decisions about repairs or upgrades. This section aims to provide a comprehensive overview of a specific 15 HP marine engine, enhancing your confidence in handling its various elements.

Throughout this exploration, we will delve into the intricate workings and functions of each component, allowing you to grasp their roles in the overall performance of the engine. From the ignition system to the fuel delivery mechanism, every piece plays a crucial part in ensuring smooth operation on the water.

Ultimately, being familiar with these essentials not only helps in troubleshooting but also empowers you to maximize the efficiency and longevity of your engine. This knowledge is invaluable for any enthusiast looking to enhance their boating experience.

Understanding Yamaha 15 HP Outboard

When it comes to small marine engines, knowledge of their components and functions is essential for effective maintenance and operation. This specific model offers a compact solution for various water activities, blending efficiency with reliability. A solid grasp of how each part works together enhances the overall experience for enthusiasts and casual users alike.

Key components play a crucial role in the performance and longevity of these engines. From the fuel system to the cooling mechanisms, understanding these elements helps users troubleshoot common issues. Regular inspection and familiarity with the internal workings can prevent minor problems from escalating, ensuring smoother outings on the water.

Moreover, access to resources that detail the structure and functionality of each section aids in maintaining optimal performance. Whether it’s sourcing replacement components or performing routine checks, comprehensive knowledge empowers users to take control of their equipment, leading to enhanced safety and enjoyment on the water.

Importance of Maintenance for Outboards

Regular upkeep of marine engines is crucial for ensuring optimal performance and longevity. Neglecting maintenance can lead to decreased efficiency, costly repairs, and even complete failure, which can compromise safety on the water. By adhering to a consistent maintenance schedule, owners can enjoy smoother rides and enhanced reliability.

Benefits of Routine Care

Preventive measures can help identify potential issues before they escalate. Regular inspections, oil changes, and component checks not only improve functionality but also help maintain the engine’s value over time. A well-maintained unit is more likely to perform reliably, allowing users to focus on enjoying their time on the water.

Environmental Considerations

Proper care contributes to reduced emissions and less pollution. Well-maintained engines operate more efficiently, minimizing their environmental impact. Emphasizing maintenance reflects a commitment to responsible boating practices and helps protect aquatic ecosystems.

Key Components of the Engine

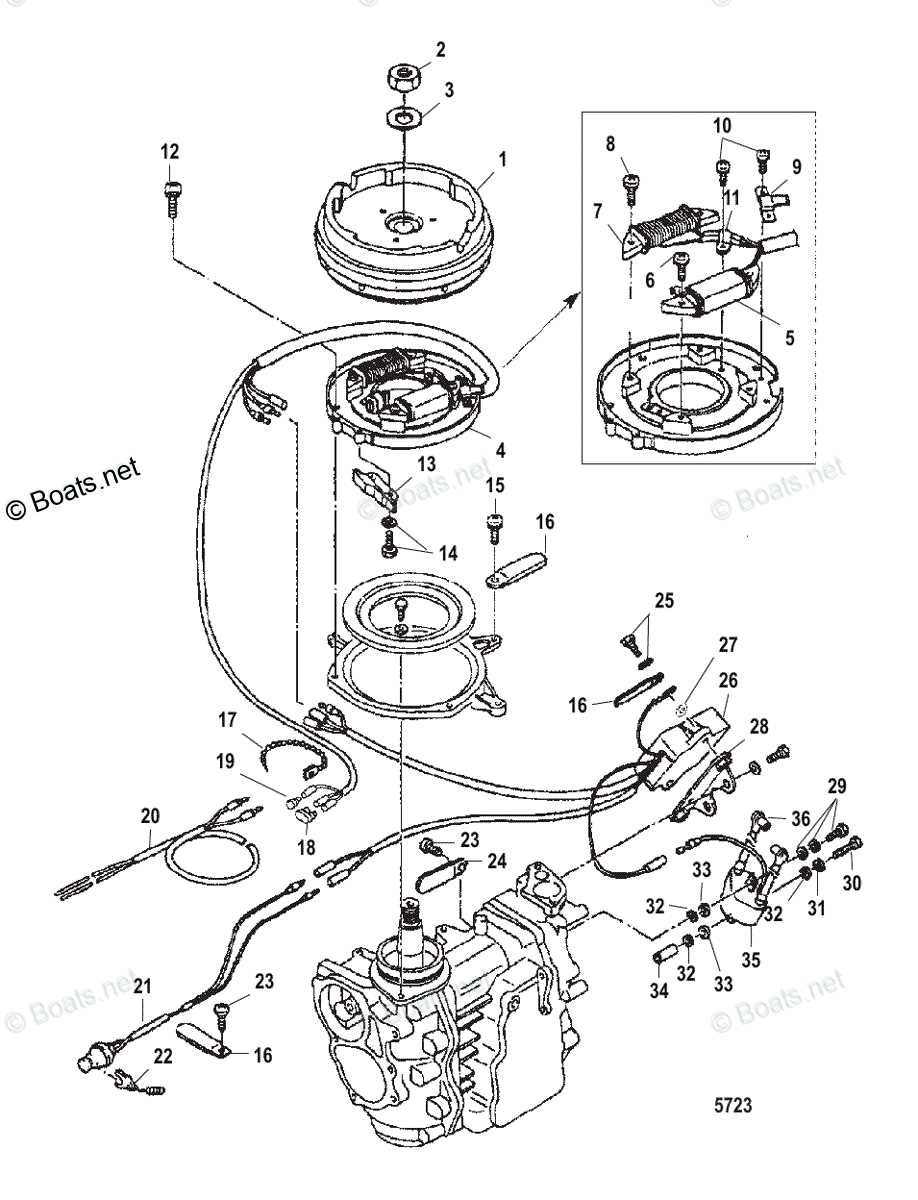

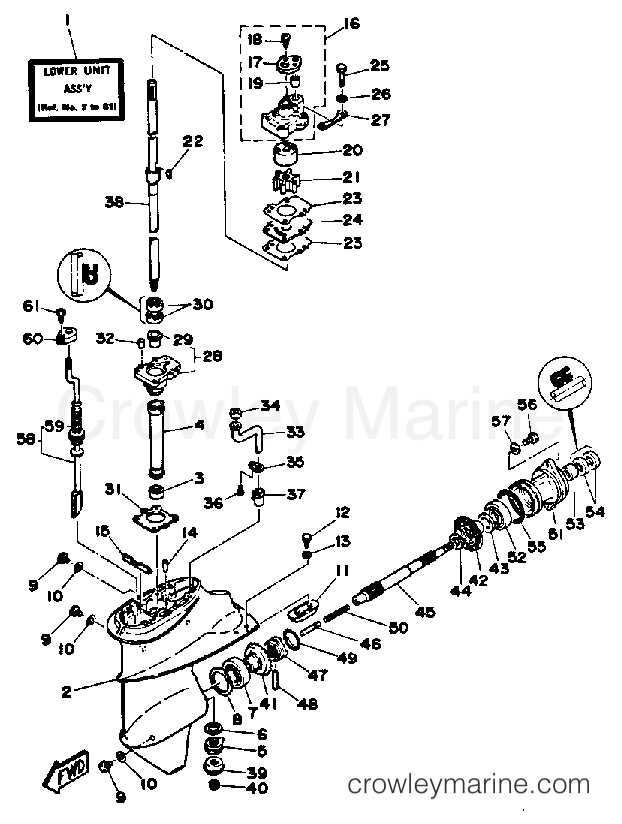

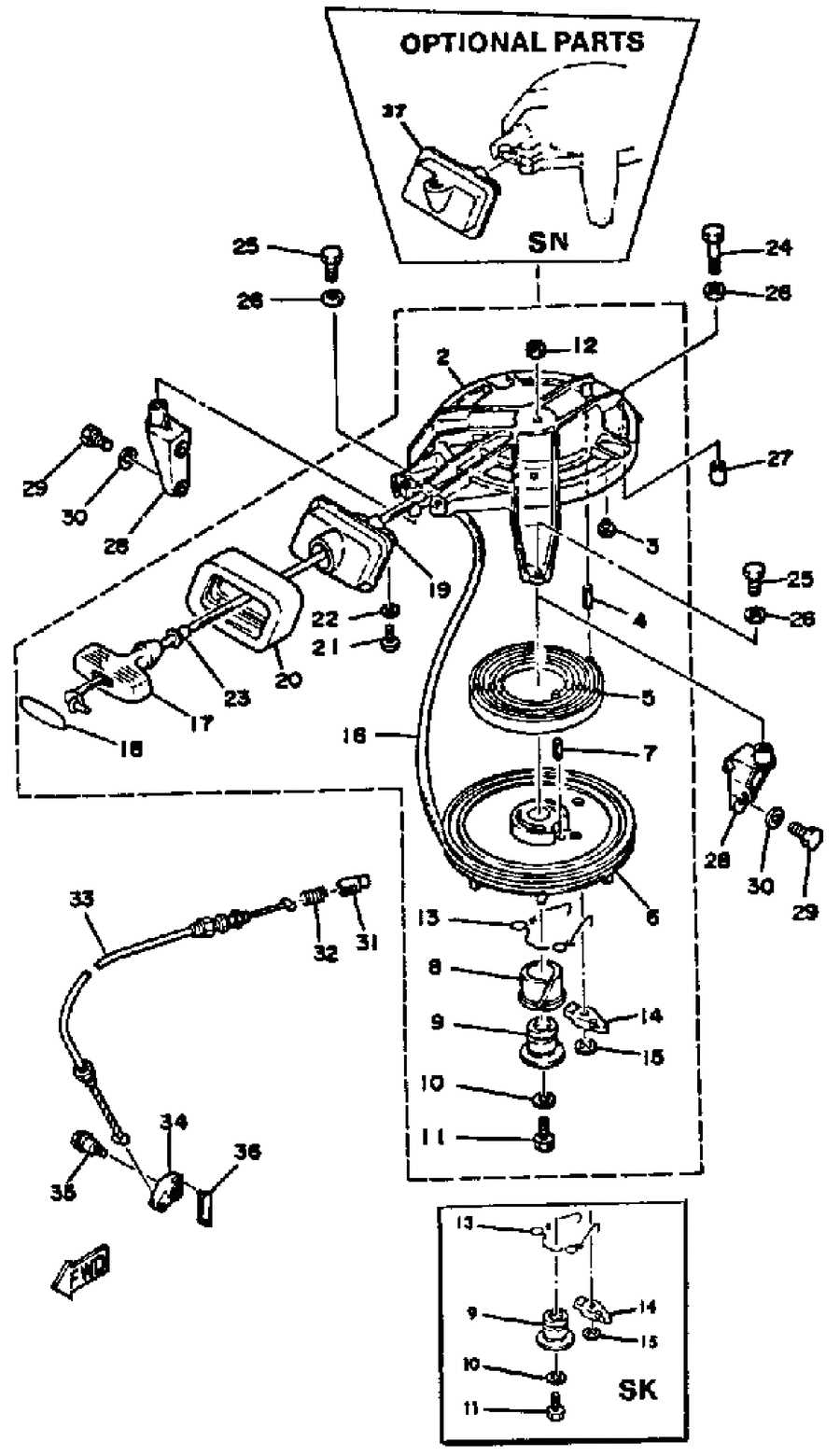

Understanding the essential elements of a marine power unit is crucial for maintaining optimal performance and efficiency. Each part plays a vital role in the overall functionality, contributing to the engine’s power output, reliability, and longevity. A comprehensive grasp of these components enables users to address issues effectively and perform necessary upgrades.

The engine block serves as the foundation, housing various critical parts, including cylinders and pistons. These components work together to convert fuel into mechanical energy. The crankshaft, another key element, transforms the linear motion of the pistons into rotational movement, ultimately driving the propeller.

Additionally, the ignition system is pivotal for initiating combustion, while the fuel delivery mechanism ensures the appropriate mixture reaches the combustion chamber. The cooling system maintains optimal operating temperatures, preventing overheating and ensuring efficient performance. Understanding these core components allows for better troubleshooting and maintenance strategies.

Common Issues with Yamaha Outboards

When operating marine engines, various challenges may arise that can affect performance and reliability. Understanding these potential issues is essential for ensuring longevity and efficient operation. Below are some of the most frequently encountered problems and their possible solutions.

Fuel-Related Problems

- Clogged fuel filters: Over time, debris can accumulate, restricting fuel flow.

- Water contamination: Presence of water in the fuel can lead to poor combustion and engine stalling.

- Poor fuel quality: Using low-grade fuel can cause knocking and inefficient burning.

Electrical System Failures

- Battery issues: A weak or dead battery can prevent the engine from starting.

- Corroded connections: Corrosion can disrupt electrical flow, leading to intermittent performance.

- Faulty ignition components: Worn spark plugs or ignition coils can cause misfires and reduced power.

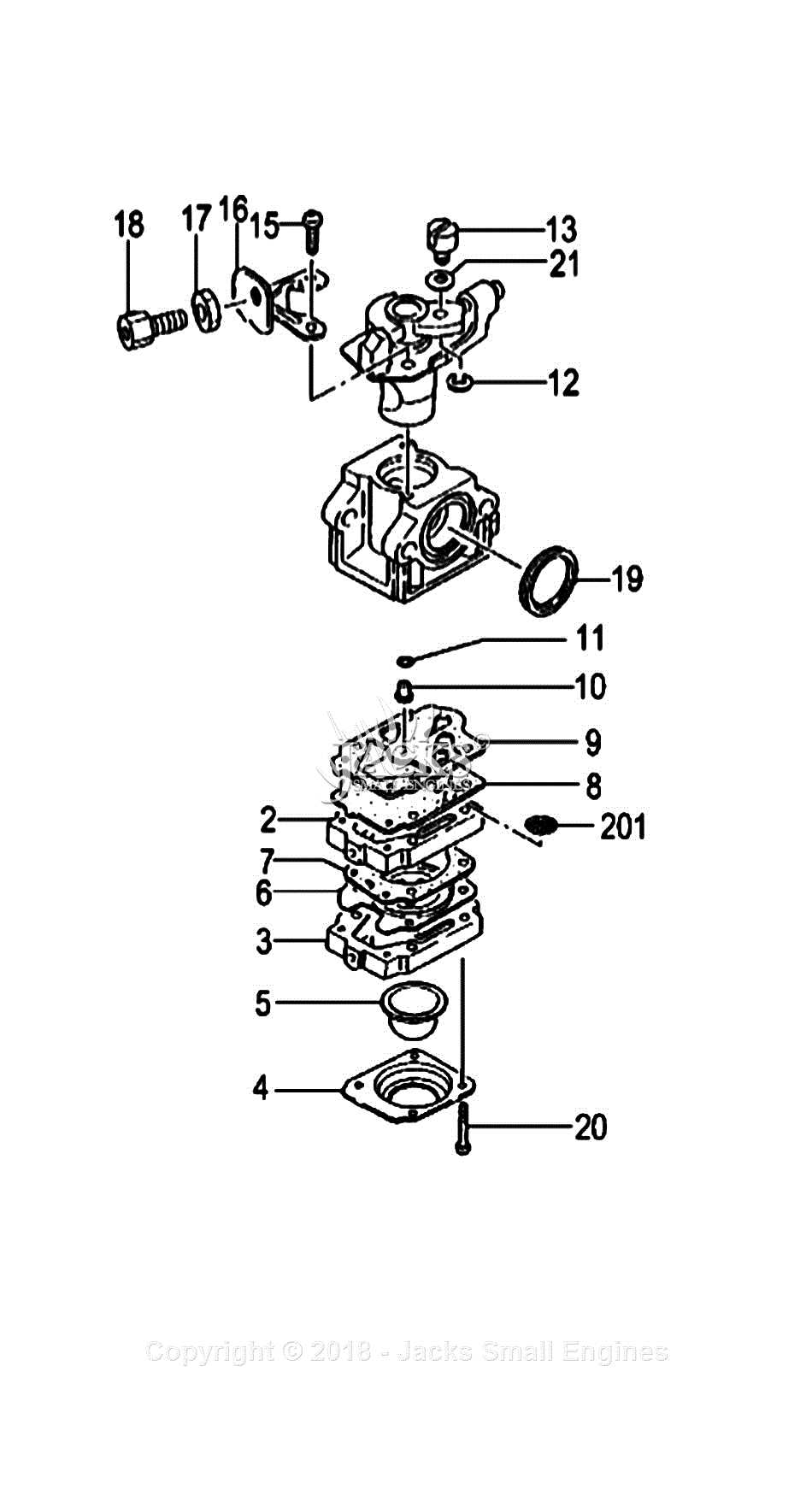

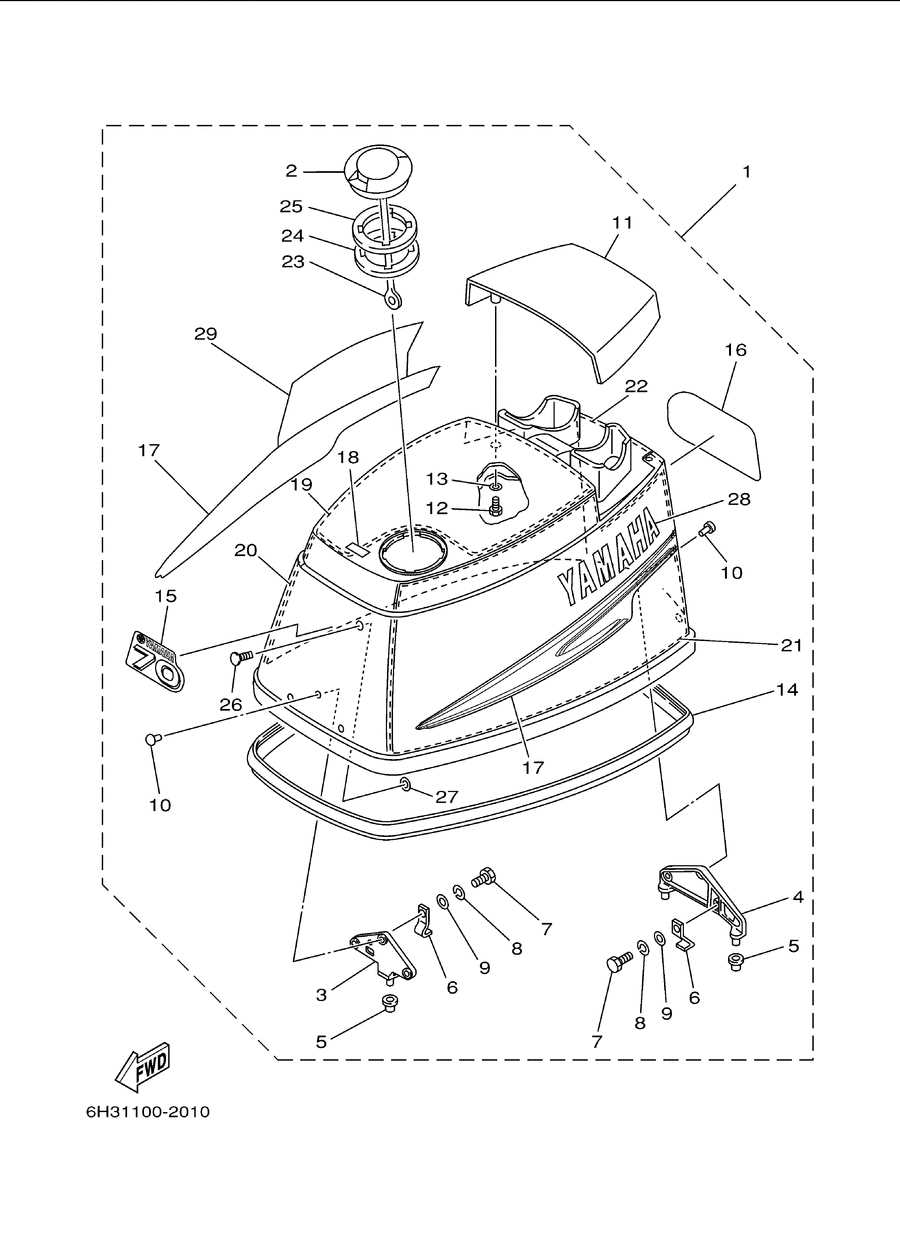

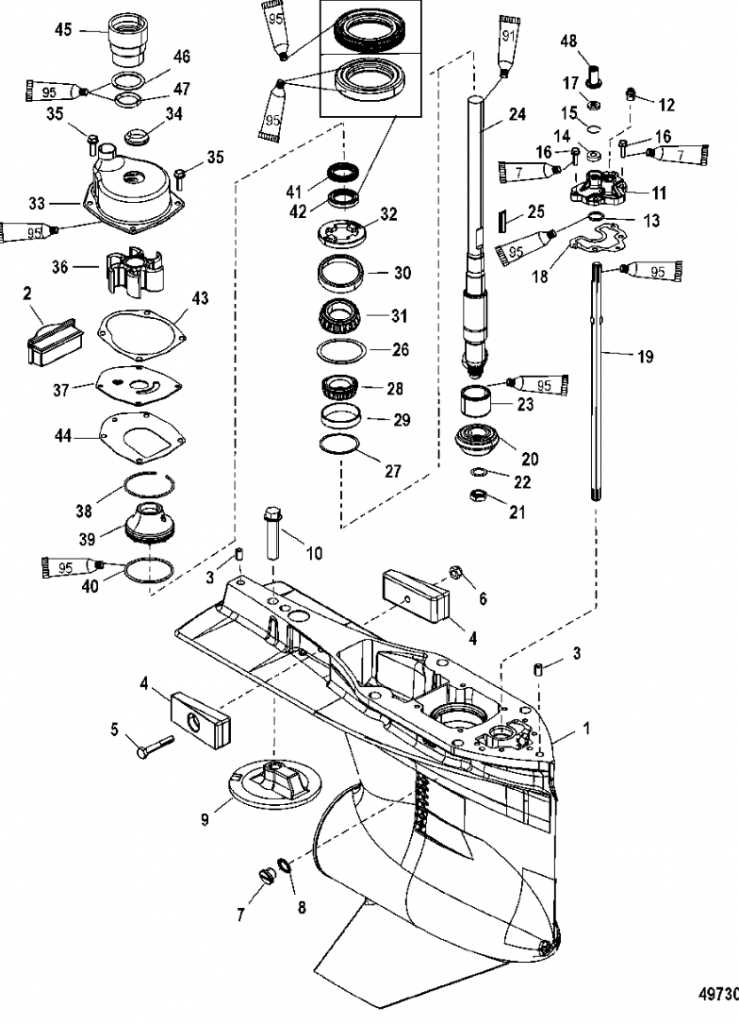

How to Read Parts Diagrams

Understanding visual representations of components can greatly enhance your ability to identify and locate necessary items for maintenance or repair. These illustrations serve as invaluable guides, allowing users to navigate complex assemblies with ease.

Key Elements to Note

When examining these visuals, pay attention to specific features such as labels, numbers, and sectional views. Each element plays a crucial role in providing clarity and ensuring accurate comprehension.

Using the Legend

Many illustrations include a legend that decodes symbols and terms used throughout. Familiarizing yourself with this legend is essential for efficient interpretation and execution of tasks.

| Element | Description |

|---|---|

| Labels | Identify individual components clearly. |

| Numbers | Reference parts in accompanying lists. |

| Sections | Provide different views for better understanding. |

Essential Tools for Repairing Outboards

When it comes to maintaining and fixing marine engines, having the right equipment is crucial for ensuring efficiency and safety. This guide outlines the fundamental instruments necessary for effective repairs, allowing enthusiasts to confidently tackle any issues that arise.

Basic Hand Tools

Every technician should start with a well-stocked toolbox. Wrenches, screwdrivers, and pliers are vital for disassembling components and making adjustments. A socket set can also significantly enhance versatility, enabling access to various fasteners with ease.

Specialized Equipment

In addition to general tools, specific instruments like a compression tester and multimeter are essential for diagnosing engine performance. These devices help pinpoint issues and ensure optimal functionality, allowing for a deeper delve into the mechanics of the system.

Replacing Worn Out Parts

Maintaining optimal performance of your marine engine often requires addressing components that have experienced wear over time. Regular inspections can help identify these areas, ensuring a smooth and efficient operation during your outings on the water. Promptly replacing degraded elements not only enhances reliability but also prolongs the lifespan of the entire unit.

Identifying Signs of Wear

Understanding the typical indicators of deterioration is crucial for timely interventions. Look for leaks, unusual noises, or a decrease in performance as primary signs that something may need replacement. Additionally, visual inspections can reveal cracks, corrosion, or other physical damage that compromises functionality.

Choosing Quality Replacements

When sourcing new components, it’s essential to prioritize quality to ensure compatibility and durability. Opt for reputable manufacturers that offer guarantees, as this can save you time and money in the long run. Moreover, consulting a service manual can provide valuable guidance on specifications and installation procedures, making the replacement process more straightforward and efficient.

Where to Find Genuine Parts

Locating authentic components for marine engines is crucial for maintaining optimal performance and reliability. Understanding where to source these essential items can save time and ensure longevity.

Official Dealers: The most reliable source is through authorized retailers who specialize in marine machinery. They offer a comprehensive selection of genuine items, backed by manufacturer support.

Online Marketplaces: Reputable websites dedicated to marine equipment can also be valuable. Always check for customer reviews and seller ratings to ensure quality.

Local Repair Shops: Many service centers have connections with suppliers, providing access to authentic items directly. They can also offer advice on what is needed for specific repairs.

Manufacturer Websites: Visiting the official site of the engine manufacturer can lead to finding an extensive catalog of available components, along with guidance on installation.

By exploring these avenues, you can ensure that your marine engine is equipped with only the best components for ultimate performance.

Tips for Efficient Troubleshooting

When facing issues with marine engines, a systematic approach can significantly enhance the efficiency of your diagnostic efforts. Identifying the root cause of a problem often requires patience, attention to detail, and a methodical strategy. This section provides practical tips to streamline the troubleshooting process and ensure that you address issues effectively.

Systematic Approach

Start by gathering all relevant information about the engine’s symptoms. Take note of any unusual sounds, performance drops, or warning indicators. Documenting these observations can provide valuable insights as you progress through your investigation. Additionally, consult the manufacturer’s guidelines or service manuals to understand the specific components and systems involved.

Use of Diagnostic Tools

Employing the right diagnostic tools can greatly aid in identifying issues. Multimeters, pressure gauges, and specialized software can help pinpoint electrical or mechanical failures. Regularly updating your toolkit ensures you are prepared for a range of problems. Furthermore, always perform tests in a controlled manner, isolating systems one at a time to prevent confusion in your findings.

DIY Repairs vs. Professional Services

When faced with mechanical issues, individuals often find themselves weighing the merits of tackling repairs on their own versus seeking expert assistance. Each approach has its own set of advantages and drawbacks, making it essential to evaluate personal skills, time constraints, and the complexity of the problem.

Advantages of DIY Repairs

- Cost savings: Doing it yourself can significantly reduce expenses.

- Learning experience: Gaining hands-on knowledge can enhance your skills.

- Flexibility: You can work at your own pace and on your own schedule.

Benefits of Professional Services

- Expertise: Professionals bring specialized knowledge and experience.

- Time efficiency: They can often resolve issues more quickly than a novice.

- Warranty protection: Using certified services may help maintain warranty coverage.

Upgrading Your Yamaha Outboard Engine

Enhancing your marine engine can significantly improve performance, fuel efficiency, and overall reliability. By focusing on specific upgrades, you can tailor your watercraft to meet your unique needs and preferences.

- Propeller Upgrade: Consider a higher-pitch or larger-diameter propeller to increase speed and acceleration.

- Fuel System Enhancements: Installing a high-performance fuel filter or carburetor can optimize fuel delivery.

- Ignition System Improvements: Upgrading to a high-output ignition system can enhance starting and throttle response.

- Cooling System Modifications: Improving the cooling system can prevent overheating during extended use.

Before proceeding with any upgrades, it is advisable to consult with professionals to ensure compatibility and to maximize the benefits of your enhancements.