Comprehensive Guide to Yamaha F25 Parts Diagram

Exploring the intricate assembly of marine engines is essential for both enthusiasts and professionals. This section aims to illuminate the key elements that contribute to the efficient operation of these powerful machines.

When one seeks to enhance performance or conduct maintenance, a comprehensive visual reference can prove invaluable. By dissecting the various segments and their interrelations, we can better appreciate the engineering marvels that drive our aquatic adventures.

In the subsequent discussions, we will delve into the ultimate components that make up these engines, providing insights that will facilitate effective repairs and upgrades. Knowledge of these crucial features empowers users to navigate their maintenance tasks with confidence.

Understanding Yamaha F25 Parts

Grasping the components of a specific outboard motor model is essential for efficient maintenance and repair. Each element plays a crucial role in the overall performance, and knowing how they interact can lead to better care and longevity of the engine.

Key Components Overview

Every engine comprises several vital sections that ensure smooth operation. These include the propulsion mechanism, fuel delivery system, and electrical components. Familiarity with these areas can significantly enhance troubleshooting efforts.

Importance of Quality Components

Utilizing high-quality replacements is critical. Substandard parts can lead to inefficiencies or even damage to the engine. Investing in reliable components not only guarantees optimal performance but also extends the lifespan of the equipment.

Understanding these essentials enables owners to make informed decisions regarding maintenance and repairs, ensuring their machinery operates at peak efficiency.

Overview of Yamaha F25 Engine

This section provides a comprehensive look at a compact and efficient outboard motor designed for various aquatic applications. Its robust engineering ensures reliability and performance, making it a popular choice among enthusiasts and professionals alike.

Key Features

The engine boasts a lightweight design, enhancing maneuverability while maintaining excellent power output. With advanced fuel efficiency and a smooth operational experience, it stands out in its category.

Applications

This outboard motor is suitable for both recreational boating and commercial uses, providing versatility across different watercraft. Its durability ensures longevity, catering to users seeking ultimate performance in challenging conditions.

Importance of Parts Diagrams

Understanding the intricate components of any machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools for technicians and enthusiasts alike, providing clarity on how various elements interact within the system. This knowledge ultimately leads to more efficient troubleshooting and ensures longevity in performance.

Enhancing Efficiency

Utilizing visual aids significantly streamlines the repair process. Technicians can quickly locate specific components, reducing downtime and allowing for more accurate assessments. This efficiency not only saves time but also minimizes the risk of errors during repairs.

Facilitating Communication

These visual resources promote better communication among team members and with clients. When discussing repairs or upgrades, having a clear reference allows for precise dialogue, ensuring everyone is on the same page. This clarity fosters trust and enhances collaboration in technical environments.

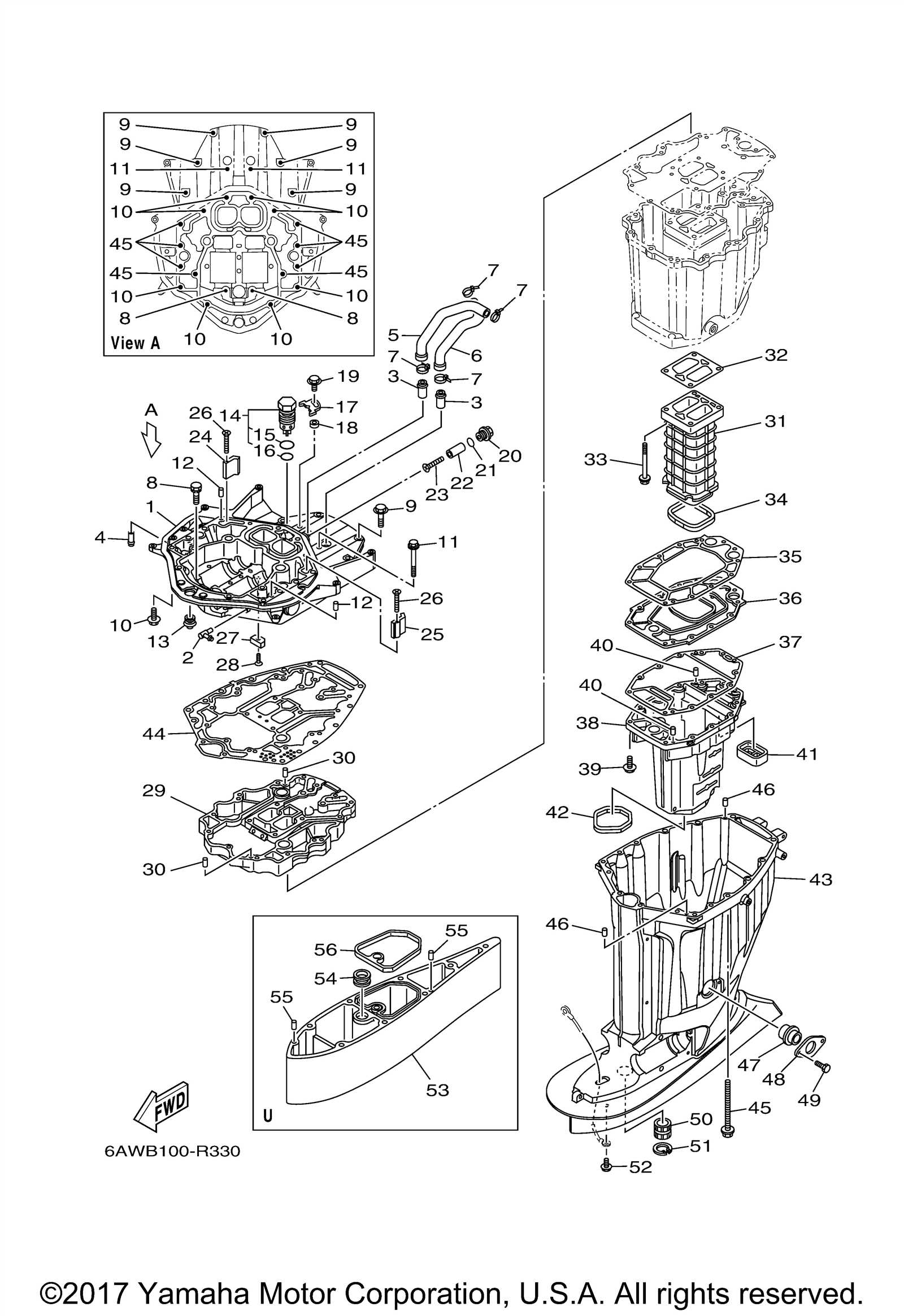

Main Components of F25 Outboard

The outboard motor comprises several essential elements that work in unison to ensure optimal performance and reliability. Understanding these components is crucial for maintenance and troubleshooting, enabling users to keep their engines in top condition. Each part plays a specific role, contributing to the overall efficiency and functionality of the unit.

| Component | Description |

|---|---|

| Engine Block | The core structure that houses the cylinders and other vital parts, providing the necessary strength and support. |

| Cylinder Head | This part contains the combustion chamber and plays a key role in regulating airflow and fuel mixture. |

| Powerhead | The assembly that includes the engine block and cylinder head, responsible for generating power. |

| Gearcase | Holds the lower unit components, including the propeller, and facilitates the transfer of power to the water. |

| Fuel System | Includes the fuel tank, lines, and injectors, ensuring the engine receives the right amount of fuel for combustion. |

| Cooling System | Utilizes water to dissipate heat, preventing the engine from overheating during operation. |

| Electrical System | Comprises the battery, ignition components, and wiring, crucial for starting the engine and powering electronics. |

Common Issues with Yamaha F25

When dealing with a specific model of outboard motor, users may encounter several frequent challenges that can affect performance and reliability. Understanding these issues can help in timely maintenance and repairs, ensuring smooth operation on the water.

- Starting Problems: Difficulty in starting the engine can be attributed to various factors, including fuel delivery issues or electrical system faults.

- Overheating: Insufficient cooling water circulation can lead to overheating, often caused by a clogged intake or faulty pump.

- Fuel System Issues: Clogged filters or fuel lines can hinder the proper flow of fuel, affecting engine performance and efficiency.

- Vibration: Excessive vibration during operation might indicate imbalances in the propeller or issues with the mounting system.

- Oil Leaks: Leaks can occur from seals or gaskets, leading to potential engine damage if not addressed promptly.

Addressing these common problems through regular inspections and maintenance can enhance the longevity and functionality of the motor.

How to Use Parts Diagrams

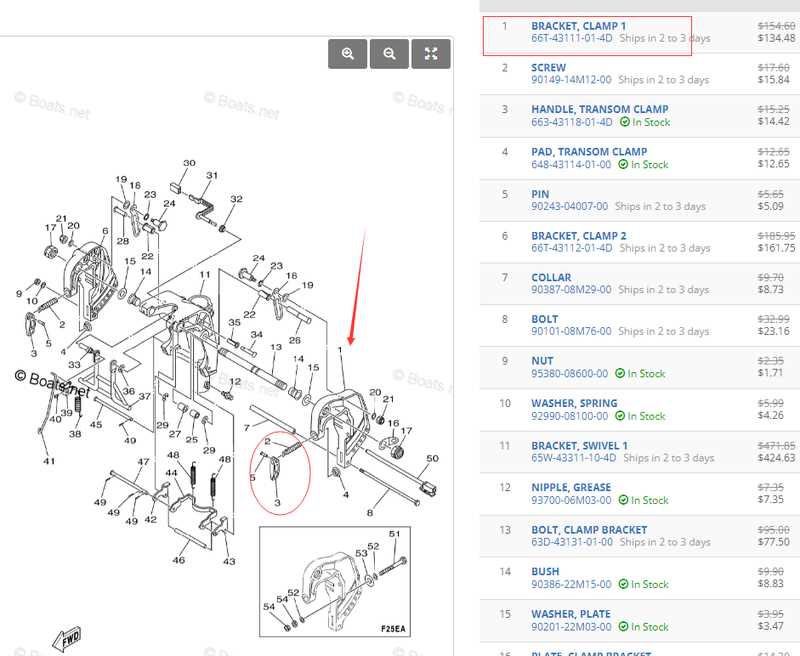

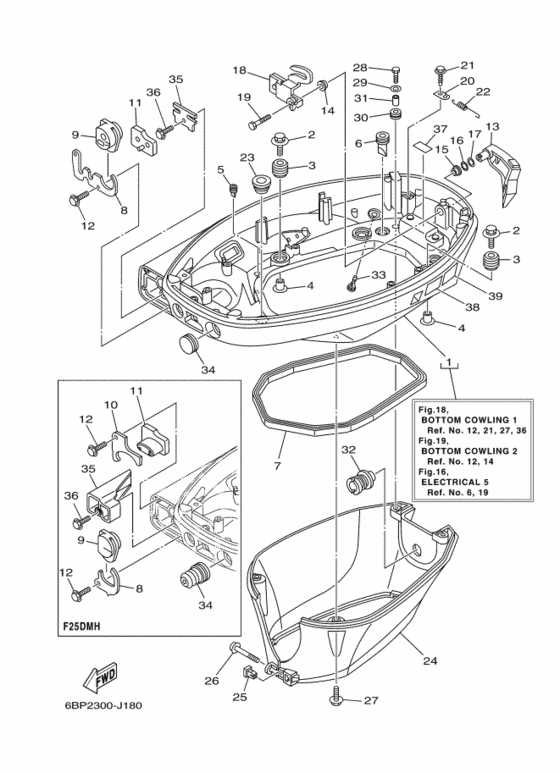

Understanding how to navigate visual representations of components is essential for effective maintenance and repairs. These illustrations provide a clear overview of each element, making it easier to identify necessary replacements or upgrades. By utilizing these visuals, users can enhance their repair processes and ensure they have the correct items on hand.

First, familiarize yourself with the layout. Each section typically highlights various components and their connections, allowing you to delve into specific areas of interest. Next, refer to the accompanying legends or notes, which often clarify the function and specifications of each part.

Additionally, cross-reference the visuals with the manufacturer’s documentation for the ultimate accuracy in identification. This practice not only streamlines repairs but also helps in understanding the overall system better.

Identifying Parts in Diagrams

Understanding components through visual representations is essential for effective maintenance and repair. These illustrations provide a comprehensive view, allowing users to recognize and differentiate various elements. By studying these visuals, one can enhance their knowledge and proficiency in handling specific machinery.

Key Considerations

- Familiarize yourself with the overall layout.

- Pay attention to labels and numbering systems.

- Note the relationships between different components.

Steps to Identify Components

- Start with a broad overview of the image.

- Zoom in on specific sections for clarity.

- Cross-reference with manuals or guides for accuracy.

- Take notes on essential parts for quick reference.

Replacement Parts for Yamaha F25

Maintaining optimal performance of your outboard engine often requires acquiring essential components that ensure smooth operation. Understanding which elements need replacement can greatly enhance longevity and efficiency.

Key Components to Consider

- Fuel system elements

- Cooling system components

- Electrical parts

- Propellers and drive systems

Where to Find Quality Replacements

- Authorized dealers

- Online marketplaces

- Specialty marine shops

Investing in high-quality components not only guarantees reliability but also maximizes the ultimate performance of your engine.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life and optimal performance of your equipment. Regular attention to key components can prevent costly repairs and enhance efficiency. By following a few essential practices, you can safeguard your investment and enjoy reliable operation for years to come.

1. Regular Inspections: Frequently check vital parts for signs of wear and tear. Early detection of issues can save time and resources.

2. Cleanliness is Key: Keep surfaces free of dirt and debris. A clean environment reduces the risk of damage and maintains functionality.

3. Lubrication: Apply appropriate lubricants to moving parts to minimize friction. This practice is crucial for smooth operation and reducing wear.

4. Follow Manufacturer Guidelines: Always adhere to the recommended maintenance schedule. Each piece of equipment has specific needs that, if met, will enhance longevity.

5. Store Properly: Ensure that equipment is stored in a suitable environment to protect it from environmental factors that could lead to deterioration.

6. Use Quality Products: When replacing parts or fluids, opt for high-quality options. Investing in superior materials contributes to overall durability.

Where to Find Parts Diagrams

Locating detailed visual guides for components of various machinery is essential for effective maintenance and repair. These resources provide invaluable insights into the arrangement and functionality of different elements, helping users to understand their equipment better and make informed decisions during servicing.

Online Resources

- Official Manufacturer Websites

- Specialized Retailers

- Community Forums and Discussion Boards

- Online Marketplaces

Printed Manuals and Guides

- Service Manuals

- User Handbooks

- Technical Bulletins

OEM vs Aftermarket Parts Comparison

When considering replacement components for marine equipment, two primary categories emerge: original manufacturer items and those produced by third parties. Each option presents distinct advantages and disadvantages, influencing both performance and cost. Understanding these differences is crucial for making informed decisions that align with individual needs and preferences.

Quality and Performance

Original components typically undergo rigorous testing and adhere to strict manufacturing standards, ensuring high quality and compatibility. In contrast, third-party offerings may vary widely in quality, with some brands meeting or exceeding OEM standards, while others fall short.

Cost Considerations

Generally, original components come at a premium price, reflecting their brand reliability and warranty options. Third-party items, however, often provide a more budget-friendly alternative, appealing to those looking to save money without compromising performance too much.

| Aspect | Original Components | Aftermarket Options |

|---|---|---|

| Quality | High, consistent standards | Varies widely |

| Compatibility | Guaranteed fit | May require adjustments |

| Cost | Higher price | More affordable |

| Warranty | Often includes warranty | Limited or no warranty |

Cost Considerations for Repairs

When it comes to maintaining and fixing marine engines, understanding the financial implications is crucial. Repair costs can vary significantly based on the components involved, labor rates, and the complexity of the issues. Planning ahead can help boat owners manage expenses effectively.

Factors Influencing Repair Costs

- Type of Repair: Minor fixes may be less expensive than extensive overhauls.

- Labor Rates: Different regions have varying rates that can impact overall expenses.

- Availability of Components: Sourcing specific items may add to costs if they are rare or custom.

- Professional vs. DIY: Choosing between hiring a technician or attempting repairs oneself can affect total costs.

Budgeting for Unexpected Repairs

- Set aside a maintenance fund for unforeseen issues.

- Regularly inspect equipment to identify potential problems early.

- Research and compare quotes from different service providers.

- Consider warranties or service plans to mitigate future expenses.

Resources for Yamaha Enthusiasts

For those passionate about marine engines and their maintenance, a wealth of information and tools is available to enhance your experience. Whether you’re a seasoned expert or a newcomer, understanding your vessel’s components and functionality is essential for optimal performance.

Online Forums: Engage with a community of like-minded individuals where you can share experiences, ask questions, and gain insights. These platforms often have a vast repository of knowledge on troubleshooting and upgrades.

Manufacturer Websites: The official websites provide comprehensive resources, including manuals and guides. They serve as an ultimate source for specifications and recommendations to ensure your engine runs smoothly.

Local Dealerships: Establishing a relationship with local distributors can offer personalized advice and access to quality components. They can assist with finding specific items and may provide maintenance tips tailored to your model.

Instructional Videos: Online video tutorials can be incredibly helpful. Visual demonstrations on repairs and installations allow for a deeper understanding of techniques and processes.

Specialized Blogs: Numerous blogs focus on marine technology, offering reviews, maintenance tips, and project ideas. These resources can help enthusiasts delve into topics that pique their interest.

Utilizing these resources will ultimately enhance your knowledge and enjoyment of your marine engine, making every outing more rewarding.