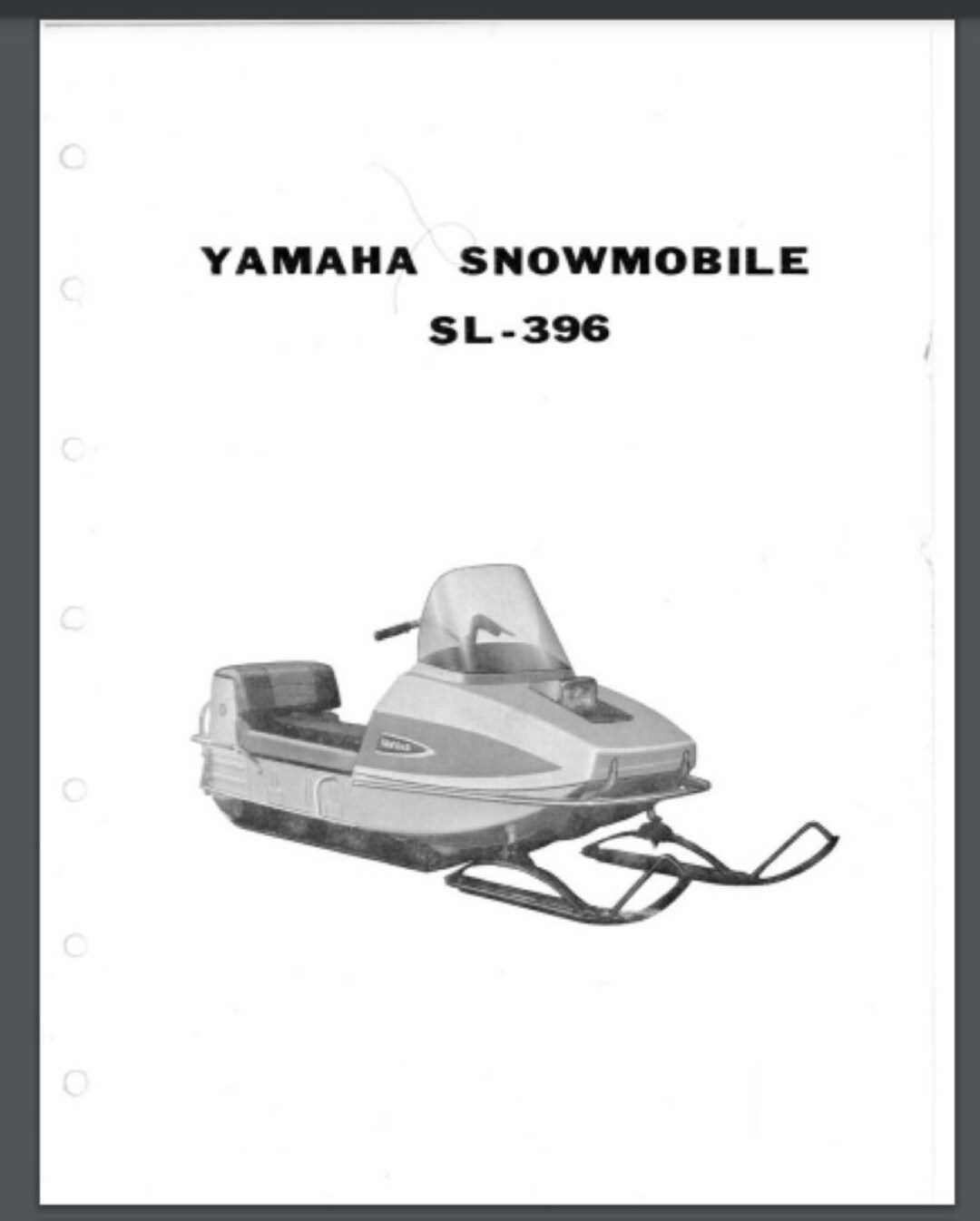

Ultimate Guide to Yamaha Sidewinder Parts Diagram

In the world of winter sports, knowledge about the various elements that make up your snow machine is crucial for optimal performance. Whether you are a seasoned rider or a newcomer, grasping the intricacies of your vehicle’s design can enhance your experience on the trails. An insightful exploration into these components not only boosts maintenance skills but also empowers you to make informed decisions during upgrades.

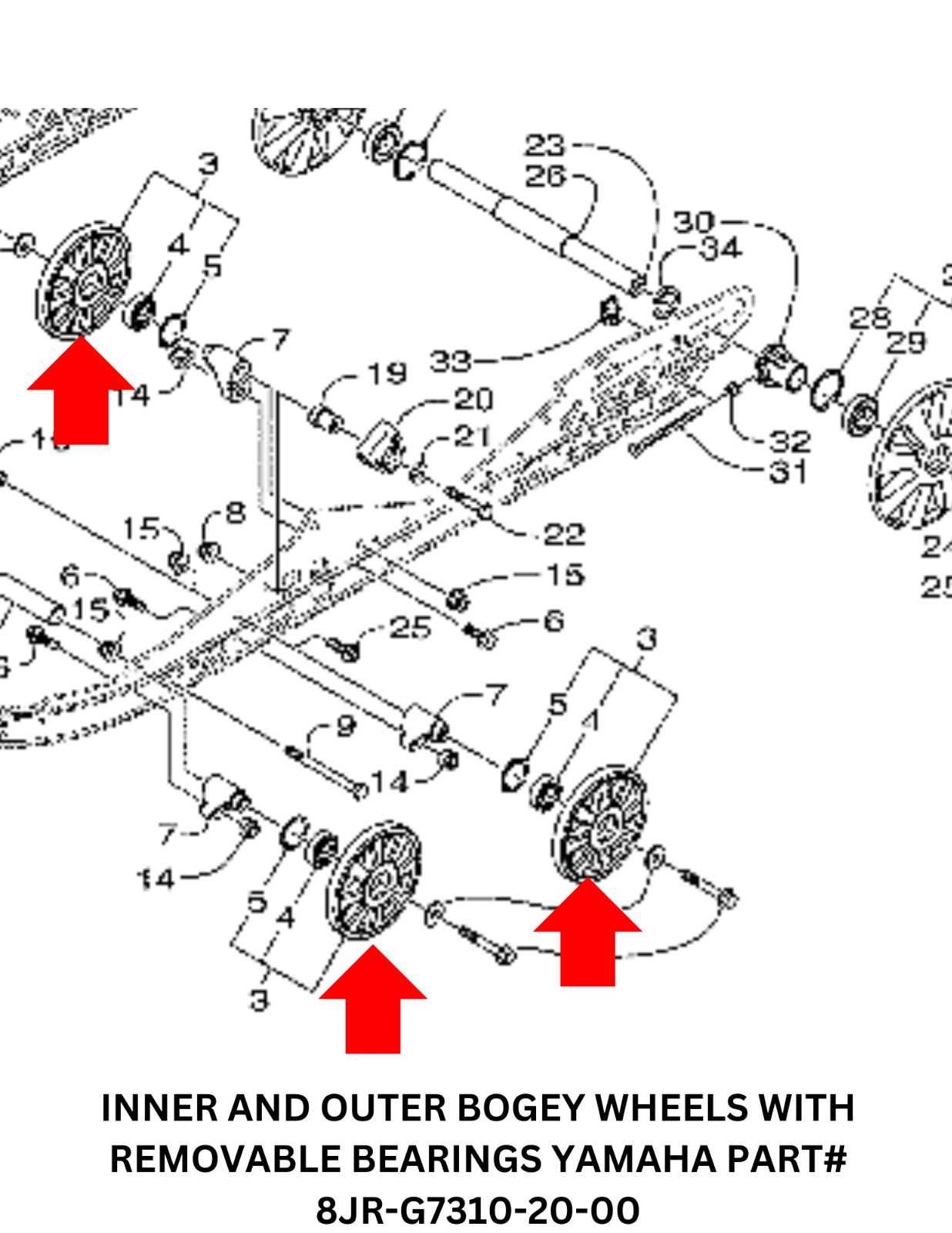

Visual aids play a significant role in comprehending the arrangement and function of each segment. By breaking down the intricate layout of these mechanisms, enthusiasts can easily identify how parts interact and contribute to the overall functionality. Such illustrations serve as a valuable resource, providing clarity on assembly and troubleshooting.

Additionally, understanding these crucial elements can lead to improved safety and performance. By familiarizing yourself with the specifics, you position yourself to tackle any issues that may arise with confidence. This knowledge ultimately equips you to maintain your vehicle’s longevity, ensuring every ride is as exhilarating as the last.

Understanding Yamaha Sidewinder Parts

This section aims to provide clarity on the components of a well-known snow machine, highlighting their roles and functions. Familiarity with these elements can enhance your maintenance and performance optimization efforts, ensuring a smoother riding experience.

Key Components Overview

Each segment of the vehicle plays a vital role in its overall functionality. From the engine to the suspension system, understanding how these elements interact will enable enthusiasts to diagnose issues more effectively and make informed upgrades.

Importance of Regular Maintenance

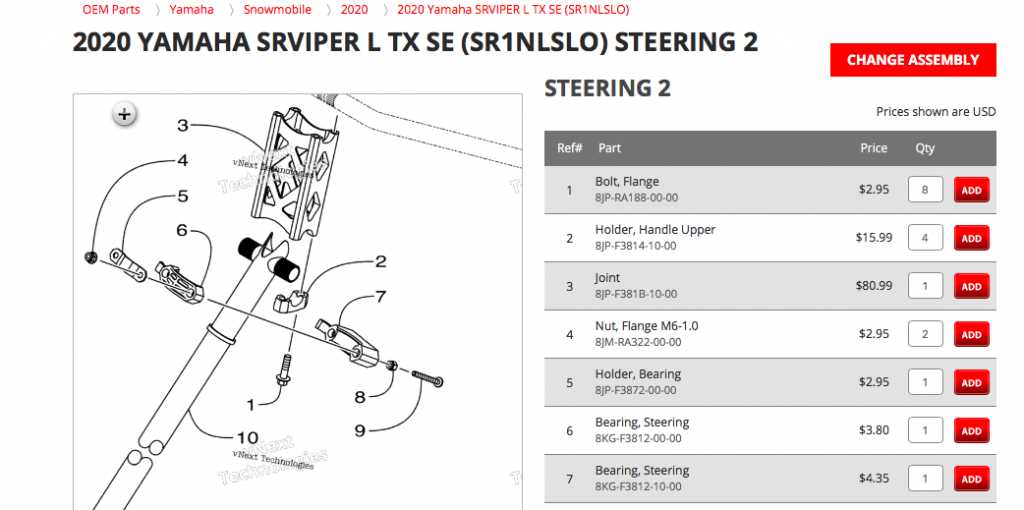

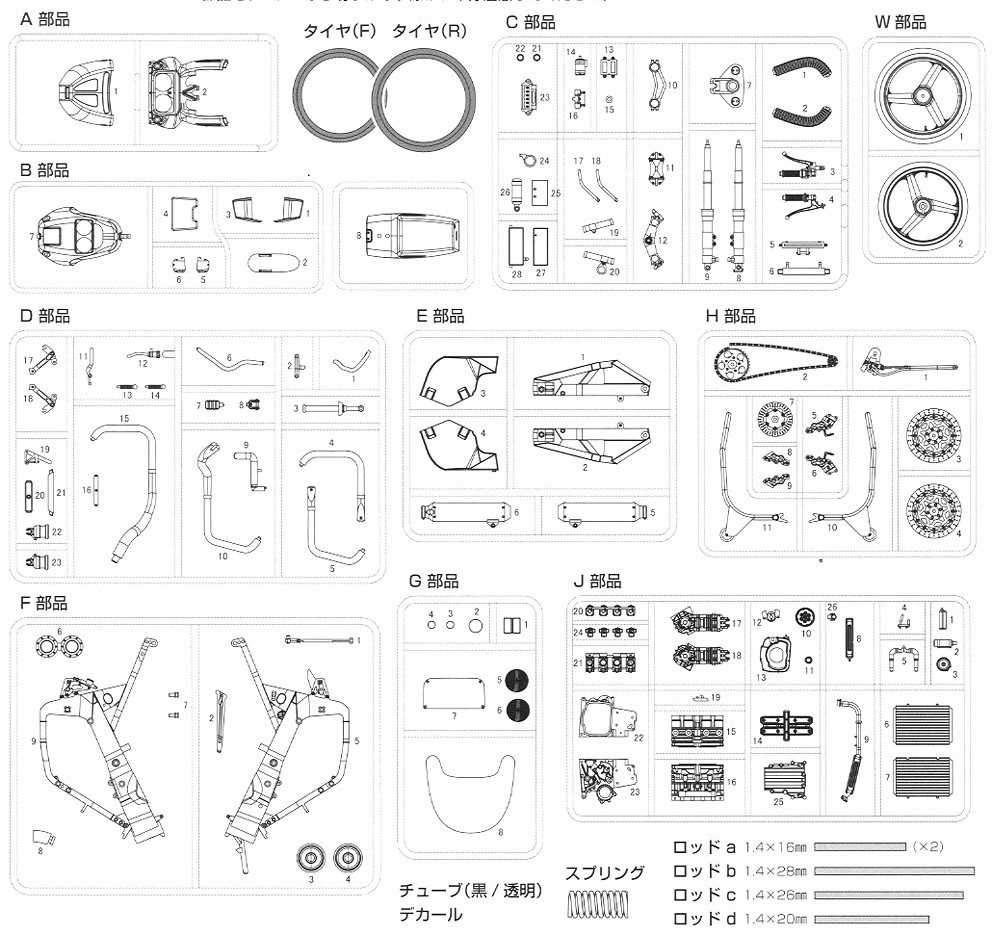

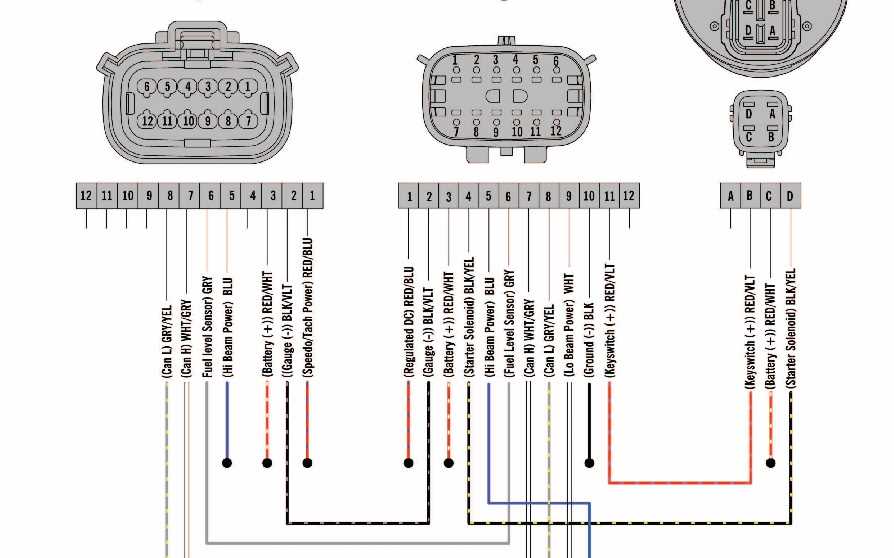

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of various machinery. They serve as valuable resources for understanding the intricate relationships between different elements, facilitating efficient troubleshooting and assembly processes.

Benefits of Visual Guides

- Enhanced Clarity: Diagrams provide a clear and concise view of how parts fit together, reducing confusion during disassembly and reassembly.

- Time Efficiency: By having a visual reference, technicians can quickly locate and identify necessary components, saving time on repairs.

- Improved Communication: These illustrations serve as a universal language, enabling clearer communication between team members and manufacturers.

Applications in Maintenance

- Identifying Components: Visual aids help users recognize specific parts, ensuring the correct items are ordered or replaced.

- Streamlining Repairs: With a comprehensive overview, mechanics can plan their work more effectively, reducing the risk of errors.

- Training Tool: They can be utilized as educational resources for training new personnel, promoting better understanding of equipment.

Key Components of Sidewinder Models

The performance and functionality of these models are driven by several critical elements, each designed to contribute to overall efficiency and durability. These components work together to ensure smooth operation, high performance, and adaptability in various conditions.

One of the essential elements is the engine system, which provides the necessary power output. Its design is focused on optimizing both power and fuel efficiency, ensuring that the machine can handle demanding tasks with ease.

The suspension system plays a crucial role in maintaining balance and control. It is engineered to absorb impacts and offer a smoother ride, especially on uneven terrain, reducing stress on both the operator and the vehicle itself.

Another important feature is the braking system, designed for precision and reliability. It provides enhanced stopping power, allowing for safe and controlled halts even in difficult situations, contributing to overall safety and handling.

Additionally, the track assembly is integral for movement and traction. It is constructed to provide grip and stability across various surfaces, ensuring that the model can maneuver effectively, regardless

How to Read Parts Diagrams

Understanding mechanical blueprints can be a key skill when maintaining or repairing complex equipment. These visual guides offer a breakdown of various components and their assembly, helping you identify each element and how they fit together. By learning to interpret these schematics, you can efficiently handle maintenance tasks and troubleshoot potential issues.

Key Elements of a Schematic

Every technical schematic is designed to provide a clear view of the components involved. Typically, these illustrations include several important details:

- Labels and Numbers: Each component is assigned a unique identifier to distinguish it from others. This can be a number or code that corresponds to a specific part in the list.

- Assembly Flow: Diagrams often use arrows or lines to show how different parts connect or interact within the system. These indicators help you understand the sequence of assembly.

Common Maintenance Tips

Regular upkeep is essential to ensure optimal performance and longevity of any vehicle. Following a consistent maintenance routine can prevent unexpected issues, reduce repair costs, and extend the overall lifespan of your equipment.

Engine Care

- Check the oil levels regularly and change the oil according to the manufacturer’s guidelines to keep the engine running smoothly.

- Inspect the air filter for dirt or debris, and replace it when necessary to maintain proper airflow.

- Monitor coolant levels to prevent overheating and maintain engine temperature during use.

Track and Suspension Maintenance

- Ensure the track is correctly tensioned to avoid unnecessary wear and improve traction.

- Lubricate the suspension components to ensure smooth movement and avoid squeaking or stiffness.

- Inspect for any signs of wear or damage and replace parts as needed to maintain optimal handling.

By adhering to these maintenance tips, you’ll keep your vehicle in peak condition and ready for any adventure

Identifying Replacement Parts Easily

Finding suitable components for your machine can often be a challenging task, but with the right approach, the process becomes much simpler. Understanding how different elements are structured and how they fit within the system is crucial for ensuring compatibility and smooth operation.

Steps to Follow for Efficient Identification

The first step is to familiarize yourself with the layout of the device. This helps in pinpointing the exact location of the required item. Once you have a clear understanding of its position, you can focus on details such as shape, size, and function.

Component Type Location Characteristics Engine-related Near the front section Heavy-duty, metallic Suspension Differences Between Models

When comparing various models, it is essential to understand the subtle distinctions that set them apart. These differences can range from performance specifications to design elements, making each model suited for different preferences and needs. The following analysis provides a comprehensive overview of the key features that differentiate the models.

Performance Specifications

One of the primary distinctions lies in the power output and engine configuration. Some models are designed for higher speeds and enhanced handling, while others prioritize fuel efficiency and stability. Additionally, the weight and suspension systems can vary, affecting the overall ride quality and control.

Design and Features

Another critical factor is the design, which includes variations in frame structure, aerodynamics, and additional features such as improved seating comfort or enhanced dashboard technology. These aspects contribute to the usability of each model, catering to both casual and professional riders.

Feature Model A Model B Engine Power High Medium Where to Find Diagrams Online

Looking for detailed visual guides to help with maintaining or repairing your vehicle? Many online platforms offer access to various schematic drawings and technical illustrations. These resources are invaluable for those seeking to understand how different components fit together or for identifying necessary replacements. With the right tools at hand, even complex assemblies become easier to handle.

Popular Platforms Offering Schematic Illustrations

Numerous websites specialize in offering these visual aids for various models and types of equipment. From general mechanics to specialized devices, these platforms allow users to search for and download high-quality schematics, often categorized by model year or equipment type. Many of these services offer both free and paid versions, depending on the level of detail you require.

Additional Resources

Beyond dedicated platforms, forums and community-driven websites can also be valuable sources of information. Users often share links to technical drawings, exchange advice, and provide feedback on different repair techniques. These communities can guide you to the exact schematics you need, saving time and effort.

DIY Repair vs. Professional Help

When faced with the challenge of fixing mechanical equipment, the choice between doing it yourself and seeking expert assistance is crucial. Both options come with their own advantages and potential pitfalls. The decision often depends on your personal experience, the complexity of the issue, and the tools available.

- Cost: DIY repairs can be more cost-effective as you’re saving on labor charges. However, mistakes might lead to higher costs in the long run if additional repairs are needed.

- Time: A do-it-yourself approach allows for flexibility in timing, but it might take significantly longer compared to a professional who is familiar with the task.

- Expertise: Professional mechanics have the experience and specialized knowledge to identify and resolve problems quickly. On the other hand, self-repair might require extensive research and trial and error.

- Tools: Specific tools may be required for certain repairs. Professionals often have access to advanced tools that may not be practical for a single-use purchase.

In summary, deciding between DIY repair and hiring a professional should consider factors like cost, time, expertise, and tools. For minor issues or si

Cost Analysis of Parts Replacement

When evaluating the expenses associated with maintaining and repairing machinery, it’s crucial to understand the various factors that influence the overall cost of replacing components. This includes not only the direct expenses but also hidden costs that may arise during the process. A well-informed approach can help avoid unnecessary expenditures and ensure that the system operates efficiently for an extended period.

Several elements contribute to the final price of replacing individual components. Below is an outline of key aspects to consider:

- Cost of New Components: Prices vary depending on the source, brand, and quality. Opting for high-grade alternatives may provide longer durability but can also be more expensive upfront.

- Labor Costs: Whether opting for professional services or performing the task independently, the time and effort involved play a significant role in the total expense.

- Shipping and Handling: For parts ordered online or from distant locations, additional fees for transport should be factored

Upgrading Your Sidewinder Components

Enhancing the performance of your vehicle by upgrading specific components can lead to significant improvements in both handling and power. Whether you are looking to boost efficiency, increase speed, or improve durability, the right modifications can make a noticeable difference in overall performance.

Performance Boosters

When upgrading your vehicle, focusing on key areas can yield the best results. Consider enhancements that impact speed, responsiveness, and fuel efficiency. Common areas to upgrade include:

- Engine tuning for optimized output

- Improved suspension for better control

- High-performance exhaust systems for enhanced power

- Advanced cooling systems to prevent overheating

Durability and Longevity

Durability is another important factor to consider when upgrading. Investing in stronger, more resilient components ensures a longer lifespan and reduces the risk of wear and tear. Key upgrades in this area include:

- Heavy-duty clutches for better torque handling

- Reinforced frames and body parts

Safety Considerations When Working

When handling mechanical components or conducting maintenance tasks, it is essential to prioritize safety. Failing to take necessary precautions can lead to injuries, damage to equipment, or even more serious consequences. Understanding basic safety principles ensures that work can be completed efficiently while minimizing risks.

Personal Protective Equipment (PPE)

Always wear appropriate protective gear, such as gloves, safety glasses, and sturdy footwear, to safeguard yourself from potential hazards. Depending on the nature of the task, additional protection like hearing protection or respirators may also be necessary. The goal is to create a barrier between you and potential risks.

Workspace Organization

Maintaining a clean and organized workspace is crucial for safety. Ensure that tools and components are stored properly and that the area is free from obstructions. A well-organized environment not only improves efficiency but also reduces the likelihood of accidents caused by tripping, falling, or improper handling of materials.

By