Exploring the Husqvarna 562 XP Parts Diagram for Ultimate Maintenance

In the world of outdoor machinery, familiarity with the various elements that make up your tools can significantly enhance both their performance and longevity. A detailed overview of these components allows users to effectively maintain and troubleshoot their devices. Whether for professional use or personal projects, grasping the intricate relationships between these parts is crucial for optimal functionality.

When engaging with a specific model of machinery, it’s essential to have access to an organized representation of its inner workings. This visual guide not only aids in identifying individual elements but also facilitates the understanding of how each part contributes to the overall operation. Being well-versed in the assembly and layout can prevent common issues and lead to more efficient repairs.

Furthermore, having a clear reference for these components empowers users to make informed decisions regarding maintenance and upgrades. Whether you’re replacing a worn-out section or simply ensuring everything is in order, knowing the configuration of your equipment is invaluable. By prioritizing this knowledge, you position yourself for success in maintaining the reliability and effectiveness of your outdoor tools.

Understanding Husqvarna 562 XP Components

Familiarizing oneself with the essential elements of a powerful outdoor tool enhances not only maintenance but also operational efficiency. Each component plays a critical role in the overall performance, ensuring that the equipment runs smoothly and effectively. From the engine to the cutting mechanism, understanding these elements can greatly benefit users in optimizing their experience.

Key Elements of the Tool

The engine serves as the heart, converting fuel into mechanical energy, while the cutting assembly directly influences the precision and speed of operations. Additionally, the air filter ensures that the engine operates under optimal conditions by preventing dust and debris from entering, which can lead to premature wear. Each element, including the ignition system and the fuel delivery mechanism, works in harmony to provide a reliable and powerful performance.

Maintenance and Upkeep

Regular inspection and maintenance of these components are crucial for longevity and efficiency. Users should familiarize themselves with the specific requirements for care, such as cleaning the air filter, checking the spark plug, and ensuring that all connections are secure. Understanding these aspects not only prolongs the life of the equipment but also enhances user safety and satisfaction during operation.

Importance of Parts Diagrams

Understanding the intricate components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools, enabling users to grasp the relationships and functions of various elements within a system. This clarity ultimately enhances efficiency and accuracy in handling equipment.

First and foremost, such illustrations facilitate quick identification of individual pieces, which is vital when troubleshooting or replacing components. By having a clear view of how everything fits together, users can make informed decisions, preventing costly mistakes and downtime.

Additionally, these visual guides foster a deeper appreciation for the mechanics at play. They encourage users to delve into the workings of their tools, promoting a proactive approach to maintenance. When individuals comprehend the roles of each component, they are better equipped to optimize performance and extend the lifespan of their equipment.

Key Features of the Husqvarna 562 XP

This advanced cutting tool is designed for professionals and serious enthusiasts, offering a blend of power, efficiency, and user-friendly features. Its engineering ensures that users can tackle a variety of tasks with ease, making it a valuable asset in any outdoor work setting.

Powerful Engine: Equipped with a high-performance engine, this model delivers impressive power output, allowing for fast and efficient cutting through tough materials. The engine’s design minimizes fuel consumption while maximizing torque.

Lightweight Construction: Weighing less than comparable models, this tool enhances maneuverability and reduces user fatigue during extended use. Its ergonomic design allows for comfortable handling, even in challenging conditions.

Advanced Air Filtration: Featuring a sophisticated air filter system, this device ensures cleaner air intake, extending the lifespan of the engine and reducing maintenance needs. The design facilitates easy access for quick cleaning or replacement.

Vibration Dampening System: Integrated technology reduces vibrations, providing a more comfortable experience for users. This feature is crucial for prolonged use, helping to prevent fatigue and strain on the hands and arms.

Durable Build Quality: Constructed from high-quality materials, this machine is built to withstand rigorous use in demanding environments. Its robust design ensures longevity and reliability over time, making it a worthwhile investment.

Adjustable Features: The ability to customize settings for different tasks enhances versatility. Users can easily modify performance parameters to suit specific cutting requirements, ensuring optimal results.

Common Replacement Parts Overview

Understanding the essential components of a high-performance outdoor tool is crucial for maintaining its longevity and efficiency. Regularly replacing certain elements ensures optimal functionality and enhances the overall user experience. Here, we explore key elements that frequently require attention.

Air Filter: A clean air filter is vital for proper airflow and engine performance. Regular replacement prevents dirt and debris from entering the system, promoting efficiency.

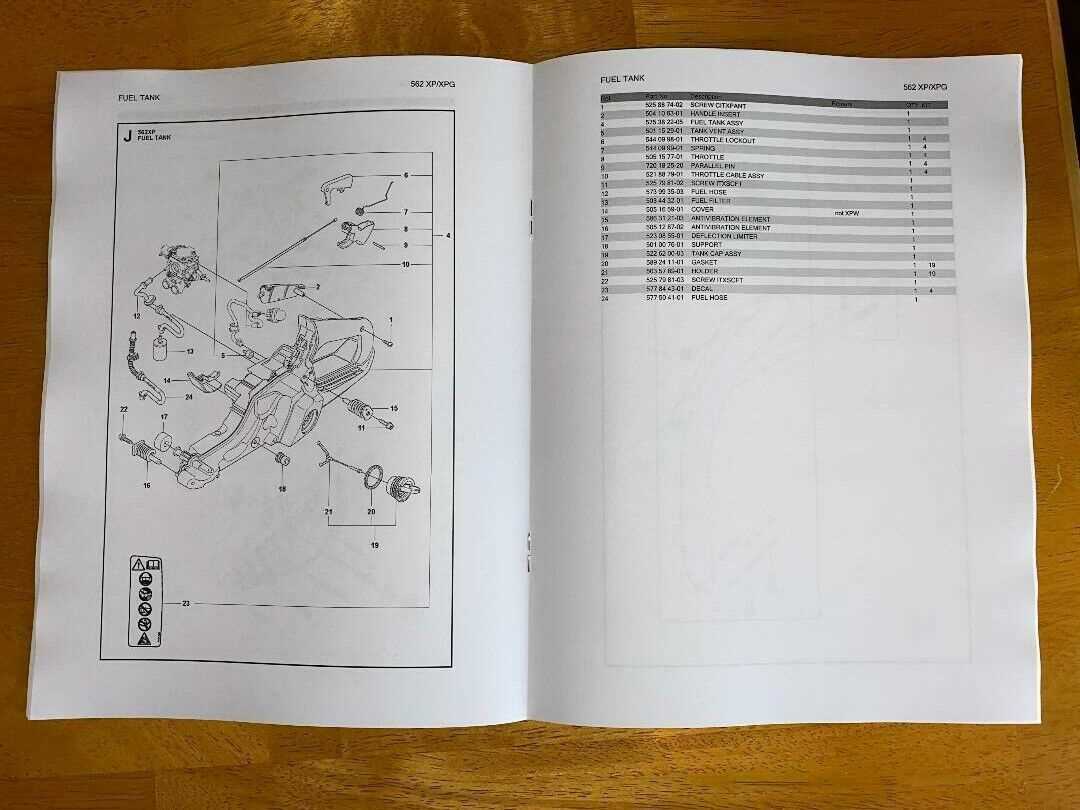

Fuel Filter: This component safeguards the engine from impurities in fuel. Changing the fuel filter regularly helps maintain engine health and performance.

Chain: The cutting chain is subject to wear and tear, necessitating periodic replacement to ensure smooth operation and effective cutting.

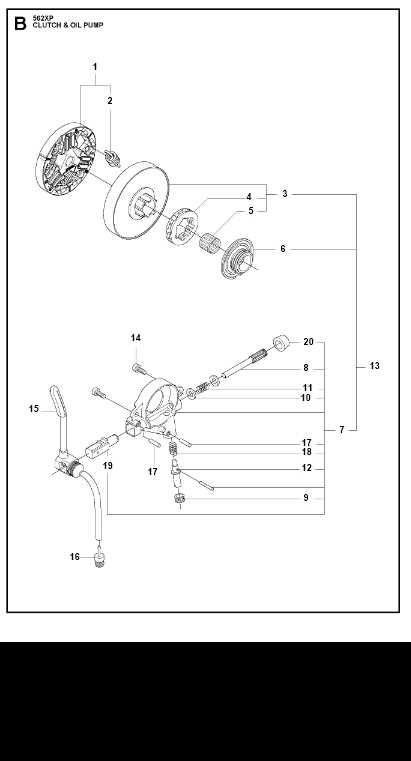

Sprocket: This element works in tandem with the chain, and its condition directly affects the tool’s performance. Replacing it at appropriate intervals can enhance cutting efficiency.

Spark Plug: A functioning spark plug is essential for ignition and engine performance. Regular checks and replacements can prevent starting issues and ensure reliable operation.

By delving into these components, users can achieve the ultimate performance from their equipment while extending its lifespan.

How to Read Parts Diagrams

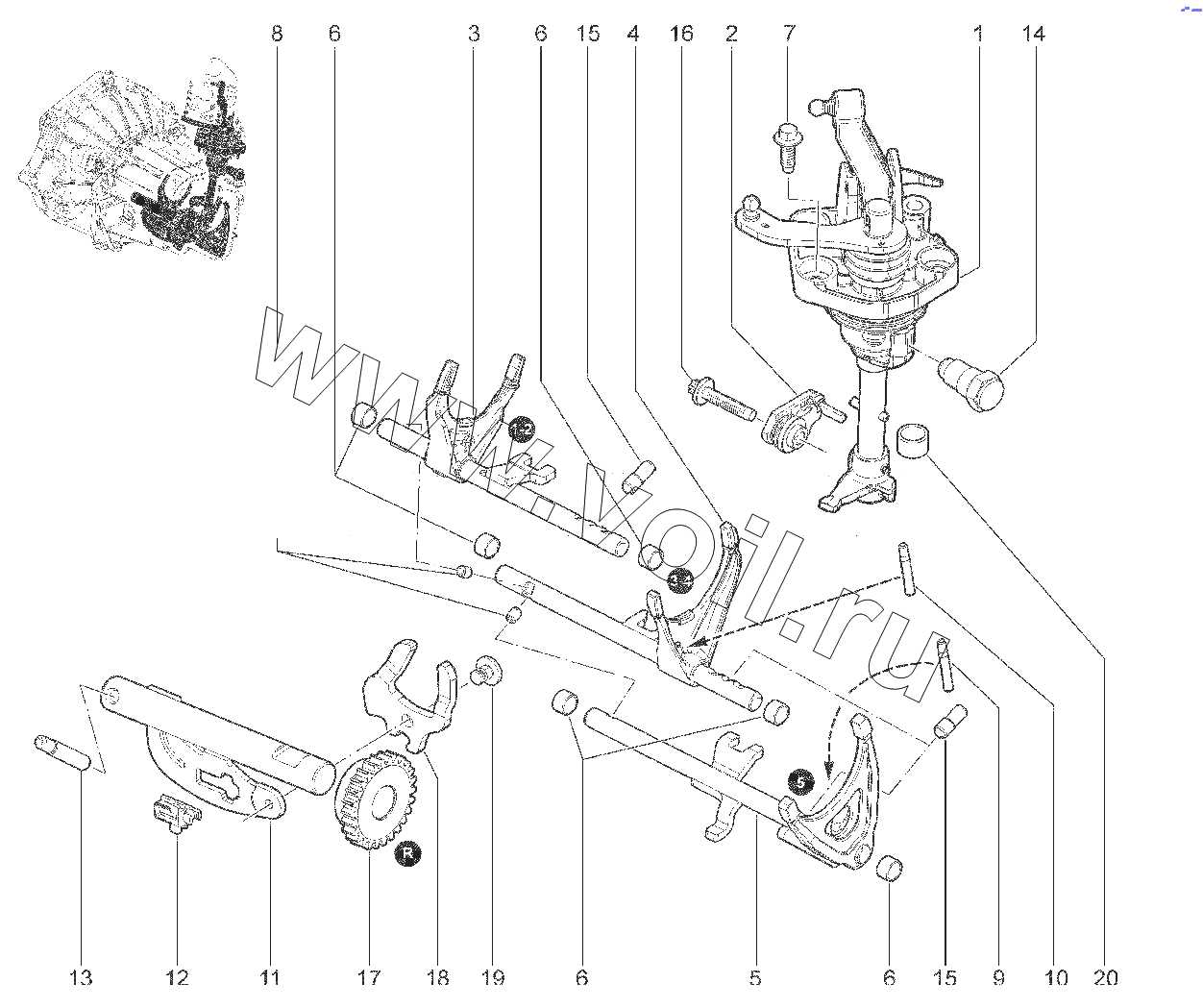

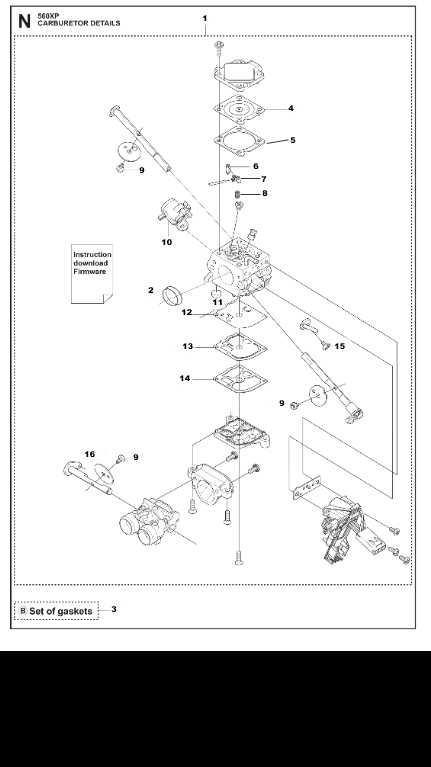

Understanding technical illustrations is essential for proper maintenance and repairs. These drawings provide a detailed breakdown of components, allowing you to identify specific elements, their positioning, and how they connect within a larger system. By learning to interpret these diagrams, you can efficiently troubleshoot issues and ensure accurate assembly.

Key Symbols and Layout

When examining technical drawings, it’s important to become familiar with the various symbols used to represent different components. These may include notations for screws, connectors, and moving parts. The layout typically follows a logical sequence, with each element arranged in the order it would appear during assembly or disassembly. Look for reference numbers and labels that correspond to a parts list or instructions for further clarification.

Cross-Referencing with Instructions

Often, diagrams are accompanied by instructional guides or tables that provide additional details. These references help you verify each component’s role and its exact placement within the system. Matching numbers and codes from the illustration to the guide ensures you’re using the right materials and following the correct steps during reassembly.

Essential Tools for Maintenance

Regular upkeep of any mechanical equipment requires the proper set of tools to ensure efficiency and longevity. Whether you’re dealing with general repairs, adjustments, or cleaning tasks, having the right instruments on hand can significantly reduce downtime and extend the life of your equipment.

Among the fundamental tools needed are adjustable wrenches and screwdrivers, allowing for precise handling of various fasteners. Lubrication applicators are crucial for minimizing wear and friction between moving parts, ensuring smooth operation. Additionally, specialized cleaning brushes and compressed air tools help to remove debris from intricate areas, maintaining optimal performance.

For those more advanced in technical maintenance, tools like torque wrenches are essential for applying accurate pressure, while digital testers help to diagnose electrical components. Having these essentials within reach will streamline your maintenance process and keep your machinery running smoothly.

Identifying Wear and Tear

Regular inspection of machinery is essential to ensure its continued performance and longevity. Over time, various components of the equipment may experience degradation due to frequent use, exposure to harsh conditions, or lack of proper maintenance. Recognizing these signs early can prevent further damage and costly repairs, ensuring that the equipment remains efficient and reliable.

Common Signs of Damage

Look out for visible cracks, loose fittings, or misalignments that may indicate excessive wear. Surface abrasions and discoloration often signal that the machinery has been exposed to rough handling or harsh environments. Pay close attention to moving parts, as any irregular movement or noise could be a sign of internal damage.

Preventative Measures

Proper maintenance schedules and timely replacements of worn parts are key to extending the lifespan of the equipment. Regular lubrication, cleaning, and adjustments can significantly reduce the wear on crucial components. Monitoring usage frequency and adhering to manufacturer recommendations also plays a major role in preventing undue stress on the machinery.

Where to Buy Genuine Parts

When it comes to maintaining the performance of your equipment, using authentic components is essential. Finding reliable sources to purchase these original replacements ensures both the longevity and safety of your machinery. Whether you’re looking for a local shop or an online retailer, it’s important to choose vendors that offer genuine replacements directly from the manufacturer.

For those seeking high-quality replacements, authorized dealerships are often the best choice. These sellers specialize in official components, guaranteeing compatibility and durability. In addition to physical stores, many online platforms provide convenient access to these original pieces, often accompanied by detailed descriptions and customer reviews to help with decision-making.

Another reliable option is certified repair centers that provide not only the correct items but also expert advice on installation and maintenance. Choosing trusted sources for obtaining these essential items ensures your machine operates efficiently and safely for years to come.

Maintenance Tips for Longevity

Proper care and regular maintenance are key to ensuring that your outdoor equipment remains reliable and performs at its best for many years. Regular checks and the timely replacement of worn-out components can prevent costly repairs and extend the lifespan of your machine. Here are some essential tips to keep in mind for optimal durability and efficiency.

Routine Cleaning

Cleaning the equipment after each use is crucial for maintaining its performance. Dirt and debris can cause parts to wear down or affect functionality.

- Clear any dust, leaves, and other debris from the engine and exterior.

- Clean air filters regularly to prevent clogging and ensure proper airflow.

- Wipe down all surfaces to protect against rust and corrosion.

Inspecting Components

Thorough inspections help identify potential issues before they become major problems. Regularly check the key components to ensure everything is functioning smoothly.

- Check the tension of the drive belt to avoid unnecessary wear.

- Inspect the fuel system for leaks or blockages.

- Examine moving parts such as chains and gears for any signs of damage or wear.

By adhering to these simple maintenance practices, you can improve the efficiency and longevity of your equipment, ensuring that it remains a reliable tool for years to come.

Troubleshooting Common Issues

When working with outdoor power tools, it’s essential to understand how to address frequent problems that may arise during use. Often, these issues can be traced to simple factors such as improper maintenance, component wear, or fuel system malfunctions. Identifying the cause quickly can save time and reduce unnecessary repairs.

Engine Won’t Start: One of the most common challenges is when the engine fails to start. This can be due to several factors, including an empty fuel tank, clogged fuel lines, or an issue with the spark plug. Always check for fuel flow and inspect the ignition system for any visible damage or debris.

Excessive Vibration: Another issue often encountered is excessive vibration during operation. This could be caused by a loose or damaged component, such as a blade or housing. Ensure all parts are tightly secured and examine for wear or cracks that may lead to imbalance.

Loss of Power: If the tool is not delivering the expected performance, the issue may lie within the air filter or carburetor. A clogged filter can restrict airflow, reducing efficiency. Similarly, carburetor problems can lead to improper fuel mixing, causing a loss of power or erratic performance.

Regular inspection and preventive maintenance are key to keeping outdoor tools running smoothly. By addressing issues early, users can extend the life of their equipment and prevent more costly repairs down the line.

Benefits of Regular Servicing

Regular maintenance is essential to ensure the longevity and efficient performance of any machine. By scheduling consistent check-ups, you help prevent unexpected failures and costly repairs. Routine servicing allows for the early detection of potential issues, ensuring your equipment operates smoothly over time.

Increased Reliability is one of the key advantages of routine upkeep. With regular attention, you minimize the risk of malfunctions, ensuring that your equipment remains dependable and ready for use when needed most.

Enhanced Performance also comes from consistent servicing. Machines that are properly maintained tend to function at peak efficiency, which can result in better output and reduced operational costs. Keeping parts in good condition leads to smoother operation and more energy-efficient performance.

Moreover, prolonging lifespan is another major benefit. Regularly caring for your equipment ensures that it can continue to serve you effectively for a longer period, saving you the expense of frequent replacements and contributing to a better return on investment.