Understanding the Husqvarna 288 Parts Diagram for Efficient Repairs

Maintaining the efficiency and longevity of your outdoor machinery is crucial for optimal performance. Knowing the individual elements that comprise your equipment can greatly enhance your ability to troubleshoot and perform necessary repairs. This section delves into the intricate layout of various components, providing insights into their functions and interconnections.

By familiarizing yourself with the assembly of these devices, you empower yourself to tackle maintenance tasks with confidence. This knowledge not only aids in identifying potential issues but also assists in sourcing replacements when needed. A clear understanding of how each piece fits together can save you time and money, ensuring your equipment remains in top shape.

In the following sections, we will explore the various sections and features of these essential machines. You’ll discover how to navigate the complexity of each part, making it easier to carry out repairs or upgrades. With a comprehensive view of the layout, you’ll be better prepared to manage your equipment effectively.

Understanding the Husqvarna 288 Parts Diagram

When it comes to machinery maintenance, comprehending the layout of components is essential. A visual representation of individual elements allows users to identify, locate, and replace parts effectively. This guide aims to demystify such illustrations, enhancing your ability to work with complex equipment.

Importance of Component Layouts

Visual schematics serve several critical purposes:

- Identification: Quickly recognize various elements and their functions.

- Organization: Understand how each part fits within the overall system.

- Maintenance: Facilitate timely repairs by pinpointing worn or damaged sections.

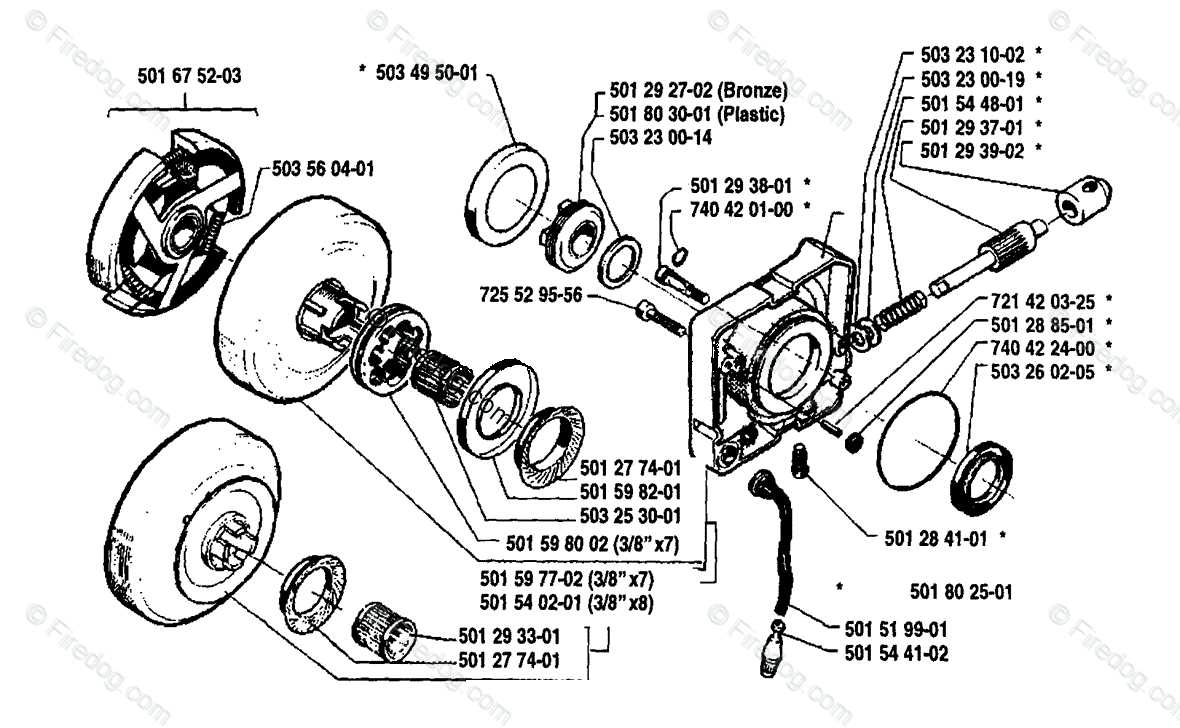

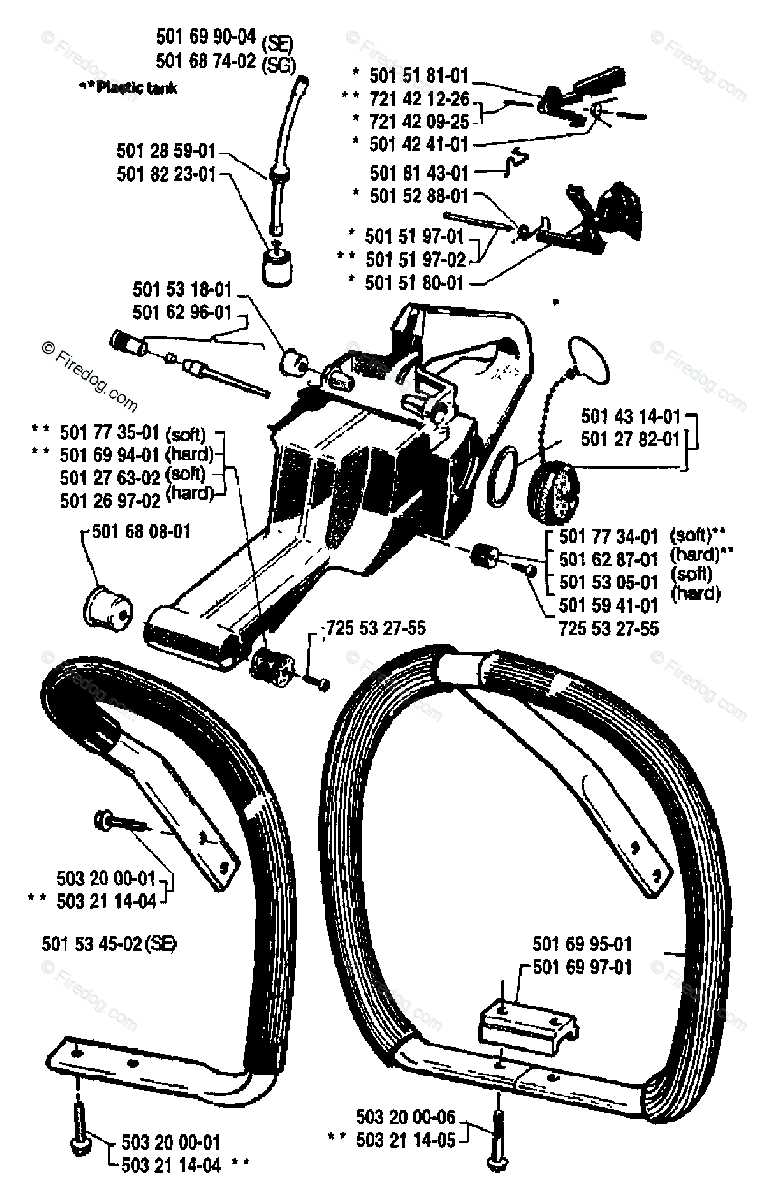

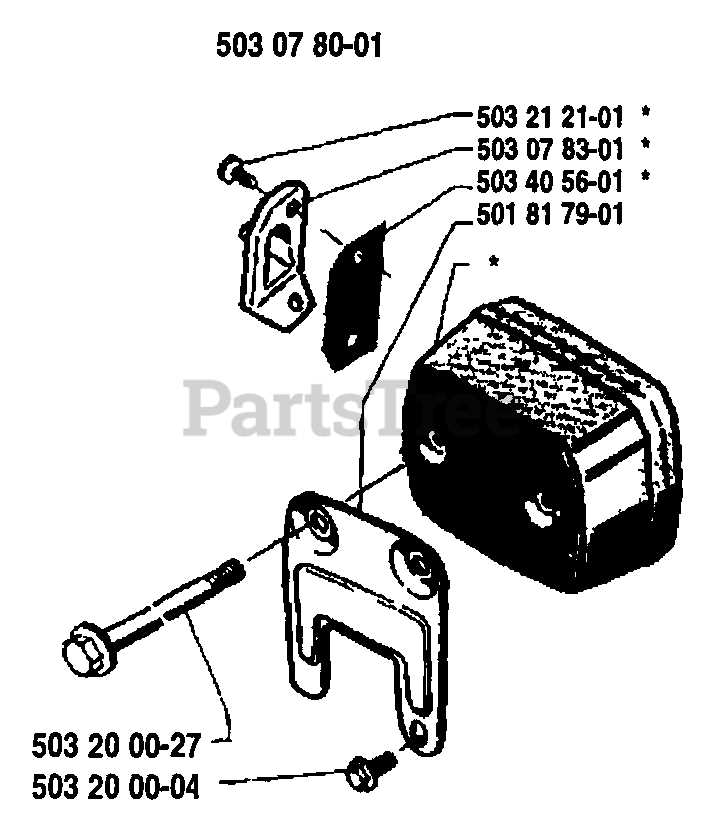

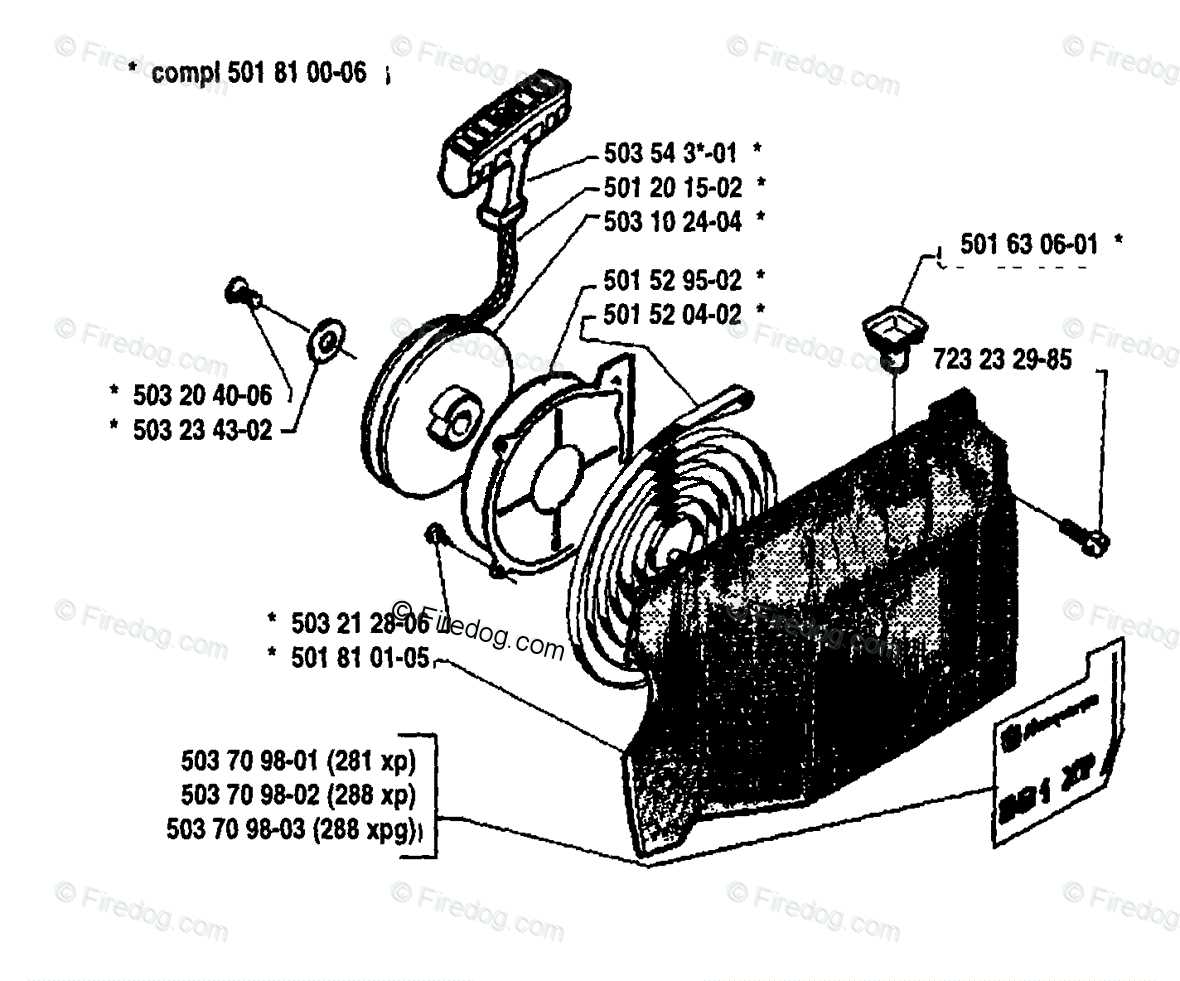

Key Elements to Observe

When examining a schematic, focus on the following:

- Labels: Pay attention to the names and numbers associated with each part.

- Connections: Observe how components interconnect, noting any specific fittings or links.

- Orientation: Note the positioning of parts, which may affect installation or removal processes.

By mastering these visual guides, you can enhance your troubleshooting skills and ensure that your machinery operates efficiently.

Key Components of the Husqvarna 288

Understanding the essential elements of this powerful outdoor tool is crucial for optimal performance and maintenance. Each component plays a vital role in ensuring efficiency and reliability during operation. Familiarity with these parts not only aids in effective troubleshooting but also enhances the overall user experience.

Core Mechanisms

The functionality of the equipment is largely determined by its core mechanisms. These components work together harmoniously to provide the desired output and durability. Key parts include the engine, ignition system, and fuel delivery components.

Supporting Structures

In addition to the core mechanisms, various supporting structures contribute to the tool’s stability and ease of use. This includes the frame, handle assembly, and vibration dampening systems, all designed to enhance user comfort and control.

| Component | Function |

|---|---|

| Engine | Powers the tool, providing necessary energy for operation. |

| Ignition System | Ensures reliable starting and efficient combustion. |

| Fuel Delivery | Transports fuel to the engine for optimal performance. |

| Frame | Supports all components and provides structural integrity. |

| Handle Assembly | Facilitates control and maneuverability during use. |

| Vibration Dampening | Reduces user fatigue and enhances comfort during operation. |

Benefits of Using OEM Parts

Choosing original components for machinery maintenance offers numerous advantages that significantly enhance performance and longevity. These parts are designed specifically for particular models, ensuring a precise fit and optimal functionality.

One of the primary benefits is reliability. Genuine components undergo rigorous testing and quality control processes, which guarantee their durability under various operating conditions. This reliability translates into fewer breakdowns and a reduced need for frequent replacements.

Additionally, utilizing original components often results in better performance. These parts are engineered to work seamlessly with existing systems, leading to improved efficiency and effectiveness. Users can expect consistent operation, enhancing overall productivity.

Another significant advantage is warranty protection. Many manufacturers offer warranties on their original components, providing peace of mind and financial security in case of defects or failures. This assurance can be invaluable in maintaining long-term equipment value.

Lastly, employing genuine components supports brand integrity and ensures compliance with safety standards. This not only protects the user but also contributes to a safer working environment, minimizing the risk of accidents related to inferior quality substitutes.

Common Issues with Husqvarna 288 Parts

When dealing with outdoor equipment, certain challenges frequently arise that can affect performance and reliability. Understanding these common complications can aid in efficient troubleshooting and maintenance, ensuring the machinery remains in optimal working condition.

Wear and Tear: Over time, components can experience significant wear, leading to reduced efficiency. Regular inspection and timely replacement of worn parts are crucial to maintain functionality.

Fuel System Problems: Clogged filters and fuel lines can hinder the flow of fuel, causing starting issues or erratic performance. Keeping the fuel system clean and well-maintained is essential.

Electrical Failures: Issues with wiring or connections can result in malfunctioning ignition systems. Checking electrical components regularly can prevent unexpected breakdowns.

Chain and Bar Concerns: Improper tension or wear on the cutting chain and bar can lead to poor cutting performance. Regular adjustments and replacements are necessary to ensure precise operation.

Cooling System Issues: Overheating can occur if the cooling system is obstructed. Ensuring that vents are clear and that the cooling fins are free of debris can help mitigate this risk.

By being aware of these potential issues, operators can take proactive measures to maintain their equipment’s performance and longevity.

How to Interpret the Diagram

Understanding the layout of components in machinery is essential for effective maintenance and repair. These visual representations serve as invaluable guides, helping users to locate, identify, and understand the relationship between various elements. By familiarizing yourself with this graphical information, you can streamline your workflow and ensure that tasks are performed accurately.

Begin by examining the overall structure. Typically, the schematic will showcase a broad overview before delving into specific sections. Take note of the labeling conventions; each symbol or part is usually marked for clarity. This initial scan will help you grasp how everything fits together.

Next, focus on the details. Pay attention to any accompanying annotations that explain the function of individual components. These notes are crucial, as they provide context that can enhance your understanding. If available, refer to a legend or key that decodes any symbols used in the illustration.

Lastly, practice makes perfect. The more you engage with these visuals, the more intuitive they become. Try cross-referencing the schematic with the actual parts to reinforce your comprehension. With time, interpreting such layouts will become a second nature, enabling you to tackle repairs with confidence.

Finding Replacement Parts Easily

Locating the necessary components for your equipment can often feel overwhelming, especially with the myriad of options available. However, with the right approach and resources, you can streamline the process and ensure that you find what you need without hassle.

Utilizing Online Resources

The internet is a treasure trove of information. Various websites specialize in offering detailed listings and images of components, making it easier to identify what you’re looking for. Search engines can also guide you to forums and communities where enthusiasts share tips and recommendations for sourcing specific items.

Local Dealers and Repair Shops

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of any mechanical equipment. By following a few key practices, users can enhance performance and extend the lifespan of their tools. Regular attention to maintenance not only prevents potential issues but also promotes optimal functionality over time.

Regular Cleaning: Keep your equipment clean by removing dirt, debris, and residues after each use. This simple step can prevent wear and tear, as well as maintain optimal performance levels.

Routine Inspections: Conduct frequent checks for any signs of damage or wear. Addressing minor issues early can prevent major repairs down the line, saving time and resources.

Lubrication: Ensure all moving parts are properly lubricated according to the manufacturer’s guidelines. This reduces friction and minimizes the risk of breakdowns, contributing to smoother operation.

Proper Storage: Store your equipment in a dry, protected area to avoid exposure to harsh weather conditions. This helps maintain the integrity of the materials and components.

Follow Manufacturer Guidelines: Adhere to the specific maintenance schedule provided by the manufacturer. Regular servicing and part replacements, when needed, are crucial for sustained performance.

By implementing these maintenance strategies, users can enjoy reliable performance and extend the life of their equipment significantly.

Popular Upgrades for the Husqvarna 288

Enhancing the performance and efficiency of your chainsaw can greatly improve your overall experience. Numerous modifications can be made to boost power, reduce weight, or improve handling, allowing enthusiasts and professionals alike to tailor their equipment to specific needs.

Carburetor Upgrade: Replacing the stock carburetor with a high-performance model can significantly improve fuel delivery and engine responsiveness. This modification helps achieve optimal performance, especially in demanding conditions.

Chain and Bar Improvement: Upgrading to a longer or more advanced chain and bar can enhance cutting speed and efficiency. Consider materials that offer better durability and reduced kickback for a safer cutting experience.

Aftermarket Muffler: Installing an aftermarket exhaust can increase power output while reducing noise levels. This upgrade often leads to better engine breathing, which enhances overall performance.

Weight Reduction: Replacing heavier components with lighter alternatives can improve maneuverability. Look for lightweight materials for handles, guards, or other parts to make handling easier during extended use.

Enhanced Grip: Adding ergonomic grips can make operating the equipment more comfortable, reducing fatigue during long work sessions. These upgrades can significantly improve user experience and control.

Consider these enhancements to elevate your tool’s capabilities, making each job smoother and more efficient.

Comparing Parts with Other Models

When exploring the components of various models, it’s essential to recognize similarities and differences that can impact functionality and maintenance. Analyzing these elements across different units can reveal valuable insights into compatibility and performance enhancements.

Understanding component variations is crucial, as manufacturers often implement slight modifications that may affect assembly or interchangeability. For instance, examining the design of specific elements such as ignition systems, fuel delivery mechanisms, and drive components can shed light on potential upgrades or replacements.

Additionally, recognizing which models share similar features can streamline the repair process and reduce costs. Enthusiasts and professionals alike can benefit from this comparative approach, ensuring they select the best options for repairs or enhancements while maximizing the lifespan of their equipment.

Tools Required for Assembly

Assembling a complex piece of equipment necessitates a specific set of tools to ensure precision and efficiency. Having the right instruments at hand not only streamlines the process but also enhances safety and reduces the likelihood of damage to components.

Essential tools include:

Wrenches: A variety of sizes will help tighten bolts securely.

Screwdrivers: Both flathead and Phillips types are crucial for working with different fasteners.

Torque wrench: This tool is vital for applying the correct amount of force to bolts, preventing over-tightening.

Pliers: Useful for gripping and manipulating small parts, especially in tight spaces.

Hex keys: Often necessary for accessing certain screws, especially in machinery designs.

Additional tools may include:

Cutting tools: Depending on the assembly, a utility knife or saw might be needed for trimming components.

Measuring tools: A ruler or caliper ensures that parts fit together as intended.

Having these instruments ready will facilitate a smooth assembly process, ensuring that every component is correctly installed and functional.

Cost Analysis of Replacement Parts

Understanding the financial implications of substituting components is crucial for efficient maintenance and budgeting. By evaluating the expenses associated with various elements, one can make informed decisions that ensure optimal performance while minimizing unnecessary expenditures.

When analyzing costs, consider the following factors:

- Quality of Components: Higher quality often means a higher price, but it can lead to longer lifespan and better performance.

- Brand Reputation: Established brands may charge more, yet they often offer reliability and warranty options that can justify the expense.

- Availability: Rarely found items might be priced higher due to limited supply, affecting overall budget considerations.

Additionally, it’s beneficial to categorize expenses into:

- Essential Components: Necessary for functionality and safety, such as engines and ignition systems.

- Wearable Items: Regularly replaced elements like chains and filters that can impact efficiency if neglected.

- Upgrades: Optional enhancements that improve performance but may require significant investment.

By conducting a thorough analysis of these aspects, individuals can optimize their maintenance strategies while managing costs effectively.

Customer Reviews on Parts Performance

Customer feedback plays a crucial role in assessing the efficiency and reliability of components used in outdoor power equipment. Users often share their experiences regarding how various elements function under different conditions, providing valuable insights for potential buyers. This collective wisdom helps in understanding the quality and longevity of specific items, allowing others to make informed decisions.

| Review Rating | Customer Comment | Performance Insights |

|---|---|---|

| 5/5 | “Outstanding performance! Exceeded my expectations.” | Durability and efficiency noted in heavy-duty tasks. |

| 4/5 | “Very good, but took a while to install.” | Installation may require additional tools; overall reliable. |

| 3/5 | “Average performance, nothing special.” | Meets basic requirements but lacks advanced features. |

| 2/5 | “Not what I expected; wore out quickly.” | Short lifespan under continuous use; consider alternatives. |

| 1/5 | “Completely failed after a few uses.” | High failure rate reported; advise caution. |