Understanding the Stihl FS 45 Parts Diagram for Easy Maintenance

When it comes to maintaining and repairing your outdoor power equipment, having a clear understanding of its inner workings is essential. Knowing how each element fits together can significantly enhance the efficiency and longevity of your machine.

In this section, we will explore the intricate layout of your trimming device, providing valuable insights into its various components. This knowledge will empower you to make informed decisions when it comes to replacements or repairs.

By delving into the specifics, you will not only grasp the ultimate functionality of your equipment but also gain confidence in tackling any issues that may arise. With a comprehensive overview, you can ensure your trimmer remains in optimal condition for all your gardening needs.

Understanding Stihl FS 45 Components

Grasping the various elements of a string trimmer is essential for optimal performance and maintenance. Each component plays a specific role, contributing to the overall functionality and efficiency of the machine. Familiarizing oneself with these elements can lead to better care and longer lifespan of the equipment.

Main Elements

- Engine: The power source that drives the tool, typically a two-stroke or four-stroke engine.

- Cutting Head: The part that houses the line or blade, responsible for trimming grass and weeds.

- Fuel Tank: Stores the mixture of gasoline and oil, crucial for engine operation.

- Shaft: Connects the engine to the cutting head, transmitting power for operation.

- Handle: Provides grip and control for maneuvering the equipment effectively.

Additional Components

- Throttle Control: Regulates the engine speed, allowing the user to adjust power as needed.

- Air Filter: Prevents dirt and debris from entering the engine, ensuring efficient combustion.

- Spark Plug: Ignites the fuel-air mixture, essential for engine starting and running.

- Starter Mechanism: Enables the user to start the engine, often through a pull cord system.

- Safety Guard: Protects the user from debris and enhances safety during operation.

Importance of Parts Diagrams

Understanding the intricacies of machinery is essential for effective maintenance and repair. Visual representations serve as valuable tools, allowing users to identify components and their interrelations easily. This clarity is crucial for ensuring optimal functionality and longevity of equipment.

Benefits of Visual Guides

- Simplifies troubleshooting by highlighting key elements.

- Enhances efficiency during repairs by providing clear references.

- Facilitates better communication among technicians and users.

Ensuring Proper Maintenance

- Regular reference to visual aids promotes timely upkeep.

- Identifying worn or damaged components becomes straightforward.

- Encourages a proactive approach to maintenance, reducing downtime.

Key Parts of Stihl FS 45

This section provides an overview of essential components that contribute to the efficient functioning of the FS 45 model. Understanding these elements is crucial for maintenance and troubleshooting, ensuring optimal performance and longevity.

Major Components

- Engine: The powerhouse that drives the entire unit, providing the necessary force for operation.

- Fuel Tank: A reservoir that holds the mixture needed for combustion, designed for easy access and refueling.

- Cutting Head: The section responsible for trimming and mowing, equipped with interchangeable attachments for various tasks.

- Throttle Control: A mechanism that allows the operator to adjust the speed, ensuring precision during use.

- Handlebar: Provides stability and maneuverability, designed for comfort during extended periods of operation.

Supporting Features

- Air Filter: Essential for maintaining engine efficiency by preventing debris from entering the combustion chamber.

- Starter Mechanism: Facilitates the ignition process, making it easier to start the unit.

- Gearbox: Transmits power from the engine to the cutting head, influencing performance and efficiency.

- Safety Guard: A protective feature that shields the user from flying debris during operation.

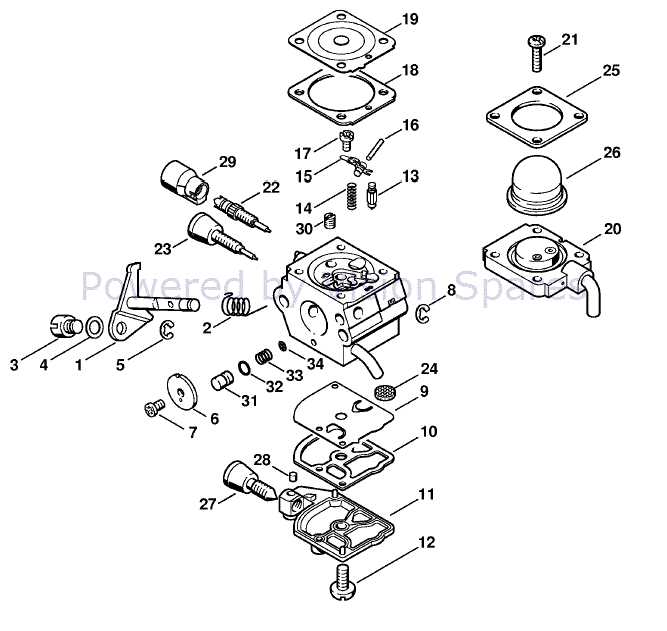

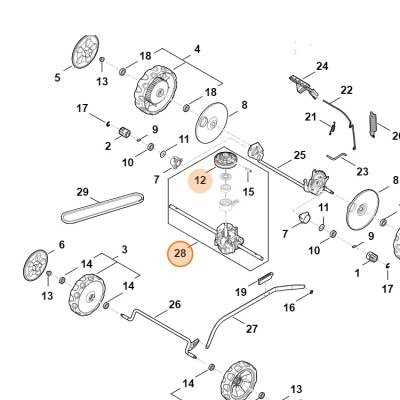

How to Read the Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. It serves as a visual guide, illustrating the relationship between various elements and their functions, allowing users to navigate through complex assemblies with ease.

Key Elements to Identify

- Labels: Look for numbers or letters that correspond to specific items.

- Connections: Pay attention to lines indicating how parts interact.

- Grouping: Notice clusters that suggest related components.

Steps to Interpret the Representation

- Start by familiarizing yourself with the overall layout.

- Identify the main components first, using labels for guidance.

- Trace the connections to understand how elements work together.

- Refer to any accompanying descriptions for additional context.

Common Replacement Parts Explained

Maintaining outdoor power equipment often requires a deep understanding of various components that may wear out or require replacement over time. Familiarity with these elements can ensure optimal performance and prolong the lifespan of the machinery. This section highlights some frequently needed components, providing insights into their functions and importance.

Trimmer Line: This is the primary cutting element, essential for trimming grass and weeds. Over time, it can wear down, necessitating regular replacement to maintain effective cutting capability. The thickness and type of line can impact the efficiency of the task at hand.

Air Filter: A crucial element for engine performance, the air filter prevents dirt and debris from entering the engine. Regular checks and replacements are vital to ensure the engine runs smoothly and efficiently, avoiding unnecessary strain.

Fuel Filter: This component plays a significant role in maintaining clean fuel flow to the engine. A clogged filter can hinder performance, leading to starting issues and reduced power. Regular replacement is essential for optimal operation.

Spark Plug: Essential for igniting the fuel-air mixture, a well-functioning spark plug is critical for engine performance. Over time, it can become fouled or worn, affecting starting and overall efficiency. Periodic inspection and replacement are recommended.

Drive Shaft: This component transfers power from the engine to the cutting head. Any wear or damage can result in decreased performance or malfunction. Ensuring the integrity of the drive shaft is vital for effective operation.

Understanding these essential components not only facilitates timely maintenance but also enhances the overall efficiency and reliability of the equipment, ensuring it remains in peak condition for all your outdoor tasks.

Maintenance Tips for Your Trimmer

Keeping your gardening tool in optimal condition is essential for efficient performance and longevity. Regular maintenance not only ensures a clean cut but also helps prevent costly repairs and replacements. Here are some practical tips to help you care for your equipment effectively.

1. Clean After Each Use: Always remove grass clippings, dirt, and debris from the cutting head and other components after each session. This practice prevents buildup that can lead to corrosion and operational issues.

2. Check the Cutting Line: Regularly inspect the cutting line for wear and tear. Replace it if it appears frayed or damaged to maintain effective cutting performance.

3. Inspect the Air Filter: A clean air filter is crucial for optimal engine performance. Check it periodically and clean or replace it as necessary to ensure proper airflow.

4. Maintain the Fuel System: Use fresh fuel and a quality oil mixture. Consider draining the fuel tank if the tool will not be used for an extended period to avoid clogging the carburetor.

5. Sharpen Blades: If your device has blades, keep them sharp for efficient cutting. Dull blades can strain the engine and produce uneven results.

6. Check Bolts and Screws: Regularly inspect all screws and bolts for tightness. Loose parts can affect performance and lead to damage over time.

7. Store Properly: When not in use, store your tool in a cool, dry place. Use a protective cover to shield it from dust and moisture.

By following these maintenance tips, you can extend the lifespan of your equipment and ensure it operates at peak efficiency throughout its use.

Where to Find Genuine Parts

Locating authentic components for your equipment is essential for ensuring optimal performance and longevity. Reliable sources offer quality items that maintain the integrity of your machinery. Here are some trusted avenues to explore:

- Authorized Dealers: Visiting an authorized dealer guarantees access to original items that meet manufacturer standards.

- Official Websites: Many brands have dedicated online platforms where you can browse and order genuine components directly.

- Specialty Retailers: Stores specializing in outdoor equipment often carry a range of authentic replacements, ensuring you get the right fit.

- Local Repair Shops: Local technicians may have access to genuine items and can provide personalized service alongside quality parts.

- Online Marketplaces: Reputable online marketplaces sometimes offer genuine components, but it’s crucial to verify the seller’s credibility.

Utilizing these sources not only helps maintain your equipment’s efficiency but also promotes safety during operation. Always prioritize quality to avoid issues in the future.

Identifying Faulty Components

Recognizing defective elements in your equipment is crucial for maintaining optimal performance. Understanding the signs of wear and tear can prevent further damage and ensure longevity. This section will guide you through common indicators of malfunctioning components and how to address them effectively.

- Unusual Noises: Listen for any strange sounds that deviate from normal operation, as they can indicate internal issues.

- Decreased Efficiency: Noticeable drops in performance, such as reduced power or longer operation times, can suggest underlying problems.

- Visual Inspection: Regularly examine parts for cracks, rust, or other visible damages that might compromise functionality.

- Excessive Vibrations: If the machinery vibrates more than usual, it could signal misalignment or damaged components.

By being vigilant and recognizing these signs, you can promptly diagnose issues and take necessary corrective actions.

- Start with a thorough visual inspection to identify obvious defects.

- Test the equipment under normal conditions to observe performance variations.

- Consult manuals or guides for troubleshooting advice related to specific symptoms.

- Consider seeking professional assistance if problems persist after your own evaluations.

Identifying these faulty elements early on can save time and resources in the long run, ensuring that your tools function smoothly and efficiently.

Assembly and Disassembly Process

The process of assembling and disassembling equipment requires careful attention to detail and a systematic approach. Understanding the sequence of steps can ensure efficiency and prevent damage to components during maintenance or repairs. Proper techniques can also enhance the longevity of the machine.

Tools Needed

| Tool | Purpose |

|---|---|

| Screwdriver | To remove screws and fasteners |

| Wrench | To loosen and tighten bolts |

| Pliers | For gripping and manipulating components |

| Safety Gloves | To protect hands during handling |

Step-by-Step Guide

Begin by ensuring the equipment is powered down and disconnected from any power source. Follow the manufacturer’s instructions to carefully remove outer casing and access internal components. Take note of the order of disassembly for easier reassembly. When putting the equipment back together, refer to your notes and verify that each part is securely fitted to avoid malfunctions.

Safety Precautions During Repairs

When undertaking maintenance on machinery, ensuring safety is paramount. Following specific guidelines can help prevent accidents and injuries, fostering a secure environment for all involved. By being mindful of potential hazards and taking necessary precautions, individuals can effectively manage the risks associated with repairs.

Wear Appropriate Protective Gear

Utilizing protective equipment is essential. Always don gloves, goggles, and sturdy footwear to shield against sharp objects and flying debris. This gear serves as your first line of defense against unforeseen incidents.

Work in a Safe Environment

Choose a well-lit and clutter-free workspace. Ensure that tools are organized and accessible, reducing the chance of accidents. Maintaining a clear area not only enhances efficiency but also minimizes potential hazards that may arise during the repair process.

Upgrading Stihl FS 45 Features

Enhancing the capabilities of your trimming equipment can significantly improve its performance and usability. Upgrades can lead to increased efficiency, reduced fatigue during extended use, and overall better results in various landscaping tasks. This section will explore some effective modifications and enhancements that can elevate the functionality of your device.

Recommended Upgrades

Several upgrades can be applied to improve efficiency and comfort. Below is a table highlighting popular enhancements and their benefits:

| Upgrade | Benefits |

|---|---|

| Enhanced Cutting Blade | Increased cutting speed and precision, better handling of thick grass. |

| Anti-Vibration Handle | Reduces user fatigue, allowing for longer operation times with less strain. |

| Fuel Efficiency Kit | Improves fuel consumption, lowering operational costs over time. |

| Custom Grip Design | Enhances comfort and control, especially during extended use. |

Installation Tips

When considering upgrades, ensure you follow the manufacturer’s guidelines for installation. Properly fitted enhancements can prevent issues and prolong the lifespan of your equipment. Always test the device after making modifications to ensure optimal performance.