Exploring the Mercury 7.5 Outboard Parts Diagram

The intricate workings of a beloved marine engine often require a deep dive into its essential components. By exploring the various elements that contribute to its functionality, one can gain valuable insights into maintenance and repair. Whether you are a seasoned technician or a passionate hobbyist, understanding these intricacies can enhance your overall experience on the water.

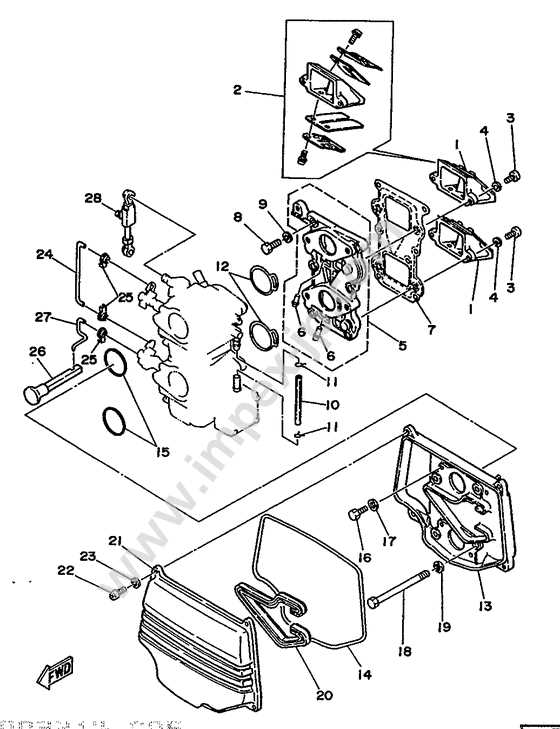

For enthusiasts seeking to restore or maintain their favorite aquatic vessel, visual representations of these components can be invaluable. Detailed illustrations can clarify the relationships between different sections, enabling a more straightforward approach to troubleshooting and assembly. This knowledge not only fosters a sense of confidence but also deepens appreciation for the engineering behind these timeless machines.

In this discussion, we will delve into the essential visual guides that showcase the specific elements of a classic engine, allowing for a clearer understanding of how each piece contributes to optimal performance. With the right information at hand, you can ensure that your marine experience remains smooth and enjoyable.

Understanding Mercury 7.5 Outboard Engines

This section explores the intricacies of a specific marine propulsion system, highlighting its components, functionality, and maintenance requirements. By examining the mechanics involved, users can gain insights into optimizing performance and longevity.

The engine in question is designed for efficiency, catering to various watercraft needs. Its construction reflects a balance between power and compactness, allowing for smooth operation in diverse aquatic environments.

Regular upkeep is crucial for ensuring reliable performance. Familiarity with the essential components enables users to identify issues early and implement corrective measures promptly, ensuring a seamless experience on the water.

Understanding the intricacies of this system not only enhances operational knowledge but also fosters a deeper appreciation for the engineering involved in marine technology.

Importance of Proper Maintenance

Key Components of the Engine

Understanding the fundamental elements of a marine propulsion unit is essential for effective maintenance and optimal performance. Each component plays a significant role in the overall functionality, contributing to the efficiency and reliability of the system on the water.

Major Elements

The main constituents of a marine engine can be categorized into several key parts. Each of these elements has a specific function that supports the overall operation and effectiveness of the unit.

| Component | Function |

|---|---|

| Cylinder Block | Houses the cylinders and provides the necessary structure for combustion. |

| Piston | Converts the energy from fuel combustion into mechanical movement. |

| Crankshaft | Transforms linear motion of the piston into rotational motion to drive the propeller. |

| Ignition System | Initiates the combustion process by creating a spark at the appropriate time. |

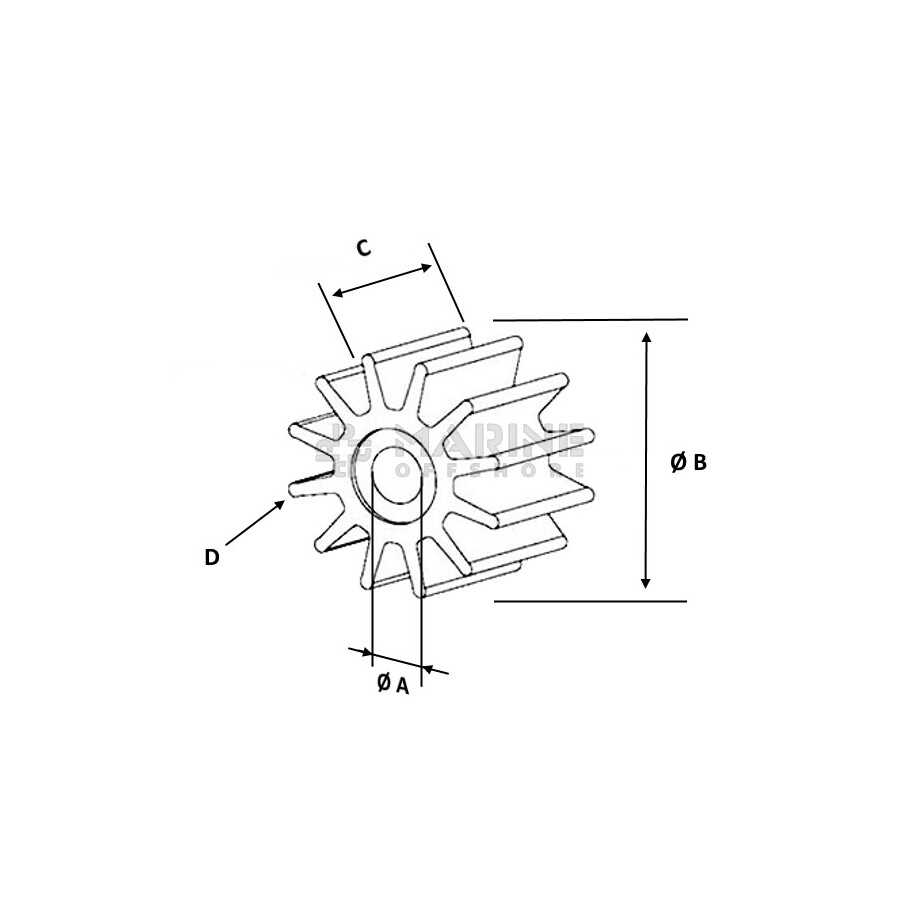

| Cooling System | Regulates the engine temperature to prevent overheating and maintain efficiency. |

Supporting Elements

In addition to the primary components, various supporting elements enhance performance and longevity. These parts work together to ensure smooth operation and durability under demanding conditions.

Parts Identification Guide

This section aims to assist users in recognizing and understanding the various components of their marine engine. Familiarity with each element is essential for maintenance, repair, and optimization of performance.

Identifying specific components can be simplified through a structured approach:

- Engine Assembly: Familiarize yourself with the main body and its accessories.

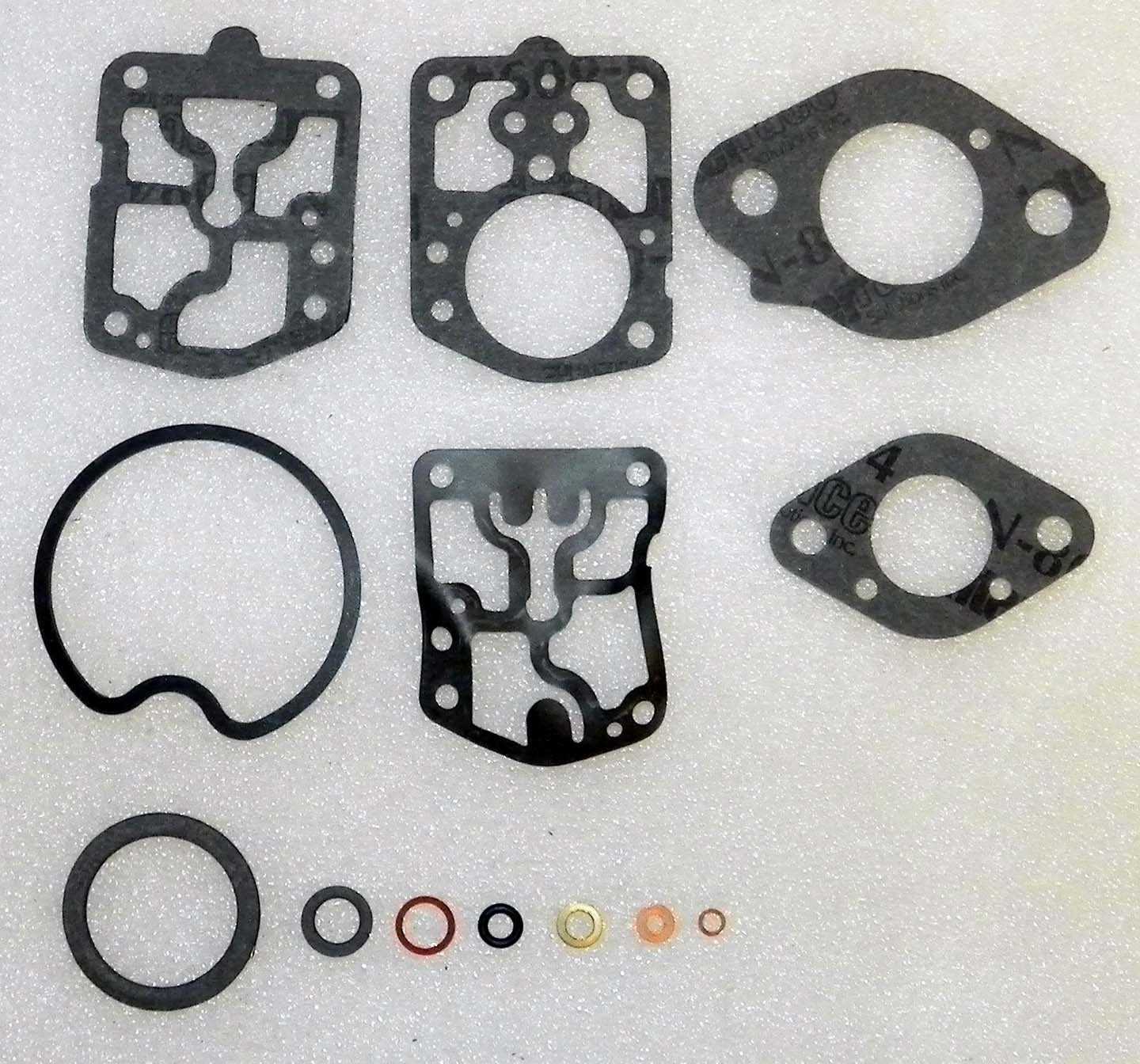

- Fuel System: Learn about the tank, lines, and filters that ensure proper fuel delivery.

- Cooling Mechanism: Understand the cooling system, including pumps and hoses, that prevent overheating.

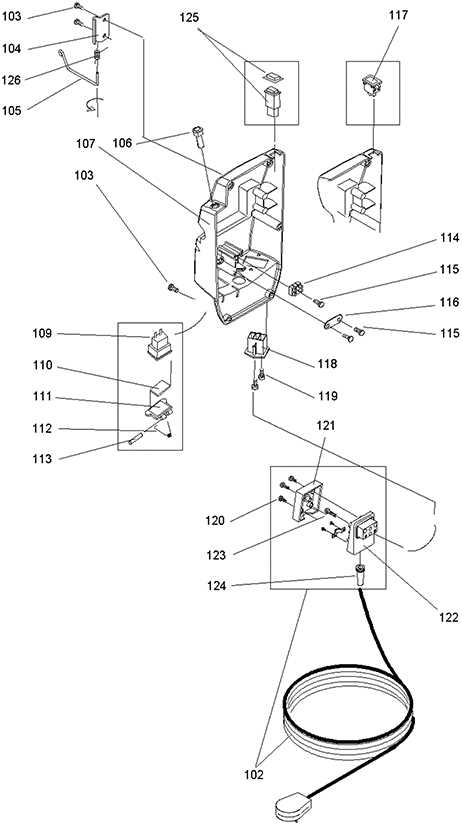

- Electrical Components: Identify batteries, wiring, and ignition systems crucial for operation.

- Propulsion Elements: Recognize the features that contribute to thrust and maneuverability.

For efficient identification, refer to a visual guide that correlates each item with its function. This will enhance your ability to troubleshoot and maintain the engine effectively.

Common Issues with Mercury 7.5

When it comes to small marine engines, various challenges can arise that affect performance and reliability. Understanding these common problems is essential for maintenance and troubleshooting, ensuring a smoother experience on the water.

Fuel System Troubles

One prevalent issue relates to the fuel system. Blockages, stale fuel, and improper mixtures can lead to starting difficulties or erratic performance. Regular inspection and maintenance of fuel lines and filters can mitigate these problems.

Electrical Failures

Another area to consider is the electrical system. Faulty connections, worn wires, and dead batteries often result in ignition issues. Keeping the electrical components clean and well-maintained is crucial for reliable operation.

Where to Find Replacement Parts

Locating suitable components for your marine engine can be a straightforward process if you know where to look. Many resources are available that cater to enthusiasts and professionals alike, ensuring you have access to the necessary items for maintenance and repair.

Online Retailers: Numerous e-commerce websites specialize in marine equipment, offering a vast selection of replacement components. Searching through these platforms can yield both new and refurbished items.

Local Dealers: Establishing a connection with nearby dealerships can provide valuable insights. These establishments often have access to specific components and can assist with ordering hard-to-find pieces.

Forums and Community Groups: Engaging with online communities dedicated to marine engines can be beneficial. Members frequently share resources, tips, and leads on where to find specific components, sometimes even selling items directly.

Salvage Yards: Visiting local salvage yards can uncover hidden gems. These places often have older models that may contain the exact parts you need, often at a fraction of the cost.

By exploring these avenues, you can effectively source the essential components required for optimal performance and longevity of your marine equipment.

Using Diagrams for Repairs

Visual representations play a crucial role in the maintenance and restoration of mechanical devices. These illustrations provide a clear overview of the assembly and functionality of various components, making troubleshooting and repairs significantly easier. By breaking down complex systems into understandable segments, users can identify issues more effectively and apply the correct solutions.

Understanding the layout of an engine or equipment through detailed visuals allows for a more intuitive approach to repairs. When faced with a malfunction, consulting these guides can illuminate the path forward, highlighting which parts need attention. This systematic approach not only saves time but also minimizes the risk of errors during the repair process.

Moreover, reference images can serve as a valuable learning tool for both novice and experienced technicians. By studying the arrangements and functions depicted, individuals can gain insights into the mechanics at play, enhancing their overall repair skills. Utilizing these resources empowers users to tackle issues with confidence, knowing they have a reliable guide to support their efforts.

Tips for DIY Maintenance

Maintaining your watercraft engine is essential for ensuring longevity and optimal performance. Regular upkeep can prevent costly repairs and enhance your overall experience on the water. With a little knowledge and the right tools, you can tackle maintenance tasks effectively and with confidence.

Regular Inspections

Perform routine checks on key components such as fuel lines, spark plugs, and the cooling system. Look for signs of wear, corrosion, or leaks. Addressing these issues early can save you time and money in the long run.

Use Quality Supplies

When replacing any components, always opt for high-quality materials. This not only ensures better performance but also extends the lifespan of your equipment. Investing in reliable supplies is crucial for effective maintenance.

Upgrading Your Outboard Parts

Enhancing the components of your marine engine can significantly improve its performance, efficiency, and longevity. By selecting high-quality alternatives or modern upgrades, you can ensure smoother operation and a better overall experience on the water. This section explores essential upgrades that can transform your vessel’s capabilities.

When considering enhancements, it’s important to identify the specific elements that need attention. This may include the fuel system, ignition, cooling, or even the propeller. Below is a table outlining some common upgrades and their benefits:

| Upgrade | Benefits |

|---|---|

| Fuel Pump | Improved fuel delivery and efficiency. |

| Ignition System | Quicker starts and enhanced throttle response. |

| Propeller | Better handling and increased speed. |

| Cooling System | Lower operating temperatures, reducing wear. |

| Exhaust Upgrade | Improved sound and performance, reduced back pressure. |

Each modification can contribute to a more enjoyable and reliable experience on the water. When planning upgrades, always consider compatibility and quality to achieve the best results for your vessel.

Understanding Fuel Systems

The functionality of aquatic propulsion systems hinges significantly on their fuel mechanisms. These systems are intricately designed to ensure optimal performance, enabling vessels to harness energy efficiently. A well-functioning fuel system is crucial for reliability and effectiveness during operation.

Components of Fuel Mechanisms

Key elements include the fuel tank, which stores the energy source, and the pump, responsible for transferring the fuel to the engine. Additionally, filters play a vital role in maintaining fuel purity, preventing contaminants from causing damage. Understanding these components is essential for troubleshooting and maintenance.

Importance of Regular Maintenance

Regular upkeep of fuel systems is imperative for longevity and efficiency. Neglecting routine checks can lead to performance issues or failures. By delving into maintenance practices, users can enhance the overall reliability of their aquatic machinery.

Wiring Diagrams Explained

Understanding electrical schematics is essential for troubleshooting and maintaining marine engines. These illustrations provide a visual representation of the connections and components within the electrical system, enabling users to follow the flow of electricity and diagnose issues efficiently.

Key elements of electrical schematics include:

- Symbols: Each component is represented by a unique symbol, making it easier to identify parts such as batteries, switches, and motors.

- Connections: Lines indicate how components are linked, showing the path that electrical current follows.

- Color Codes: Wires may be color-coded to signify different functions or voltage levels, aiding in quick identification during repairs.

When interpreting these diagrams, consider the following steps:

- Familiarize Yourself with Symbols: Review the legend to understand the meanings of various icons used in the schematic.

- Trace Connections: Follow the lines to see how each part connects to others, paying attention to any junctions or nodes.

- Check for Annotations: Look for notes or additional information that may clarify specific aspects or instructions related to the wiring.

By mastering these schematics, users can improve their troubleshooting skills and ensure the reliable operation of their engines.

Consulting Technical Manuals

Understanding machinery often requires thorough exploration of specialized documents that provide essential information for maintenance and repairs. These resources are invaluable for ensuring proper functionality and longevity.

When engaging with these manuals, consider the following points:

- Clarity: Ensure that the language and diagrams are straightforward.

- Detail: Look for comprehensive descriptions of components and systems.

- Updates: Verify that the manual reflects the latest modifications and standards.

Utilizing these documents effectively can lead to enhanced performance and fewer issues in the long run. Adhering to the guidelines presented is crucial for successful operation.

Benefits of Regular Inspections

Conducting routine evaluations of marine equipment is essential for ensuring optimal performance and longevity. These assessments help identify potential issues before they escalate, ultimately saving time and resources.

Enhancing Safety

Regular checks play a critical role in maintaining safety on the water. They help to:

- Detect mechanical failures early, reducing the risk of accidents.

- Ensure all safety features are functional, providing peace of mind.

- Minimize the likelihood of breakdowns during outings, allowing for a safer experience.

Improving Efficiency

In addition to safety, routine inspections contribute to the overall efficiency of the equipment. Benefits include:

- Optimizing fuel consumption by identifying and addressing performance issues.

- Extending the lifespan of components through early detection of wear and tear.

- Enhancing overall operational reliability, ensuring smoother experiences on the water.