Comprehensive Guide to Ezgo Marathon Steering Parts Diagram

When it comes to optimizing the maneuverability of recreational vehicles, a comprehensive grasp of the essential elements involved is crucial. These components play a pivotal role in ensuring smooth operation and effective control, enhancing the overall experience for users.

In this section, we delve into the intricate framework that supports vehicle directionality. By exploring various elements and their interconnections, enthusiasts can better appreciate how each piece contributes to the vehicle’s performance and reliability.

Whether you are a seasoned expert or a newcomer, familiarizing yourself with these intricate systems can empower you to make informed decisions regarding maintenance and upgrades. Understanding the layout and functionality of these mechanisms is key to ensuring optimal performance and longevity.

Understanding Ezgo Marathon Steering Systems

This section explores the intricacies of the control mechanisms in various utility vehicles, focusing on their functionality and components. By grasping these systems, one can enhance driving experience and ensure optimal performance.

Components Overview

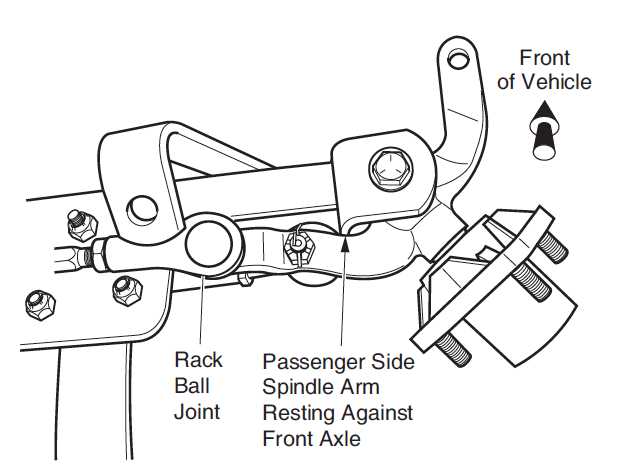

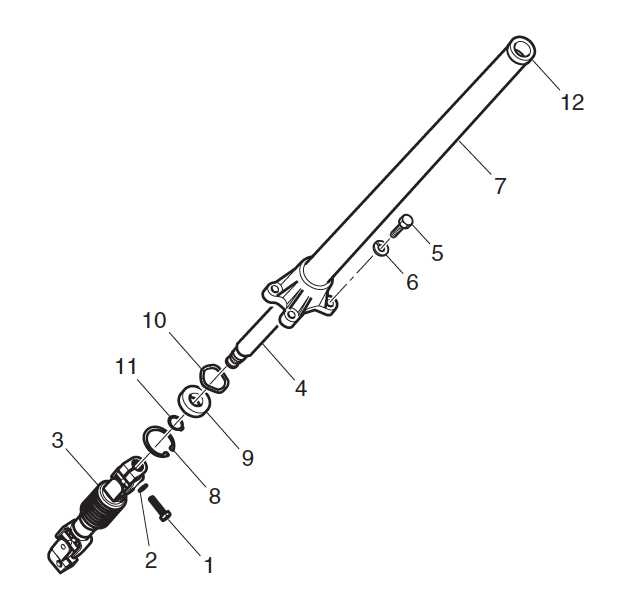

The primary elements include the wheel mechanism, linkages, and connecting rods, each contributing to the overall maneuverability. Understanding how these pieces interact is crucial for effective maintenance and troubleshooting.

Maintenance Tips

Regular inspection of the key components is essential for longevity. Lubrication of joints and timely replacements of worn parts can prevent more serious issues and ensure a smooth operation.

Components of Ezgo Marathon Steering

The mechanism responsible for directional control in various vehicles consists of several crucial elements that work together to ensure smooth handling and responsiveness. Understanding these components is essential for maintenance and performance optimization.

- Wheel Assembly: This includes the main rotating part that connects to the axle, enabling the vehicle to change direction.

- Column: The vertical structure that connects the wheel assembly to the control elements, allowing for ergonomic operation.

- Linkages: These rods and joints transmit motion from the column to the wheel assembly, ensuring precise movements.

- Knuckles: Pivot points that facilitate turning and provide stability during maneuvers.

- Bearings: These reduce friction in the moving parts, enhancing overall efficiency and longevity.

Each of these components plays a vital role in maintaining control and ensuring a pleasant driving experience. Regular inspection and maintenance of these elements can prevent issues and extend the lifespan of the entire system.

Importance of Proper Steering Maintenance

Maintaining the control mechanism of any vehicle is crucial for ensuring safe and efficient operation. Neglecting this essential aspect can lead to serious safety concerns, increased wear and tear, and costly repairs. Regular upkeep not only enhances performance but also prolongs the lifespan of the vehicle.

Key Benefits of Regular Upkeep

- Enhanced Safety: A well-maintained control system reduces the risk of accidents by ensuring accurate handling and response.

- Improved Performance: Regular checks and adjustments can lead to smoother operation and better overall responsiveness.

- Cost Efficiency: Preventive maintenance often costs less than emergency repairs caused by neglect.

- Increased Longevity: Consistent care helps in extending the life of the vehicle, reducing the need for frequent replacements.

Essential Maintenance Practices

- Regular inspections for wear and tear.

- Lubrication of moving components to prevent friction.

- Adjustment of alignment to ensure proper tracking.

- Replacement of worn-out elements before they cause issues.

In summary, prioritizing the maintenance of the control mechanism is vital for both safety and efficiency. By investing time in regular upkeep, vehicle owners can enjoy a more reliable and enjoyable driving experience.

Common Issues with Steering Parts

Various challenges can arise with the components that control direction in vehicles. Understanding these issues can enhance maintenance efforts and improve overall performance.

- Worn Components: Frequent use can lead to wear and tear, affecting responsiveness.

- Alignment Problems: Misalignment can cause uneven handling and increased tire wear.

- Loose Connections: Loose fittings can result in instability and rattling noises.

- Corrosion: Exposure to elements may lead to rust, compromising structural integrity.

- Fluid Leaks: Leaks can hinder functionality and lead to other mechanical issues.

Addressing these common problems proactively can significantly enhance the longevity and effectiveness of the directional control system.

Tools Needed for Steering Repair

When undertaking the task of fixing the navigation mechanism in your vehicle, having the right tools at your disposal is crucial. The appropriate equipment not only ensures efficiency but also enhances the quality of the repair process. Below is a comprehensive list of essential tools required for this type of maintenance.

Essential Hand Tools

- Socket set – for loosening and tightening fasteners.

- Wrench set – to grip and turn nuts and bolts securely.

- Torque wrench – to apply the correct amount of force to fasteners.

- Screwdrivers – both flathead and Phillips for various screws.

- Pliers – for gripping and twisting components.

Specialized Tools

- Ball joint separator – to detach the joint without damage.

- Steering wheel puller – for safely removing the wheel from the shaft.

- Alignment tool – to ensure proper alignment after repairs.

- Fluid pump – for refilling or bleeding hydraulic systems.

- Measuring tape – to check dimensions and ensure correct fitting.

Having these tools ready will facilitate a smoother repair experience and help achieve optimal results in restoring functionality.

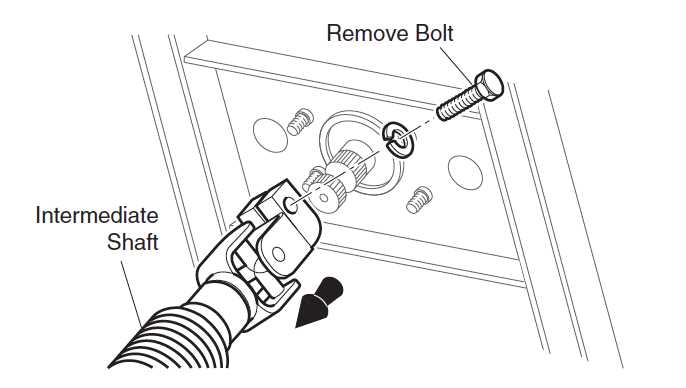

Step-by-Step Steering Inspection Guide

This guide aims to provide a thorough approach to assessing the directional control system of your vehicle, ensuring optimal performance and safety. By following these structured steps, you can identify potential issues and maintain the overall functionality of the mechanism.

Initial Visual Examination

Start with a detailed visual check of the assembly. Look for any obvious signs of wear, damage, or loose connections. Pay attention to the integrity of components and ensure that nothing is out of place.

Functional Testing

Once the visual inspection is complete, conduct a functional test. Turn the wheel and observe the responsiveness of the mechanism. Listen for unusual noises and check for smooth operation, noting any irregularities that may require further investigation.

Identifying Worn-Out Steering Components

Recognizing signs of wear in crucial components is essential for maintaining optimal performance and safety in your vehicle. Over time, various elements can degrade, leading to compromised functionality and control. This section explores key indicators that suggest certain parts may need replacement.

Common Signs of Deterioration

Several symptoms can signal that components are nearing the end of their lifespan. Look for unusual noises, looseness, or difficulty in maneuvering, as these may indicate underlying issues.

Inspection Checklist

| Component | Signs of Wear |

|---|---|

| Universal Joints | Excessive play or clunking noises |

| Bearings | Grinding sounds or rough movement |

| Linkage | Increased friction or resistance |

Replacing Steering Parts: What to Know

Maintaining the control mechanism of your vehicle is crucial for ensuring a smooth and safe driving experience. Over time, components may wear out, necessitating their replacement. Understanding the essentials of this process will empower you to tackle any issues effectively.

Signs of Wear and When to Replace

Look out for unusual noises, difficulty in maneuvering, or instability while driving. These symptoms indicate that some elements may need attention. Regular inspections can help you identify problems before they escalate.

Preparation and Tools Needed

Before starting the replacement, gather the necessary tools and familiarize yourself with the assembly layout. Having the right equipment will streamline the process and ensure a successful outcome. Always consult the manufacturer’s guidelines for specific recommendations.

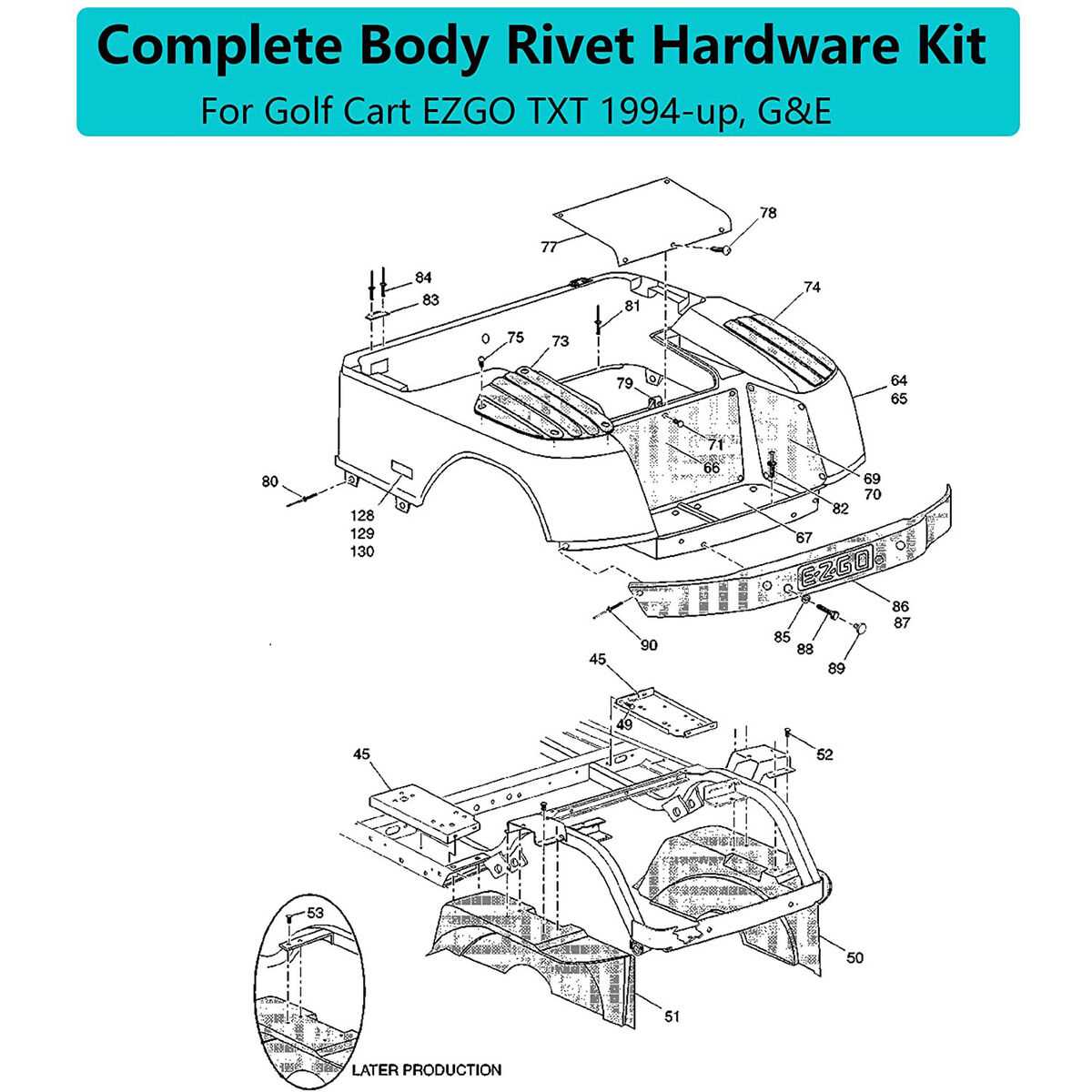

Diagram Analysis: Key Features Explained

This section focuses on the essential characteristics and components illustrated in the schematic representation. Understanding these elements is crucial for enhancing functionality and ensuring optimal performance of the vehicle’s control system.

Critical Components

- Framework: The structural foundation that supports the entire mechanism.

- Linkages: Connective elements that facilitate motion transfer.

- Bearings: Essential for smooth operation and reducing friction.

- Adjustment Mechanisms: Allow fine-tuning for precision handling.

Operational Insights

- Understanding how each component interacts is vital for troubleshooting.

- Identifying wear points helps in maintenance and longevity.

- Recognizing the role of each part enhances overall user experience.

Upgrading Ezgo Marathon Steering System

Enhancing the control system of your vehicle can significantly improve its performance and handling. By focusing on key components, you can achieve a more responsive and stable driving experience. This section explores the various upgrades available to elevate your vehicle’s maneuverability and overall functionality.

One of the first areas to consider is the replacement of worn-out components with high-quality alternatives. Investing in premium bushings, links, and connectors can reduce play and enhance precision. Additionally, upgrading to a performance-driven assembly can provide a more robust structure that withstands rigorous use.

Another critical aspect involves the incorporation of modern technologies. Advanced systems, such as electronic controls or improved feedback mechanisms, can offer drivers greater responsiveness. These innovations help create a more intuitive and enjoyable driving experience.

Finally, regular maintenance of the enhanced components is essential for optimal performance. Ensuring that all elements are correctly lubricated and aligned will prolong their lifespan and maintain the quality of handling. By prioritizing these improvements, you can achieve the ultimate in driving satisfaction.

Tips for Enhancing Steering Performance

Optimizing the control system of your vehicle can significantly improve handling and responsiveness. By focusing on several key areas, you can achieve a smoother and more enjoyable driving experience. Here are some essential recommendations to enhance the performance of your directional control mechanism.

| Tip | Description |

|---|---|

| Regular Maintenance | Routine checks and servicing can prevent wear and ensure all components function properly. |

| Tire Quality | Using high-quality tires with the correct pressure enhances traction and control. |

| Alignment Check | Ensuring proper alignment prevents uneven tire wear and improves handling precision. |

| Upgrade Components | Investing in performance-enhancing upgrades can lead to better responsiveness and durability. |

| Regular Lubrication | Applying appropriate lubricants reduces friction and prolongs the lifespan of moving elements. |

Implementing these strategies can lead to a noticeable difference in your vehicle’s performance. A well-maintained and optimized control system not only enhances safety but also increases overall enjoyment while driving.

Preventive Measures for Steering Longevity

Ensuring the durability of your vehicle’s directional system requires regular attention and care. Implementing proactive strategies can significantly extend the lifespan of components and enhance overall performance.

Regular Inspections

- Check for wear and tear on all relevant components.

- Inspect fasteners for tightness and security.

- Examine the alignment to prevent uneven wear.

Lubrication Practices

- Apply appropriate grease to moving parts to reduce friction.

- Ensure that all joints are well-lubricated to enhance functionality.

- Regularly clean excess lubricant to prevent buildup.

Resources for Ezgo Parts and Support

When it comes to maintaining and upgrading your vehicle, having access to reliable resources is essential. Whether you are looking for components, guidance, or troubleshooting tips, numerous avenues can assist you in finding what you need. From official suppliers to community forums, a wealth of information is available to ensure your vehicle operates smoothly.

Official Suppliers and Retailers

Visiting authorized dealers is one of the best ways to obtain quality components. These suppliers often have extensive inventories and can provide expert advice on the best products for your specific model. Additionally, many official retailers offer online catalogs, making it easy to browse and order items from the comfort of your home.

Community Forums and Online Support

Engaging with fellow enthusiasts can be incredibly beneficial. Online forums and social media groups provide a platform for sharing experiences and solutions. You can ask questions, seek recommendations, and even find DIY guides. These communities are invaluable for anyone looking to enhance their understanding and maintenance skills.

In summary, utilizing a combination of authorized retailers and community resources can significantly improve your experience in managing your vehicle. Explore these options to ensure you have the right support at your fingertips.