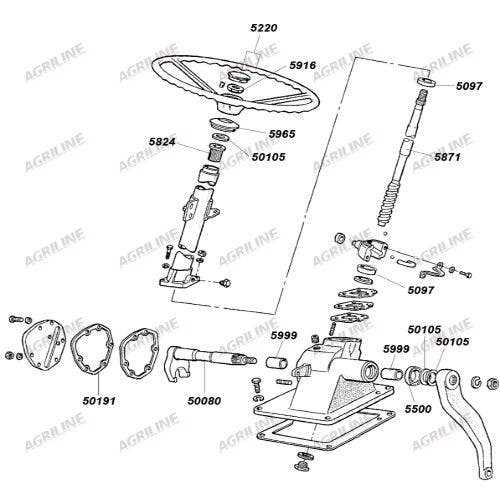

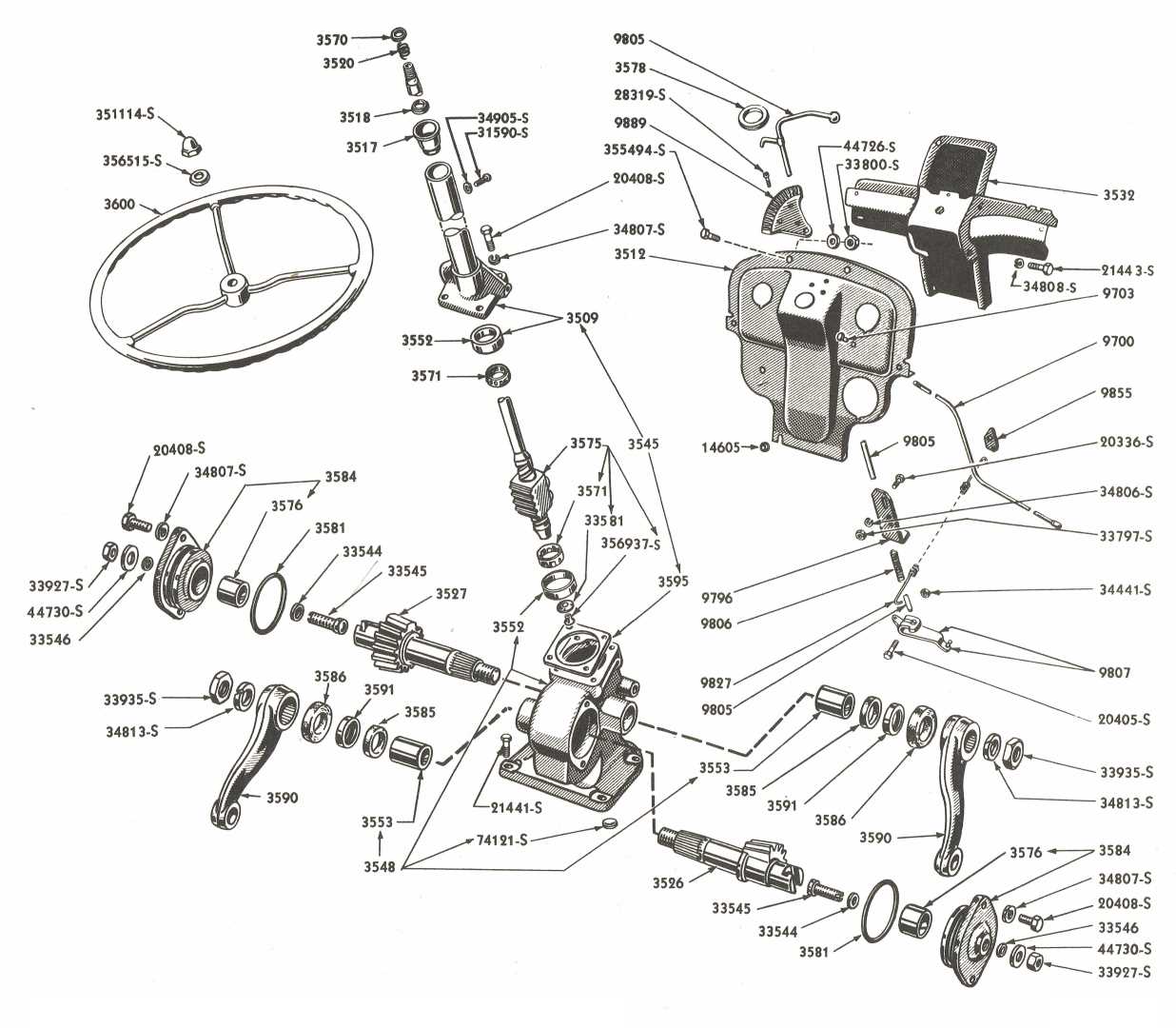

Ford 3000 Steering Components Diagram

Understanding the intricate elements of machinery is crucial for effective maintenance and operation. This section delves into the essential components involved in the management system, providing clarity on their roles and interactions. Knowledge of these elements enhances both troubleshooting and operational efficiency.

The illustration presented here serves as a comprehensive reference, detailing the various components that contribute to the maneuverability of the machine. Each element is meticulously identified, facilitating easy recognition and understanding of their specific functions within the overall system. This visual guide aids users in grasping how each part integrates into the larger assembly.

By familiarizing oneself with these crucial components, operators can ensure better performance and longevity of the machinery. Regular maintenance and proper adjustments are vital for optimal functionality, making this information invaluable for both novice and experienced users alike.

Understanding the Components

The functionality of a vehicle’s control mechanism relies on various essential elements working in harmony. These components ensure smooth navigation and precise handling, contributing to the overall driving experience. Familiarity with these elements can aid in better maintenance and troubleshooting.

Key Elements of the Control System

Central to the mechanism are the linkages, which connect the driver’s input to the wheels. These linkages transmit force, allowing for effective maneuvering. Additionally, the gearing system plays a vital role by adjusting the force and direction of the movement, enhancing responsiveness and control.

Maintenance and Care

Regular inspection of these components is crucial for optimal performance. Checking for wear and tear, ensuring proper lubrication, and tightening connections can prevent potential issues. Keeping these parts in good condition will ensure a reliable and safe driving experience.

Identifying Key Steering Parts

Understanding the essential components that facilitate direction control is crucial for efficient vehicle operation. These elements work in harmony to ensure responsive handling and stability, making them vital for safe navigation.

Main Components Overview

Key components involved in the directional control mechanism include the wheel assembly, linkages, and the control mechanism. Each of these elements contributes significantly to the overall performance and responsiveness of the vehicle.

Importance of Maintenance

Regular inspection and maintenance of these components are essential for optimal functionality. Proper care can prevent premature wear and ensure that the vehicle responds effectively to driver inputs.

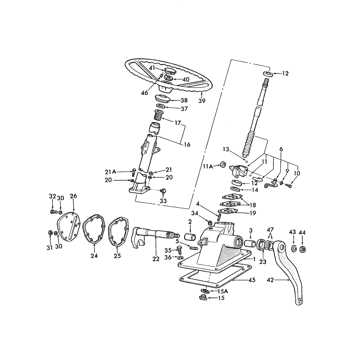

Exploring the Steering Gearbox

The mechanism responsible for directing the vehicle’s movement is crucial for ensuring optimal handling and control. This essential component translates the driver’s input into precise adjustments, allowing for smooth navigation and maneuverability.

Understanding the different elements that make up this mechanism can enhance maintenance and performance. Below is a table highlighting key components and their functions:

| Component | Function |

|---|---|

| Housing | Encloses and protects internal components. |

| Input Shaft | Connects the steering wheel to the gearbox. |

| Sector Shaft | Translates rotational movement into lateral movement. |

| Gear Teeth | Facilitate the transfer of motion and force. |

| Bearings | Reduce friction between moving parts. |

| Seals | Prevent contamination and fluid leakage. |

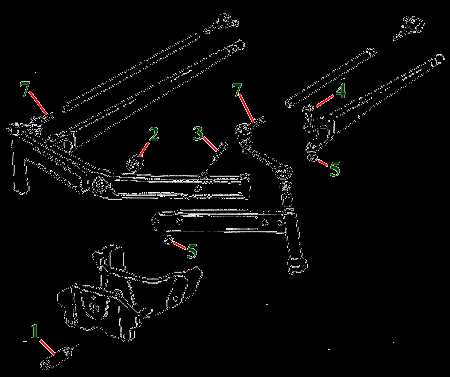

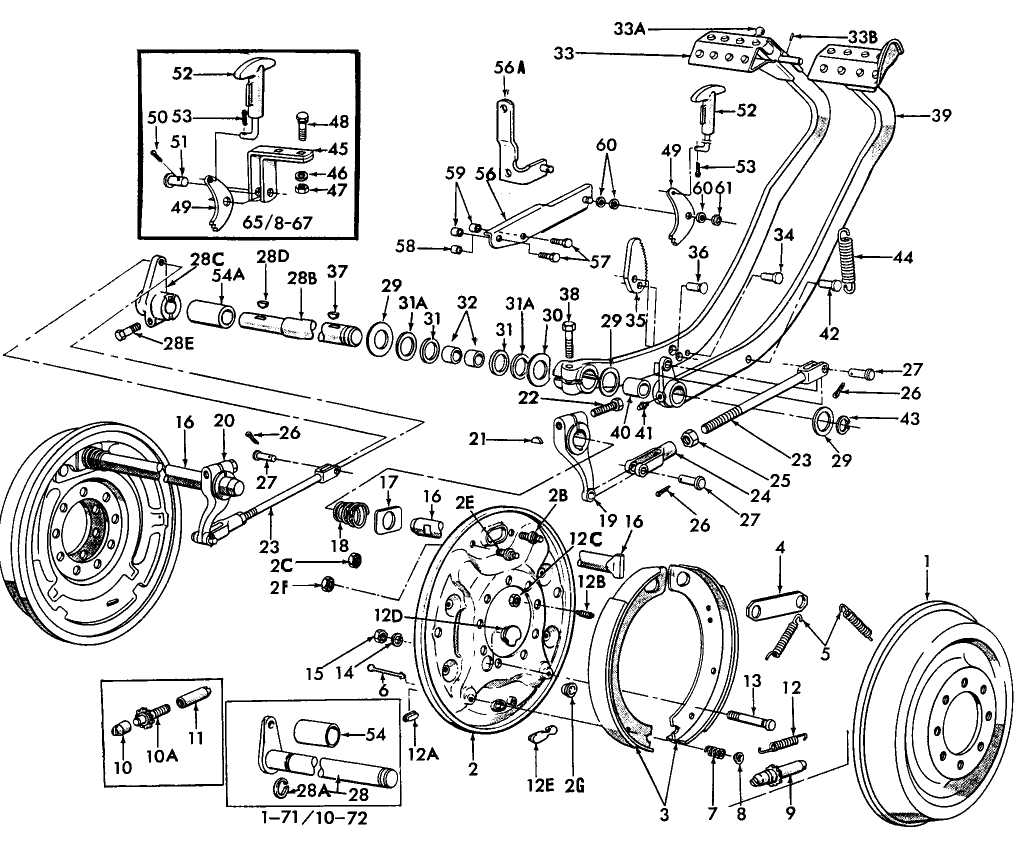

Analyzing the Steering Linkage

The linkage system plays a crucial role in the control and maneuverability of agricultural machinery. Understanding its components and functionality is essential for effective operation and maintenance. This section delves into the various elements that contribute to this system, ensuring optimal performance and safety.

Components of the Linkage System

The primary components include rods, joints, and connectors that facilitate the transfer of movement from the operator to the wheels. Each element must be carefully inspected for wear and tear to maintain reliability. Regular checks help prevent unexpected failures during operation.

Maintenance Practices

Implementing routine maintenance is vital for longevity. Lubrication of joints and connections reduces friction, while alignment adjustments ensure proper functionality. Monitoring for any signs of damage or misalignment can save time and resources in the long run.

Diagramming the Power Steering Setup

The arrangement of the hydraulic control system plays a crucial role in enhancing vehicle maneuverability. Understanding the configuration of this assembly can significantly improve maintenance practices and troubleshooting efforts. By visually representing the various components and their interconnections, one can gain valuable insights into how the system operates and where potential issues may arise.

Component Identification: Each element within the setup, such as the pump, hoses, and reservoir, serves a specific function that contributes to the overall effectiveness of the system. Familiarizing oneself with these components is essential for anyone looking to perform repairs or upgrades.

Flow and Function: Mapping out the flow of hydraulic fluid is vital for diagnosing problems. A clear representation allows one to track the movement of fluid throughout the assembly, ensuring that every part is functioning as intended. Properly diagramming this flow aids in identifying leaks or blockages that could hinder performance.

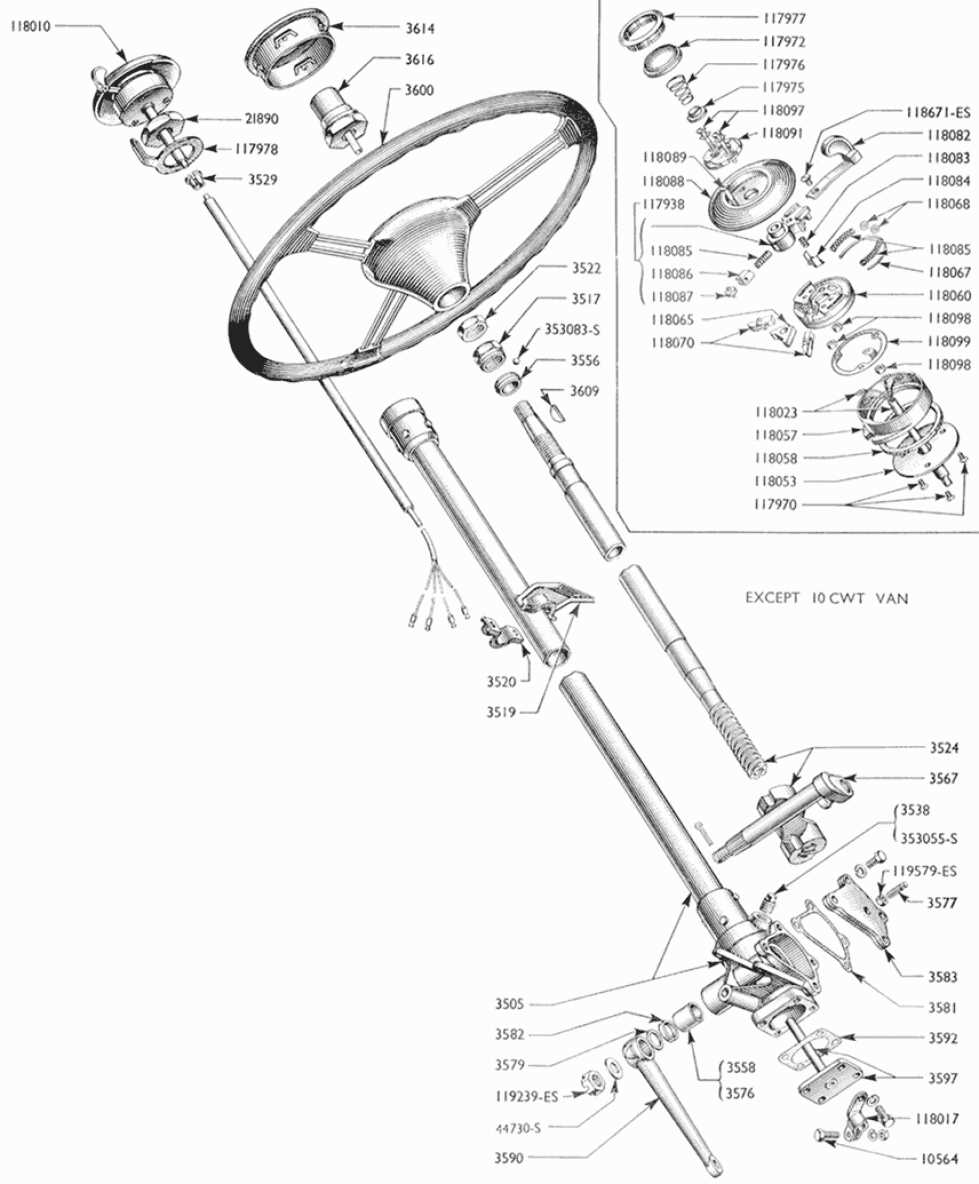

How to Interpret the Steering Diagram

Understanding a schematic representation of the control mechanism is crucial for effective maintenance and repair. This illustration serves as a visual guide, showcasing the interconnections and functionalities of various components involved in vehicle handling. Familiarizing oneself with the layout and symbols used can greatly enhance comprehension and troubleshooting skills.

Key Components to Identify

When examining the representation, it is essential to recognize the primary elements that contribute to the overall system’s functionality. These components can include various linkages, joints, and control devices that facilitate precise maneuvering.

Reading the Symbols

Different symbols are utilized to depict specific functions and connections within the mechanism. Mastering these symbols is vital for interpreting the information accurately and applying it to practical scenarios.

| Symbol | Description |

|---|---|

| Circle | Represents a pivot point or joint |

| Arrow | Indicates the direction of movement |

| Line | Shows connection between components |

| Square | Denotes a fixed point in the assembly |

Step-by-Step Guide to Using the Diagram

This section aims to provide a comprehensive approach to effectively utilizing a schematic representation of components for a specific vehicle model. Following these steps will help in understanding the layout and functionality of various elements, facilitating efficient troubleshooting and maintenance.

Understanding the Layout

Begin by familiarizing yourself with the overall arrangement shown in the illustration. Pay attention to the labels and symbols, which represent different elements. Recognizing these features is crucial for effective navigation through the schematic.

Following the Connections

Once you grasp the layout, focus on the connections indicated in the illustration. Trace the paths between components to understand how they interact. This insight will assist you in identifying potential issues or areas that require attention during repairs.

Common Issues and Troubleshooting Tips

When operating machinery, encountering certain challenges can impede performance. Recognizing these issues promptly is essential for effective resolution and maintaining optimal functionality.

Frequent Challenges

Operators often experience difficulties such as inconsistent response or unusual noises during operation. These symptoms may indicate underlying mechanical problems, such as wear in components or misalignment.

Resolving Issues

To address these concerns, first conduct a thorough inspection of the affected system. Look for signs of damage or wear. Regular maintenance can also prevent many common problems. If issues persist, consulting a professional can provide valuable insights into further actions needed.

Where to Find Replacement Parts

Locating suitable components for your machinery can be a straightforward process with the right resources. There are several avenues to explore, ensuring that you can obtain high-quality items that fit your needs perfectly.

Online Retailers

Numerous online platforms specialize in selling machinery components. Websites dedicated to equipment and accessories often provide a wide selection of items. Utilize search filters to narrow down your options, ensuring compatibility with your specific machinery model. Check user reviews to gauge the quality and reliability of the products.

Local Dealers and Distributors

Visiting local dealerships or authorized distributors can be advantageous. They often carry a variety of components and can offer expert advice on which items are best suited for your requirements. Establishing a relationship with local suppliers may also lead to better deals and faster access to essential items.

Best Practices for Maintenance

Regular upkeep is essential for ensuring the longevity and optimal performance of machinery. By following a set of best practices, operators can effectively minimize wear and tear, enhance safety, and prevent unexpected breakdowns. This approach not only improves functionality but also extends the lifespan of critical components.

Routine Inspections

Conducting frequent inspections helps identify potential issues before they escalate into major problems. Check for signs of wear, leaks, or unusual noises during these evaluations.

Proper Lubrication

Using the appropriate lubricants at specified intervals is crucial for reducing friction and preventing overheating. Always follow manufacturer recommendations regarding lubrication points and products.

| Maintenance Activity | Frequency | Notes |

|---|---|---|

| Visual Inspection | Weekly | Look for wear and damage. |

| Lubrication | Monthly | Use recommended products. |

| Full Maintenance Check | Annually | Conduct a thorough evaluation. |