Comprehensive Parts Diagram for 2000 Yamaha Big Bear 400

When it comes to maintaining your off-road machine, having a comprehensive grasp of its individual elements is crucial. Whether you’re tackling routine upkeep or embarking on a more significant restoration, familiarity with each section of your vehicle can greatly enhance your experience. This knowledge not only aids in identifying potential issues but also empowers you to make informed decisions during repairs.

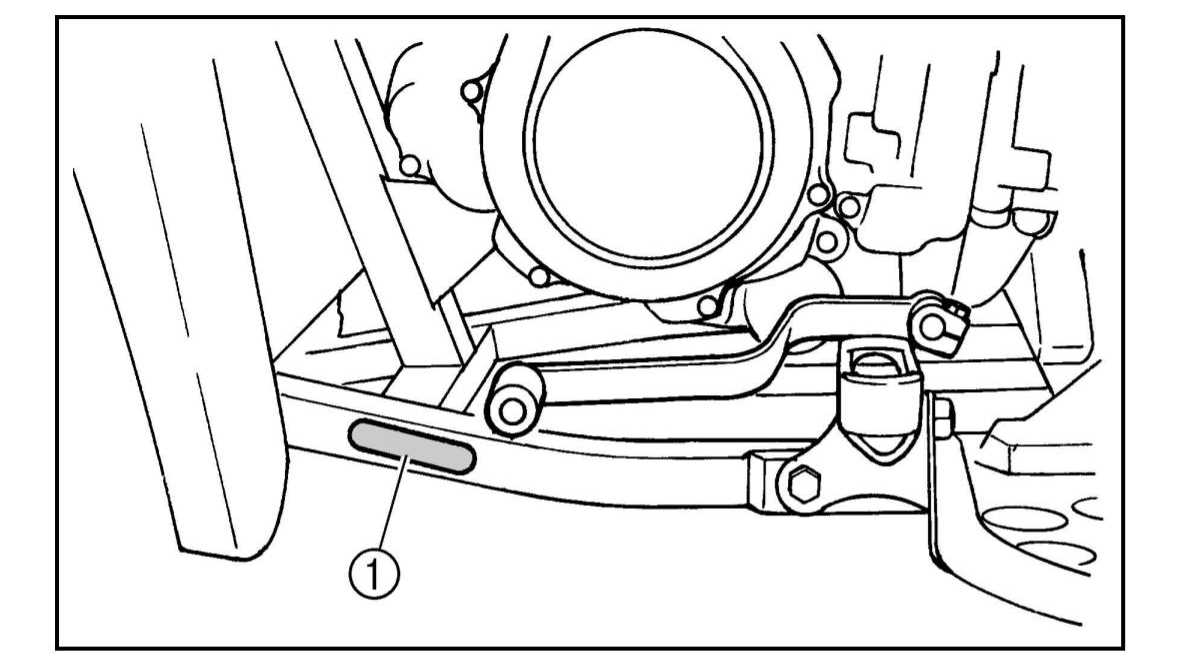

Visual representations of your vehicle’s architecture can be invaluable tools. They offer a clear insight into how various components fit together and function in harmony. With a detailed layout, you can pinpoint specific areas that may require attention, ensuring that every aspect of your ride operates smoothly and efficiently.

Moreover, understanding the intricate relationships between different elements allows for more effective troubleshooting. By recognizing where parts connect and interact, you can isolate problems more easily and avoid unnecessary complications. This approach not only saves time but also enhances your overall understanding of the machinery, paving the way for more successful maintenance and upgrades.

Overview of Yamaha Big Bear 400

This section provides a comprehensive look at a versatile off-road vehicle renowned for its reliability and performance. Designed for both recreational use and utility, it combines power with comfort, making it a popular choice among enthusiasts and outdoor workers alike.

Key Features

This remarkable machine stands out due to its robust build and user-friendly features. Its capable engine and well-thought-out suspension ensure a smooth ride across various terrains. Additionally, it offers a range of accessories that enhance functionality and adaptability.

| Feature | Description |

|---|---|

| Engine | High-performance power unit providing excellent torque and acceleration. |

| Transmission | Efficient gearing system that allows for seamless transitions and handling. |

| Suspension | Advanced setup ensuring stability and comfort over rough surfaces. |

| Durability | Built with high-quality materials to withstand harsh conditions and heavy usage. |

Applications

This vehicle excels in various roles, from farm work to recreational activities. Its ability to navigate challenging landscapes makes it an ideal companion for outdoor adventures, while its utility capabilities serve practical needs efficiently.

Key Specifications of the 2000 Model

This section provides an overview of the essential features and characteristics that define this particular all-terrain vehicle. Understanding these specifications is crucial for enthusiasts and potential buyers who seek reliable performance and versatility in off-road adventures.

The engine is a robust four-stroke design, delivering ample power for various terrains. Its displacement allows for smooth acceleration and efficient torque, ensuring a responsive ride. The transmission system offers multiple gears, facilitating easy navigation through challenging landscapes.

Suspension plays a vital role in comfort and handling. This model is equipped with an advanced setup that absorbs shocks and enhances stability, making it suitable for both rugged trails and smoother paths. The frame is constructed from durable materials, contributing to the vehicle’s overall strength and longevity.

The braking system features hydraulic disc brakes, ensuring reliable stopping power under different conditions. Additionally, the vehicle is designed with an ergonomic layout, providing comfort for long rides and easy access to controls.

Storage options are practical, allowing riders to carry necessary gear while maintaining balance and agility. The overall design emphasizes functionality and durability, making it a preferred choice among outdoor enthusiasts.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations of these elements not only aid in identifying individual pieces but also enhance the overall comprehension of how everything fits together. This clarity is essential for both novice and experienced users alike, ensuring that they can navigate the complexities of their equipment with confidence.

Utilizing these visual guides allows for quicker troubleshooting, as users can easily pinpoint issues and determine necessary replacements. Furthermore, these schematics foster a deeper knowledge of the device’s functionality, enabling individuals to make informed decisions about upgrades or modifications. In essence, they serve as invaluable resources for anyone engaged in upkeep or restoration efforts.

In addition, having access to detailed illustrations can streamline the ordering process for replacements. Knowing exactly what is needed reduces the likelihood of errors and delays, saving both time and resources. As such, these tools are not merely helpful; they are essential for maintaining the longevity and performance of any mechanical system.

Understanding ATV Maintenance Basics

Regular upkeep of all-terrain vehicles is essential for ensuring longevity and optimal performance. By adhering to a consistent maintenance routine, enthusiasts can prevent mechanical issues and enhance the riding experience. This guide outlines fundamental practices that every owner should consider for their vehicle’s health.

Essential Maintenance Tasks

To keep an ATV running smoothly, several key maintenance tasks should be prioritized. These activities not only prolong the vehicle’s lifespan but also improve safety during rides. Below is a summary of vital tasks:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50-100 hours | Replace old oil to maintain engine performance and reduce wear. |

| Air Filter Cleaning | Every ride or as needed | Keep the air filter clean to ensure optimal airflow to the engine. |

| Tire Inspection | Before each ride | Check tire pressure and tread for safe handling. |

| Brake System Check | Monthly | Inspect brake pads and fluid levels for effective stopping power. |

Importance of Seasonal Maintenance

Seasonal maintenance is crucial for adapting to varying riding conditions. During colder months, specific preparations help safeguard the vehicle against harsh elements. Likewise, pre-ride checks in warmer seasons ensure readiness for off-road adventures. Understanding these seasonal requirements can lead to enhanced durability and reliability of the vehicle.

Common Issues with the Big Bear 400

This section explores frequent problems encountered with a specific off-road vehicle model, highlighting the common challenges that users face and offering insights into maintenance and repairs.

Mechanical Concerns

- Engine performance issues, including difficulty starting and loss of power.

- Transmission problems, such as slipping gears or rough shifting.

- Brake system failures, leading to decreased stopping capability.

Electrical Troubles

- Battery drainage, often due to faulty wiring or poor connections.

- Lighting malfunctions, which can stem from blown fuses or defective bulbs.

- Starter issues, where the motor may fail to engage consistently.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and restoration tasks. Each job demands specific instruments to ensure efficiency and precision. A well-organized toolkit not only streamlines the repair process but also enhances the overall experience.

Wrenches are fundamental for loosening and tightening various components. Investing in a quality set that includes both standard and metric sizes will cover a wide range of applications. Additionally, screwdrivers in different shapes and sizes are essential for accessing screws in various locations.

Pliers come in handy for gripping, twisting, and cutting materials, making them versatile for multiple tasks. A pair of needle-nose pliers can be particularly useful for reaching tight spaces. Moreover, having a reliable socket set is important for quickly changing bolts and nuts.

Another critical tool is a ratchet, which provides the necessary torque without excessive effort. For those involved in more intricate repairs, a torque wrench is indispensable for ensuring that fasteners are tightened to the correct specifications.

Lastly, don’t overlook the importance of safety gear. Items such as gloves, goggles, and masks protect against potential hazards while working. Having these essential tools at your disposal will significantly improve your repair capabilities and contribute to successful outcomes.

Where to Find Replacement Parts

Finding suitable components for your vehicle can be a straightforward task if you know where to look. Numerous resources are available to help you locate the necessary items, whether you’re restoring an older model or simply maintaining your current ride. It’s important to explore various avenues to ensure you get quality replacements that fit your needs.

Online Retailers

The internet is a treasure trove of options. Numerous e-commerce platforms specialize in automotive components, offering a wide selection that includes both original equipment and aftermarket alternatives. Popular sites often provide detailed descriptions, user reviews, and competitive pricing, making it easier to compare different products before making a decision.

Local Dealerships and Repair Shops

Your local dealership can be an excellent resource for authentic items. They typically carry inventory specific to your model and can offer insights on the latest upgrades or enhancements. Additionally, independent repair shops often have connections with suppliers and may assist in locating hard-to-find items, ensuring you have access to reliable options tailored to your specific requirements.

Aftermarket vs. OEM Components

When it comes to vehicle repairs and upgrades, enthusiasts often face the choice between original equipment manufacturer (OEM) parts and those produced by third-party manufacturers. Each option presents its own set of advantages and disadvantages, which can significantly impact performance, longevity, and cost-effectiveness.

Understanding the Options

OEM components are crafted by the vehicle’s original manufacturer, ensuring compatibility and quality that aligns with the original specifications. Conversely, aftermarket products are developed by independent companies, offering a variety of alternatives that may enhance performance or provide cost savings.

Benefits and Drawbacks

- OEM Components:

- Guaranteed fit and compatibility

- High-quality materials and craftsmanship

- Often backed by warranties

- Aftermarket Components:

- Potential for enhanced performance features

- Usually more affordable options

- A wider range of choices for customization

Ultimately, the decision between aftermarket and OEM parts depends on individual needs, budget considerations, and desired performance outcomes. Each choice carries its own implications, making it crucial to weigh the options carefully before proceeding with repairs or enhancements.

Tips for Proper Installation

Ensuring a successful assembly of your vehicle components requires attention to detail and careful execution. By following best practices, you can avoid common pitfalls and achieve optimal performance.

Preparation Steps

- Review the assembly manual thoroughly to understand the components and their placements.

- Gather all necessary tools and replacement items before starting the process.

- Work in a clean, organized area to prevent loss of small parts and maintain focus.

Installation Techniques

- Always start with a dry run to familiarize yourself with the assembly without any fasteners.

- Follow a logical sequence when attaching components to avoid confusion.

- Use the correct torque settings for fasteners to prevent over-tightening or loosening.

- Double-check alignments and clearances before securing components completely.

By adhering to these guidelines, you can enhance the longevity and reliability of your machine while ensuring a smooth installation process.

Resources for DIY Repairs

Engaging in self-repair projects can be both fulfilling and cost-effective. With the right tools and information, anyone can tackle maintenance tasks and enhance their understanding of mechanical systems. Below are various resources that can assist you in your DIY endeavors.

- Online Forums: Communities of enthusiasts often share valuable tips, troubleshooting advice, and personal experiences. Participating in discussions can provide insight into common issues and solutions.

- Video Tutorials: Platforms like YouTube feature countless instructional videos that demonstrate repair techniques step-by-step, making complex tasks more accessible.

- Repair Manuals: Obtaining a comprehensive manual specific to your model can provide detailed instructions, diagrams, and specifications necessary for repairs.

- Parts Suppliers: Many websites specialize in aftermarket and original components. These can help you find the exact items needed for your project.

- Local Workshops: Participating in hands-on workshops can enhance your skills and offer practical advice from experienced mechanics.

Utilizing these resources can greatly simplify the repair process and empower you to confidently address issues as they arise.

Upgrades to Enhance Performance

Improving the capabilities of your all-terrain vehicle can significantly enhance your riding experience. Various modifications can be made to boost power, handling, and overall efficiency. By focusing on key components, enthusiasts can achieve noticeable performance gains while maintaining reliability.

Engine Modifications: Upgrading the engine is one of the most effective ways to increase horsepower and torque. Options include installing a high-performance air filter and exhaust system, which can improve airflow and enhance engine efficiency. Tuning the fuel injection system may also optimize performance for different riding conditions.

Suspension Enhancements: A well-tuned suspension is crucial for handling rough terrain. Consider replacing stock shocks with adjustable aftermarket options. This allows for customization based on weight, riding style, and terrain type, leading to better stability and control.

Tire Upgrades: Choosing the right tires can dramatically affect traction and handling. All-terrain or mud-specific tires can improve grip and performance in challenging conditions. Additionally, ensuring the correct tire pressure can enhance comfort and maneuverability.

Braking System Improvements: Enhancing the braking system is vital for safety and control. Upgrading to performance brake pads and rotors can provide better stopping power and responsiveness. Regular maintenance of the braking components is also essential for optimal performance.

Implementing these enhancements can lead to a more enjoyable and capable riding experience. Always consider the compatibility of upgrades with your specific model to ensure optimal results.