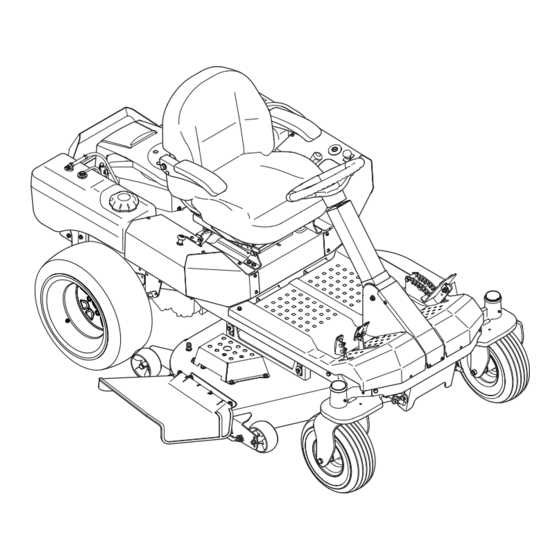

Complete Parts Diagram for Cub Cadet Z-Force 50

In the world of outdoor maintenance equipment, familiarity with the internal structure is essential for optimal performance. A comprehensive exploration of the layout of essential elements can greatly enhance both efficiency and longevity. By grasping how different sections interact, users can ensure smooth operation and timely repairs.

Visual representation of machinery components serves as a valuable resource for both seasoned professionals and newcomers alike. An organized layout not only simplifies the identification of individual parts but also aids in troubleshooting common issues. Understanding these connections can lead to improved maintenance practices and a better grasp of the equipment’s overall functionality.

Whether tackling routine upkeep or addressing specific malfunctions, having a clear view of how various elements fit together is crucial. This knowledge empowers users to make informed decisions, ensuring their equipment remains in peak condition for years to come. Dive into the intricacies of these schematics to unlock the full potential of your lawn care tool.

Understanding the Cub Cadet Z-Force 50

This section explores a popular model of riding mower, known for its efficiency and maneuverability. It is designed to handle a variety of tasks, making it a reliable choice for homeowners and professionals alike. Familiarizing oneself with its components and functionality enhances the user experience and maintenance efficiency.

Key features of this mower include:

- Powerful engine options for effective cutting performance

- Robust construction for durability and longevity

- Advanced steering system for easy navigation

- Comfortable seating to enhance operator experience

Regular maintenance is crucial for optimal performance. Key maintenance tasks include:

- Checking and replacing the oil regularly

- Inspecting blades for wear and sharpening them as needed

- Cleaning air filters to ensure proper airflow

- Examining tires for proper inflation and wear

Understanding these elements can significantly improve the lifespan and efficiency of the mower. Knowledge of the inner workings allows for better troubleshooting and repairs, ensuring a smooth operation for years to come.

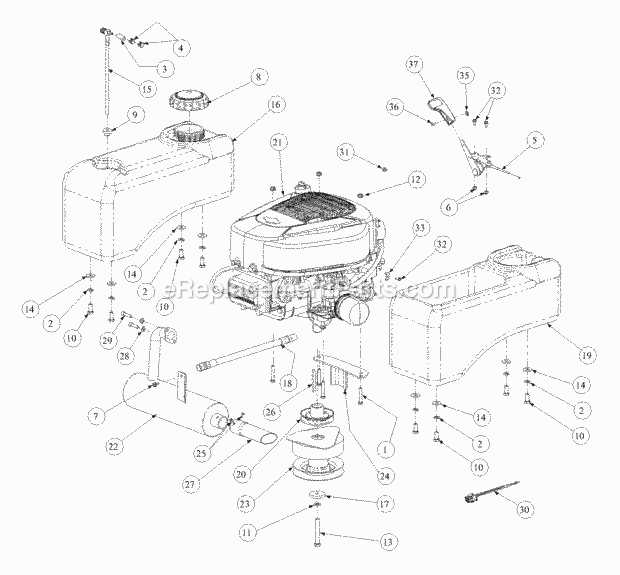

Key Components of the Mower

Understanding the essential elements of a mower is crucial for optimal performance and maintenance. Each component plays a significant role in ensuring that the machine operates efficiently, providing a smooth cutting experience and enhancing longevity.

Major Elements

The main parts that contribute to the overall functionality include the engine, cutting deck, transmission, and wheels. Each part must work harmoniously to achieve the desired results.

Table of Key Components

| Component | Description |

|---|---|

| Engine | Powers the mower and drives the cutting blades. |

| Cutting Deck | Houses the blades and defines the width of the cut. |

| Transmission | Controls the movement and speed of the mower. |

| Wheels | Provide mobility and stability during operation. |

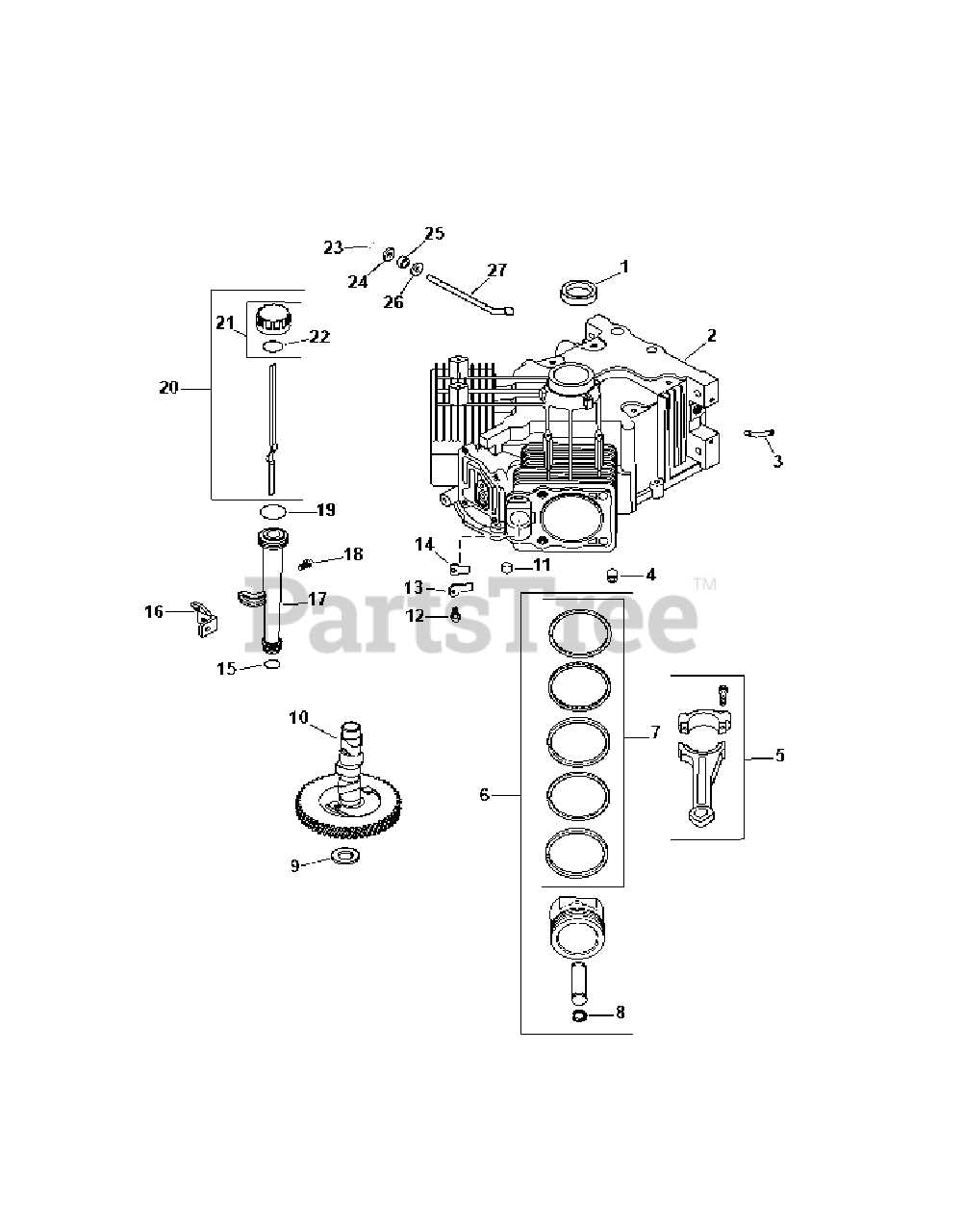

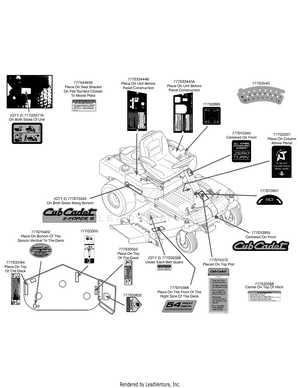

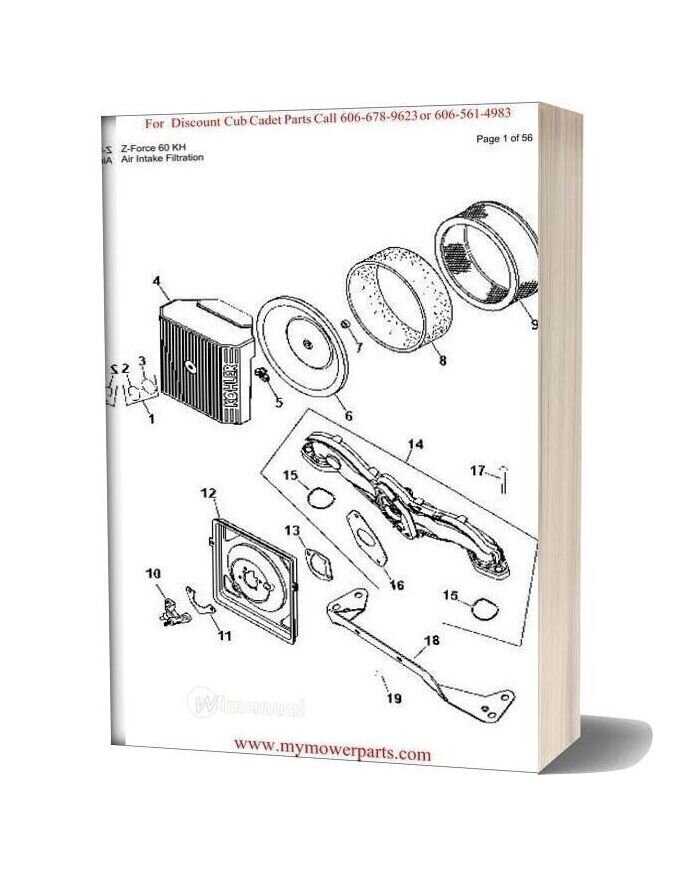

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. They simplify the identification of various elements, facilitating a better understanding of the assembly and disassembly processes. This clarity helps users troubleshoot issues efficiently, ensuring that repairs are conducted accurately.

Enhanced Understanding

Utilizing visual aids allows operators to grasp complex structures quickly. By breaking down machinery into manageable segments, users can focus on specific areas without becoming overwhelmed.

Improved Maintenance

Regular upkeep is essential for optimal performance. Clear illustrations guide users in recognizing wear and tear, making it easier to schedule replacements and repairs, ultimately prolonging the lifespan of the equipment.

| Benefit | Description |

|---|---|

| Clarity | Simplifies identification of components. |

| Efficiency | Facilitates quicker troubleshooting. |

| Longevity | Supports timely maintenance and repairs. |

How to Read Parts Diagrams

Understanding illustrations that depict components can greatly enhance your ability to identify and locate specific items in machinery. These visual guides provide a systematic way to understand how each piece interacts within the overall structure. Mastering this skill can ultimately simplify maintenance and repairs, ensuring your equipment remains in top condition.

Key Elements to Focus On

When examining these illustrations, pay close attention to labels and part numbers. Each item typically has a unique identifier, often accompanied by descriptions that clarify its function. Familiarize yourself with the layout, as it usually follows a logical order, grouping related components together.

Utilizing the Information

Once you’ve grasped the essential details, use the information to guide your procurement of replacements or upgrades. Ensure that you cross-reference the identifiers with available resources or suppliers to find the exact match for your needs. This approach will save time and minimize errors during your repair process.

Common Replacement Parts for Z-Force 50

Maintaining the efficiency of your lawn mower is crucial for optimal performance. Over time, certain components may wear out and require replacement. Understanding the common elements that often need to be swapped can help ensure your machine operates smoothly.

Blades: One of the most frequently replaced components are the cutting blades. Dull or damaged blades can result in uneven cutting, making regular replacement essential for maintaining a pristine lawn.

Belts: Drive and mower belts are also subject to wear and tear. Cracks or fraying can lead to decreased performance, so monitoring their condition and replacing them as needed is vital.

Filters: Air and oil filters play a significant role in engine performance. Clogged filters can reduce efficiency and increase fuel consumption, making timely changes important for long-term functionality.

Batteries: As with any powered equipment, batteries may need replacement over time. A weak battery can hinder starting and overall performance, so keeping an eye on battery health is advisable.

Tires: Maintaining proper tire condition is essential for maneuverability and traction. Worn or damaged tires should be replaced to ensure stability and safety while operating.

By staying informed about these essential components, you can keep your mower in peak condition and extend its lifespan significantly.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires regular care and attention. Implementing a routine maintenance schedule can significantly enhance its lifespan and efficiency, minimizing the likelihood of unexpected breakdowns.

Routine Checks

Conducting periodic inspections is essential. Look for signs of wear and tear, and ensure all components are functioning correctly. A proactive approach can prevent larger issues down the line.

Cleaning and Lubrication

Keep your machinery clean from debris and grime. Regularly lubricate moving parts to reduce friction and wear, promoting smoother operation.

| Maintenance Task | Frequency |

|---|---|

| Inspect Belts and Blades | Every 20 hours |

| Change Oil | Every 50 hours |

| Clean Air Filters | Every season |

| Sharpen Blades | As needed |

Where to Find Replacement Parts

Finding components for your lawn care equipment can be a straightforward task if you know where to look. Numerous resources are available, ranging from online retailers to local shops, making it easier to source what you need for maintenance or repairs.

Online Retailers

The internet is a treasure trove for sourcing necessary components. Websites specializing in outdoor equipment often provide extensive catalogs, allowing you to search by model or category. Popular marketplaces also feature a variety of vendors, offering competitive prices and user reviews to aid your decision-making.

Local Dealers and Repair Shops

Your local dealers and repair shops can be invaluable resources. They often stock essential items and may even have connections to order specialized equipment. Additionally, their expertise can help you identify the right pieces for your machine.

Assembly Instructions for Key Parts

Understanding the assembly process of essential components is crucial for optimal performance and maintenance. Proper installation ensures longevity and efficiency of your equipment. The following guide outlines the steps necessary for assembling key elements effectively.

-

Engine Mounting

- Begin by positioning the engine onto the frame.

- Align the mounting holes and secure with bolts, ensuring a tight fit.

- Connect the throttle and choke cables, following manufacturer specifications.

-

Blade Installation

- Place the blades on the spindle assembly, ensuring correct orientation.

- Use a torque wrench to tighten the blade bolts to the recommended specifications.

- Verify the blades are level for optimal cutting performance.

-

Wheels and Tires

- Attach the wheels to the axle, ensuring they are seated correctly.

- Inflate the tires to the recommended pressure for stability.

- Double-check all lug nuts for security after initial use.

-

Electrical Connections

- Identify the wiring harness and connect all cables as indicated in the manual.

- Secure connections with zip ties to prevent movement.

- Test the electrical system before final assembly to ensure functionality.

By following these instructions, you will enhance the reliability and performance of your machinery. Regular checks and maintenance after assembly will help in prolonging the lifespan of these key components.

Troubleshooting Common Issues

Maintaining optimal performance of your equipment requires understanding and addressing frequent complications. Identifying symptoms early can prevent further damage and ensure efficient operation. This section outlines common challenges and solutions to enhance your overall experience.

Engine Performance Problems

If the engine fails to start or runs inconsistently, check the fuel supply, spark plug condition, and air filter cleanliness. Inspecting these components can often reveal simple fixes. Regular maintenance can significantly reduce these occurrences.

Cutting Deck Issues

Uneven cutting can stem from dull blades or improper deck height. Sharpening blades and adjusting the deck can lead to a more uniform cut. Additionally, ensure that the drive belts are in good condition, as they play a crucial role in the overall functionality.

Comparing Z-Force 50 to Other Models

When evaluating different mower options, it’s essential to understand how one model stacks up against its competitors. This analysis focuses on performance, features, and user experience, highlighting the strengths and weaknesses of the mower in question compared to similar products.

- Engine Power: The horsepower of various models varies significantly, influencing cutting efficiency and handling of challenging terrains.

- Cutting Width: Different models offer a range of cutting widths, which affects the time taken to mow larger areas.

- Durability: The materials used and overall build quality can determine longevity and maintenance needs.

- User Comfort: Ergonomics play a crucial role; seat design and controls can enhance or detract from the mowing experience.

In conclusion, understanding these differences helps consumers make informed decisions based on their specific needs and preferences.

Owner Experiences and Reviews

Exploring the insights of users who have engaged with their mowing machines reveals a wealth of knowledge. These personal accounts provide a nuanced understanding of performance, durability, and ease of maintenance, helping potential buyers make informed decisions.

Positive Feedback

Many users praise the robust construction and reliability of their machines. They often highlight the smooth operation and effective cutting performance, noting that the equipment handles various terrains with ease. The comfortable seating and intuitive controls are also frequently mentioned, contributing to a pleasant mowing experience.

Challenges Faced

While the majority of experiences are favorable, some owners report issues with specific components over time. Common concerns include the need for periodic adjustments and occasional maintenance tasks. These insights underscore the importance of regular upkeep to ensure long-lasting performance.