Understanding the Components of a Pressure Washer

In the world of high-efficiency cleaning tools, a thorough comprehension of their components is essential for optimal performance. Each segment plays a vital role in ensuring the unit operates smoothly, delivering impressive results for various tasks. A well-maintained machine not only enhances effectiveness but also prolongs its lifespan, making knowledge of its internal structure invaluable.

Every element within these devices serves a specific function, from generating powerful streams to controlling the flow of water. By familiarizing oneself with the arrangement and interactions of these elements, users can troubleshoot issues more effectively and undertake necessary maintenance. This understanding empowers operators to make informed decisions about repairs and upgrades, enhancing their cleaning capabilities.

Moreover, recognizing how these components work together fosters a deeper appreciation for the technology behind modern cleaning solutions. As tasks become more demanding, having a clear insight into the machinery’s configuration ensures that users can harness its full potential. Ultimately, this knowledge transforms routine cleaning into a more efficient and satisfying experience.

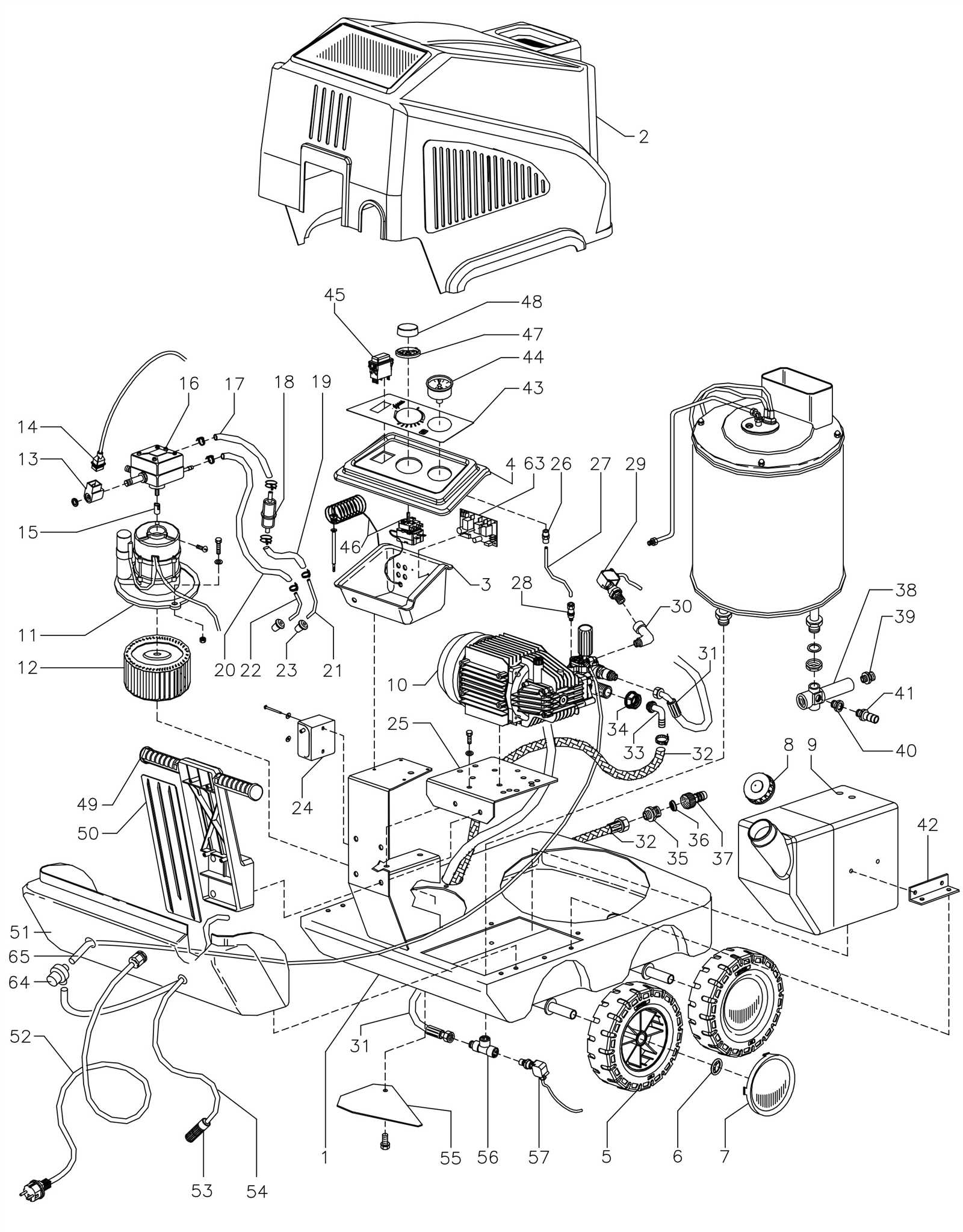

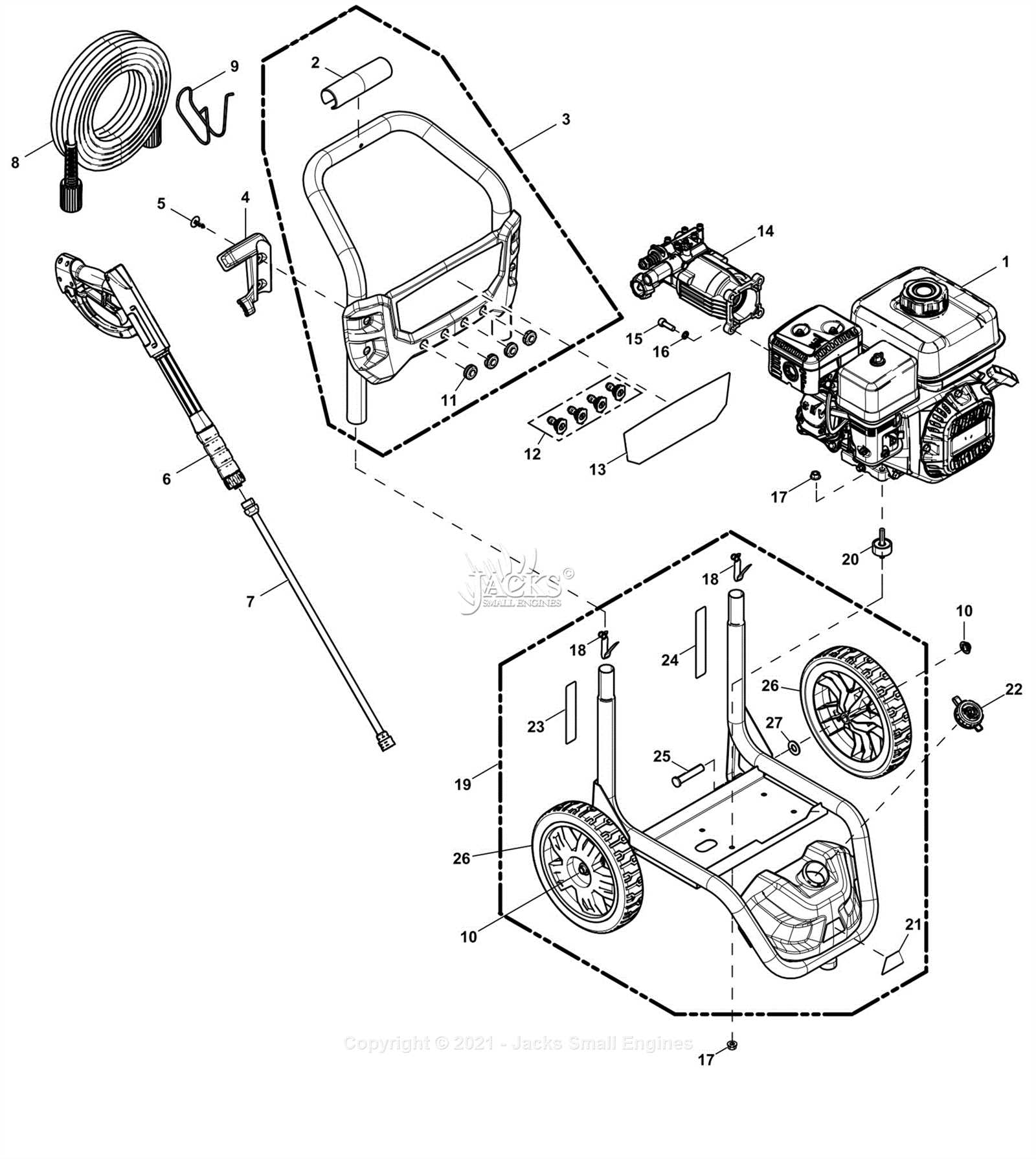

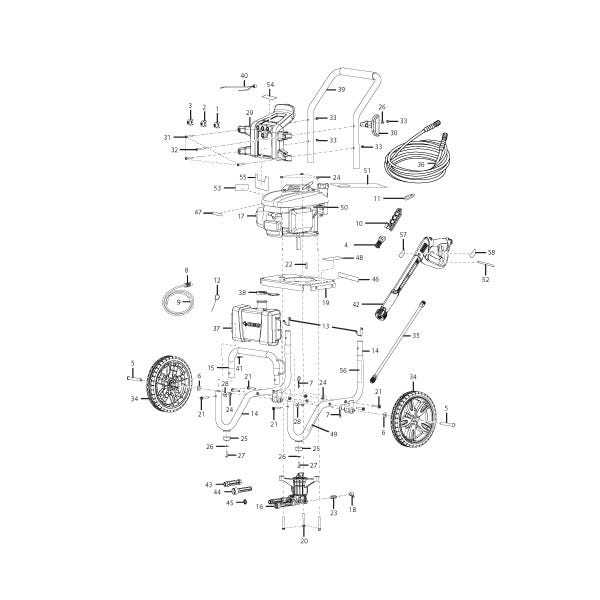

Understanding Pressure Washer Components

In the realm of outdoor cleaning tools, various elements work together to ensure efficiency and effectiveness. Each component plays a critical role, contributing to the overall functionality and performance of the equipment. Familiarity with these elements can enhance your maintenance practices and improve operational understanding.

Key components include:

- Motor or Engine: The powerhouse that drives the unit, providing the necessary force to generate high-speed water flow.

- Pump: This crucial component elevates the water pressure, allowing for powerful cleaning action.

- Nozzle: Different types adjust the spray pattern, affecting the cleaning intensity and coverage.

- Hoses: Essential for directing the flow of water from the source to the cleaning area, ensuring flexibility and reach.

- Trigger Gun: The control mechanism that allows users to start and stop the water flow easily.

- Filter: Protects the internal components by trapping debris and contaminants from the water supply.

- Wheels: Facilitate mobility, making it easier to transport the unit across various terrains.

Understanding these elements helps users appreciate the mechanics behind the tool, leading to better maintenance and usage practices. Regular inspection and care can prolong the lifespan and enhance performance, ensuring optimal results in all cleaning tasks.

Types of Pressure Washer Models

Understanding the various types of cleaning machines available can help users choose the right tool for their needs. Each model is designed to tackle specific tasks, making it essential to recognize their unique features and applications.

Electric models are popular for household use due to their lightweight design and ease of operation. They are ideal for small jobs, such as cleaning patios or vehicles, and are generally quieter than their gas counterparts.

Gas-powered variants are more robust and suitable for heavy-duty tasks. These machines deliver higher performance, making them perfect for commercial use or larger residential projects, such as removing tough stains from driveways or decks.

Portable models offer convenience and flexibility, often designed for on-the-go cleaning. Their compact size allows for easy storage and transport, making them an excellent choice for those with limited space or who require mobility.

Finally, there are specialized machines tailored for specific applications, such as hot water units for grease removal or cold water models for everyday cleaning. Choosing the right type ensures efficiency and effectiveness in any cleaning endeavor.

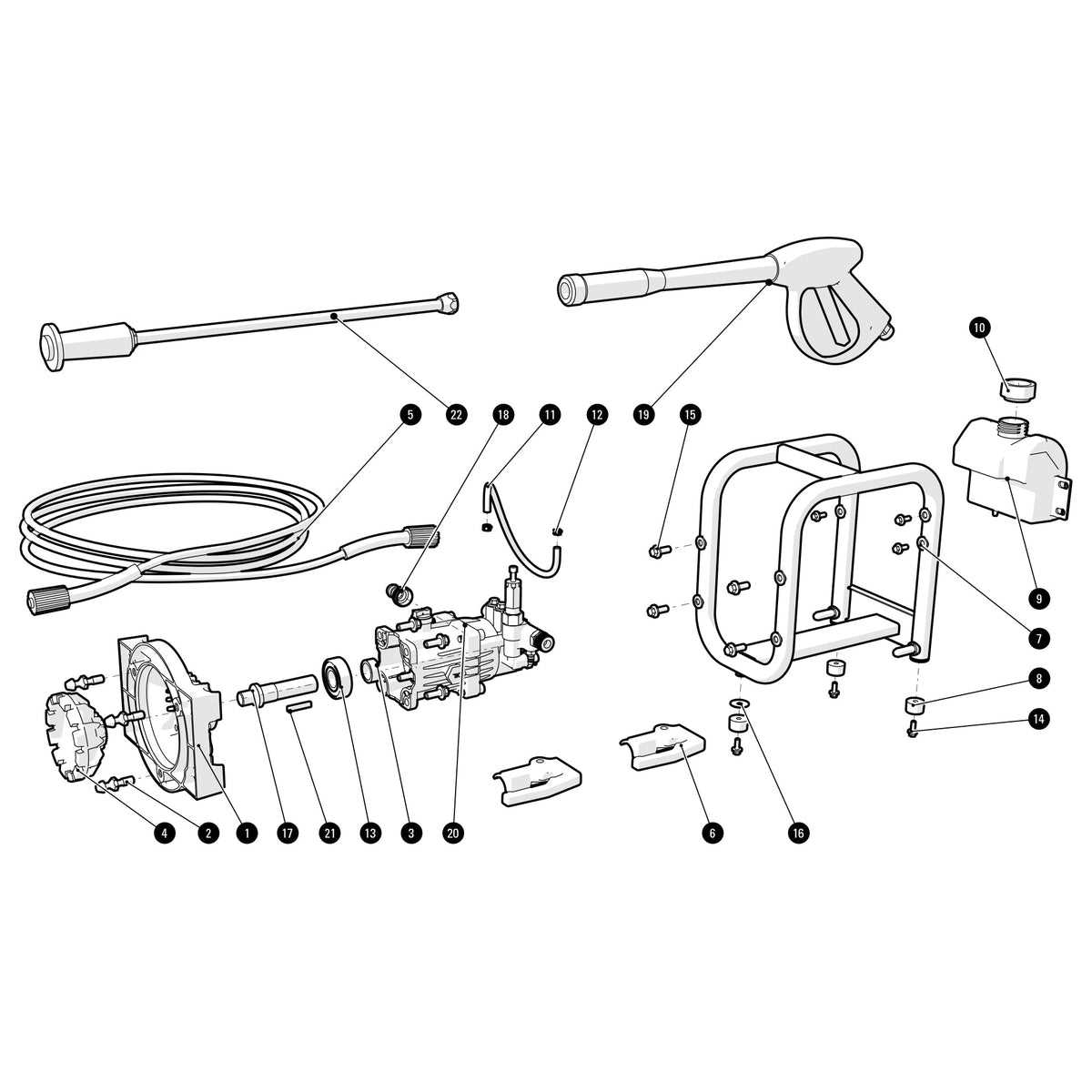

Key Parts of a Pressure Washer

Understanding the essential components of a cleaning machine is crucial for effective operation and maintenance. Each element plays a significant role in ensuring optimal performance, contributing to efficiency and longevity. Familiarity with these crucial segments allows users to troubleshoot issues and enhance the overall cleaning experience.

Motor or Engine: This is the powerhouse of the equipment, providing the necessary energy to generate high-pressure fluid. Depending on the model, it can be electric or gas-powered, each with its advantages.

Pump: Often regarded as the heart of the system, the pump elevates the fluid’s pressure, enabling it to be expelled forcefully. It transforms the rotational energy from the motor into hydraulic energy.

Hose: The flexible tubing connects the pump to the nozzle, facilitating the flow of the pressurized fluid. Its durability and length can affect maneuverability and reach during cleaning tasks.

Nozzle: This component directs the flow of the fluid, allowing users to adjust the spray pattern. Different types can cater to various cleaning needs, from wide sprays for gentle cleaning to narrow jets for stubborn grime.

Trigger Gun: The user interface for operating the equipment, the trigger gun controls the release of the fluid. A safety latch is often included to prevent accidental activation.

Detergent Tank: Many models come with a built-in reservoir for cleaning agents, which can enhance the effectiveness of the cleaning process. It allows for easy mixing and application of soap during use.

Wheels: Mobility is essential for maneuvering the device around different areas. Sturdy wheels enable ease of transport across various surfaces.

Familiarity with these critical elements equips users to make informed decisions about maintenance, repairs, and upgrades, ultimately maximizing the effectiveness of their cleaning endeavors.

Function of the High-Pressure Hose

The high-pressure hose is a crucial component that enables the effective transfer of water from the motor unit to the nozzle. It is designed to withstand intense force and ensure that the fluid maintains its velocity, allowing for efficient cleaning and rinsing. Understanding its function helps in maintaining and optimizing the overall system performance.

Key Features and Benefits

One of the primary features of this hose is its robust construction, which allows it to handle elevated levels of stress without compromising integrity. This durability not only extends the lifespan of the component but also enhances safety during operation. Furthermore, the design minimizes the risk of leaks, ensuring that the water is delivered precisely where it is needed.

Maintenance Considerations

Regular inspection of the high-pressure hose is essential to detect any signs of wear or damage. Checking for kinks, abrasions, or weak points can prevent unexpected failures during use. Proper storage and handling also play a significant role in maintaining its functionality, ensuring that the hose remains in optimal condition for effective cleaning tasks.

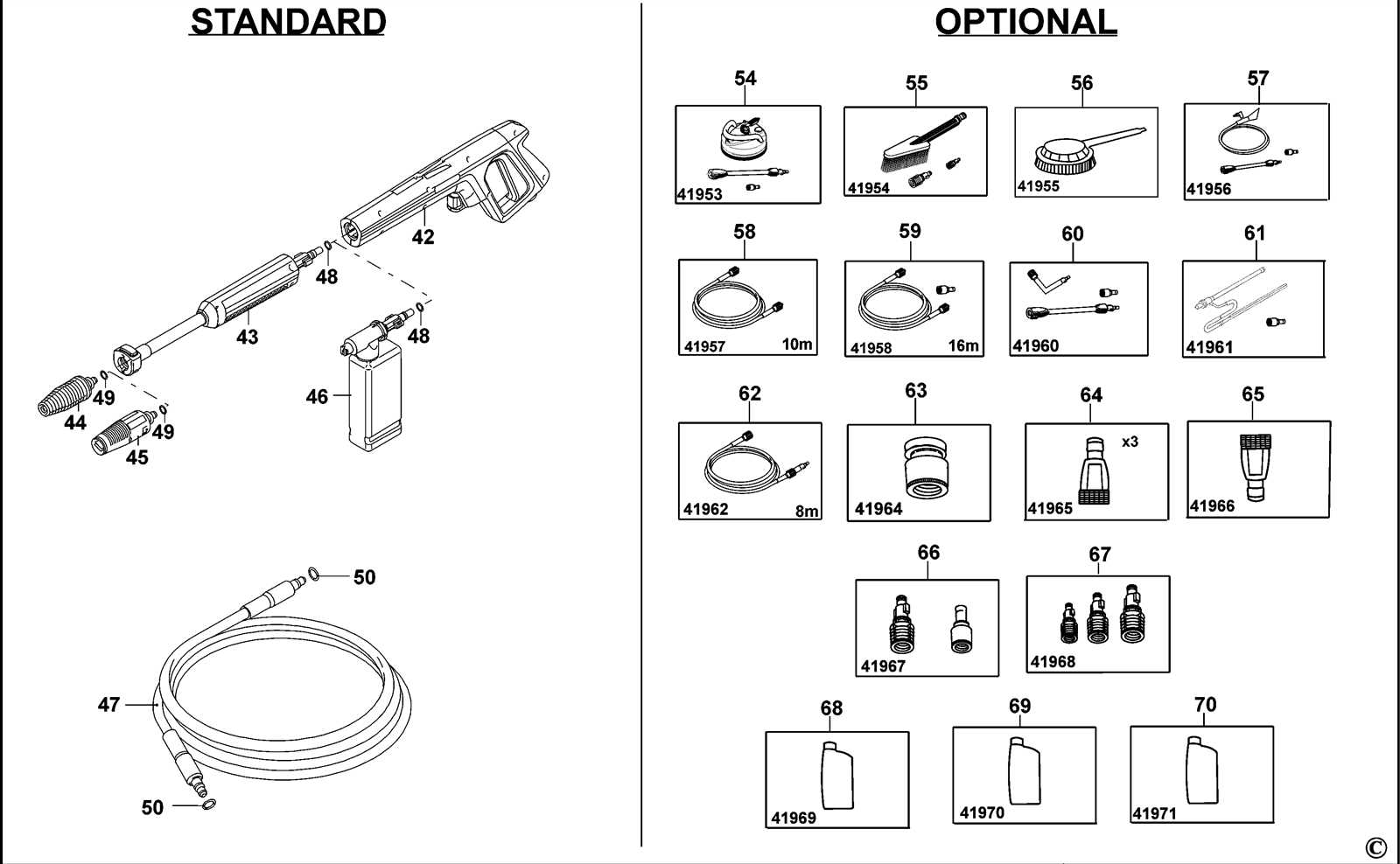

Importance of the Spray Gun

The spray gun plays a crucial role in any cleaning system, serving as the primary interface between the user and the equipment. Its design and functionality significantly influence the effectiveness and efficiency of various cleaning tasks. Understanding its significance can enhance the overall performance of the cleaning process.

Efficiency in Cleaning

A well-designed spray gun allows for precise control over water flow and spray patterns, which are essential for tackling different surfaces and types of grime. This adaptability ensures that users can achieve optimal results without wasting resources or time.

Safety and Comfort

The ergonomics of a spray gun directly affect user experience. A comfortable grip and manageable weight can reduce fatigue during prolonged use, while features such as trigger locks can enhance safety. Investing in a quality spray gun can lead to a more enjoyable and safer cleaning experience.

| Feature | Benefit |

|---|---|

| Adjustable Spray Patterns | Versatile for various cleaning tasks |

| Ergonomic Design | Reduces user fatigue |

| Durable Materials | Long-lasting performance |

| Trigger Locks | Increased safety during use |

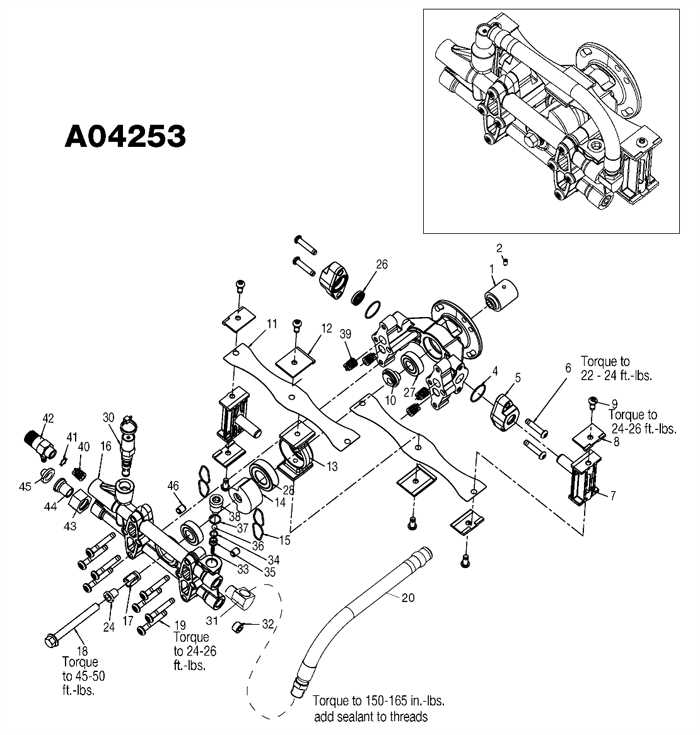

Role of the Pump in Operation

The pump serves as the heart of the cleaning equipment, playing a crucial role in generating the necessary force for efficient cleaning. This component is responsible for converting mechanical energy into fluid motion, which enables the system to function effectively.

Key functions of the pump include:

- Creating high-pressure flow: The pump elevates the fluid pressure, allowing it to dislodge dirt and grime effectively.

- Regulating fluid movement: It ensures a consistent flow rate, crucial for maintaining optimal cleaning performance.

- Facilitating various applications: Different types of pumps can be utilized for specific tasks, such as light cleaning or heavy-duty applications.

Moreover, the efficiency of the pump directly influences the overall performance of the equipment:

- Increased efficiency: A well-functioning pump maximizes cleaning power while minimizing water consumption.

- Enhanced durability: Quality pumps are designed to withstand high pressures and prolonged use, ensuring longevity.

- Improved versatility: By adjusting pump settings, users can tailor the pressure and flow for different surfaces and cleaning needs.

Understanding the importance of this component helps users appreciate its role in achieving effective results during operation.

Choosing the Right Nozzle

Selecting the appropriate attachment for your cleaning equipment is crucial for achieving optimal results. The right choice can enhance efficiency, reduce water consumption, and protect surfaces from damage. Understanding the different types of nozzles available is essential to meet various cleaning needs.

There are several factors to consider when making your selection. Angle is one of the most significant aspects; nozzles typically range from 0 to 65 degrees. A narrower angle delivers a concentrated stream, ideal for tough stains, while wider angles are suitable for broader coverage and delicate surfaces.

Additionally, pressure rating is vital. Higher-rated attachments generate stronger jets, perfect for heavy-duty tasks. However, using a nozzle with excessive force on delicate materials can lead to damage. Always match the attachment’s specifications with the task at hand.

Another consideration is material. Some nozzles are made from plastic, while others are constructed from metal. The choice between these materials can affect durability and performance, so it’s important to evaluate your cleaning frequency and environment.

Finally, accessories can enhance versatility. Many attachments come with interchangeable tips, allowing for easy adjustments to meet specific cleaning requirements. By carefully considering these factors, you can ensure that you choose the right nozzle for any project.

Maintenance of Pressure Washer Filters

Regular upkeep of filtration components is essential for optimal performance and longevity of your cleaning equipment. Ensuring that these elements are clean and functioning properly can prevent clogs and enhance the efficiency of the machine. Proper maintenance not only extends the life of the equipment but also ensures effective cleaning results.

Begin by regularly inspecting the filters for any signs of dirt buildup or damage. If the filtration systems appear dirty, it’s crucial to remove them and clean thoroughly according to the manufacturer’s guidelines. In many cases, a simple rinse with water can eliminate debris. However, for stubborn particles, a mild detergent may be necessary.

Additionally, it’s important to check the condition of the filters periodically. Replace any damaged or excessively worn components to maintain optimal performance. Keeping a schedule for these maintenance tasks can help you stay proactive and ensure your equipment remains in top condition.

Lastly, ensure that the installation of filters is secure after cleaning or replacement. A well-maintained filtration system will contribute to the overall efficiency and effectiveness of your cleaning operations, providing satisfactory results every time.

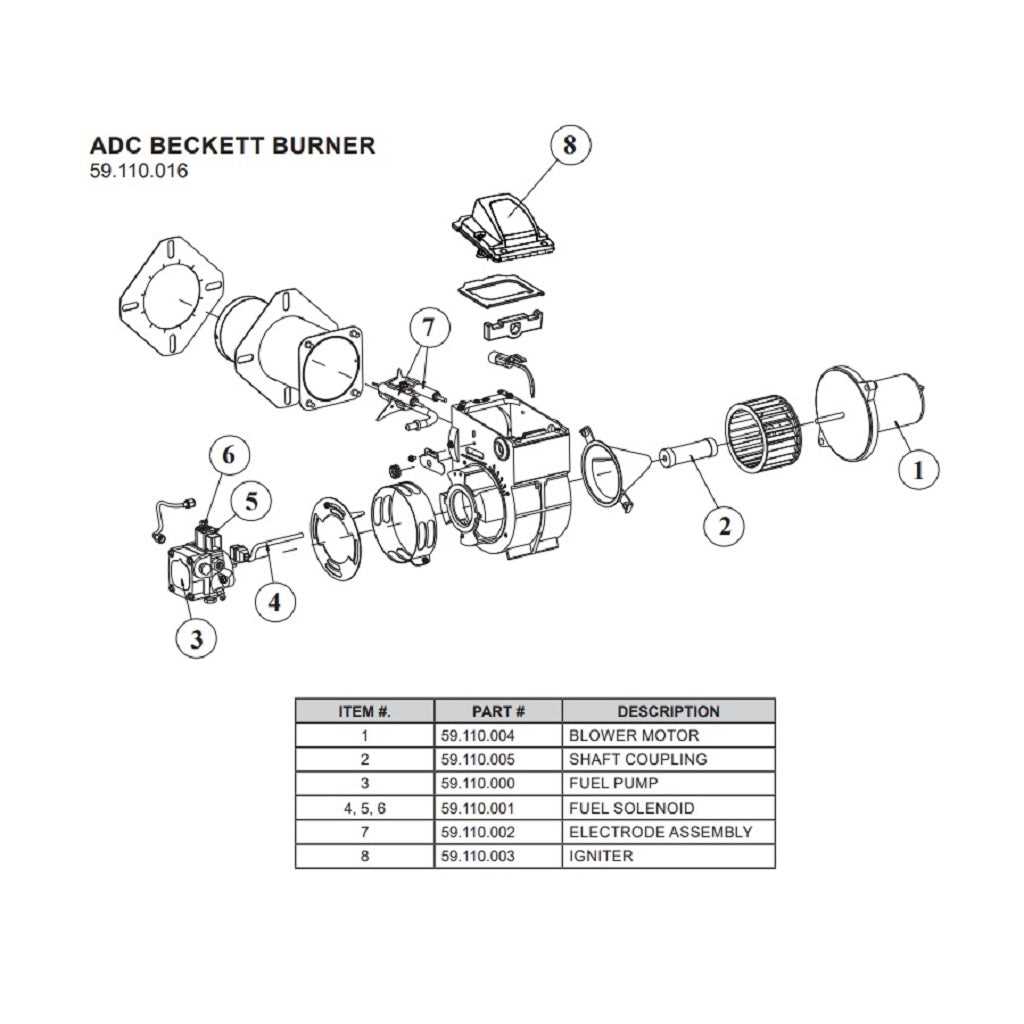

Identifying Electrical System Elements

Understanding the components of an electrical system is crucial for maintaining and troubleshooting any device. Each element plays a specific role in ensuring the proper functioning of the machine. By familiarizing oneself with these components, users can enhance performance and extend the lifespan of the equipment.

Below is a table outlining common electrical system elements along with their functions:

| Component | Description |

|---|---|

| Power Supply | Provides the necessary voltage and current for operation. |

| Motor | Converts electrical energy into mechanical motion. |

| Switch | Controls the flow of electricity to various components. |

| Circuit Board | Houses and connects electrical pathways for signal distribution. |

| Wiring | Conducts electrical current between components. |

| Fuse | Protects the system from overcurrent by breaking the circuit. |

By recognizing these elements, users can better navigate the complexities of their equipment and ensure it operates smoothly.

Common Troubleshooting Techniques

When dealing with equipment issues, it is essential to identify the root causes efficiently. This section outlines various strategies to diagnose and resolve common problems that may arise during operation. By employing these techniques, users can save time and enhance the performance of their devices.

First, always start with a thorough inspection. Check for any visible signs of wear, leaks, or damage. This initial step can often reveal obvious problems that need addressing. Next, consult the user manual for guidance on troubleshooting specific issues, as it often contains valuable information tailored to the model.

Additionally, ensure that all connections are secure and that the unit is receiving adequate power. Power issues are a common source of malfunction and can often be resolved with simple adjustments. If the device is not functioning correctly, try resetting it or checking the circuit breaker to restore operation.

Moreover, regular maintenance is crucial. Cleaning filters and nozzles can prevent blockages that lead to decreased efficiency. Keeping components well-maintained not only improves functionality but also extends the lifespan of the equipment.

Lastly, if problems persist, consider seeking help from online forums or contacting customer support. Engaging with other users can provide insights and solutions that may not be immediately apparent. By using these troubleshooting methods, users can effectively address issues and maintain optimal performance.

Upgrading Parts for Better Performance

Enhancing the components of your cleaning equipment can lead to significant improvements in efficiency and effectiveness. By focusing on key elements, users can experience a boost in overall functionality and longevity, making their tasks easier and more enjoyable.

One of the primary upgrades to consider is the motor. A more powerful engine can drastically increase the flow rate and pressure, allowing for a more thorough clean. Additionally, investing in a high-quality pump ensures consistent performance and durability over time.

Another vital area for enhancement is the nozzle. Different nozzles cater to various cleaning needs, enabling better handling of tough stains and grime. Switching to adjustable or turbo nozzles can provide versatility, making it easier to switch between tasks.

Furthermore, examining the hose and accessories can lead to improved usability. A longer, reinforced hose allows for greater reach and reduces the risk of kinking, while specialized attachments can tailor your approach to specific cleaning challenges.

Ultimately, upgrading these essential components not only boosts performance but also ensures a more satisfying and efficient experience. Regularly assessing and updating your equipment will keep it operating at its best, transforming your cleaning routine.