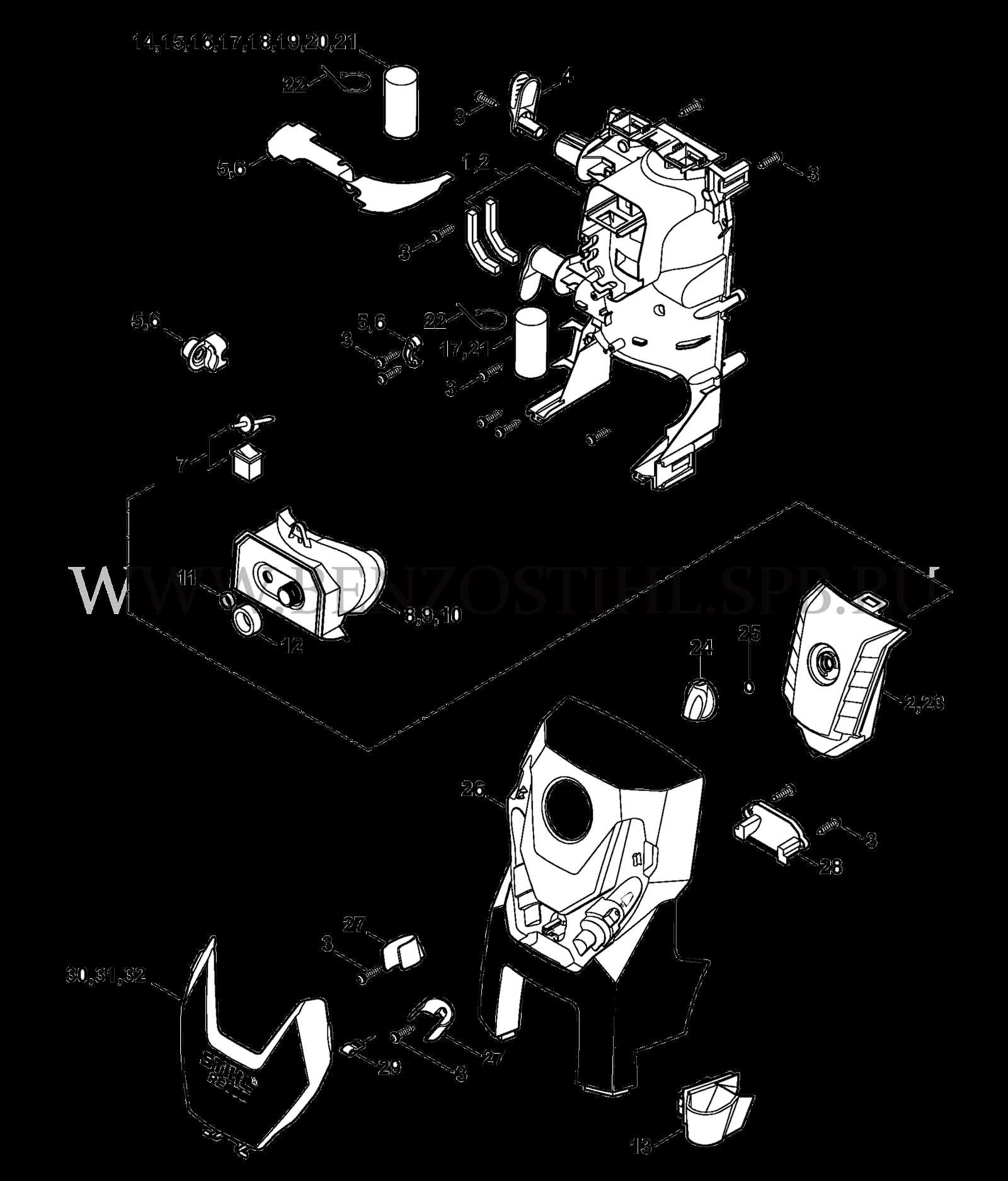

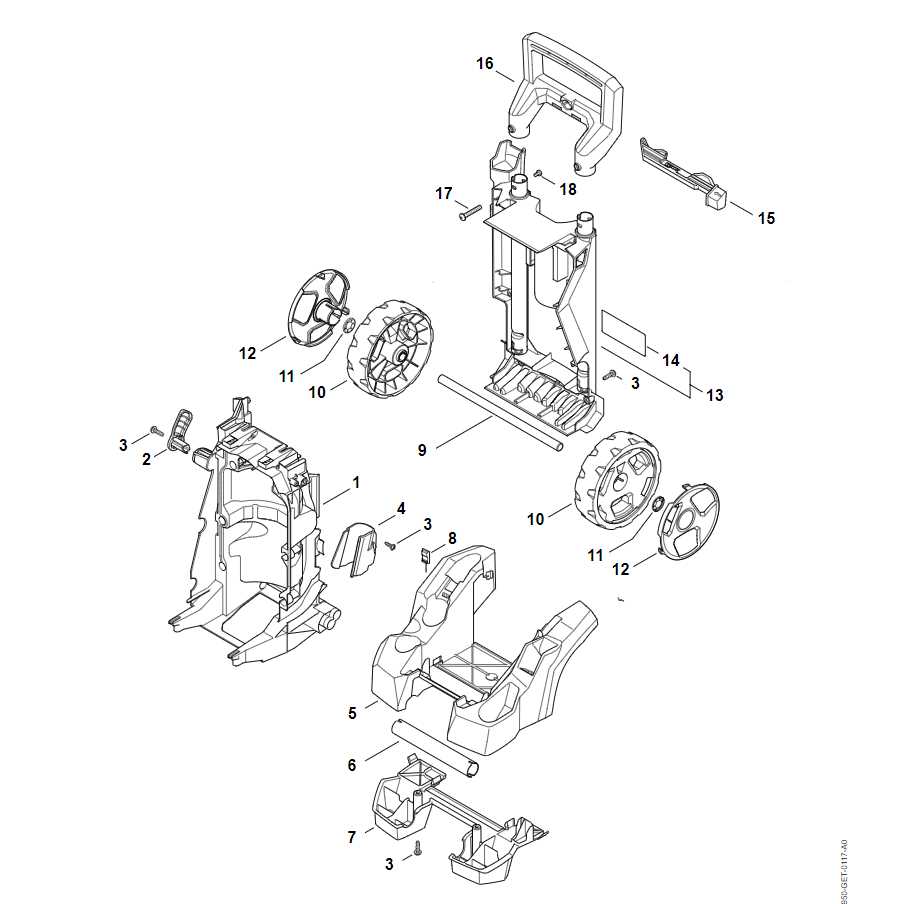

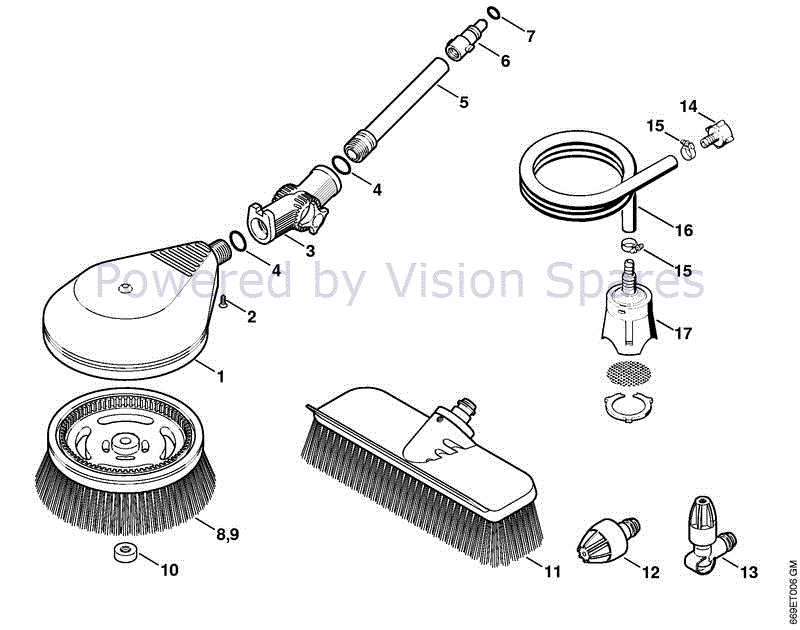

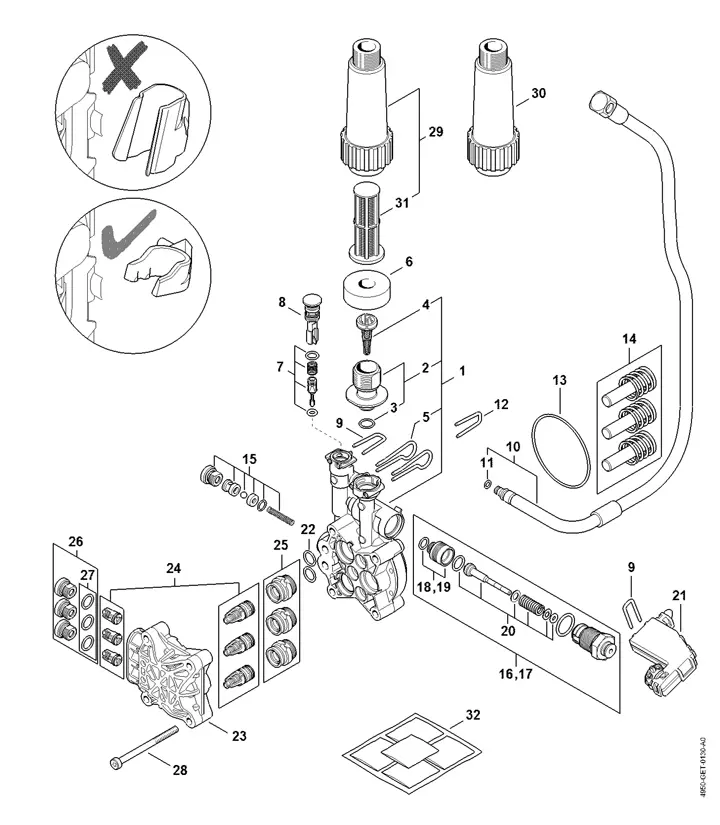

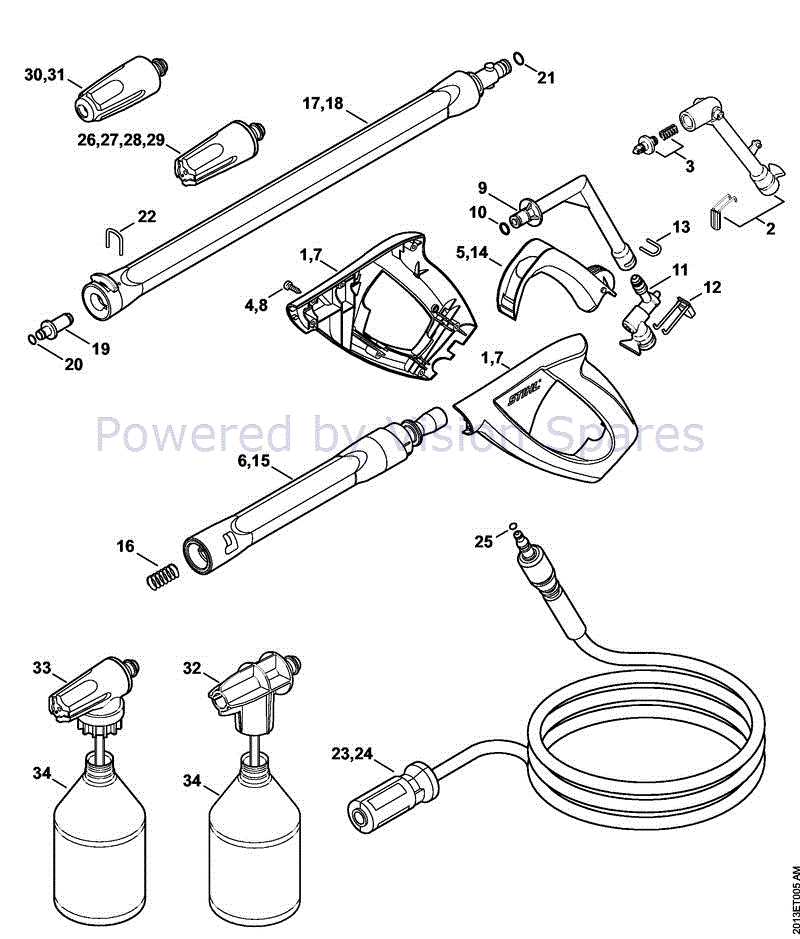

Parts Diagram for Stihl RE 129 Plus

When it comes to maintaining outdoor machinery, having a clear understanding of its components is essential for efficient operation. Knowing how each element interacts within the system not only enhances functionality but also extends the life of your equipment. This section aims to provide a comprehensive overview of the essential elements that make up your device.

In order to perform repairs or upgrades effectively, a visual representation can be incredibly helpful. By examining a well-structured outline of the various components, users can quickly identify parts that may need attention or replacement. This approach facilitates a smoother maintenance process and allows for informed decision-making regarding any necessary actions.

By familiarizing yourself with the intricate details of your machine’s structure, you can empower yourself to tackle any issues that may arise. Whether you are a seasoned professional or a casual user, understanding these crucial aspects will enhance your experience and ensure your equipment operates at its best.

This section aims to provide a comprehensive overview of a powerful cleaning machine designed for various tasks. Understanding its components and functionalities is essential for users to maximize its efficiency and maintain its performance over time.

Key Features

The machine boasts several notable features that enhance its usability and effectiveness:

- Robust construction ensuring durability

- Efficient operation for effective cleaning

- Versatile accessories for different applications

Common Applications

This versatile device is suitable for a range of cleaning tasks, making it a valuable tool for both home and professional use:

- Washing vehicles and outdoor equipment

- Cleaning patios and driveways

- Maintaining garden furniture and tools

Maintenance Tips

Proper care and maintenance are crucial for ensuring the longevity and reliability of this cleaning unit:

- Regularly check and replace worn-out components

- Keep the machine clean and free of debris

- Store in a dry and safe location when not in use

Key Features of the Model

This model is designed with advanced functionalities that cater to a variety of cleaning needs. It combines efficiency and user-friendliness, making it suitable for both professionals and homeowners. The thoughtful engineering ensures that users can tackle a range of tasks effectively, resulting in a reliable cleaning experience.

Ergonomic Design

The product boasts an ergonomic design that enhances user comfort during operation. Its lightweight structure allows for easy maneuverability, while the adjustable components enable personalized handling, reducing strain during extended use.

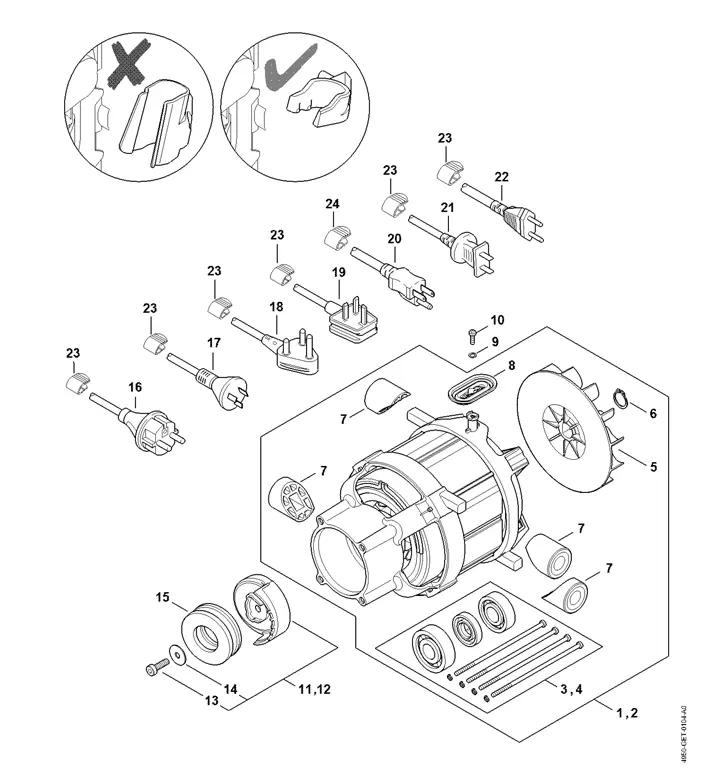

Powerful Performance

Equipped with a robust motor, this unit delivers exceptional cleaning power. The high-performance capabilities ensure that even the toughest dirt and grime can be effectively managed, making it an ideal choice for various surfaces and environments.

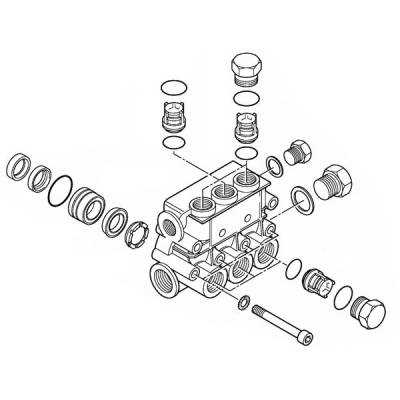

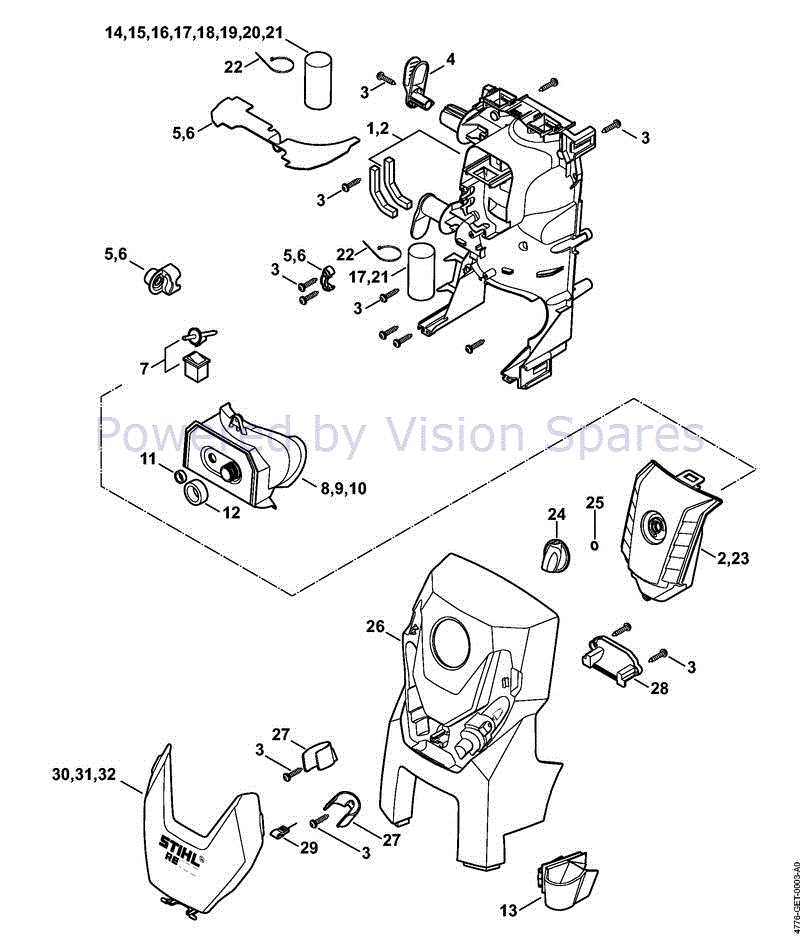

Understanding the Parts Diagram

Gaining a comprehensive understanding of the assembly illustrations is crucial for effective maintenance and repair of your equipment. These visual representations provide valuable insights into the various components, their arrangement, and how they interact within the system. By familiarizing yourself with these illustrations, you can enhance your troubleshooting skills and streamline the repair process.

Importance of Visual Guides

Visual aids serve as an essential tool in grasping the complexity of machinery. They simplify intricate designs into easily digestible formats, making it easier to identify individual elements and their respective roles. Understanding these guides can significantly reduce the risk of errors during assembly or disassembly, ensuring that every part is in its proper location.

How to Use Assembly Illustrations Effectively

To utilize these visual aids effectively, start by focusing on each section of the illustration. Take note of the labels and corresponding numbers, which indicate specific components. It’s beneficial to reference these illustrations during the maintenance process, as they provide a clear roadmap for identifying parts and understanding their functionalities. Engaging with these visual representations can greatly enhance your confidence in handling repairs.

Proper upkeep is essential for extending the lifespan of your equipment. Regular attention to maintenance not only ensures optimal performance but also minimizes the likelihood of unexpected failures. Here are some practical strategies to keep your machine running smoothly over time.

Routine Checks

Performing frequent inspections is vital. Look for any signs of wear or damage that may require immediate attention. This proactive approach can prevent minor issues from escalating into major repairs.

Cleaning Procedures

Keeping your equipment clean is equally important. Dust, debris, and grime can accumulate and lead to inefficiencies. Regularly clean the exterior and internal components to maintain functionality and aesthetics.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Weekly | Check for wear and damage |

| Cleaning | Monthly | Remove dirt and debris |

| Lubrication | Every 3 Months | Use appropriate lubricant |

| Parts Replacement | As Needed | Replace worn components |

Tools Required for Repairs

When undertaking maintenance or repairs on equipment, having the right tools is essential for a successful outcome. A well-equipped toolkit not only simplifies the process but also ensures that tasks can be completed efficiently and effectively.

Common tools necessary for performing repairs typically include a set of screwdrivers, pliers, and wrenches. Additionally, specialized tools such as socket sets and torque wrenches may be required depending on the complexity of the job. Safety equipment, including gloves and goggles, is also crucial to protect the user during the repair process.

Moreover, having a good quality workbench and proper storage for tools can help keep the workspace organized, making it easier to locate items as needed. Investing in reliable tools is vital for any repair endeavor, as they contribute significantly to achieving a high standard of workmanship.

Identifying Components by Number

Understanding how to recognize different elements in a machine is essential for effective maintenance and repairs. Each component is usually assigned a unique identifier, which aids in locating and replacing parts when necessary. Familiarity with this numbering system can significantly streamline the process of ordering replacements and ensuring compatibility with your equipment.

Why Use Identification Numbers?

Identification numbers serve multiple purposes:

- Facilitates accurate ordering of replacements.

- Reduces the likelihood of errors during repairs.

- Enables easy communication with suppliers.

How to Find Identification Numbers

To locate the identification numbers of components, consider the following methods:

- Check the user manual for a comprehensive list of identifiers.

- Examine the equipment itself, as many parts are marked with their respective numbers.

- Consult online resources or manufacturer websites for diagrams and breakdowns.

Where to Purchase Components

Finding the right elements for your equipment is essential for maintaining its performance and longevity. There are various avenues to explore when seeking out these essential supplies, ensuring you have access to quality options that meet your needs.

Authorized Dealers: One of the most reliable sources for acquiring necessary components is through authorized retailers. These outlets typically offer genuine items, ensuring compatibility and durability for your machinery.

Online Marketplaces: The internet provides a vast array of choices through various e-commerce platforms. These sites often feature competitive pricing and a wide selection, making it convenient to compare different options and read customer reviews.

Local Repair Shops: Visiting a nearby repair shop can also yield beneficial results. These establishments may have components available for sale or can order specific items for you, often with expert advice on installation and use.

Manufacturer’s Website: Checking the manufacturer’s official website can provide access to a full range of components, including specific models and accessories. This can be a reliable option for ensuring you are purchasing authentic products.

Installation Procedures for Parts

This section provides guidance on the assembly and integration of components for optimal functionality. Understanding the proper techniques for installing various elements is crucial for maintaining efficiency and extending the lifespan of the equipment. Each step must be followed diligently to ensure the proper operation of the machine.

Preparation Steps

Before beginning the installation, gather all necessary tools and components. It is essential to review the manufacturer’s guidelines for specific recommendations regarding the equipment in question. Make sure the work area is clean and organized to facilitate a smooth installation process.

Assembly Instructions

Start by carefully aligning the components according to the provided specifications. Ensure that all fasteners are tightened securely, but avoid over-tightening, which could lead to damage. Once the initial assembly is complete, conduct a thorough inspection to confirm that everything is positioned correctly and functions as intended. Following these procedures will help achieve a reliable setup.

Troubleshooting Common Issues

When operating your equipment, various challenges may arise that hinder performance. Identifying and resolving these problems promptly is essential for maintaining efficiency and extending the lifespan of the device. Below are some common issues that users encounter, along with suggested solutions.

1. Device Won’t Start

If the equipment fails to start, check the power source. Ensure that all connections are secure and that the power supply is functioning correctly. Additionally, inspect the ignition components for any signs of wear or damage. If the issue persists, consult the user manual for further troubleshooting steps.

2. Reduced Power Output

A decline in power output may indicate a clogged filter or worn-out components. Regularly clean or replace air and fuel filters to ensure optimal airflow and fuel delivery. It’s also advisable to check for any blockages in the exhaust system that could restrict performance.

3. Unusual Noises

Strange sounds during operation can signal potential mechanical issues. Inspect the moving parts for any signs of looseness or misalignment. Lubrication may be necessary to prevent friction and noise. If the sounds continue, consider seeking professional assistance to avoid further damage.

4. Overheating

Overheating can result from insufficient airflow or excessive load. Ensure that cooling vents are unobstructed and that the machine is not overloaded beyond its capacity. Allow the device to cool down and monitor usage to maintain proper operating conditions.

Safety Precautions During Maintenance

Ensuring safety during maintenance tasks is crucial for preventing accidents and injuries. Proper precautions not only protect the individual performing the work but also contribute to the longevity and efficiency of the equipment being serviced. Adhering to safety guidelines creates a secure environment, facilitating effective maintenance procedures.

Before starting any maintenance activity, it is essential to wear appropriate personal protective equipment (PPE). This includes safety goggles, gloves, and sturdy footwear to shield against potential hazards. Additionally, it is advisable to work in a well-ventilated area to avoid inhaling harmful fumes or dust.

Always disconnect the power source or ensure the equipment is turned off before performing any service. This simple step minimizes the risk of accidental starts, which can lead to severe injuries. Moreover, familiarizing oneself with the equipment’s manual and safety instructions can provide valuable insights into specific precautions that need to be taken.

During maintenance, keep the workspace tidy and free from clutter to reduce tripping hazards. It is also beneficial to use proper tools for the job, as using inappropriate tools can result in injuries or damage to the equipment. Lastly, it is recommended to have a first aid kit readily accessible in case of emergencies.