Kubota BX 3 Point Hitch Parts Diagram Explained

For anyone involved in the operation and maintenance of compact tractors, comprehending the intricate assembly of connecting elements is crucial. These components play a pivotal role in ensuring effective attachment and operation of various implements, enhancing the overall functionality of your machinery. A thorough understanding of how these elements interact can significantly improve both performance and efficiency.

In this section, we will explore the essential elements that constitute the linkage system of your compact tractor. From the fundamental structures to the various accessories that enhance adaptability, grasping their layout and function will enable operators to make informed decisions regarding maintenance and upgrades. This knowledge not only aids in troubleshooting but also empowers users to maximize the utility of their equipment.

Whether you are a seasoned operator or a newcomer to the world of compact tractors, familiarizing yourself with these connections can lead to better handling and longevity of your machine. As we delve deeper into this topic, we aim to equip you with valuable insights that will enhance your operational capabilities and overall experience.

Kubota BX Overview

The BX series represents a range of compact utility tractors designed to cater to various agricultural and landscaping needs. These versatile machines combine power and efficiency, making them ideal for both residential and commercial applications.

Key Features

- Compact Design: Engineered for maneuverability in tight spaces.

- Powerful Engine: Delivers robust performance for various tasks.

- Hydraulic System: Facilitates easy attachment and operation of implements.

- Comfortable Operator Station: Ensures a pleasant experience during extended use.

Applications

- Landscaping: Perfect for maintaining lawns and gardens.

- Agriculture: Useful for small-scale farming operations.

- Snow Removal: Equipped to handle winter conditions effectively.

- Construction: Assists in light construction and earth-moving tasks.

Importance of Three-Point Hitches

The significance of these versatile attachments in agricultural machinery cannot be overstated. They serve as a crucial link between the tractor and various implements, enabling efficient operation across a wide range of tasks. This connection enhances the overall functionality and adaptability of farming equipment, making it easier for operators to handle diverse applications.

Stability and Control: One of the primary benefits of these connections is the stability they provide. By securing implements firmly, they allow for better control during operation, reducing the risk of accidents and improving overall safety. This stability is essential for tasks that require precision, such as plowing and tilling.

Versatility: These attachments allow operators to easily switch between different tools, such as mowers, cultivators, and loaders. This versatility enhances productivity, as farmers can quickly adapt their machinery to meet changing demands without the need for extensive modifications.

Ease of Use: The design of these systems makes them user-friendly, allowing even those with minimal experience to attach and detach implements with relative ease. This accessibility encourages more efficient use of equipment, maximizing operational time and minimizing downtime.

In summary, the role of these essential connectors in modern agricultural practices highlights their importance in enhancing efficiency, safety, and versatility in farming operations.

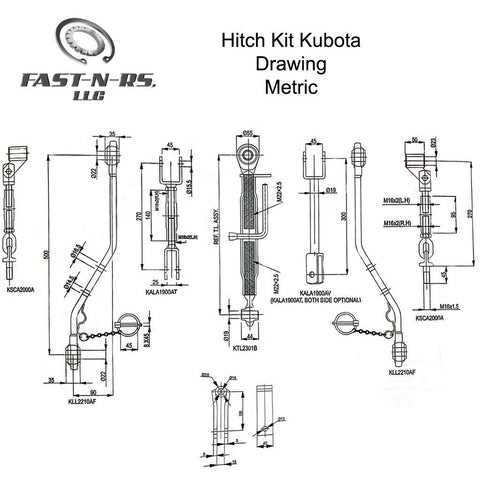

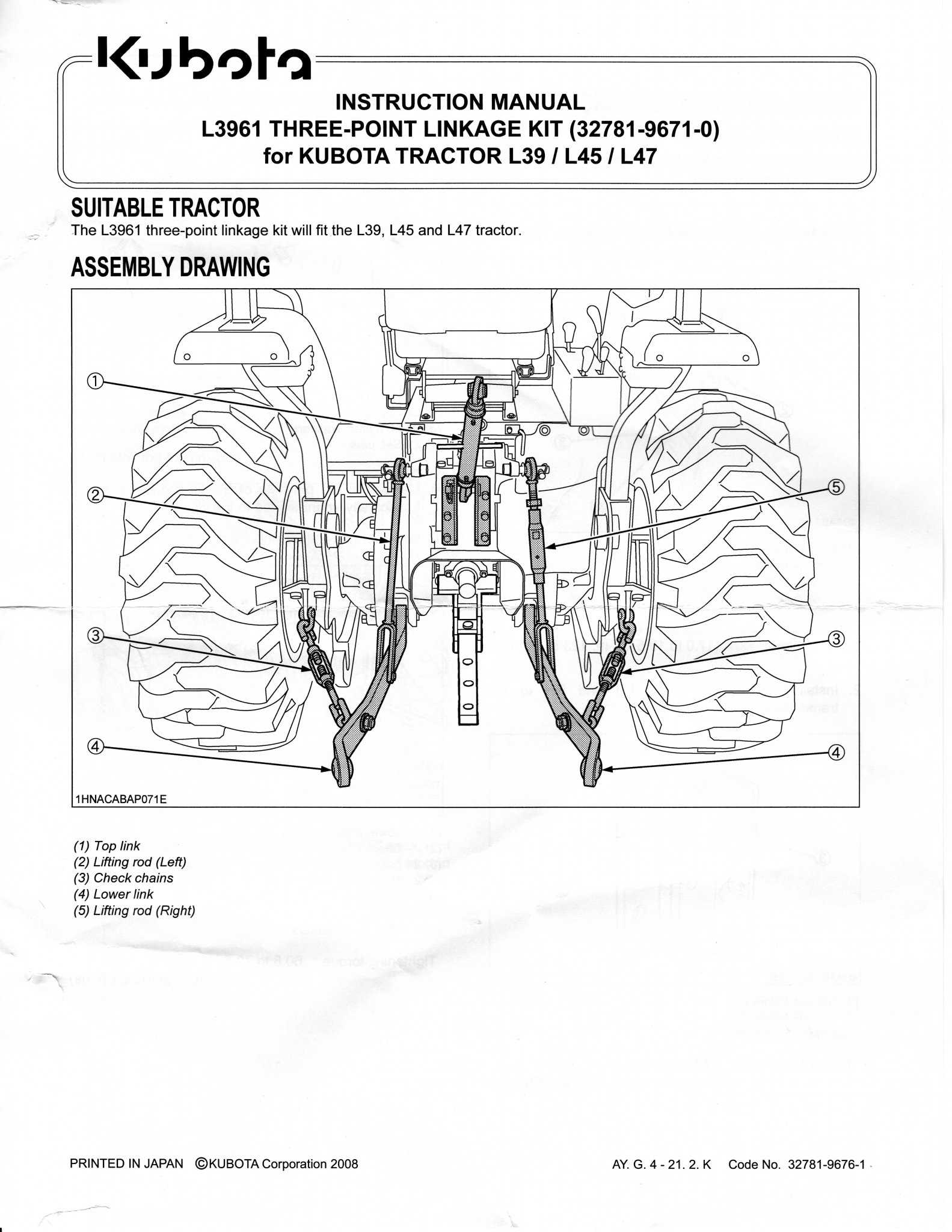

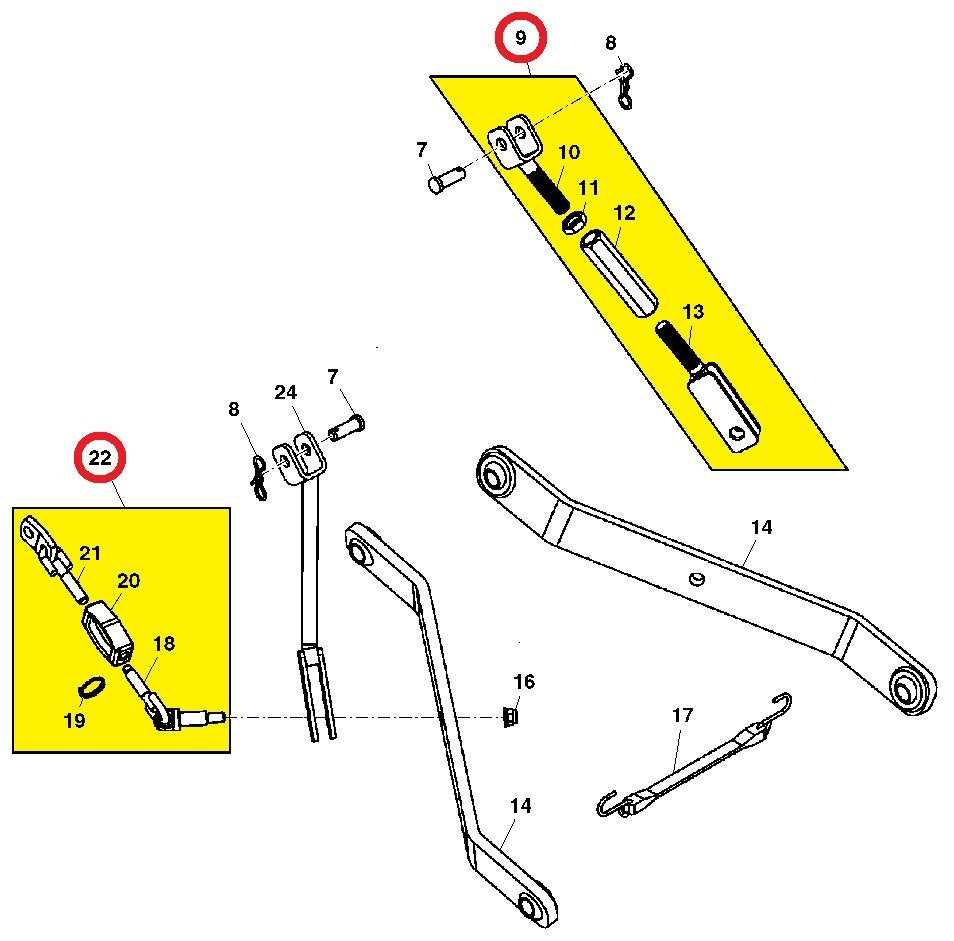

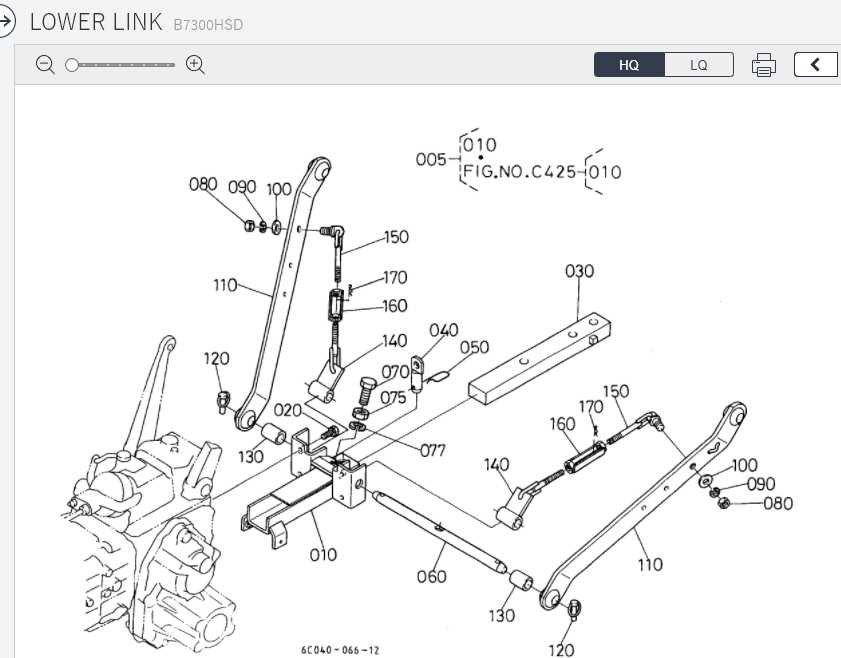

Components of the BX Hitch System

The BX system is designed to enhance the functionality of compact tractors by providing a versatile framework for attaching various implements. Understanding its components is essential for effective operation and maintenance, allowing users to maximize the machine’s potential. Each element plays a critical role in ensuring compatibility and stability during operation.

Key Elements of the System

Central to this system are the arms that facilitate attachment to implements. These arms are designed for strength and durability, ensuring that heavy loads can be managed efficiently. Additionally, the linkage mechanisms connect the arms to the tractor, allowing for smooth adjustments and movement. The incorporation of adjustable lift links further enhances control over implement positioning.

Support and Stability Features

To ensure robust support, the system includes a frame that provides a solid foundation. This framework is engineered to withstand the stresses of various tasks, from lifting to towing. The inclusion of a control system allows for precise manipulation of the implements, making it easier for operators to achieve desired results while maintaining safety and efficiency.

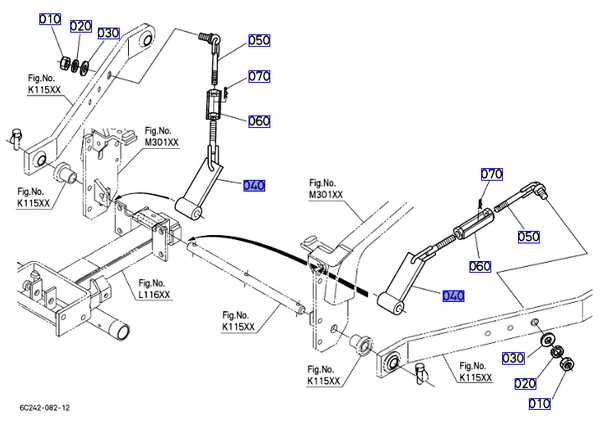

Understanding Parts Diagrams

Diagrams illustrating component layouts are essential tools for anyone working with machinery. They provide a visual representation of how various elements are interconnected, aiding in both assembly and maintenance processes. By examining these illustrations, users can gain insights into the structure and functionality of the equipment, enabling more effective troubleshooting and repairs.

Benefits of Visual Representation

Visual representations simplify complex relationships between different components, making it easier to understand their interactions. These illustrations often highlight crucial elements, helping technicians identify parts quickly and accurately. Furthermore, they serve as valuable references for assembling or disassembling machinery, ensuring that no essential piece is overlooked.

Navigating the Illustrations

Understanding how to navigate these illustrations is crucial for effective use. Typically, each component is labeled, and connections are clearly marked. Familiarity with the layout and terminology used can significantly enhance one’s ability to interpret the information presented, leading to more efficient and successful maintenance efforts.

Common Issues with BX Hitches

Many users encounter various challenges when operating the rear attachment systems of their compact tractors. Understanding these common issues can help ensure smoother functionality and prolong the lifespan of the equipment.

- Misalignment:

Components may become misaligned due to wear and tear or improper installation, leading to inefficient performance.

- Hydraulic Leaks:

Leaks in hydraulic lines can result in a loss of power, making it difficult to raise or lower attachments effectively.

- Worn Out Pins:

Over time, the pins that connect implements can wear down, which affects stability and functionality.

- Corrosion:

Exposure to the elements can lead to rust and deterioration, compromising the integrity of the components.

- Improper Load Distribution:

Uneven weight distribution can cause excessive strain on the system, resulting in potential damage or malfunction.

Addressing these issues promptly can enhance the overall efficiency of the tractor’s rear attachment systems and minimize costly repairs.

Maintenance Tips for Optimal Performance

Regular upkeep is essential to ensure the longevity and efficiency of your agricultural equipment. Proper maintenance not only enhances performance but also prevents unexpected breakdowns, saving both time and money. By following a few simple guidelines, you can keep your machinery running smoothly and effectively throughout its lifespan.

Routine Inspections

Conducting routine inspections is crucial for identifying potential issues before they escalate. Check for signs of wear and tear, such as loose bolts, cracks, or rust. Ensure that all moving components are well-lubricated to reduce friction and prevent premature damage. Regularly reviewing your machinery’s condition allows for timely repairs and helps maintain optimal functionality.

Cleaning and Storage Practices

Keeping your equipment clean is vital to its performance. Remove dirt, debris, and corrosive materials after each use to prevent buildup that can hinder operations. When storing machinery, ensure it is in a dry, sheltered location to protect it from the elements. Using covers can also shield it from dust and moisture, contributing to its longevity and readiness for the next task.

Identifying Replacement Parts

When it comes to maintaining your agricultural machinery, recognizing the correct components for replacement is crucial. Proper identification ensures compatibility and optimal performance, ultimately extending the life of your equipment. Understanding the various elements involved will simplify the replacement process and help you avoid unnecessary complications.

To effectively pinpoint the necessary components, consider the following steps:

| Step | Description |

|---|---|

| 1 | Refer to the owner’s manual for specific details about your equipment. |

| 2 | Inspect the existing components for any identification numbers or markings. |

| 3 | Consult online resources or forums dedicated to machinery maintenance for insights. |

| 4 | Contact a local dealer or parts supplier for expert assistance and recommendations. |

By following these guidelines, you can ensure that you select the correct components, leading to improved efficiency and reliability in your agricultural tasks.

Where to Buy BX Components

Finding the right components for your equipment can be essential for optimal performance and longevity. Whether you’re looking for specific accessories or replacement items, knowing where to shop can make all the difference. This guide outlines various avenues for sourcing quality BX components, ensuring you keep your machinery running smoothly.

Authorized Dealers

One of the most reliable sources for acquiring these items is through authorized dealers. They often provide genuine products with the assurance of quality and compatibility. Additionally, authorized dealers may offer valuable expertise and customer support, helping you select the right components for your needs.

Online Retailers

The internet has made it easier than ever to find a wide range of components at competitive prices. Numerous online retailers specialize in agricultural and construction equipment, offering everything from essential parts to specialized accessories. Be sure to check reviews and ratings to ensure the seller’s credibility before making a purchase.

Installation Guide for BX Hitches

This section provides a comprehensive overview of the installation process for the BX attachment system. Understanding the various components and their proper assembly is essential for achieving optimal functionality and safety. Whether you are a seasoned user or a newcomer, following these guidelines will ensure a smooth installation experience.

Required Tools and Materials

Before starting, gather all necessary tools and materials to streamline the process. Below is a list of items you will need:

| Tool/Material | Purpose |

|---|---|

| Socket Wrench | For securing bolts |

| Screwdriver | For attaching brackets |

| Level | To ensure proper alignment |

| Measuring Tape | To verify distances |

| Safety Gear | For personal protection |

Step-by-Step Installation Process

Follow these steps to install the BX attachment system correctly:

1. Begin by preparing the area where the installation will take place. Ensure it is clean and free from obstacles.

2. Assemble the primary components according to the provided specifications. Make sure to follow the orientation guidelines closely.

3. Secure the components using the appropriate fasteners, ensuring they are tight but not overly tightened to avoid damage.

4. Utilize the level to check that everything is aligned correctly, making adjustments as needed.

5. After confirming proper alignment and security, conduct a final inspection before operating the equipment.

By adhering to these guidelines, you will successfully install the BX attachment system, ready for efficient use in various applications.

Benefits of Upgrading Your Hitch

Enhancing your towing system can lead to a multitude of advantages that significantly improve your overall experience and efficiency during operations. By investing in a modernized setup, you can expect greater performance, enhanced compatibility, and increased durability.

- Improved Load Capacity: Newer systems are designed to handle heavier loads, allowing for more efficient transportation of equipment and materials.

- Increased Stability: Upgraded models often feature better design and construction, resulting in improved stability while towing, reducing the risk of accidents.

- Enhanced Versatility: Modern configurations offer compatibility with a wider range of attachments, providing more flexibility for various tasks.

- Ease of Use: Many new designs incorporate user-friendly features that simplify attachment and detachment processes, saving you time and effort.

- Longer Lifespan: Upgrading to higher quality components typically results in a more durable setup, reducing maintenance costs and prolonging service life.

In summary, modernizing your towing apparatus not only boosts functionality but also contributes to a safer and more productive working environment.

Comparing BX with Other Models

When evaluating compact machines, it’s essential to consider how various models stack up against each other in terms of functionality, versatility, and overall performance. This comparison helps users identify which machine best suits their specific needs and operational tasks. The BX series is often highlighted for its unique features, but understanding how it measures against other similar units can provide valuable insights.

| Feature | BX Series | Other Compact Models |

|---|---|---|

| Engine Power | 20-25 HP | 15-30 HP |

| Lift Capacity | 500-700 lbs | 400-800 lbs |

| Attachment Options | Wide variety | Limited options |

| Turning Radius | Narrow | Standard |

| Price Range | Mid-range | Varied |

Overall, comparing the BX series with other compact machinery reveals distinct advantages in power and maneuverability, while also showcasing differences in attachment compatibility and pricing. Each model offers unique benefits, making it crucial for potential users to assess their specific requirements before making a decision.

Frequently Asked Questions

This section addresses common inquiries related to the components and mechanisms that enhance the functionality of agricultural equipment. Understanding these elements can help users make informed decisions and troubleshoot issues effectively.

What are the key components of the system?

The primary elements include the lift mechanism, control arms, and attachments that facilitate the connection of various implements. Familiarity with these parts ensures proper maintenance and optimal performance.

How can I ensure proper installation?

To achieve accurate installation, it’s essential to follow the manufacturer’s guidelines. Additionally, using the correct tools and verifying all connections will contribute to the longevity and effectiveness of the system.