Comprehensive Parts Diagram for New Holland 492 Haybine

In the realm of modern agriculture, efficient machinery plays a crucial role in ensuring optimal productivity. This specialized equipment, designed for cutting and conditioning forage, relies on various intricate elements working in harmony. Grasping the layout and functionality of these components is essential for effective maintenance and troubleshooting.

Farmers and technicians alike benefit from a comprehensive overview of the machinery’s structure. A detailed visual representation can simplify the identification of each segment, enabling users to understand how these pieces contribute to the overall operation. Such insights are invaluable when it comes to ensuring longevity and efficiency in the field.

Furthermore, familiarity with the specific roles of each part not only aids in repairs but also enhances the user’s ability to optimize performance. By delving into the various elements that constitute this agricultural tool, one can unlock the full potential of their equipment, making the harvesting process more efficient and less time-consuming.

Understanding the New Holland 492 Haybine

The machinery designed for cutting and conditioning grass plays a crucial role in modern agriculture. Its efficient operation significantly enhances the quality and speed of hay production, making it an invaluable asset for farmers. Familiarity with the components and functionality of such equipment is essential for optimal use and maintenance.

Key Features and Benefits

This type of implement is renowned for its durability and performance. Equipped with advanced technology, it ensures even cutting and effective conditioning of forage. Farmers appreciate its ability to handle various types of vegetation, enabling them to maximize yield and minimize waste. Additionally, the user-friendly design simplifies operation, allowing for efficient workflow on the field.

Maintenance Tips

Regular upkeep is vital for longevity and efficiency. Inspection of cutting components, belts, and bearings should be a routine practice. Proper lubrication and timely replacement of worn parts can prevent costly repairs and downtime. Moreover, adhering to the manufacturer’s guidelines for adjustments and servicing will ensure that the machine operates at peak performance.

Key Features of the Haybine Model

This section explores the essential attributes of a popular mowing machine designed for efficient grass cutting and haymaking. It emphasizes the innovative technologies and design elements that enhance productivity and ease of use in agricultural operations.

Efficient Cutting Mechanism

The cutting mechanism of this model is engineered for precision and efficiency, ensuring that grass is cut cleanly and evenly. Key aspects include:

- High-quality blades that provide a sharp and smooth cut.

- Adjustable cutting height for versatile operations.

- Wide cutting width to cover larger areas in less time.

User-Friendly Design

Ease of operation is a critical feature, making this equipment suitable for users of all experience levels. Notable design elements include:

- Intuitive controls that allow for effortless adjustments.

- Robust frame construction for enhanced stability and durability.

- Simple maintenance procedures that minimize downtime.

Importance of Regular Maintenance

Consistent upkeep of agricultural machinery is crucial for optimal performance and longevity. Routine inspections and servicing can prevent minor issues from escalating into major problems, ensuring that equipment operates efficiently during critical periods.

Regular maintenance not only enhances the reliability of machines but also boosts productivity. When equipment is well-cared-for, it reduces downtime and the likelihood of unexpected breakdowns, allowing farmers to focus on their work rather than repairs. Additionally, maintaining machinery helps to preserve its resale value, making it a wise investment in the long term.

Furthermore, adhering to a maintenance schedule promotes safety for operators. Well-maintained equipment is less likely to malfunction, minimizing risks on the farm. Ultimately, investing time and resources in regular care translates into smoother operations and greater peace of mind.

Common Issues with Haybine Parts

In the world of agricultural machinery, several challenges can arise with essential components, impacting overall efficiency and performance. Understanding these typical problems is crucial for maintaining optimal operation during harvest seasons.

One frequent concern involves wear and tear on cutting elements, which can lead to ineffective mowing and increased fuel consumption. Regular inspection and timely replacement can mitigate this issue.

Another common problem pertains to the drive system, where misalignments or damaged belts can cause loss of power transmission. Ensuring proper alignment and maintaining tension in belts is vital to prevent breakdowns.

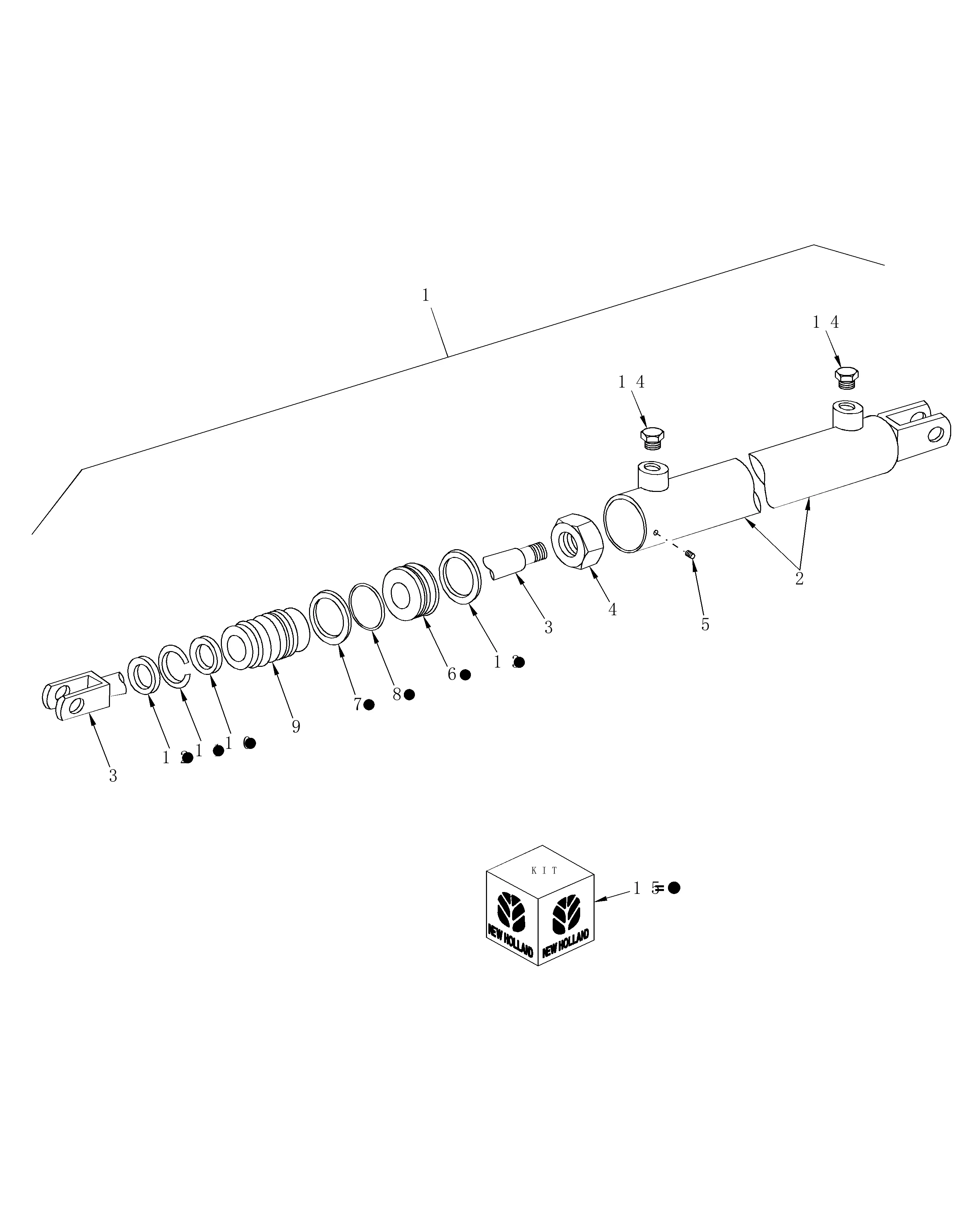

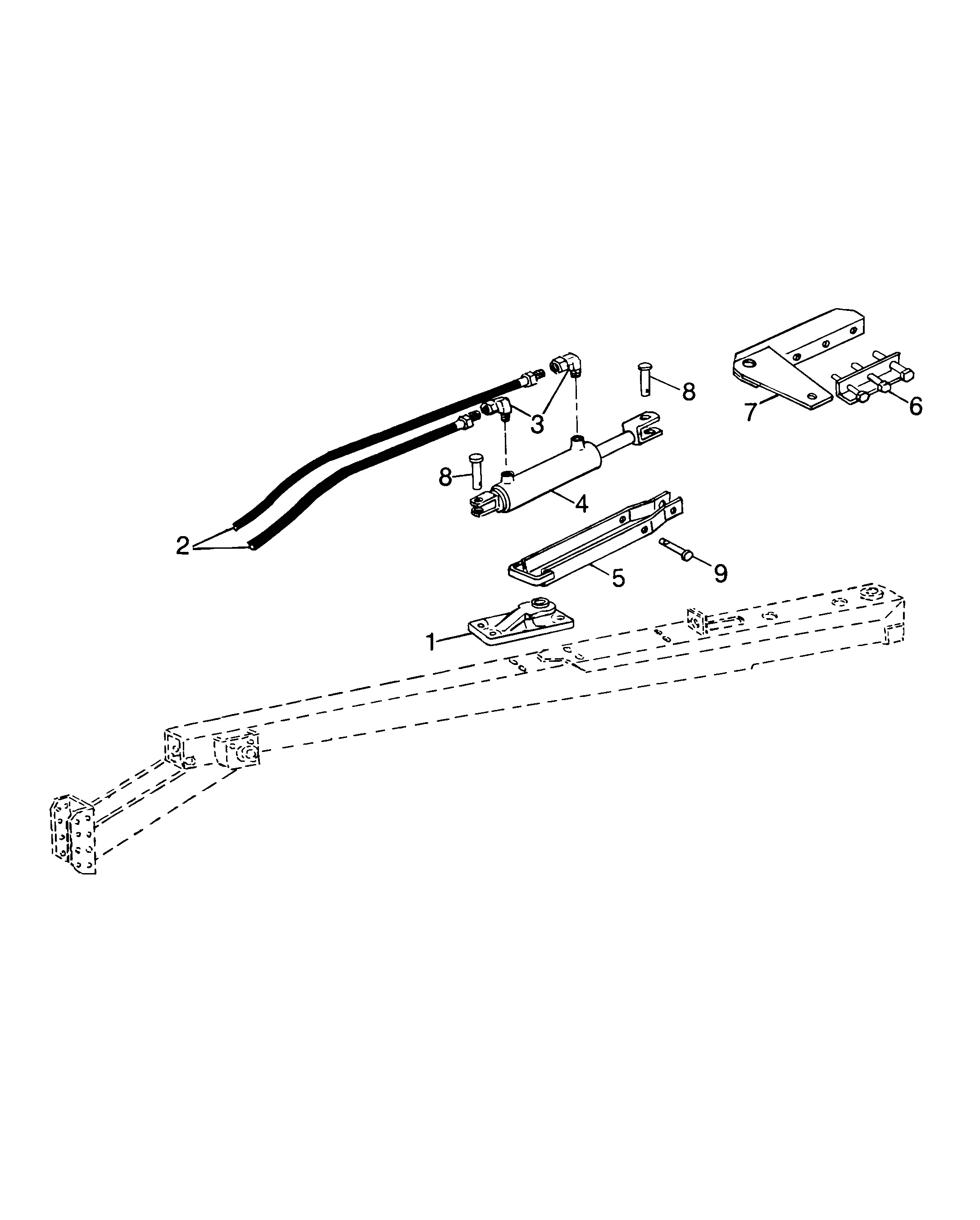

Additionally, hydraulic systems may face leaks or pressure drops, affecting the functionality of the equipment. Routine checks and maintenance of hydraulic lines can help address these issues before they escalate.

Finally, bearing failures are often a result of inadequate lubrication or contamination. Regular lubrication and cleaning can prolong the life of these components, ensuring smooth operation.

How to Identify Replacement Parts

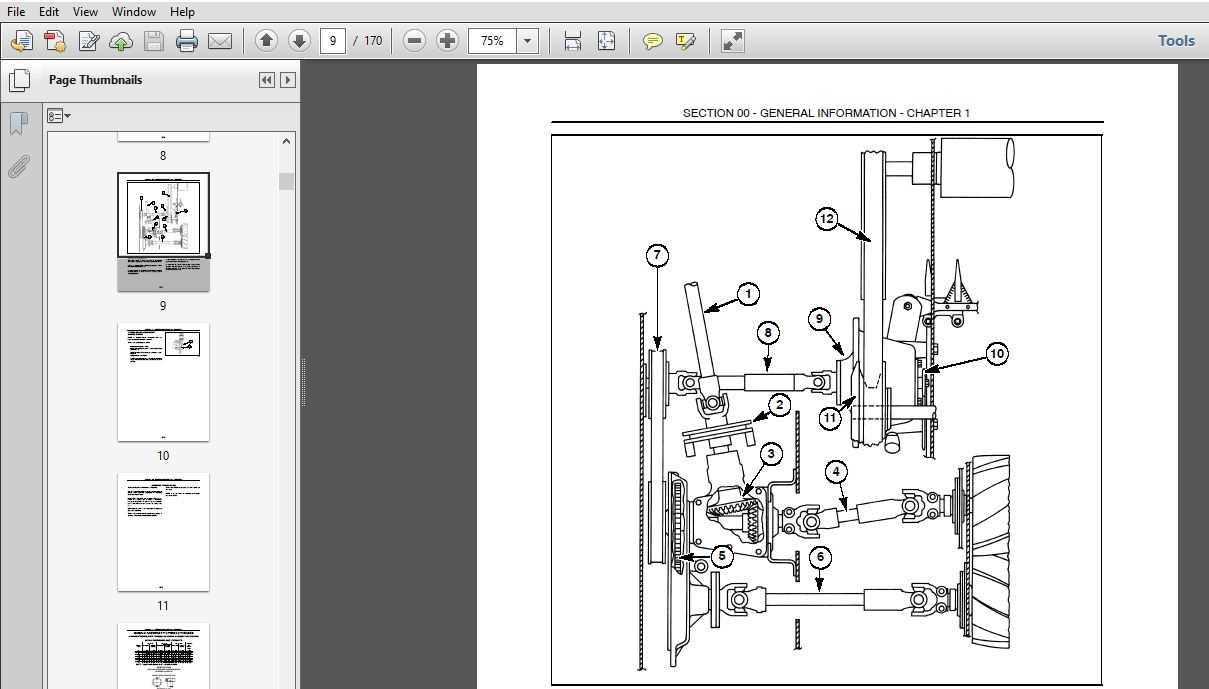

Identifying components for agricultural machinery can be a straightforward process if approached methodically. Understanding the key elements of your equipment is essential for ensuring optimal functionality and longevity. Whether you are looking to replace worn-out items or upgrade specific features, knowing how to find the right alternatives is crucial.

Start by gathering information about your machine. Look for the model number and serial number, which are usually found on a nameplate or tag affixed to the equipment. This information provides a clear reference for locating specific items that are compatible with your model.

Utilize technical manuals or service guides. These documents often include detailed illustrations and descriptions that can help you pinpoint the exact components needed for replacement. Pay attention to the specifications, as even minor variations can affect compatibility.

Consult authorized dealers or online resources dedicated to agricultural equipment. Many manufacturers provide parts catalogs that allow you to search for the required components based on your machine’s specifications. This can save time and ensure you are obtaining quality replacements.

Examine existing components for identifying marks or part numbers. Often, the original items will have identifiers that can be referenced when searching for new equivalents. Taking note of these can streamline your search process.

Join community forums or groups related to agricultural machinery. Engaging with other enthusiasts and professionals can yield valuable insights and recommendations regarding reliable sources for obtaining replacement items.

By following these steps, you can effectively navigate the process of finding the correct components, ensuring your equipment remains in peak operating condition.

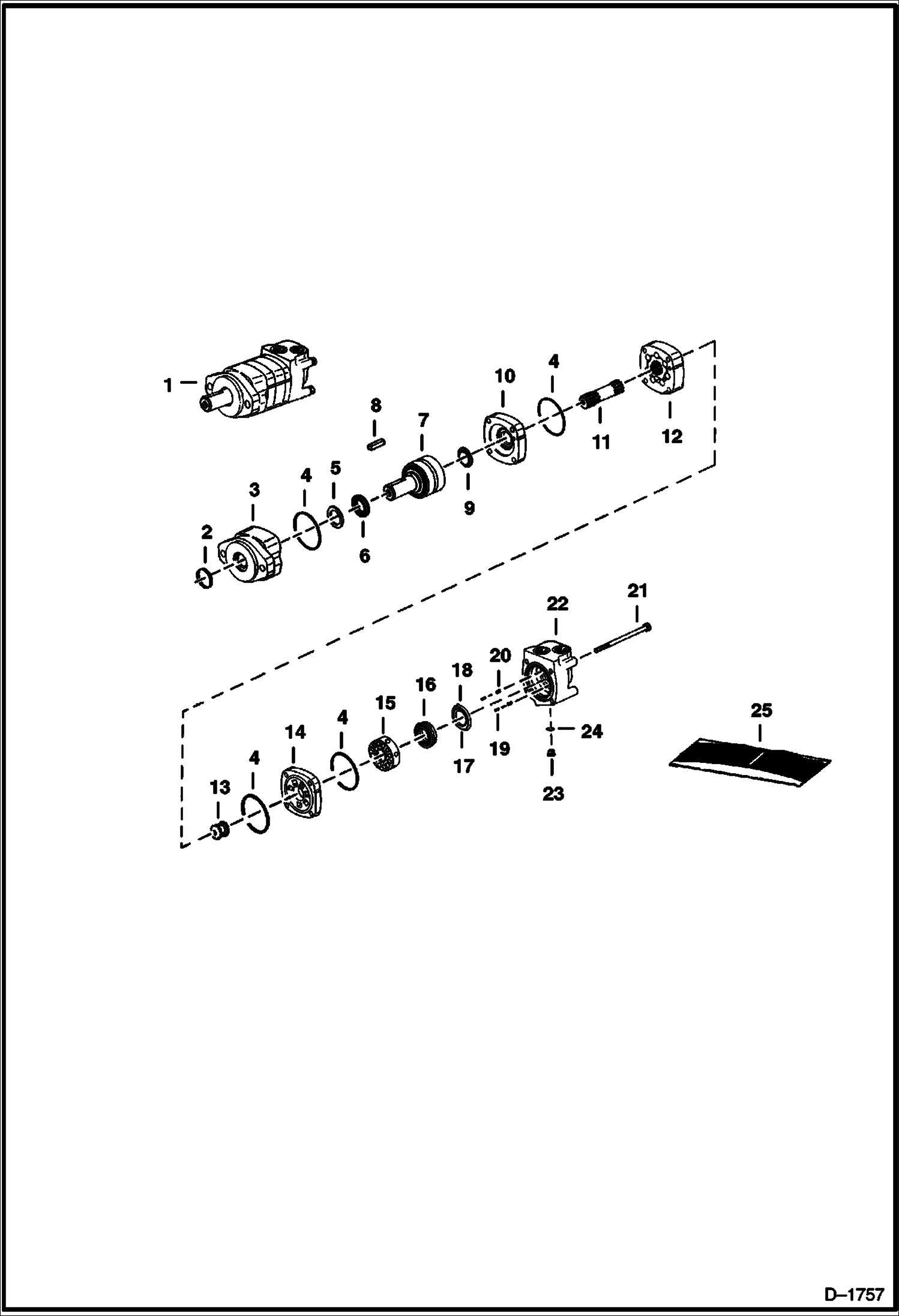

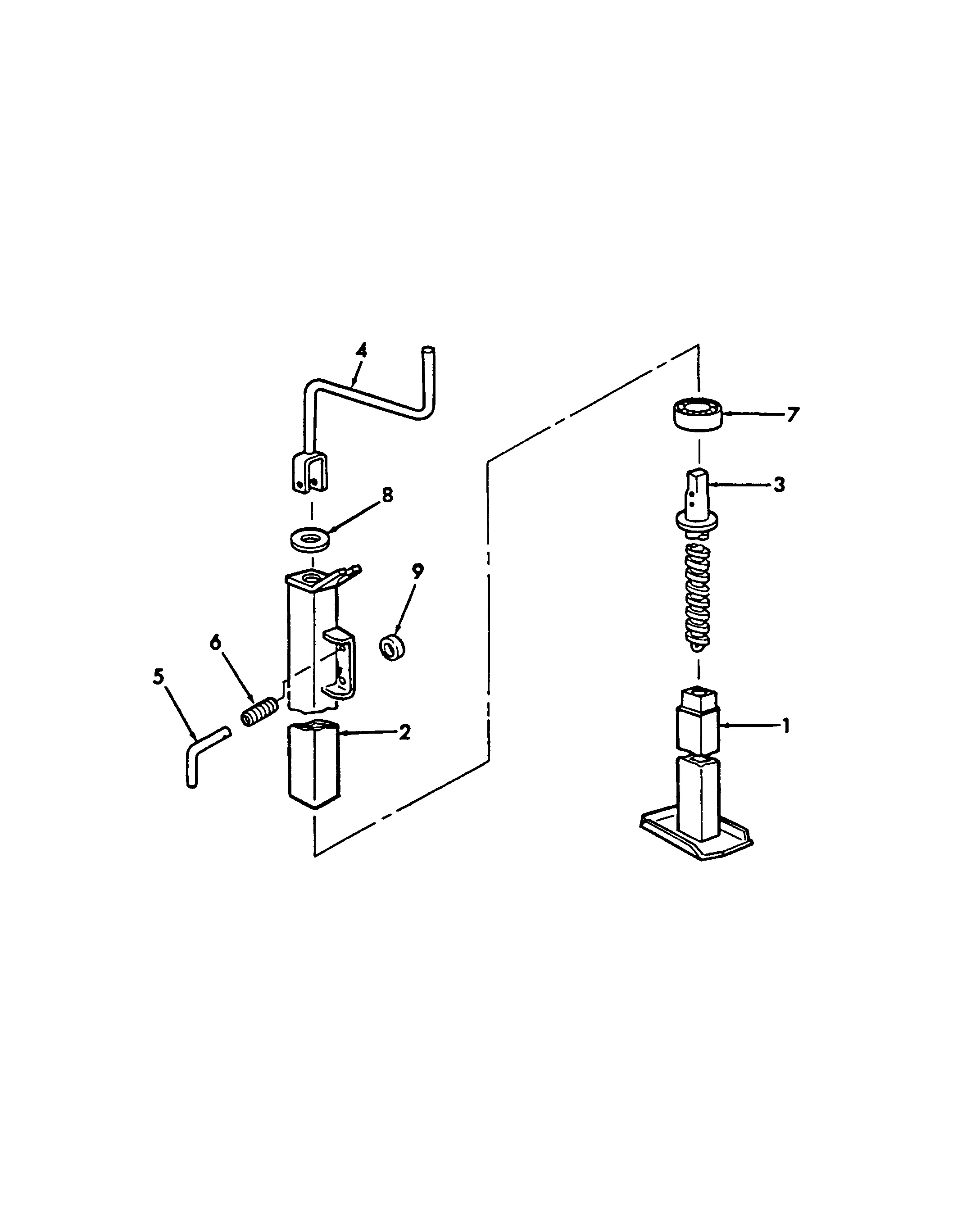

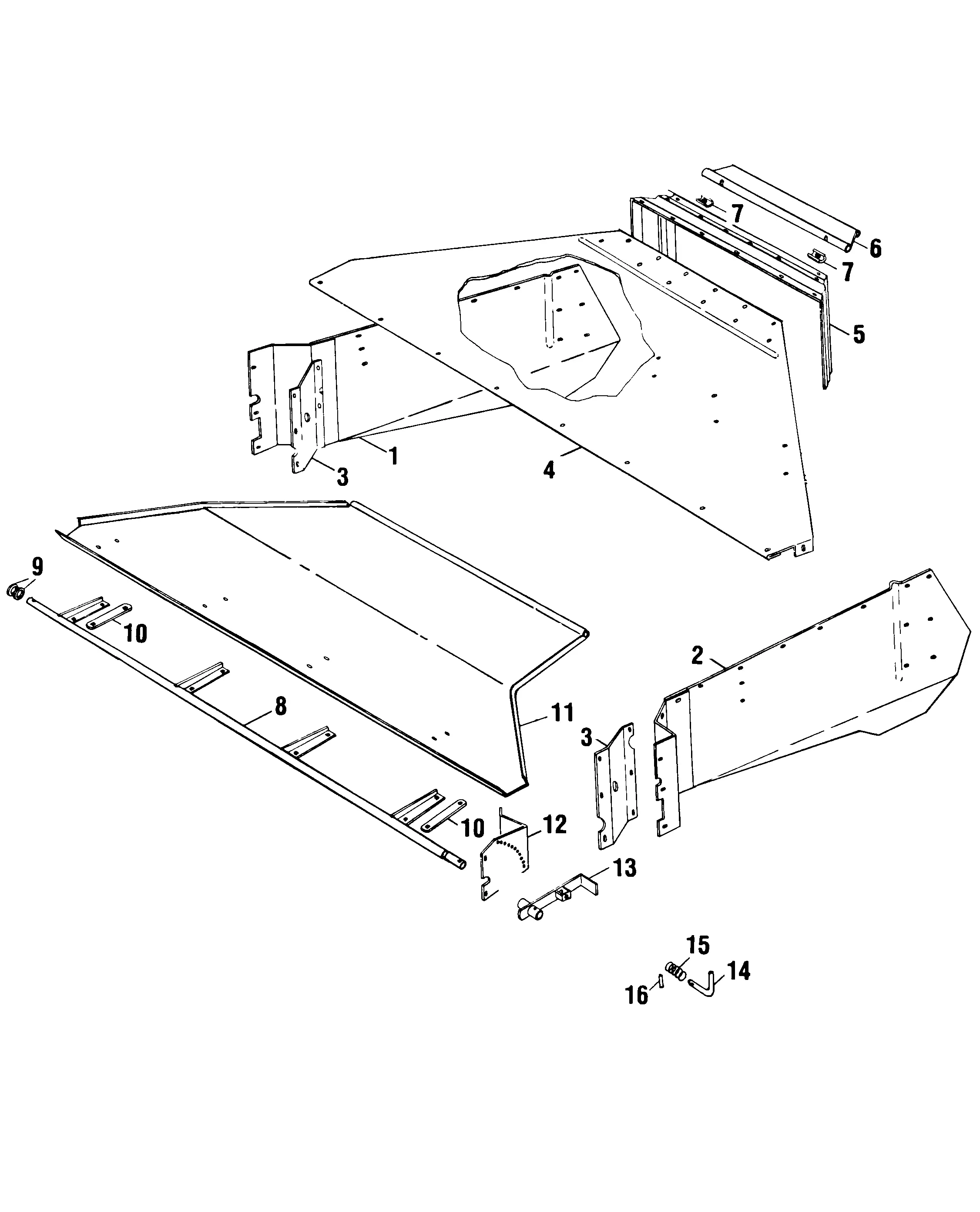

Exploring the Parts Diagram

Understanding the intricacies of agricultural machinery is essential for effective maintenance and operation. A visual representation showcasing the various components offers a clear insight into how each piece interconnects and functions. This overview aids users in identifying necessary replacements or repairs, ensuring the equipment operates at peak efficiency.

Key Components Overview

In any agricultural implement, certain elements are fundamental to its operation. Each component plays a specific role, contributing to the overall performance. Below is a simplified breakdown of crucial sections within the machinery.

| Component | Description |

|---|---|

| Cutter Bar | Responsible for cutting the crop efficiently. |

| Conveyor System | Moves the cut material to the collection area. |

| Frame | Provides structural support and stability. |

| Drive Mechanism | Powers the movement of various parts. |

Importance of Understanding Each Element

A comprehensive grasp of each section’s functionality not only enhances the user’s ability to troubleshoot issues but also promotes proactive maintenance practices. Regular inspections and familiarity with the machinery’s layout can lead to longer operational life and reduced downtime.

Where to Find OEM Parts

Locating original equipment manufacturer components can be essential for maintaining the efficiency and longevity of your machinery. These parts ensure compatibility and reliability, ultimately contributing to optimal performance. When seeking these specialized components, it is crucial to explore various avenues to guarantee you find what you need.

Authorized Dealers: Visiting an authorized dealer is one of the most reliable methods. They often have direct access to the manufacturer’s inventory, ensuring you receive genuine components designed specifically for your equipment.

Online Retailers: Numerous online platforms specialize in selling OEM components. Reputable websites often provide detailed descriptions and specifications, allowing you to verify that you are purchasing the correct items.

Manufacturer’s Website: Checking the manufacturer’s official website can yield a wealth of information. Many companies have dedicated sections for parts, offering diagrams and lists that make it easier to identify what you require.

Local Distributors: Don’t overlook local distributors who may carry OEM components. Establishing a relationship with nearby suppliers can lead to quicker access and potentially better pricing.

Forums and Community Groups: Engaging with online forums or community groups focused on similar equipment can provide invaluable insights. Members often share experiences and recommendations for sourcing authentic components.

By utilizing these resources, you can ensure that your machinery remains in peak condition with quality parts that meet industry standards.

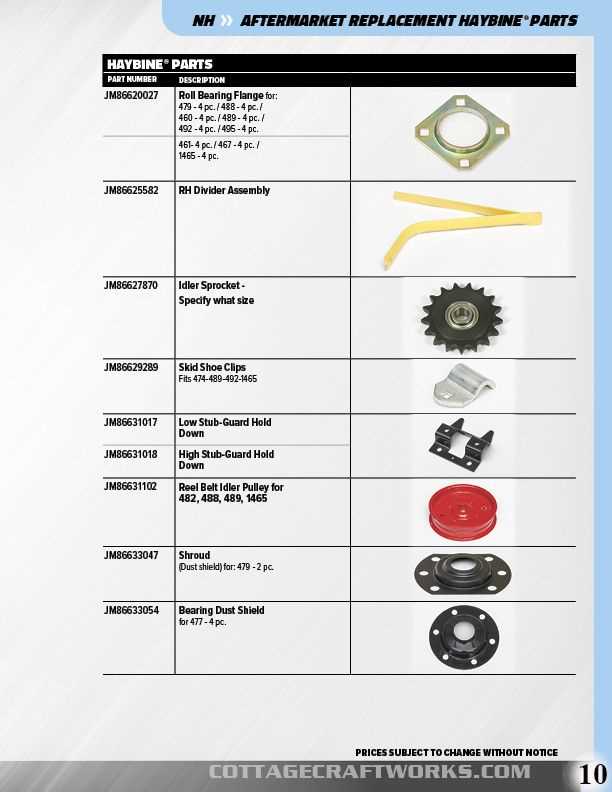

Aftermarket Options for Haybine Parts

When maintaining and repairing agricultural equipment, considering alternatives to original components can be a smart choice. These alternatives often provide comparable quality at competitive prices, catering to the diverse needs of farmers and operators. Exploring such options can lead to significant savings and enhanced functionality for machinery.

Quality Assurance: Many aftermarket manufacturers prioritize quality, ensuring that their offerings meet or exceed industry standards. It’s crucial to research and select reputable brands known for their reliability and durability.

Cost-Effectiveness: One of the most appealing aspects of choosing alternative components is the potential for reduced expenses. This is particularly beneficial for those managing tight budgets, allowing for more efficient allocation of resources across operations.

Compatibility and Customization: Aftermarket options often provide a wider range of compatibility, allowing for customization that meets specific operational needs. This flexibility can enhance performance and adapt machinery to various conditions.

In conclusion, exploring alternatives to original components can lead to better performance, cost savings, and tailored solutions for agricultural equipment. Evaluating these options can significantly impact the efficiency and productivity of farming operations.

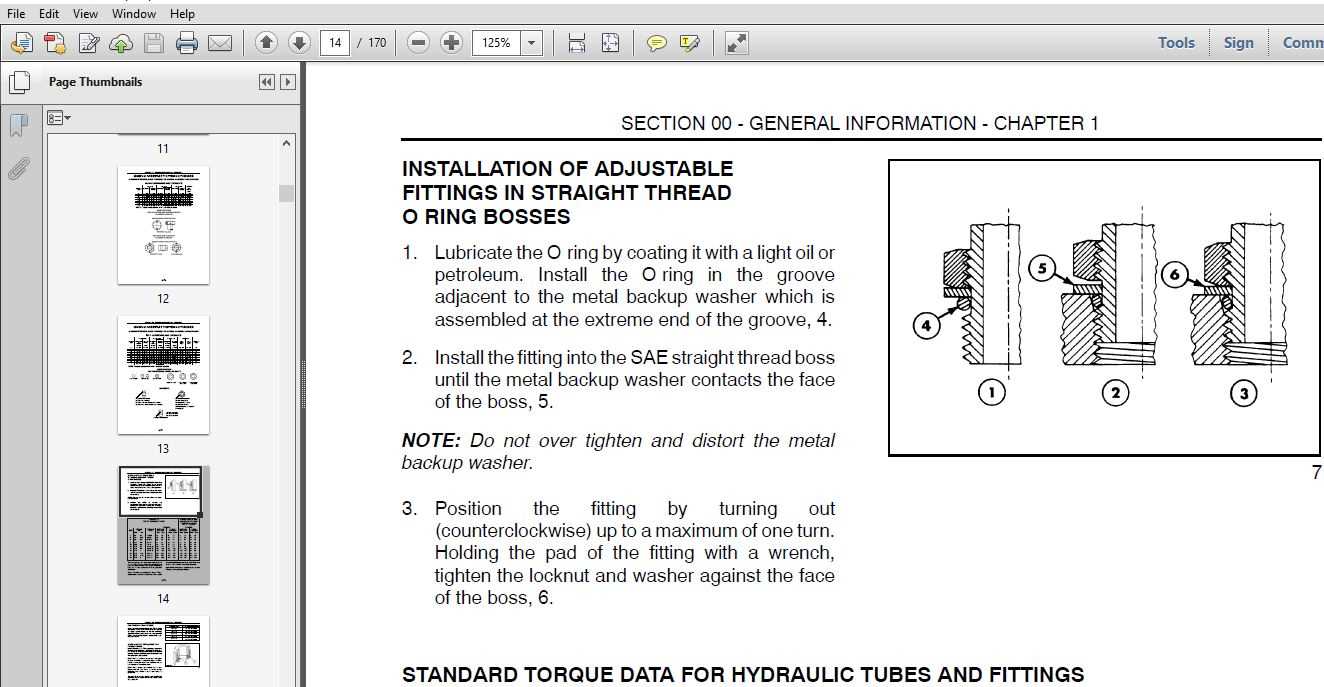

Tips for Installing New Components

When integrating fresh elements into agricultural machinery, ensuring a smooth installation process is crucial for optimal performance. Proper techniques can prevent future issues and enhance the longevity of your equipment.

Before starting the installation, familiarize yourself with the components and their functions. Understanding how each piece interacts will streamline the assembly process and reduce the likelihood of errors.

| Step | Tip |

|---|---|

| 1 | Gather all necessary tools and materials beforehand to avoid interruptions. |

| 2 | Refer to the manufacturer’s guidelines for specific installation instructions. |

| 3 | Inspect all new components for damage or defects before installation. |

| 4 | Ensure that all connections are tight and secure to prevent leaks or malfunctions. |

| 5 | Test the equipment after installation to confirm everything operates smoothly. |

Following these guidelines will help ensure that your new components function effectively, ultimately leading to improved productivity and reliability in your agricultural tasks.

Cost Analysis of Replacement Parts

Evaluating the financial implications of component substitution is crucial for maintaining equipment efficiency. Understanding the expenses associated with each element can help in making informed decisions, ultimately leading to better budget management and prolonged machinery lifespan.

Factors Influencing Costs

Several elements contribute to the overall pricing of replacement components. These include the brand reputation, material quality, and market demand. Moreover, the complexity of installation and the frequency of required maintenance play significant roles in determining total ownership costs.

Comparison of Costs

| Component Type | Average Cost ($) | Warranty Period (months) |

|---|---|---|

| Drive Belts | 75 | 12 |

| Cutter Bar | 300 | 24 |

| Roller Bearings | 50 | 6 |

| Gearbox Assembly | 450 | 36 |

By analyzing these costs, operators can prioritize which components require immediate attention and budget accordingly, ensuring that machinery remains operational and efficient for longer periods.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your agricultural machinery is essential for optimal performance. Regular upkeep not only extends the life of your equipment but also enhances its reliability in the field. Here are some key practices to follow for maintaining your implement effectively.

- Regular Inspections: Conduct frequent checks to identify any signs of wear or damage. Look for issues such as rust, cracks, or loose components.

- Cleanliness: Keep the machinery clean from dirt and debris. Regular cleaning prevents buildup that can lead to mechanical failures.

- Lubrication: Ensure all moving parts are adequately lubricated to reduce friction and wear. Use appropriate oils and greases as specified in the manufacturer’s guidelines.

- Belts and Cables: Regularly inspect belts and cables for fraying or stretching. Replace them as needed to maintain efficient operation.

By adhering to these maintenance practices, you can significantly improve the longevity of your agricultural equipment, ensuring it remains a reliable asset for years to come.

- Storage: Store the machinery in a dry, sheltered environment to protect it from the elements.

- Calibration: Regularly calibrate settings to ensure optimal performance during operation.

Investing time in proper maintenance routines will yield long-term benefits, safeguarding your machinery’s functionality and performance.

Community Resources for Haybine Owners

For those engaged in the agricultural sector, sharing knowledge and resources is invaluable. Numerous platforms exist where owners can connect, exchange ideas, and seek assistance regarding their equipment. These communal spaces offer a wealth of information that can enhance understanding and optimize the use of machinery.

Online Forums and Discussion Groups: Various online forums serve as hubs for enthusiasts and professionals alike. Members often share troubleshooting tips, maintenance advice, and personal experiences. Participating in these discussions can provide insights that aren’t found in manuals.

Local Agricultural Cooperatives: Many communities have cooperatives that offer support to farmers. These organizations frequently host workshops, provide access to experienced technicians, and create opportunities for networking among local equipment owners.

Social Media Groups: Platforms like Facebook and Instagram have dedicated groups where individuals can post questions, share photos, and discuss modifications. Engaging with these communities can foster relationships and enhance one’s knowledge base.

Educational Resources: Websites dedicated to farming and machinery often feature articles, videos, and tutorials that cover various aspects of equipment usage and care. These resources can be invaluable for both novices and seasoned operators looking to refine their skills.

Trade Shows and Expos: Attending agricultural trade shows allows owners to connect with manufacturers and suppliers. These events provide a great opportunity to learn about the latest advancements, gather information on equipment enhancements, and build a network of contacts.

Leveraging these community resources can significantly improve the experience of equipment ownership, ensuring that every user has access to the support and knowledge necessary for success.