Stihl MS 660 Parts Diagram PDF for Easy Reference

When it comes to maintaining outdoor machinery, having a clear visual representation of components is essential. Understanding how each element fits together not only enhances performance but also simplifies repair processes. This resource aims to provide valuable insights into the inner workings of your device, enabling you to tackle maintenance tasks with confidence.

In the realm of mechanical upkeep, clarity is key. By utilizing visual aids, you can easily identify crucial segments and ensure proper functionality. This guide serves as a reference point, helping you navigate through intricate systems while promoting longevity and efficiency in your tools.

Whether you are a seasoned professional or a passionate hobbyist, grasping the layout of your machinery can significantly impact your overall experience. This exploration into the structure of your equipment will empower you to make informed decisions, ultimately leading to enhanced performance and reliability.

Understanding Stihl MS 660 Components

Grasping the various elements of a powerful chainsaw is crucial for both maintenance and optimal performance. Each component plays a vital role in the functionality and efficiency of the machine. By familiarizing oneself with these parts, users can ensure better care and troubleshooting when issues arise.

The heart of this equipment lies in its engine, responsible for converting fuel into mechanical energy. The ignition system initiates this process, providing the necessary spark to ignite the fuel mixture. Furthermore, the carburetor is essential for mixing air and fuel in the right proportions, ensuring smooth operation.

In addition to the engine components, the guide bar and chain are integral for cutting performance. The guide bar provides stability, while the chain is designed for precision cutting, showcasing the importance of sharpness and tension. Proper lubrication systems also contribute significantly to extending the life of these elements by reducing friction.

Lastly, safety features cannot be overlooked. The chain brake and throttle controls are designed to protect the user while enhancing control over the tool’s operation. Understanding these components is key to not only achieving optimal performance but also ensuring safe usage of the equipment.

Importance of Parts Diagrams

Understanding the layout and components of a machine is crucial for effective maintenance and repair. Detailed illustrations serve as invaluable resources for both professionals and hobbyists. They simplify the process of identifying, replacing, and reassembling individual elements, ensuring that everything functions smoothly.

Benefits of Utilizing Visual Guides

- Enhanced Clarity: Visual representations eliminate ambiguity, allowing users to easily locate specific components.

- Improved Efficiency: Quick reference to diagrams speeds up repair tasks, reducing downtime.

- Streamlined Communication: Facilitates better discussions between technicians and clients regarding repairs or modifications.

Key Considerations When Using Illustrations

- Accuracy: Always verify that the visual guide corresponds to the exact model to avoid mistakes.

- Detail Orientation: Pay attention to minor parts that may not seem significant but are essential for overall function.

- Regular Updates: Use the most current versions to ensure that any changes in design or components are reflected.

Leveraging these visual tools significantly enhances the overall experience of maintaining machinery, promoting a deeper understanding and fostering a culture of proactive care.

How to Access PDF Resources

Finding and obtaining digital documents can greatly enhance your understanding and usage of various tools and equipment. With the right approach, you can easily navigate through available resources and locate the information you need. This section will guide you on effective methods to access and utilize these valuable files.

Searching Online

The internet offers a vast array of resources. Utilizing search engines with specific keywords can lead you to relevant documents. Consider the following tips for efficient searching:

| Tip | Description |

|---|---|

| Use Specific Keywords | Be precise in your search terms to narrow down results. |

| Utilize File Type Filters | Add “filetype:pdf” to your search query for direct results. |

| Check Manufacturer Websites | Visit official sites for authentic documentation and guides. |

Accessing through Online Libraries

Many online libraries and educational platforms provide access to a wealth of documents. These can include manuals, guides, and technical documentation. Here’s how to maximize your use of these resources:

| Resource Type | Benefits |

|---|---|

| Public Libraries | Often provide free access to a range of documents. |

| Academic Databases | Access scholarly articles and detailed manuals for in-depth information. |

| Community Forums | Engage with other users who may share links to useful documents. |

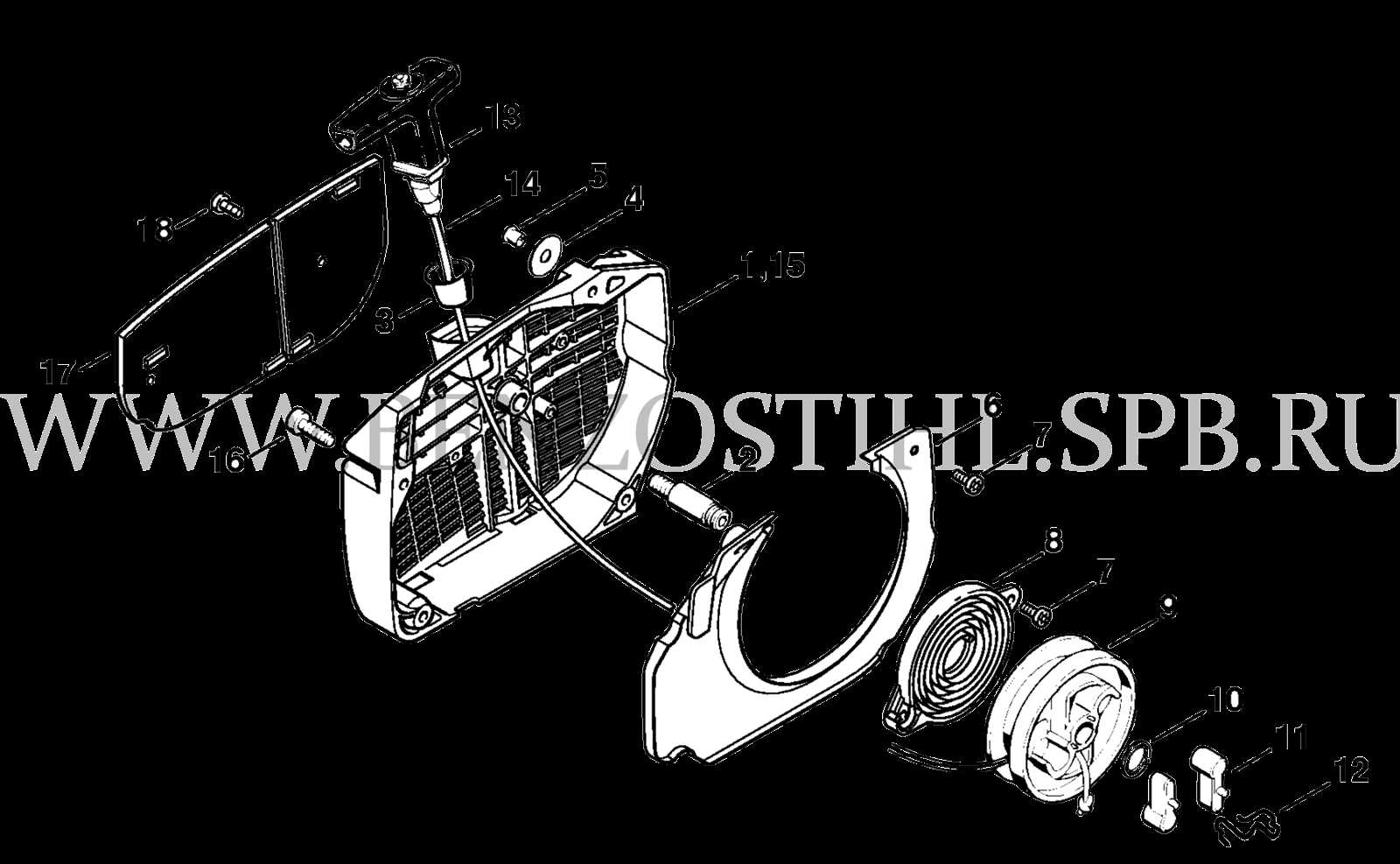

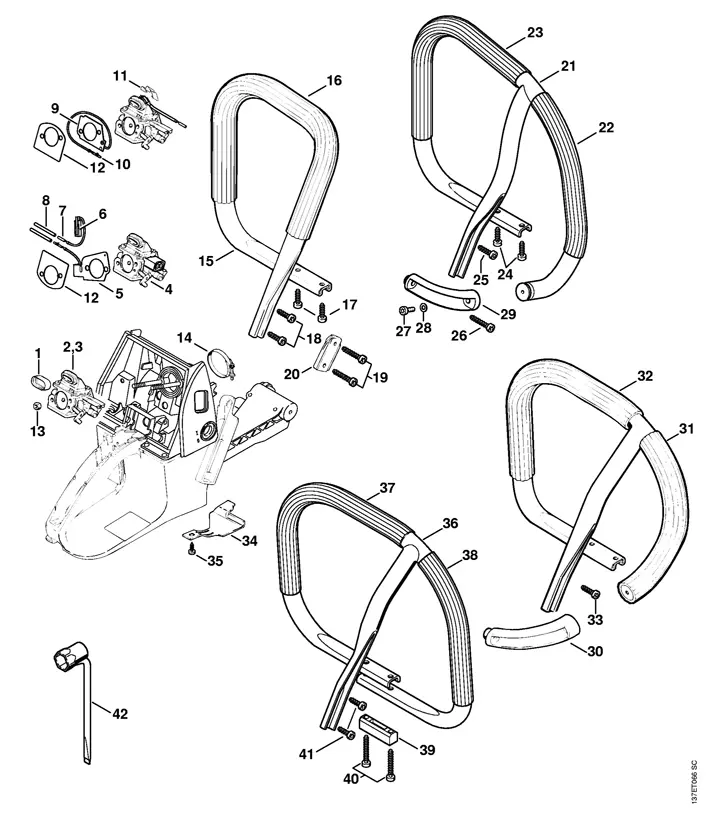

Identifying Key Parts in Diagrams

Understanding complex illustrations is crucial for effective maintenance and repair of equipment. These visuals provide a detailed view of various components, allowing users to recognize and locate essential elements within a machine. By familiarizing oneself with the layout and symbols used, individuals can enhance their troubleshooting skills and streamline their repair processes.

Key components are often highlighted through specific markings or color coding, making it easier to identify their function. Pay attention to labels that indicate the purpose of each part, as they can guide users in determining how different elements interact. Familiarity with the arrangement of components can significantly aid in both assembly and disassembly.

Furthermore, understanding the relationships between various parts can lead to more efficient repairs. For instance, recognizing how a certain element connects to others can prevent unnecessary disassembly, saving both time and effort. Always consult the accompanying notes or legends for additional context that clarifies each component’s role.

Common Issues with Stihl MS 660

Chainsaw enthusiasts often encounter various challenges when operating high-performance models. Understanding these common problems can enhance maintenance practices and improve overall functionality. Below are several typical issues that users may face, along with potential solutions.

Fuel System Troubles

- Clogged Fuel Filter: Over time, debris can accumulate, obstructing fuel flow.

- Incorrect Fuel Mixture: An improper blend of fuel and oil can lead to poor performance.

- Damaged Fuel Lines: Cracks or leaks in the lines may hinder operation.

Starting Difficulties

- Carburetor Issues: A malfunctioning carburetor can prevent the engine from starting smoothly.

- Faulty Spark Plug: Worn or dirty plugs may lead to ignition problems.

- Air Filter Blockage: A dirty filter can restrict airflow, making it hard to start the machine.

Addressing these issues promptly can help ensure optimal performance and longevity of your equipment. Regular maintenance checks and using high-quality fuel can significantly reduce the likelihood of encountering these common challenges.

Replacement Parts Overview

When it comes to maintaining outdoor power equipment, understanding the components that may require replacement is crucial for ensuring optimal performance. This section provides insights into various elements that are essential for the functionality and longevity of your machine. Knowing what to look for and how to address wear and tear can make a significant difference in your equipment’s efficiency.

Key Components to Consider

Among the primary elements to keep an eye on are the engine components, cutting systems, and drive mechanisms. Each of these plays a vital role in the overall operation, and being aware of their signs of wear can help in planning timely replacements. Regular checks can prevent minor issues from escalating into more significant problems.

Maintaining Performance

In addition to understanding what parts may need replacement, it is essential to know where to find quality alternatives. Using reliable suppliers ensures that your equipment remains in peak condition. Regular maintenance and timely substitutions not only enhance performance but also extend the lifespan of your machinery.

Being proactive about component care leads to smoother operation and reduces the risk of unexpected breakdowns, allowing you to focus on the tasks at hand.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended lifespan and optimal performance of your equipment. By adhering to a few simple practices, you can significantly reduce wear and tear, leading to fewer repairs and greater reliability. The following guidelines will help you maintain your machinery effectively.

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Inspect the Air Filter | Every 10 hours | Clean or replace as needed to ensure proper airflow. |

| Check the Chain Tension | Before each use | Adjust to prevent wear and ensure safe operation. |

| Clean the Spark Plug | Every 25 hours | Replace if worn; a clean plug enhances ignition efficiency. |

| Lubricate Moving Parts | Every 50 hours | Use the appropriate lubricant to minimize friction. |

| Sharpen the Blade/Chain | Every 20 hours | A sharp blade ensures smoother cutting and reduces strain. |

| Inspect for Damage | After each use | Look for cracks, wear, or loose components to address issues early. |

Following these maintenance practices will help prolong the life of your equipment, ensuring it remains reliable for years to come. Regular attention not only enhances performance but also contributes to safety during operation.

Tools Needed for Repairs

When it comes to maintaining and fixing machinery, having the right equipment at hand is essential for efficient and effective work. Proper tools not only facilitate the repair process but also ensure safety and precision, allowing you to address any issues with confidence.

Essential Tools

- Wrenches: For tightening and loosening various fasteners.

- Screwdrivers: Both flathead and Phillips for handling screws of different types.

- Socket Set: Provides versatility for various nut sizes and shapes.

- Pliers: Useful for gripping, twisting, and cutting wires.

- Torque Wrench: Ensures proper tightness without over-torquing.

- Cleaning Supplies: Brushes and cloths for maintaining parts.

Safety Equipment

- Safety Goggles: Protects eyes from debris.

- Gloves: Provides hand protection while handling components.

- Ear Protection: Essential when working with loud machinery.

- Work Boots: Offers safety and stability on various surfaces.

Where to Purchase Genuine Parts

Acquiring authentic components for your equipment is essential for maintaining optimal performance and longevity. Genuine items ensure compatibility and reliability, helping you avoid potential issues associated with counterfeit alternatives. Here are some recommended sources to obtain these high-quality items.

Authorized Dealers

One of the best ways to find original components is through authorized dealers. These establishments offer a wide selection of products and provide expert advice. Consider the following:

- Search for local dealers through the official website.

- Verify their reputation and customer reviews.

- Inquire about warranties and return policies.

Online Retailers

The internet offers numerous platforms where you can purchase genuine components conveniently. When shopping online, keep these tips in mind:

- Choose well-known e-commerce sites with reliable feedback.

- Look for specific filters that categorize items as genuine.

- Check for detailed descriptions and images to ensure authenticity.

By utilizing these sources, you can ensure that you are equipping your machinery with the right components, enhancing its efficiency and durability.

Comparing OEM vs Aftermarket Parts

When it comes to replacement components for outdoor equipment, there are generally two categories available: original manufacturer offerings and alternative options produced by third parties. Each choice comes with its own set of advantages and drawbacks, making the decision process significant for users seeking reliability and performance.

Original manufacturer parts, often referred to as OEM, are crafted specifically for a particular model, ensuring a perfect fit and optimal functionality. These components typically come with warranties and are designed to meet stringent quality standards set by the manufacturer. As a result, users can expect longevity and efficiency, as well as peace of mind regarding compatibility.

On the other hand, aftermarket alternatives present a budget-friendly option. While they may not always match the exact specifications of their original counterparts, many aftermarket manufacturers strive to provide acceptable quality and performance. These parts can often be found at lower prices, making them appealing for those looking to save on maintenance costs. However, it’s essential to assess the reputation of the aftermarket supplier, as quality can vary significantly.

Ultimately, the choice between OEM and aftermarket components hinges on individual priorities. If performance, longevity, and reliability are paramount, original parts may be the better investment. Conversely, if cost is the primary concern, and users are willing to research and ensure quality, aftermarket options can serve as a viable alternative.

Assembly and Disassembly Guide

This section provides a comprehensive overview of the procedures for assembling and disassembling your equipment. Understanding these processes is essential for proper maintenance, repairs, and upgrades, ensuring optimal performance and longevity of your tool.

Before you begin, it is crucial to gather all necessary tools and components. A clean workspace will help prevent losing small parts and ensure a smooth workflow.

Tools Needed

- Wrenches

- Screwdrivers (flat and Phillips)

- Pliers

- Torque wrench

- Safety gloves

- Protective eyewear

Disassembly Steps

- Ensure the equipment is turned off and unplugged from any power source.

- Remove any protective covers or guards to access internal components.

- Carefully disconnect electrical connections, taking note of their arrangement.

- Unscrew and detach components in the reverse order of assembly, placing them in a labeled container.

- Inspect each part for wear or damage as you disassemble.

Assembly Steps

- Start with the main components, ensuring they are clean and free of debris.

- Reconnect electrical components as per the original configuration.

- Secure each part with screws and fasteners, following the manufacturer’s torque specifications.

- Reattach any covers or guards that were removed during disassembly.

- Conduct a final inspection to ensure everything is correctly assembled and secure.

Following these guidelines will help maintain your equipment in optimal condition, enhancing its efficiency and lifespan.

Safety Precautions During Repair

When undertaking any maintenance or repair tasks, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions not only protect the individual performing the work but also ensure that the equipment operates correctly once the repairs are completed. Understanding the potential hazards and taking proactive measures can significantly reduce risks associated with mechanical tasks.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is essential. This includes safety goggles to shield the eyes from debris, gloves to protect the hands from sharp objects, and sturdy footwear to safeguard the feet. Additionally, using ear protection can help mitigate noise exposure, especially when working with loud machinery. Ensuring that all PPE is in good condition and properly fitted will provide the best protection.

Work Environment Safety

Creating a safe workspace is equally important. Ensure that the area is well-lit and organized, with all tools and materials easily accessible. Remove any clutter that could pose a tripping hazard. It is also advisable to have a first aid kit on hand, as well as an understanding of emergency procedures. Keeping the workspace free of distractions will allow for greater focus and reduce the likelihood of accidents.